Bottle preprocessing unit of equipment for printing wine bottles with crooked mouths

A technology of pretreatment unit and printing equipment, applied in printing, printing machine, rotary printing machine and other directions, can solve the problems of inability to use crooked wine bottles, low efficiency, etc., and achieve smooth and reliable conveying processing, high degree of automation, adjustment handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

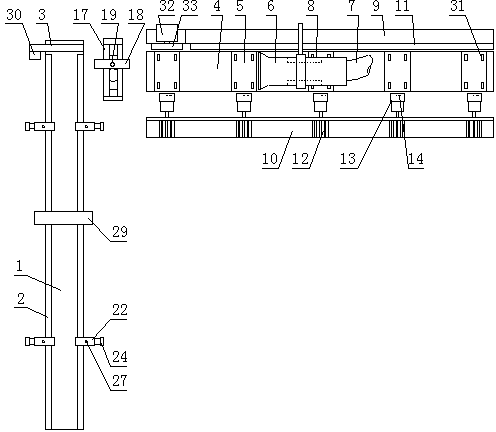

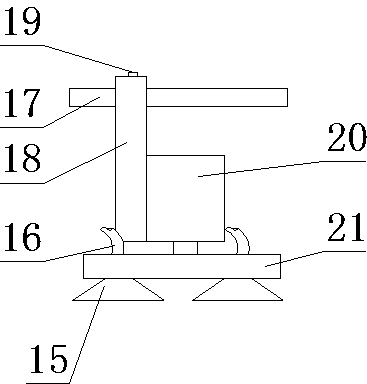

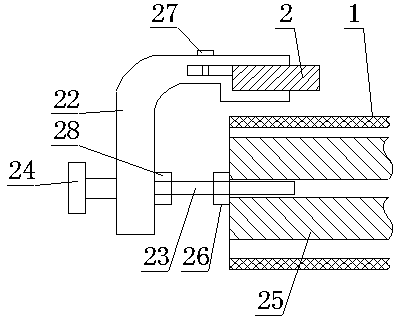

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] as follows Figure 1-Figure 3 As shown in the figure, a bottle-feeding pretreatment unit of crooked-mouth wine bottle printing equipment includes a bottle-feeding conveying device, a wine bottle preheating device, and a bottle-feeding transfer device arranged between them;

[0034] The bottle feeding conveying device includes a conveying belt 1 arranged horizontally, the belt rollers at both ends of the conveying belt 1 are arranged on the frame and driven by the belt motor to rotate, and the two sides of the upper part of the conveying belt 1 extend horizontally along the length direction of the belt to set limit stops. Plate 2, a bottle baffle 3 on the upper part of the bottle outlet end of the conveyor belt 1;

[0035] The preheating device includes a preheated wine bottle installation platform 4 arranged horizontally, and several wine bottle insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com