Formula and production technology used for preparing A grade non-combustible thermal insulation boards from cement polyphenyl particles

A polystyrene particle and production process technology, applied in the field of cement board production, can solve the problems of general compressive strength and tensile strength, high brittleness, poor mechanical properties, etc., and achieve outstanding compressive strength and tensile strength, compressive strength Increased strength and tensile strength, and ease of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

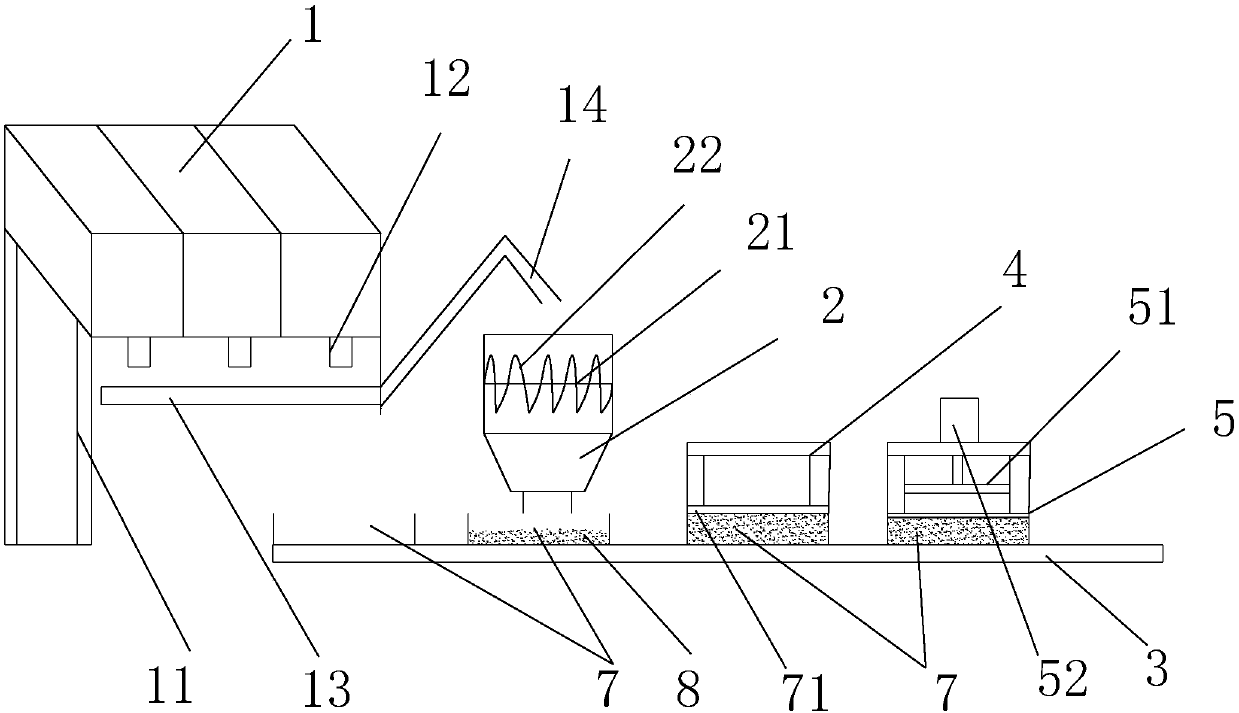

Method used

Image

Examples

Embodiment 1

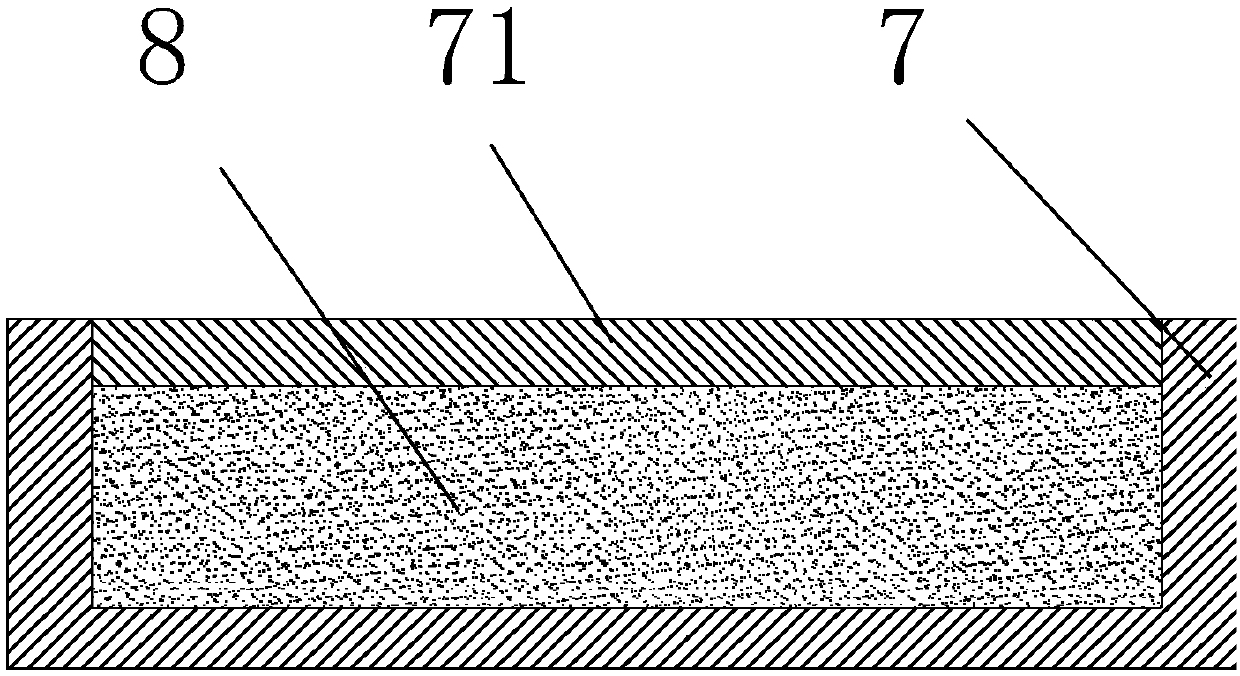

[0032] The formula of this example can be used to make lightweight insulation boards; the original proportions are: 34kg tap water, 3kg water-enhancing agent, 4kg special cellulose for insulation board, 0.3kg expansion agent, 100kg ordinary portland cement, 2 cubic polystyrene particles , Among them, the polystyrene particles are 8kg / cubic.

[0033] In this embodiment, the temperature of the tap water is 0-70°C;

[0034] In this embodiment, the water-enhancing agent adopts waterproof emulsion, Tianjin World Sanwei Chemical Trading Co., Ltd.;

[0035] In this embodiment, the special cellulose for insulation boards is produced from Shijiazhuang Runbo Cellulose Factory;

[0036] In this embodiment, the expansion agent is modified cellulose, 0.3 kg is dissolved in 8 kg of 70° hot water, and the modified cellulose is produced in Shijiazhuang Runbo Cellulose Factory;

[0037] In this embodiment, the model of ordinary Portland cement is 525# or 425#.

[0038] The above-mentioned raw materials ...

Embodiment 2

