Elastic waistline sheet material processing method

A technology of elastic waistline and elastic sheet, which is applied in medical science, clothing, underwear, etc., can solve problems such as difficulty in mass production, and achieve the effect of ensuring processing quality, saving space and time, and avoiding bad effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

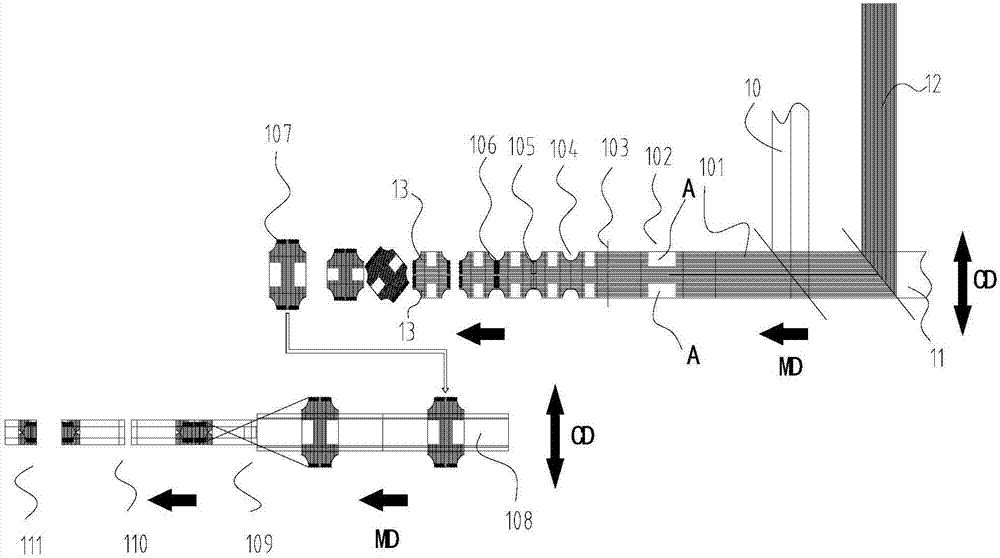

[0030] Please also refer to Figures 1 to 6 , a method for manufacturing a wearing article, comprising the following steps:

[0031] 1. First, add a group of rubber bands 12 between the upper non-woven fabric 10 and the lower non-woven fabric 11 for compounding to make a strip-shaped elastic sheet 101; then stretch along the flow direction MD and stretch along the flow direction The step of conveying the belt-shaped elastic sheet 101 stretched in MD along the flow direction MD.

