Patents

Literature

76results about How to "Easy packing operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

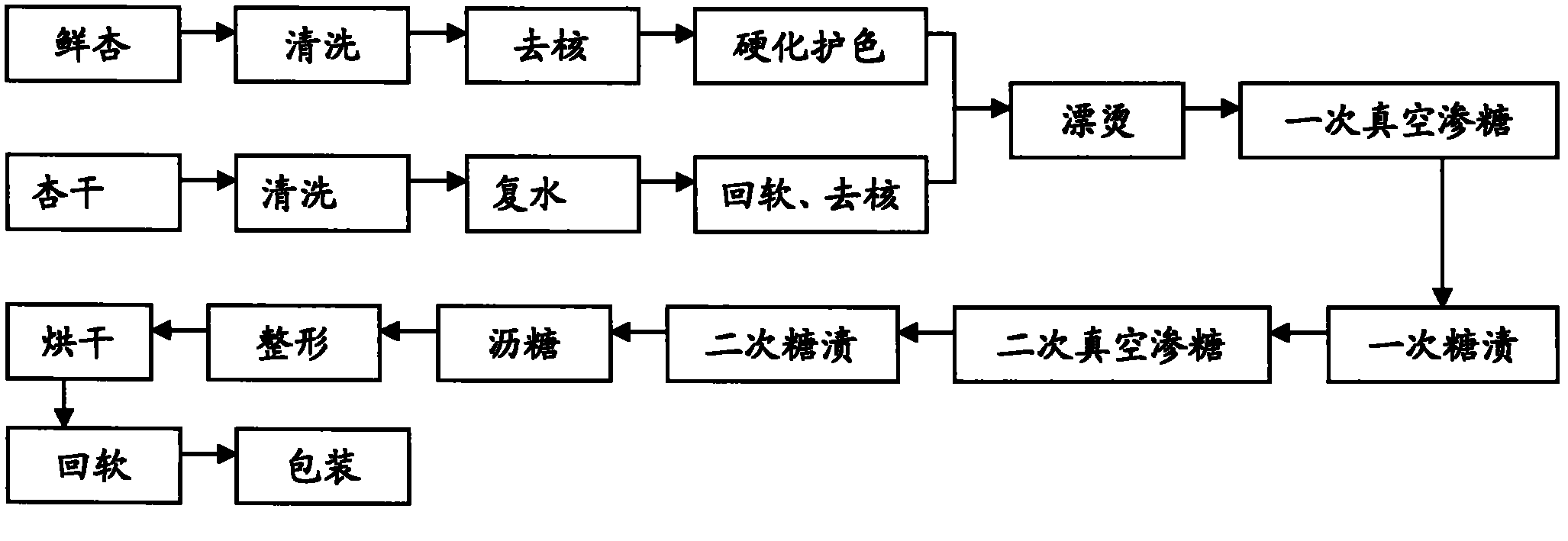

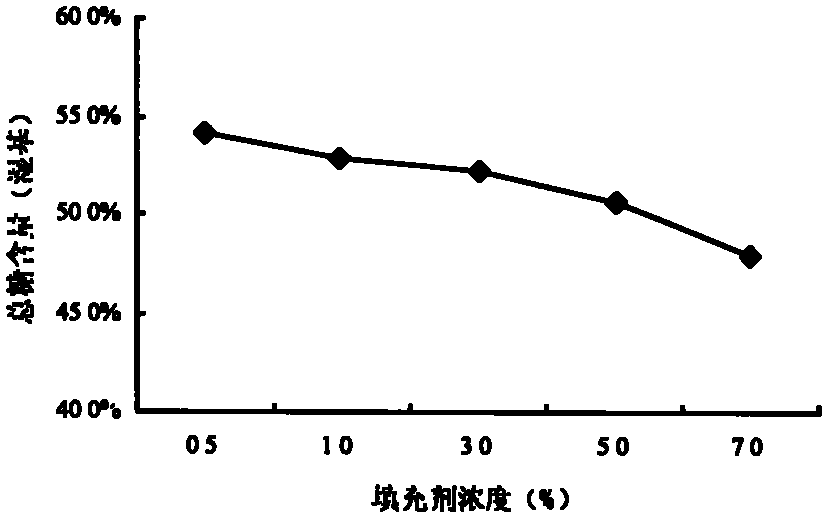

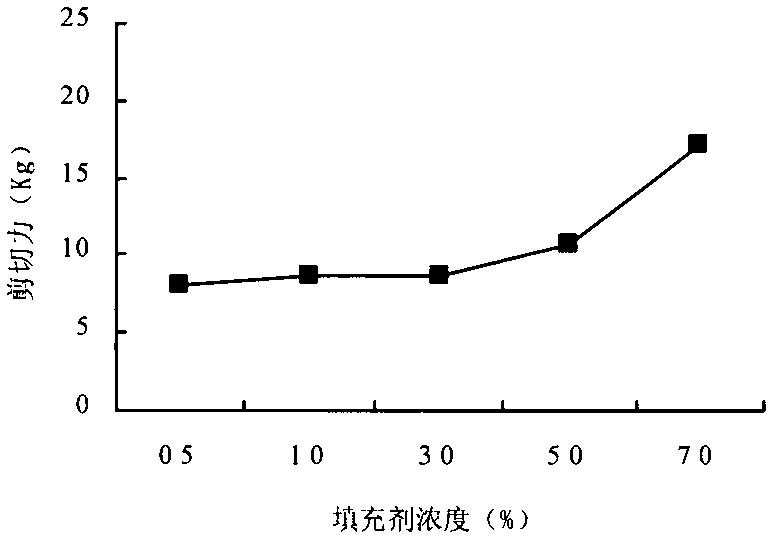

Method for preparing low sugar preserved apricots

ActiveCN102204618AIncrease production capacityHigh technology contentConfectionerySweetmeatsLow glucoseDried apricot

The invention discloses a method for preparing low sugar preserved apricots. Key technical parameters which can influence the quality of the low glucose preserved apricots are determined by using dried apricots or fresh apricots as raw materials and adopting novel nutritive sweeteners with specific physiological functions, i.e., maltooligosaccharides as a filler and using fructose syrups as a sweetener, wherein in the primary vacuum sugar permeability process, the concentration of sugar solution is in the range of 30-35 percent, the time is 20min, the sugar solution has a temperature of 60 DEG C, the vacuum degree is 0.07Mpa, and the sugaring time under normal pressure is in the range of 10-15 hours; in the secondary vacuum sugar permeability process, the concentration of the sugar solution is in the range of 40-45 percent, the time is 20min, the sugar solution has a temperature of 60 DEG C, the vacuum degree is 0.07MPa, and the sugaring time under normal pressure is in the range of 10-15hours; and color, plumpness, sugar content and shearing force of a product are used as integrated quality evaluation indexes, so that the method for preparing the low sugar preserved apricots is determined. The preserved apricots prepared by adopting the method provided by the invention not only has low total sugar content, but also has specific nutritional value and has wide applicable consumer range.

