Rubber diaphragm circular vulcanizing device for brake chamber in automobiles

A technology of rubber diaphragm and automobile braking, applied in household components, household appliances, other household appliances, etc., can solve the problems of long production cycle, low production efficiency, low equipment utilization rate, etc., to simplify production operations, improve quality, Effects for easy setup and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the examples.

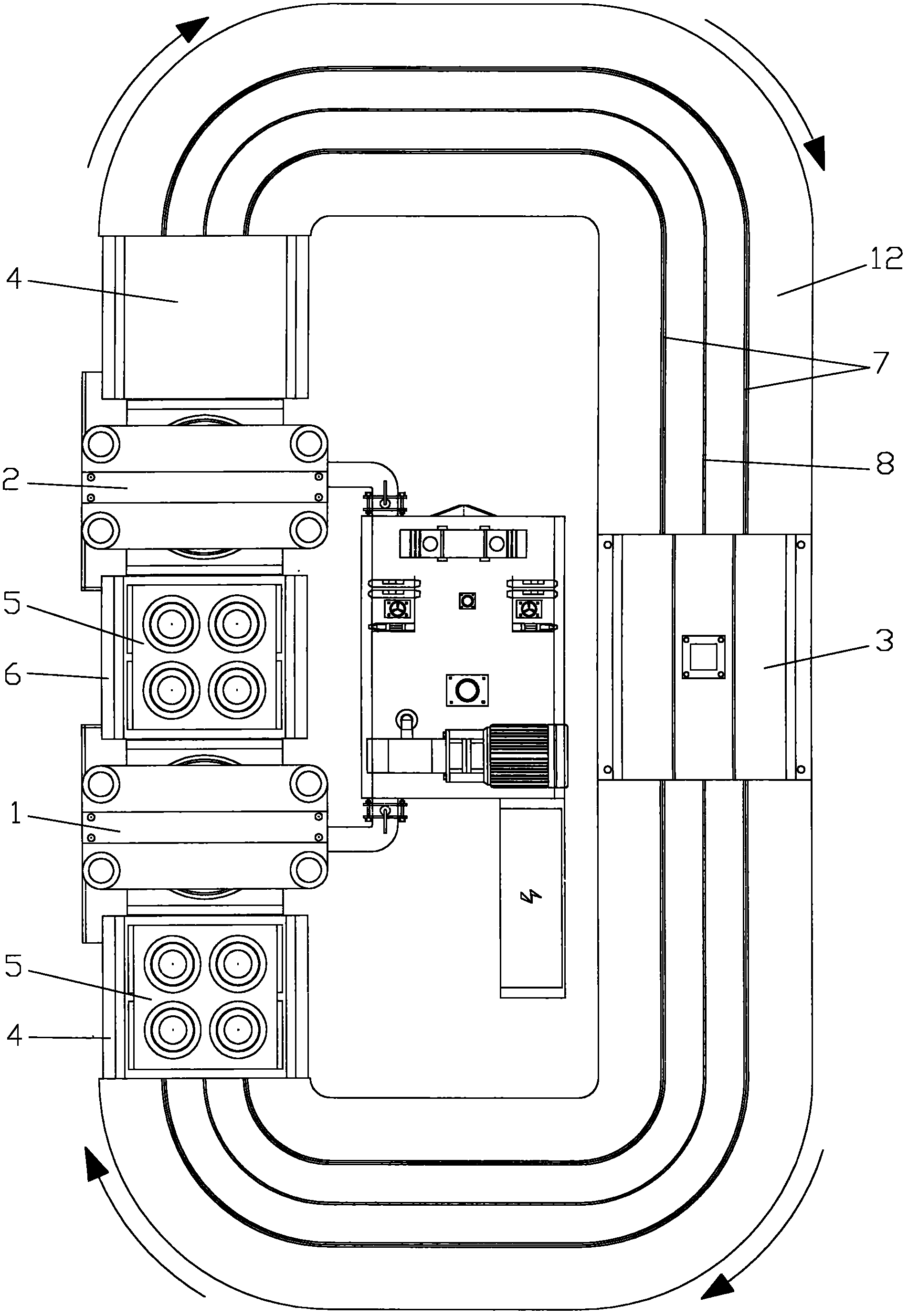

