Batch detection and packaging system for temperature controller

A packaging system and batch testing technology, applied in packaging, sorting and other directions, can solve the problems of high labor cost, large usage, omission of quality inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

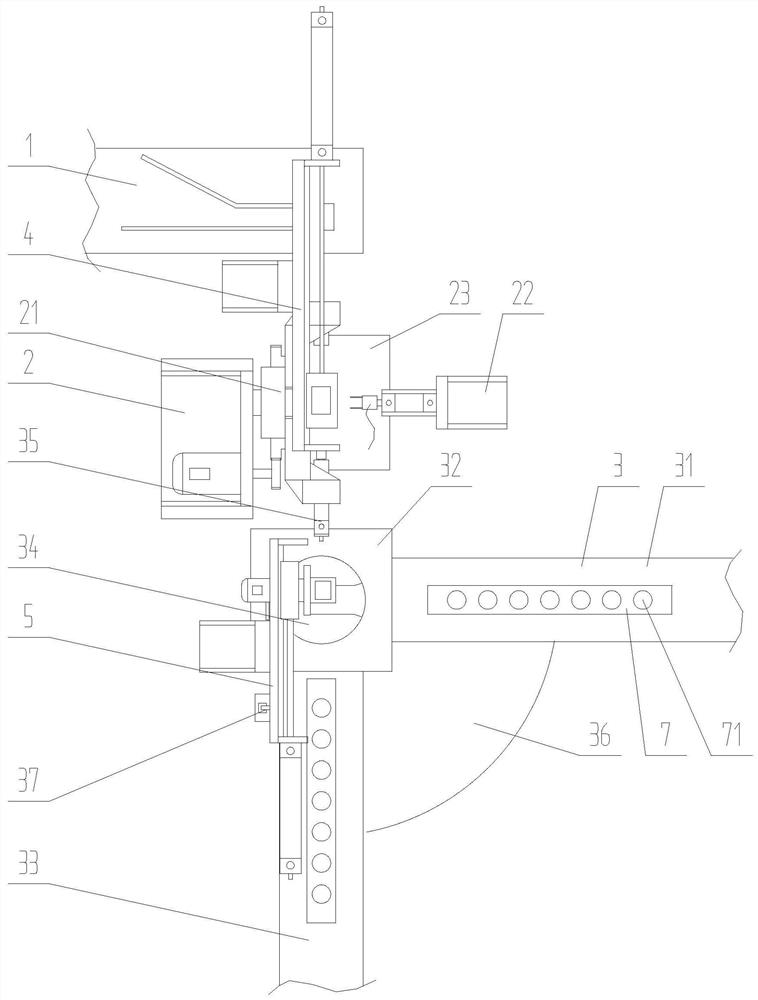

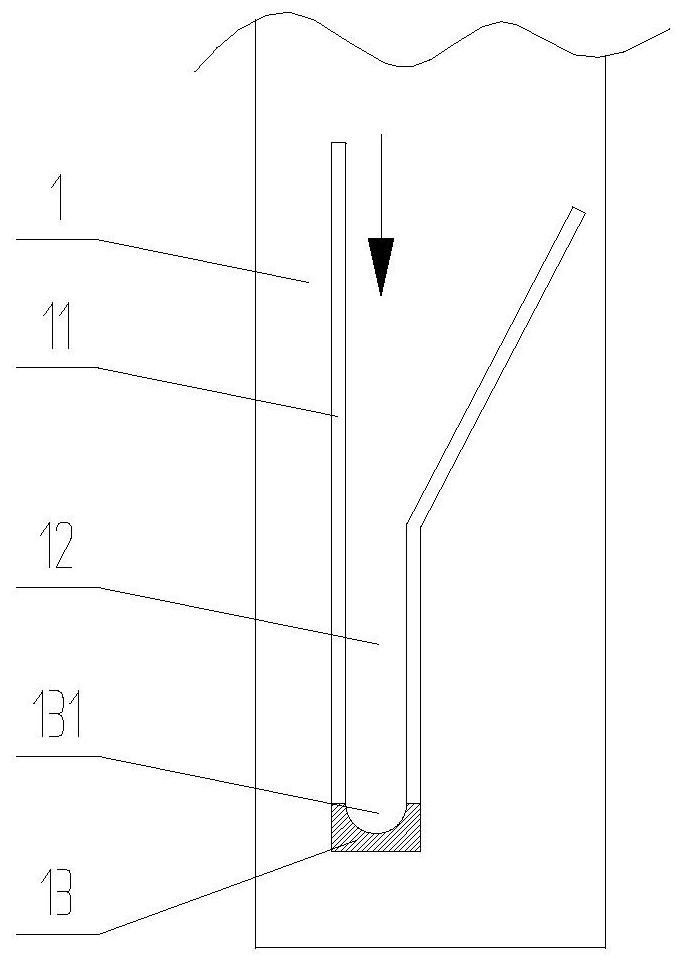

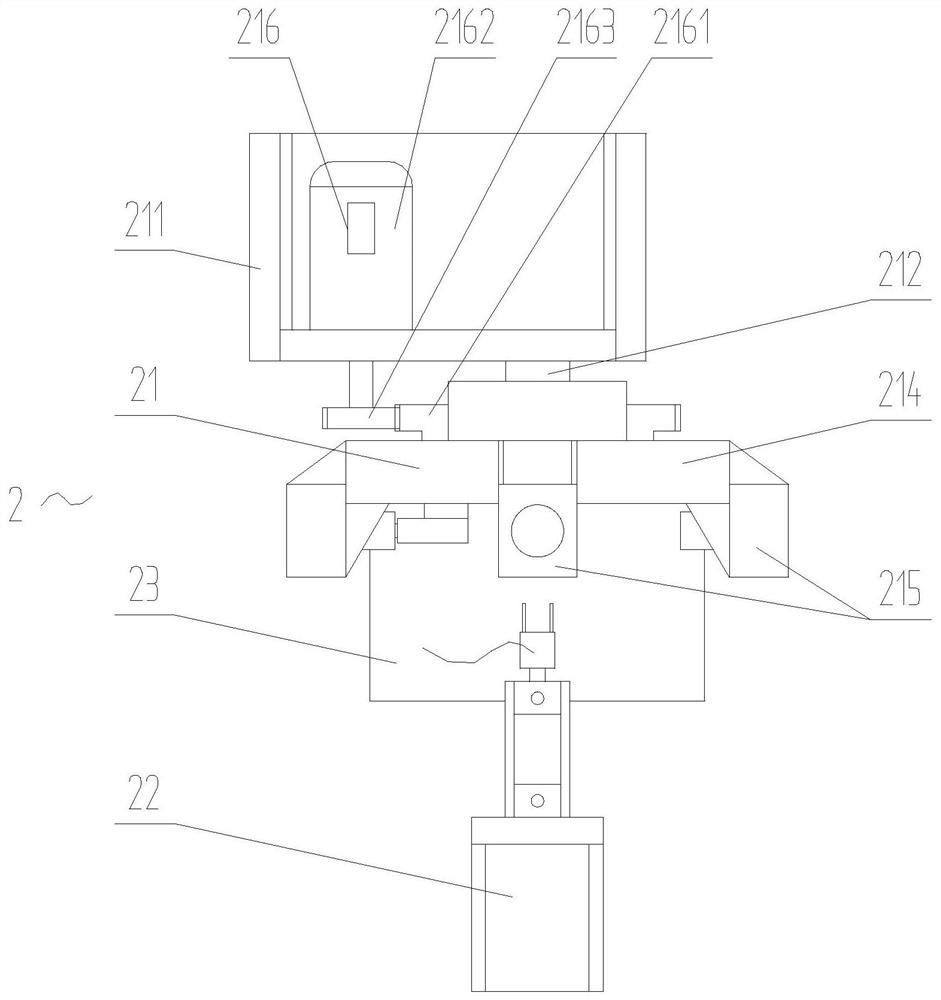

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The descriptions of "left" and "right" in the present invention are all based on figure 1 For the reference direction:

[0028] The temperature controller 6 applicable to the present invention is as Figure 12 As shown in the shape, two power supply pins 61 are arranged under the temperature controller 6 .

[0029] The thermostat packing strip 7 that the packaging line of the present invention adopts has a plurality of thermostat mounting holes 71, and a group of induction stickers 72 are arranged on both sides of the thermostat packaging strip 7, and the quantity of each group of induction stickers 72 is the same as that of the thermostat. The number of installation holes 71 is consistent, and the induction stickers 72 are arranged in one-to-one correspondence with the installation holes 71 of the thermostat.

[0030] Such as Figure 1 to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com