Owner:XINJIANG AGRI UNIV

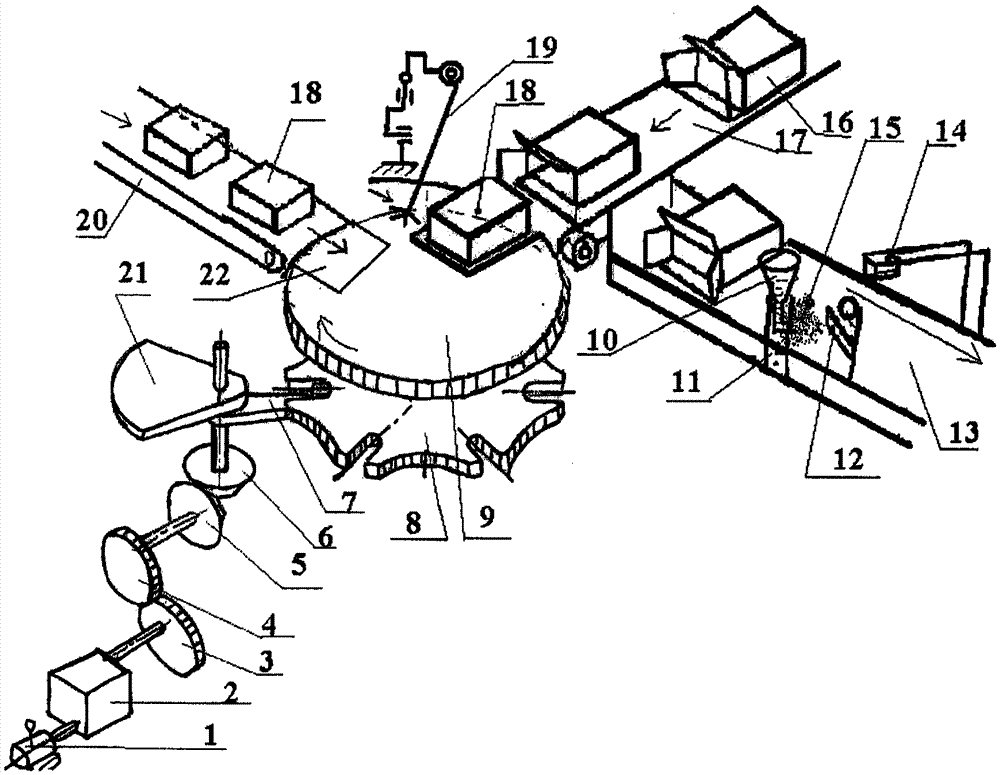

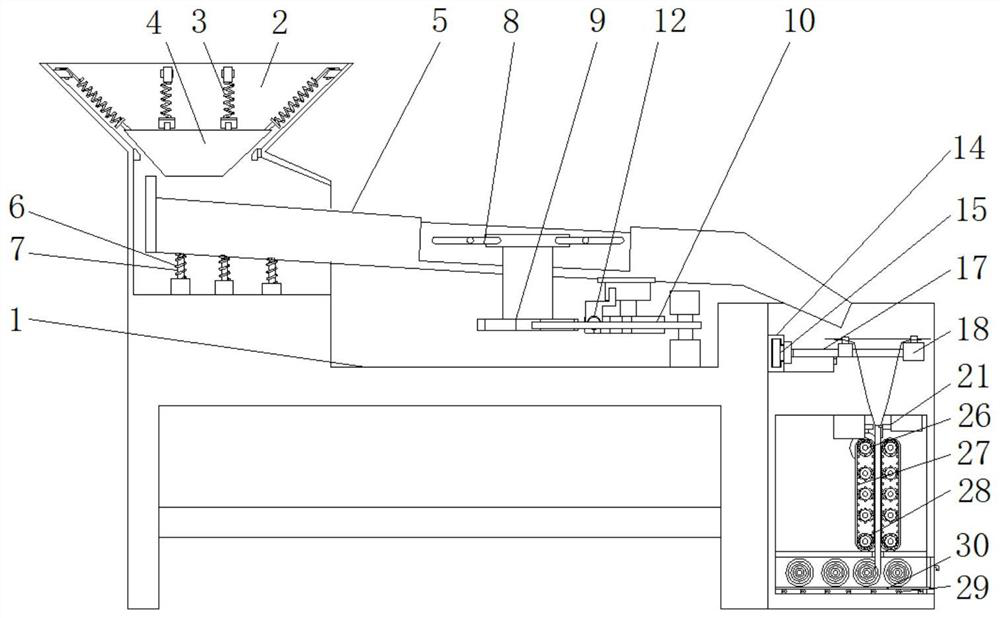

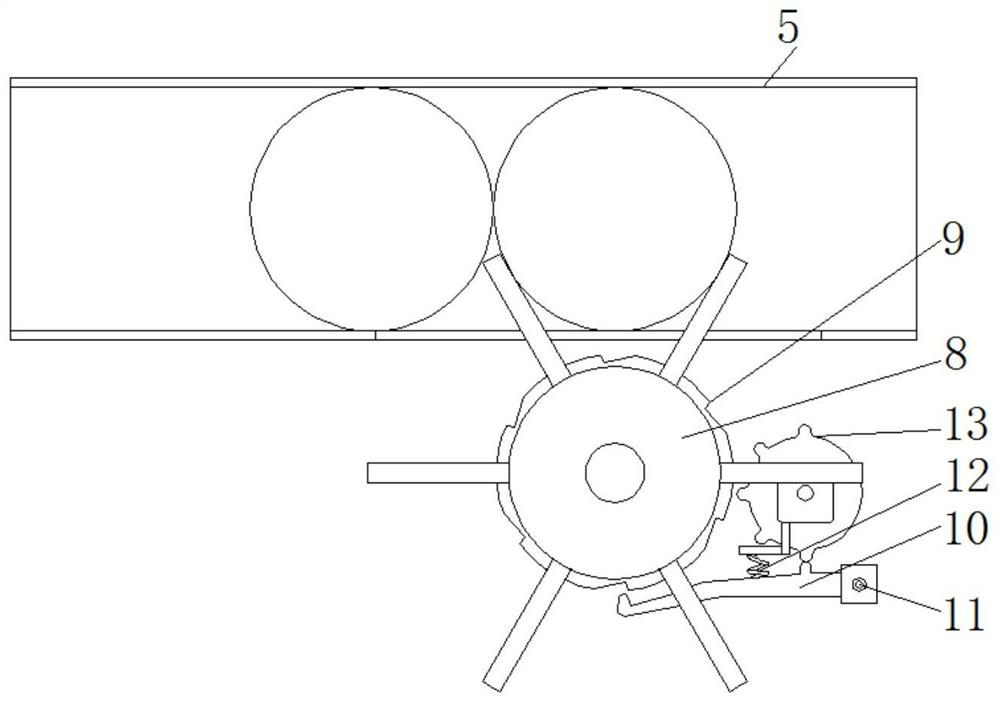

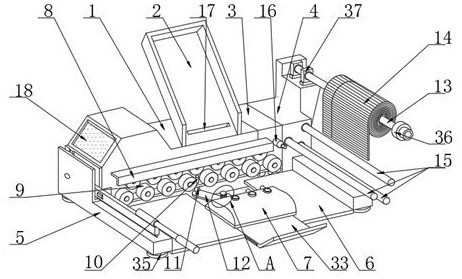

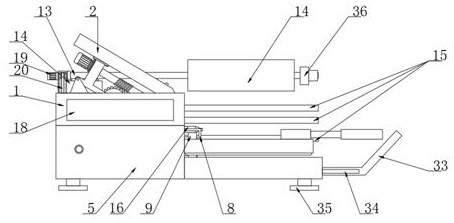