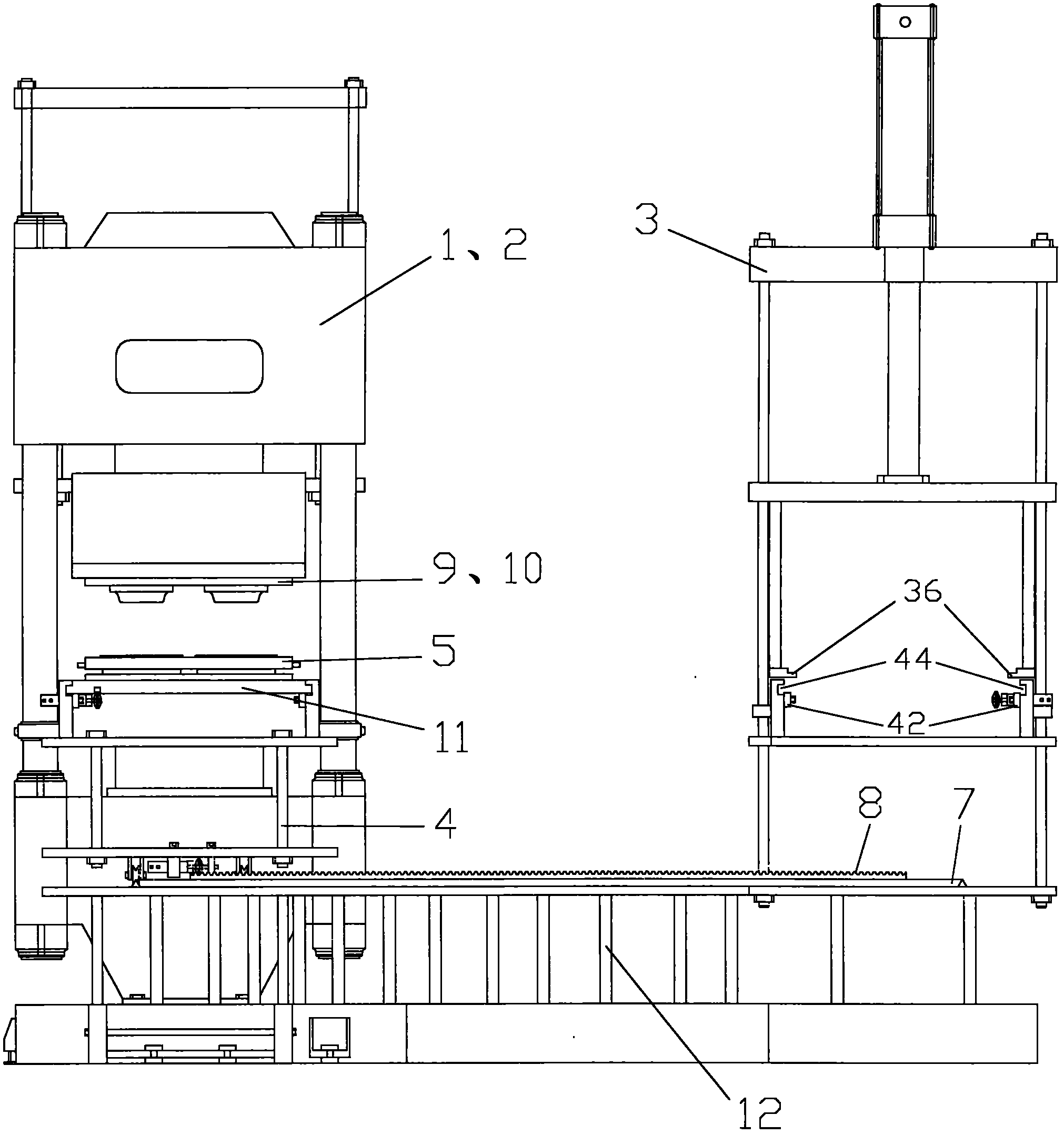

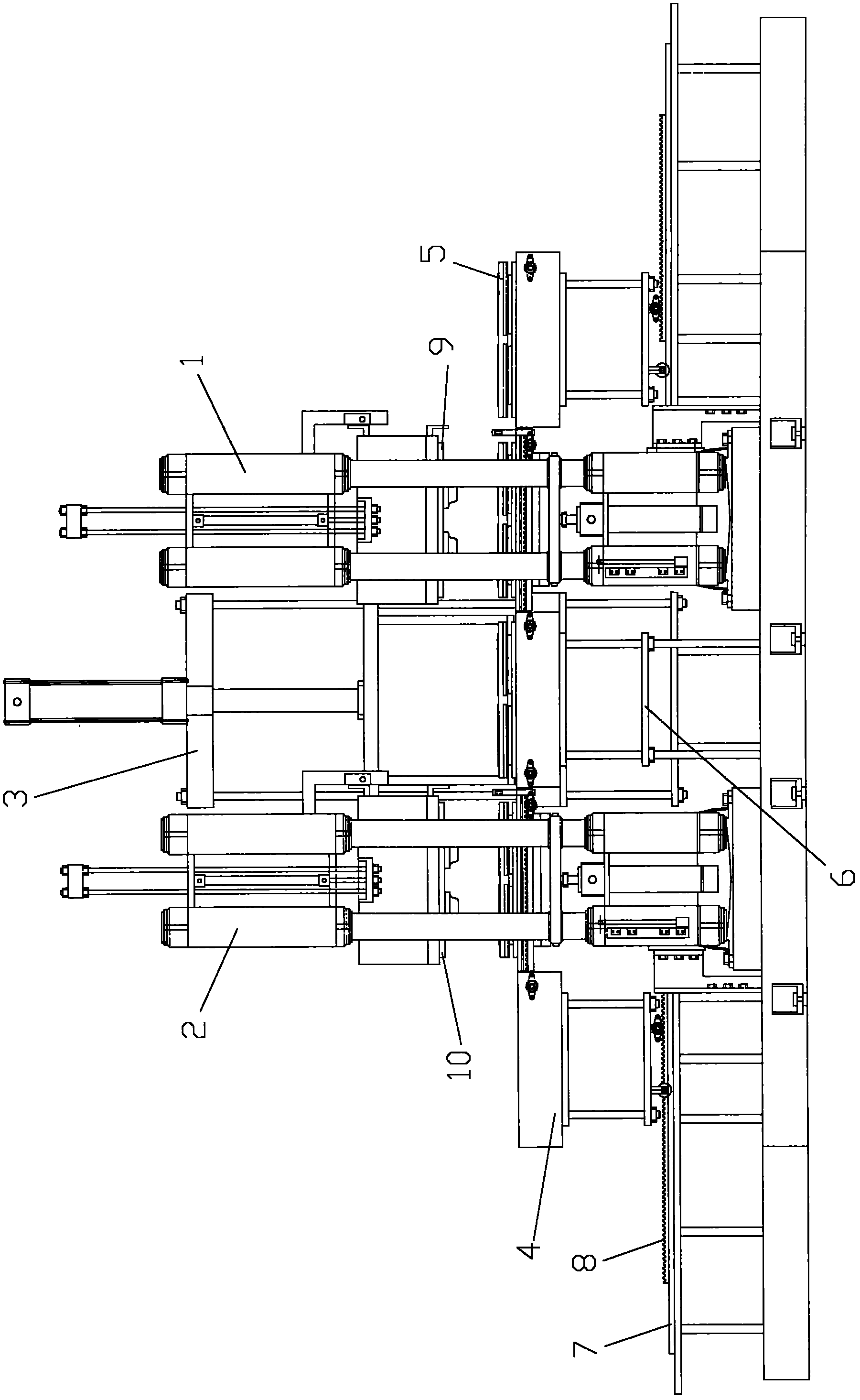

[0024] Such as Figure 1-Figure 9 As shown, the automobile brake air chamber rubber diaphragm cycle vulcanization device of the present invention includes a first vacuum vulcanization press 1, a second vacuum vulcanization press 2, a demoulding mechanism 3, and a rubber diaphragm vulcanization molding die, wherein the rubber diaphragm vulcanization molding die It is a compound mold structure including four sets of rubber diaphragm vulcanization molding units, including lower mold, middle mold, first upper mold, second upper mold, lower mold, pressure ring, upper mold for primary vulcanization and secondary mold in each unit. The upper mold for vulcanization is respectively arranged on the lower mold plate, the middle mold plate, the first upper mold plate and the second upper mold plate.

[0025] The first press 1 is used for the primary vulcanization treatment of the rubber dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com