Winding needle mechanism with variable winding diameter and winding device

A needle winding, variable technology, applied in battery assembly, climate sustainability, sustainable manufacturing/processing, etc., which can solve problems such as difficulty in adjusting the winding diameter of the needle winding mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

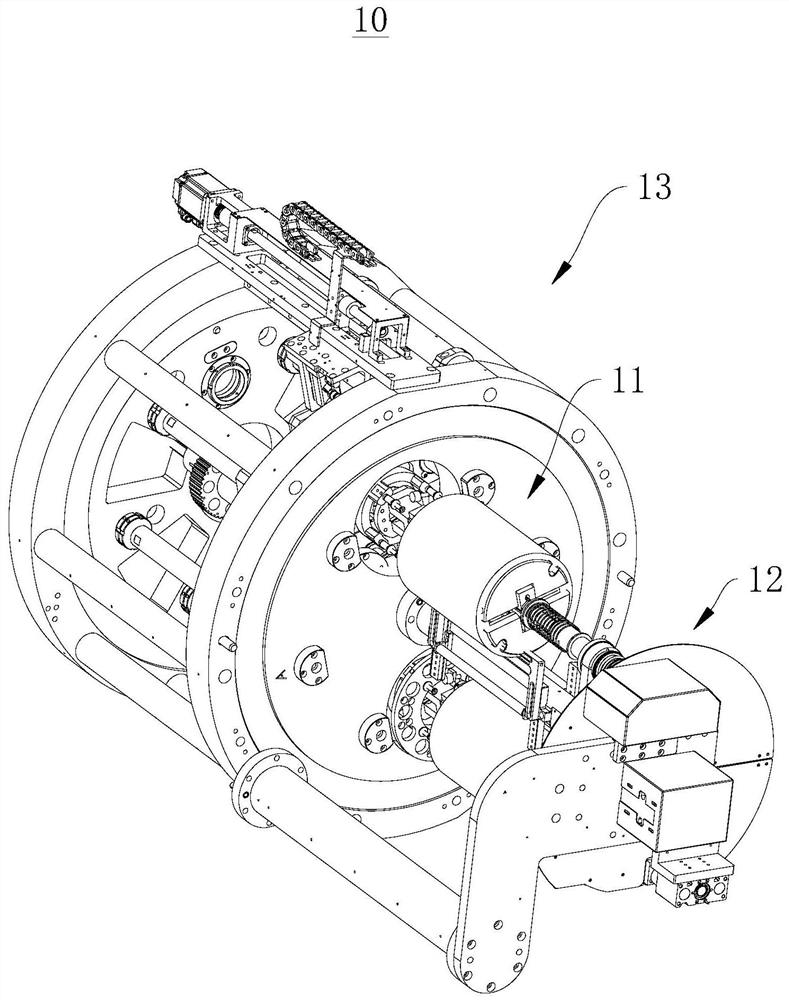

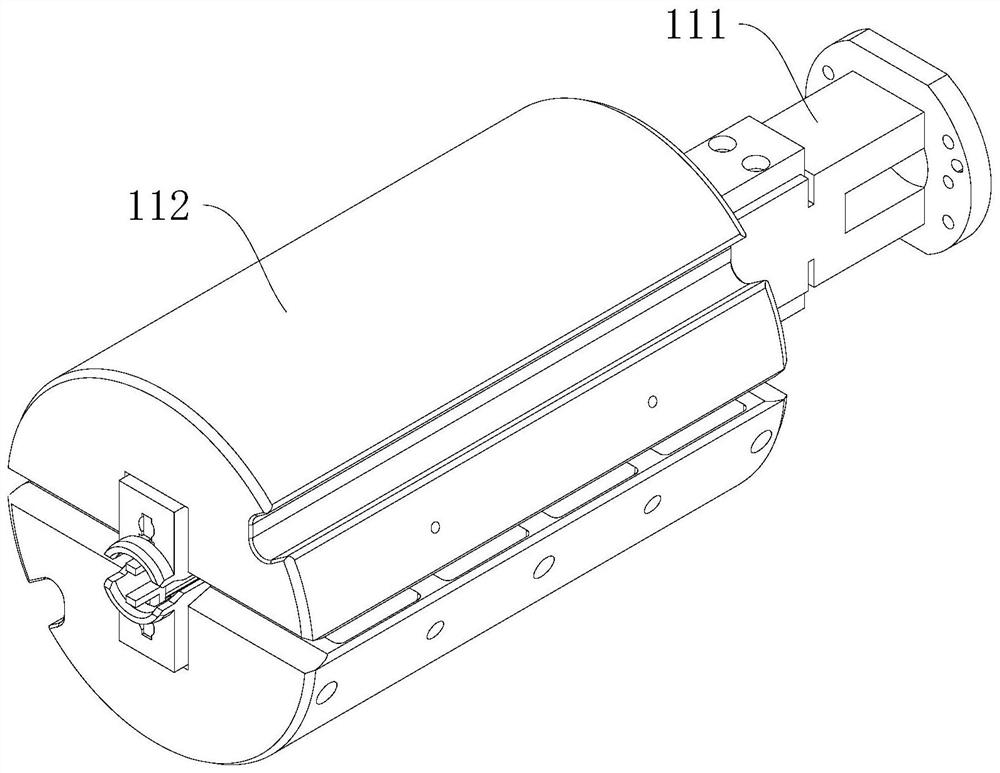

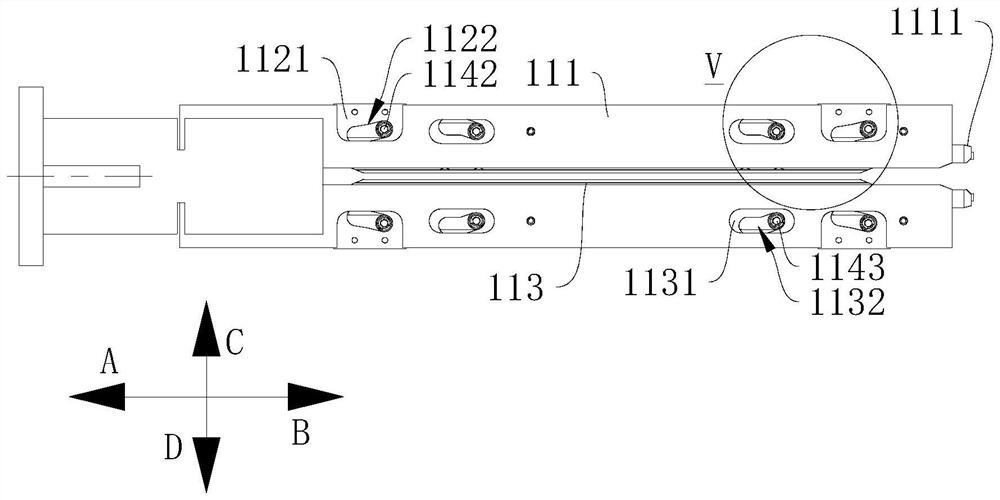

[0046] see figure 1 , figure 1 It is a schematic perspective view of the three-dimensional structure of the variable diameter needle winding mechanism 10 provided by the embodiment of the present invention.

[0047] The embodiment of the present invention provides a needle winding mechanism 10 with a variable winding diameter. The needle winding mechanism 10 with a variable winding diameter has the characteristic of being able to adjust the winding diameter. The needle winding mechanism 10 with variable winding diameter can be applied to electric core production scenarios such as winding devices. When the needle winding mechanism 10 with variable winding diameter is applied to a winding device (not shown in the figure), the winding of the winding device The driving member can drive the needle winding assembly 11 of the variable winding diameter needle winding mechanism 10 to rotate to perform the work of winding the battery core. Since the winding device adopts the variable w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com