Embossing device for artificial leather production

An artificial leather and embossing technology, applied in textiles, papermaking, textile material cutting and other directions, can solve problems such as unreachable hand feel and elasticity, limited area of embossed panels, increased production costs, etc., to reduce labor production costs, The effect of better use flexibility and stronger use flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

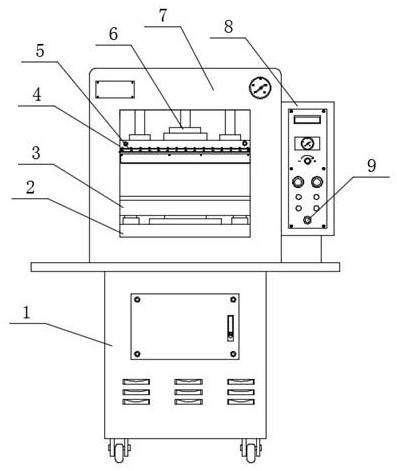

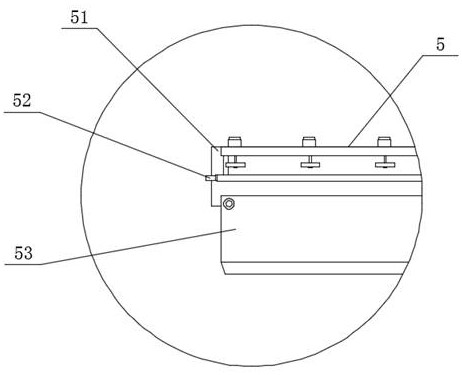

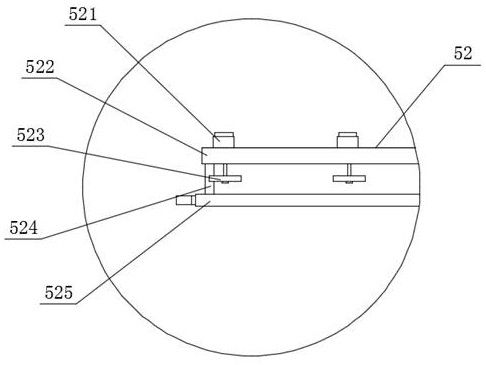

[0026] Such as Figure 1-2 As shown, an embossing device for the production of artificial leather includes a body 1 and a stamping table 7, the top end of the body 1 is connected with a stamping table 7, and the upper end of the front end of the stamping table 7 is connected with a connecting rod 6 , the bottom end surface of the connecting rod 6 is connected with the stamping panel 4 by bolts, the cutting knife group 5 is connected to the lower position of the front end surface of the stamping panel 4, the workbench 3 is arranged below the cutting knife group 5, and the bottom of the workbench 3 The end face is connected with a buffer table 2 by bolts, and the right side of the buffer table 2 is provided with a control box 8 on the right end face of the stamping table 7, and a power switch 9 is connected to the lower end of the front end face of the control box 8, and a cutting knife set 5 It includes a fixed knife plate 51 , a cleaning plate 52 and a cutting blade 53 , a cle...

Embodiment 2

[0029] Such as Figure 1-3 As shown, an embossing device for the production of artificial leather includes a body 1 and a stamping table 7, the top end of the body 1 is connected with a stamping table 7, and the upper end of the front end of the stamping table 7 is connected with a connecting rod 6 , the bottom end surface of the connecting rod 6 is connected with the stamping panel 4 by bolts, the cutting knife group 5 is connected to the lower position of the front end surface of the stamping panel 4, the workbench 3 is arranged below the cutting knife group 5, and the bottom of the workbench 3 The end face is connected with a buffer table 2 by bolts, and the right side of the buffer table 2 is provided with a control box 8 on the right end face of the stamping table 7, and a power switch 9 is connected to the lower end of the front end face of the control box 8, and a cutting knife set 5 Comprising a fixed knife plate 51, a cleaning plate 52 and a cutting blade 53, a cleani...

Embodiment 3

[0032] Such as Figure 1-4 As shown, an embossing device for the production of artificial leather includes a body 1 and a stamping table 7, the top end of the body 1 is connected with a stamping table 7, and the upper end of the front end of the stamping table 7 is connected with a connecting rod 6 , the bottom end surface of the connecting rod 6 is connected with the stamping panel 4 by bolts, the cutting knife group 5 is connected to the lower position of the front end surface of the stamping panel 4, the workbench 3 is arranged below the cutting knife group 5, and the bottom of the workbench 3 The end face is connected with a buffer table 2 by bolts, and the right side of the buffer table 2 is provided with a control box 8 on the right end face of the stamping table 7, and a power switch 9 is connected to the lower end of the front end face of the control box 8, and a cutting knife set 5 It includes a fixed knife plate 51, a cleaning plate 52 and a cutting blade 53, a clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com