Automatic packaging equipment

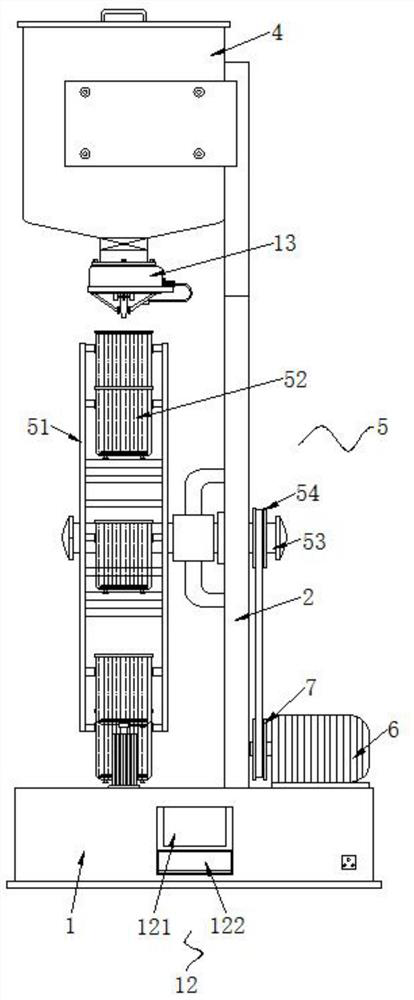

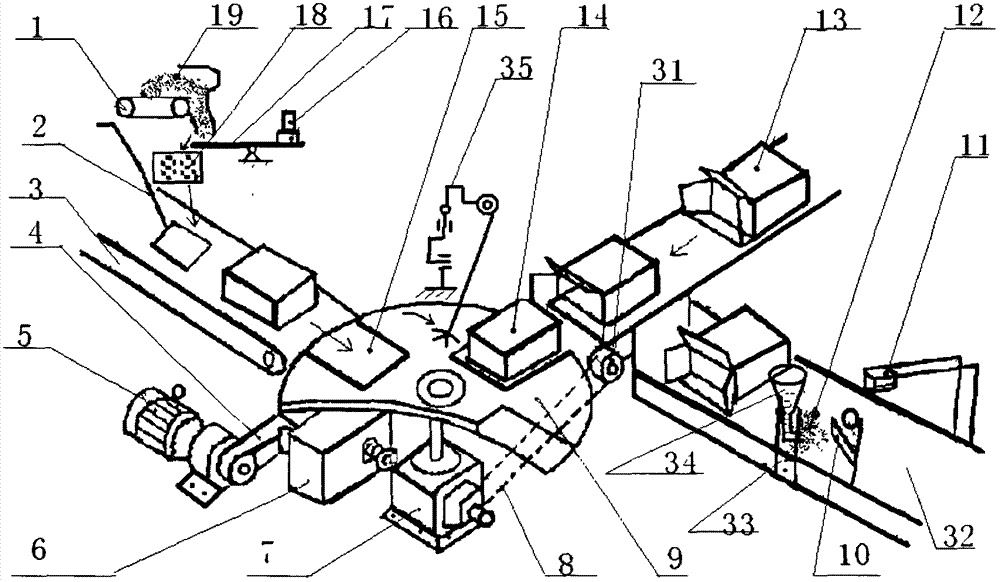

InactiveCN105438534AFully automatedReduce labor intensityWrapper twisting/gatheringTransmission beltReduction drive