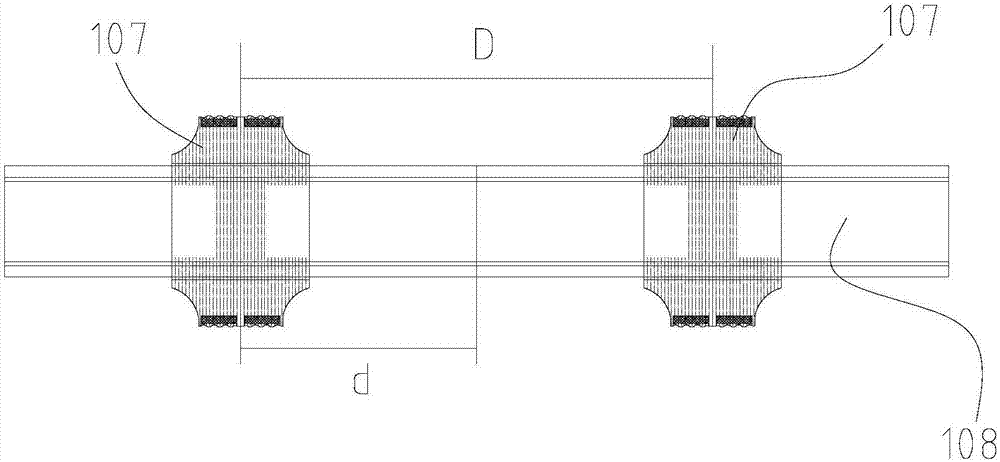

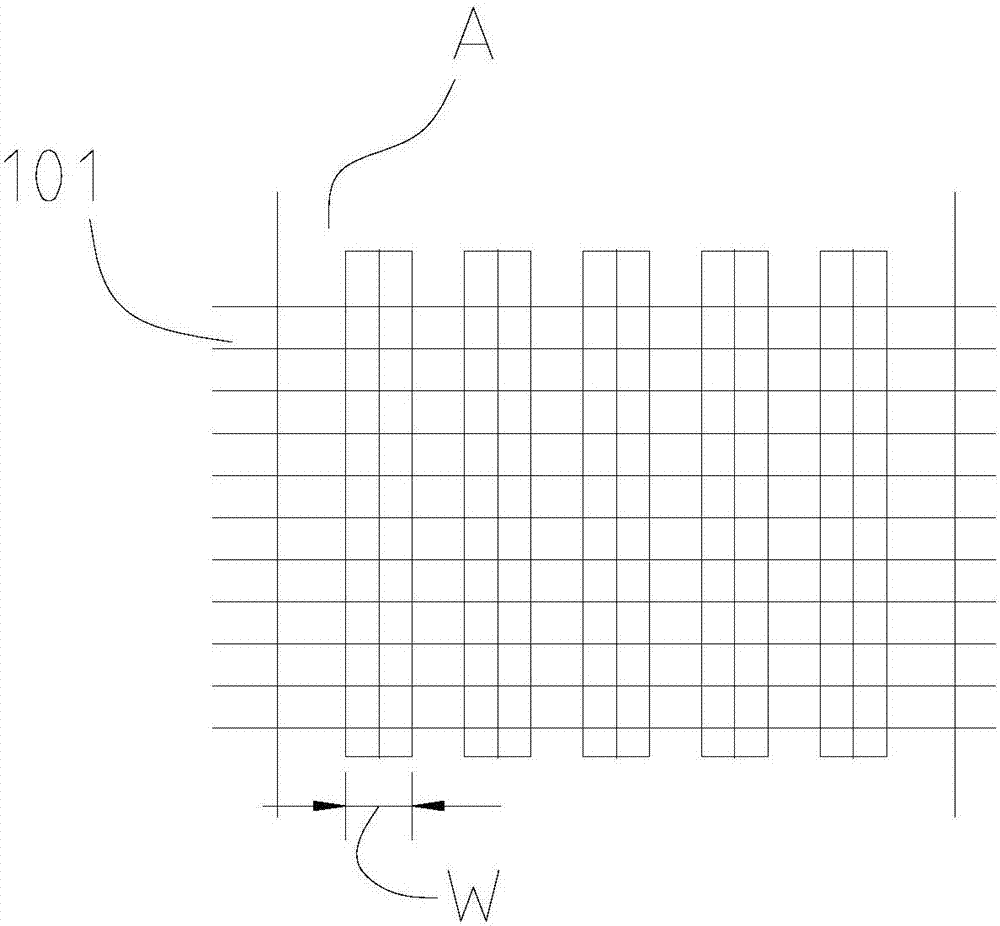

[0032] 2. Partial elastic cutting 102 is performed on both sides of the elastic sheet 101 in the width direction CD. The cutting knife used to cut off the local elastic on the elastic sheet 101 has two blades arranged at intervals, such as image 3 The two blades shown cut out an elastic body cut-off area A on the elastic sheet 101. In the above-mentioned area A, by changing the intermittent glue application mode of the glue gun, the width W of several glue patterns in this area is changed, so as to...

Embodiment 2

[0048] Please also refer to Figures 7 to 9 , a method for manufacturing a wearing article, comprising the following steps:

[0049] 1. First, add a group of rubber bands 12 between the upper non-woven fabric 10 and the lower non-woven fabric 11 for compounding to make a strip-shaped elastic sheet 101; then stretch along the flow direction MD and stretch along the flow direction The step of conveying the belt-shaped elastic sheet 101 stretched in MD along the flow direction MD.

[0050] 2. Partial elastic cutting 102 is performed on one side of the elastic sheet 101 in the width direction CD. The cutting knife used to cut off the local elastic on the elastic sheet 101 has two blades arranged at intervals. The two blades cut out an elastic body cutting area A on the elastic sheet 101. The way of glue makes the width W of several glue patterns in this area change, so as to achieve the purpose of changing the tension in area A. Specifically, when the width W of the glue type i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com