Device for automatically coupling optical communication sub-assemblies and method for eliminating delaying in coupling procedures

An automatic coupling and sub-module technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve problems affecting product production, many subjective judgment factors, and difficult to control product quality consistency, so as to improve production efficiency and reduce manpower Production costs, the effect of improving monitoring capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

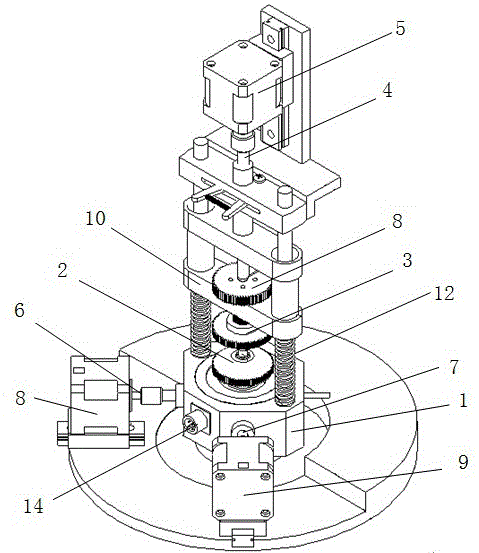

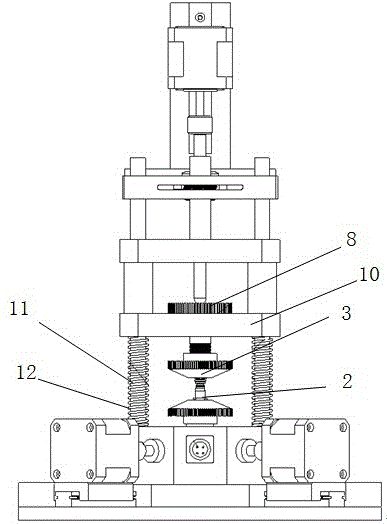

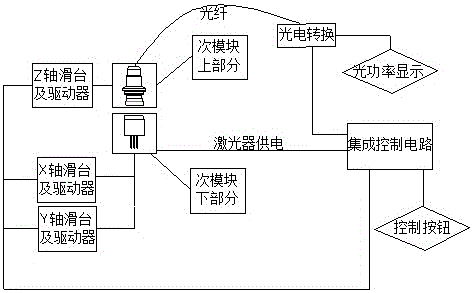

[0031] see Figure 1 to Figure 6 As shown, the optical communication sub-module automatic coupling device includes a base 1, a lower fixture 2 carried on the base 1, an upper fixture 3 arranged corresponding to the lower fixture 2 and located on the lower fixture 2, connected to the upper fixture 3 and vertically Z-axis 4 that moves, Z-axis driver 5 that drives Z-axis 4 to move, X-axis 6 that connects lower fixture 2 and moves laterally, Y-axis 7 that also connects lower fixture 2 and moves laterally, and X-axis that drives X-axis 6 to move The driver 8, the Y-axis driver 9 that drives the Y-axis 7 to move; the lower part of the lower fixture 2 extends into the base 1, the X-axis 6 and the Y-axis 7 are also inserted into the base 1 and connected with the lower fixture 2; the X-axis 6 and the Y-axis The directions of motion of 7 are perpendicular to each other. The optical communication sub-module automatic coupling device also includes a beam 10 and a pair of supporting legs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com