[0040] The formula of this example can be used to make Class A non-combustible insulation board; its original proportions are: tap water 40kg, water increase agent 2kg, insulation board special cellulose 4kg, expansion agent 0.3kg, ordinary portland cement 120kg, 1.5 cubic polystyrene Particles, of which polystyrene particles are 8kg / cubic.

[0041] In this embodiment, the temperature of the tap water is 0-70 degrees;

[0042] In this embodiment, the water-enhancing agent adopts waterproof emulsion, Tianjin World Sanwei Chemical Trading Co., Ltd.;

[0043] In this embodiment, the special cellulose for insulation boards is produced from Shijiazhuang Runbo Cellulose Factory;

[0044] In this embodiment, the expansion agent is modified cellulose, 0.3 kg is dissolved in 8 kg of 70° hot water, and the modified cellulose is produced in Shijiazhuang Runbo Cellulose Factory;

[0045] In this embodiment, the model of ordinary Portland cement is 525# or 425#.

[0046] Mix the above-mentioned raw ...

Embodiment 3

[0048] The formula of this example can be used to make Class A non-combustible insulation board; its original proportions are: tap water 56-60kg, water reducing agent 1-2kg, early strength agent 1-2kg, redispersible latex powder 2-6kg, ordinary silicic acid 150kg of cement, 1.6 cubic polystyrene particles, of which the polystyrene particles are 8-12kg / cubic.

[0049] In this embodiment, the temperature of tap water is 4-70 degrees.

[0050] Start mixing and sequentially add the above-mentioned raw materials, blanking to discharging for 15 minutes, the finished cement polystyrene particle board has a dry density of 175-190kg / cubic, fireproof grade A 2, compressive strength 0.4-0.5MPa, tensile strength Strength> 0.1 MPa, water absorption <10%, thermal conductivity of 0.045-0.069.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com