The invention relates to packaging automation flow-line equipment and particularly relates to automatic packaging equipment. The automatic packaging equipment comprises a goods transmission system, a cam indexing rotary plate transmission system, an empty box transmission system and a package seal printing system, and is characterized in that the goods transmission system comprises goods and a goods transmission belt; the cam indexing rotary plate transmission system is composed of a motor, a speed reducer, a small elliptical gear, a large elliptical gear, a small cone gear, a large cone gear, a connecting rod, a grooved wheel, a rotary plate, a driver plate and a groove; and the grooved wheel and the rotary plate are assembled on the same shaft through two common flat keys. Due to the adoption of the automatic packaging equipment provided by the invention, the labor intensity of tedious work such as manual package, production date printing and the like can be lowered greatly, detecting automation and serialization can be achieved, the sealing operation is convenient, the weighting speed is fast, and the practicability is strong.

Owner:徐怡恺

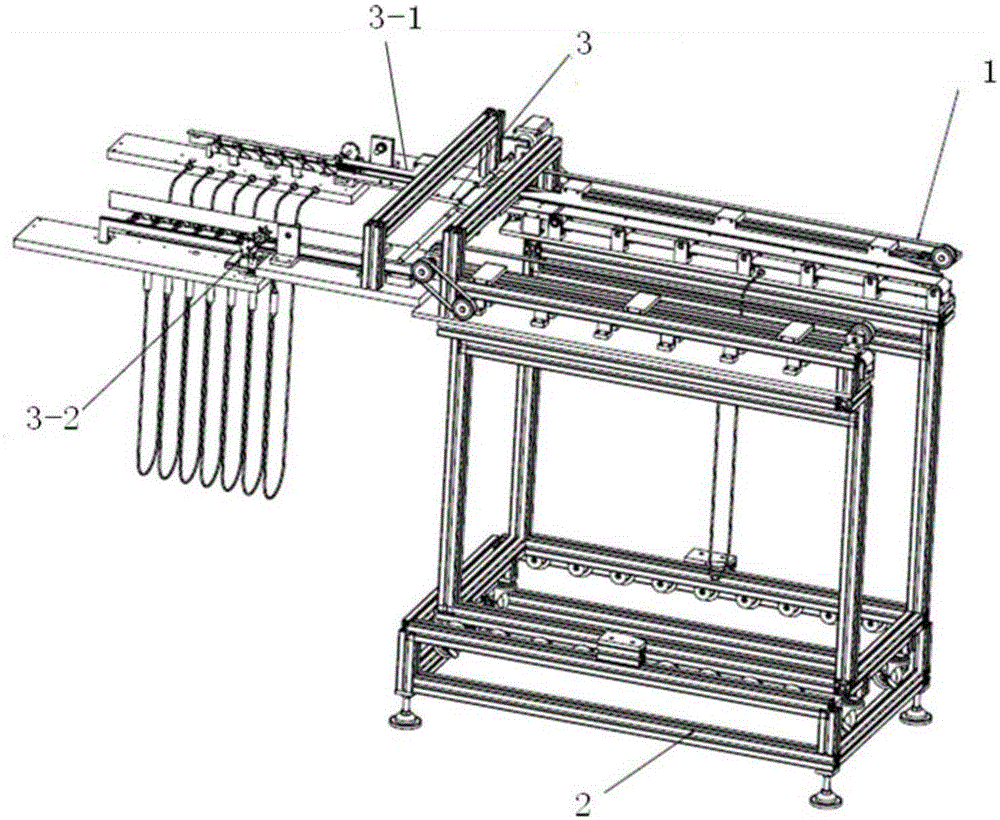

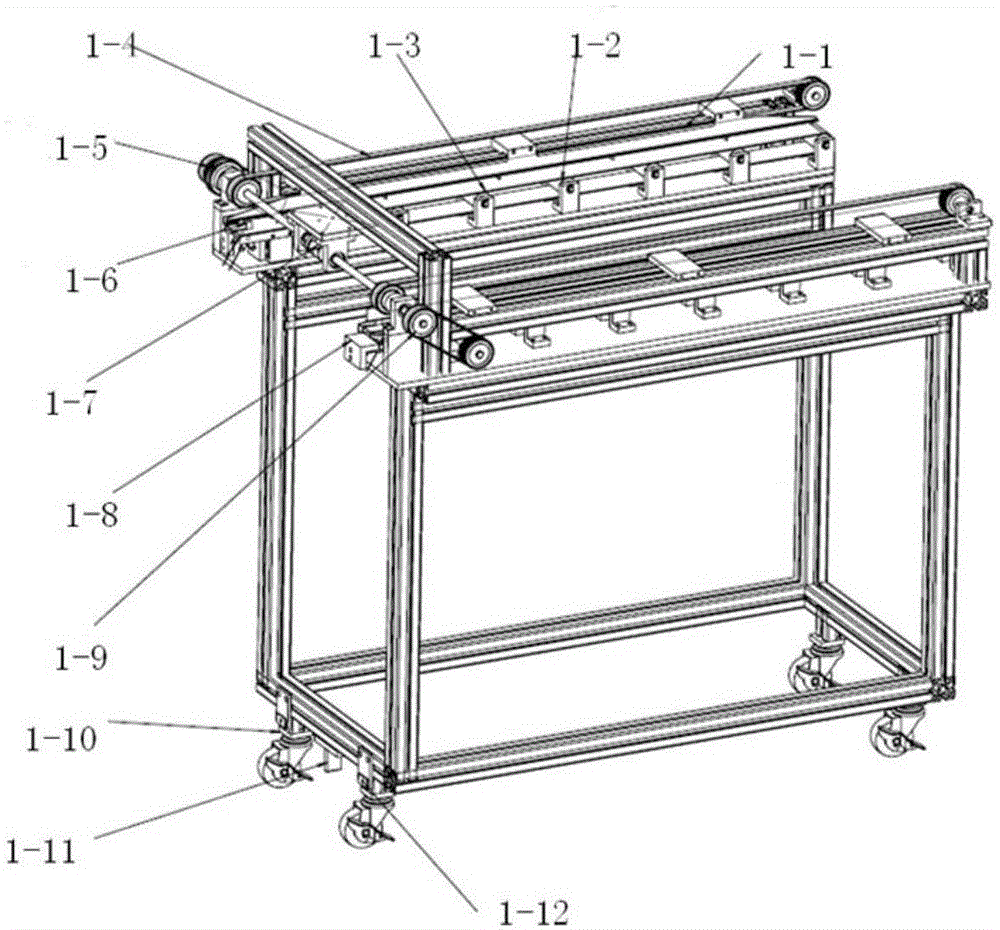

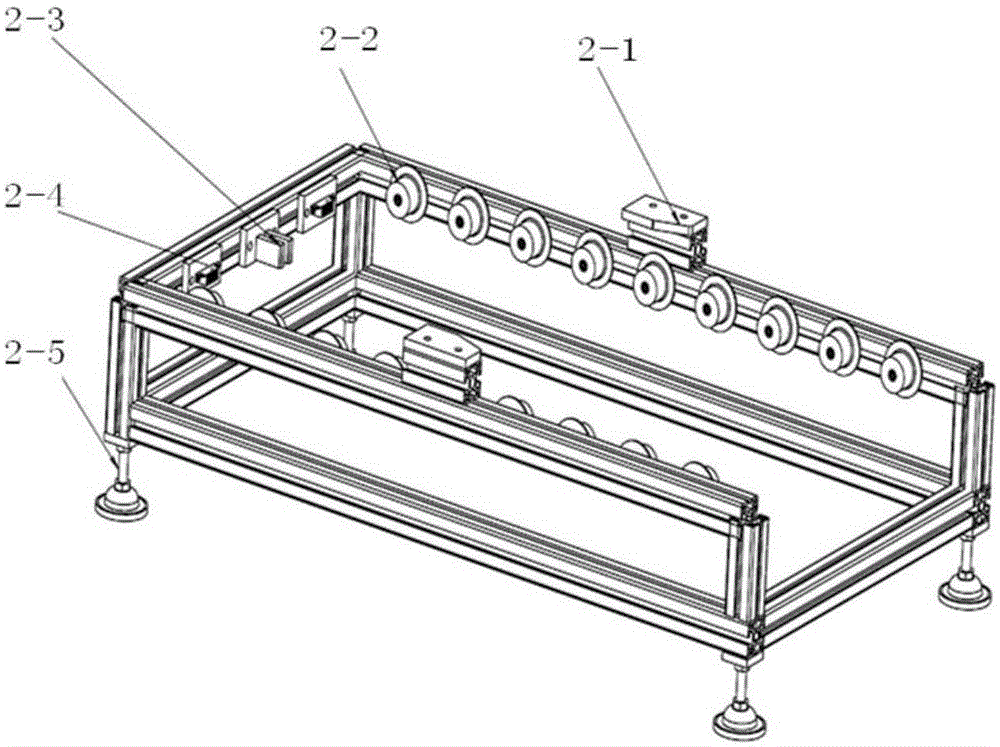

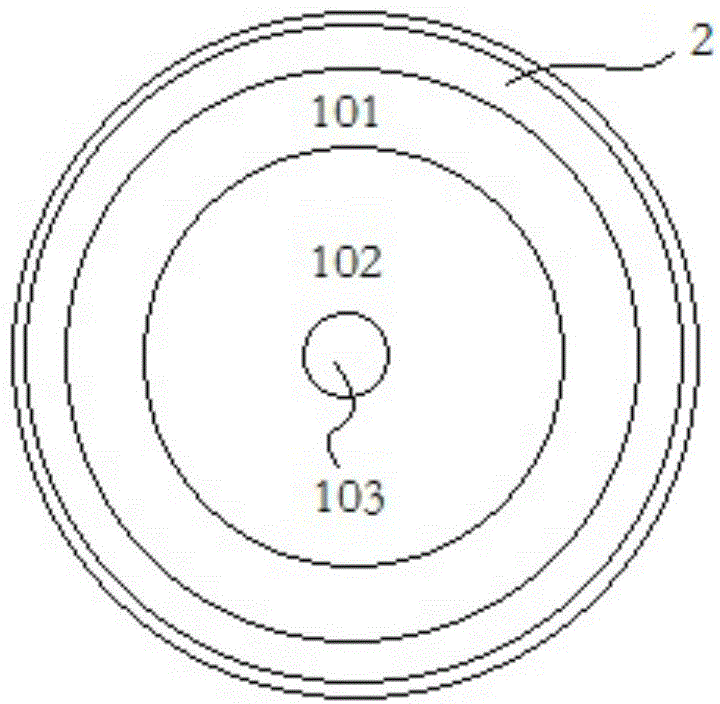

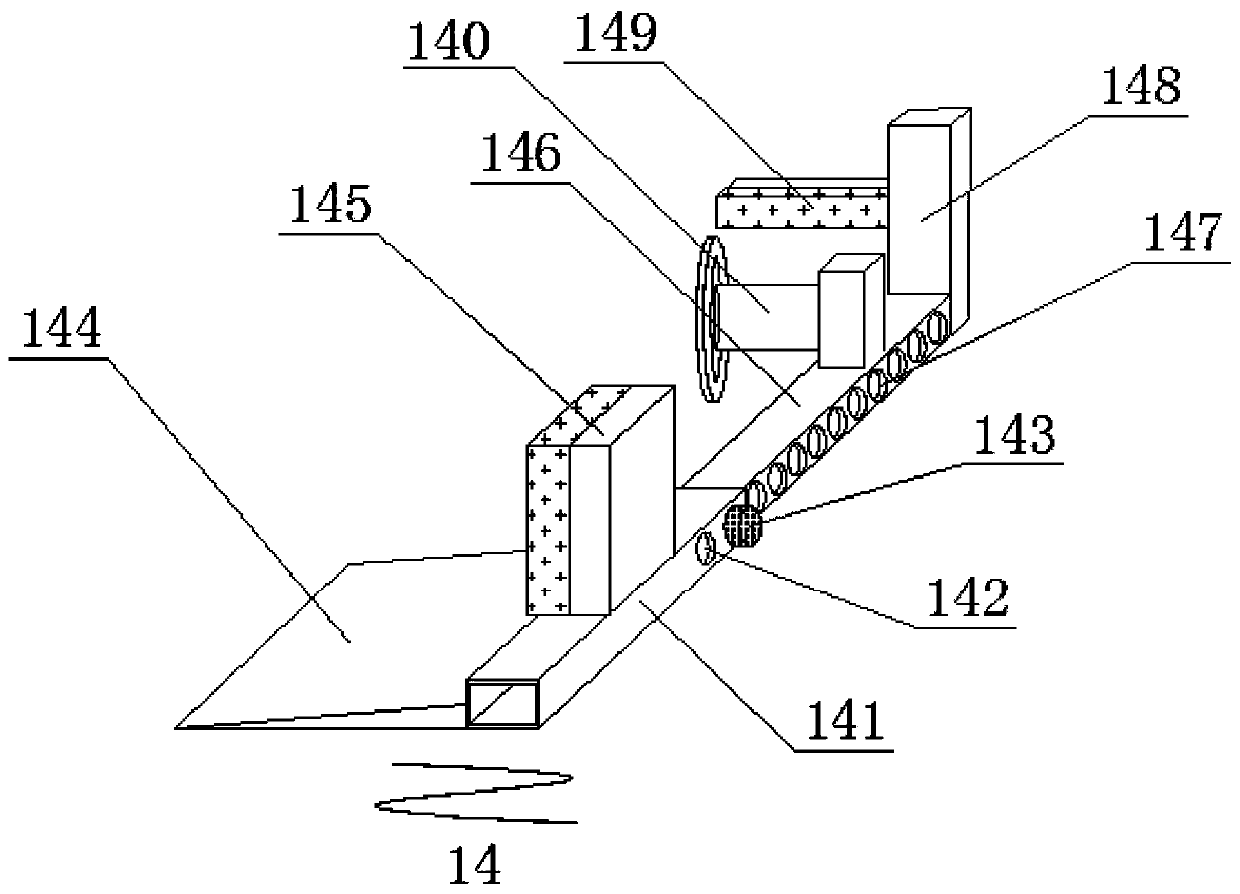

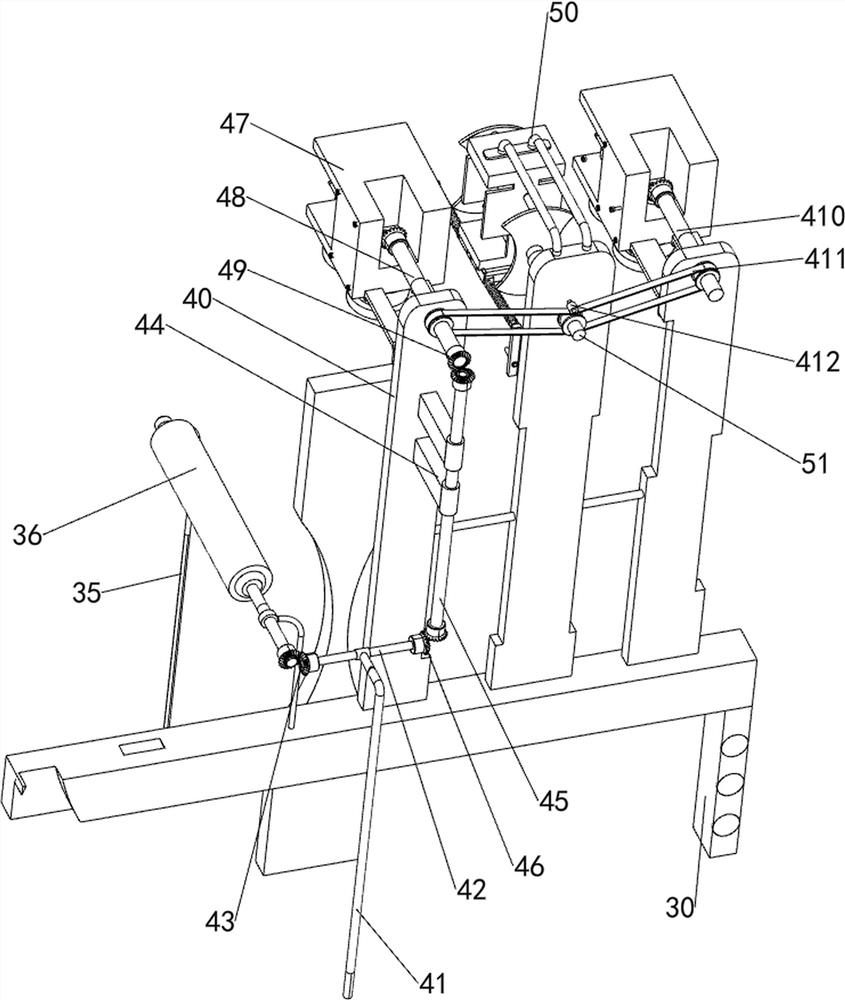

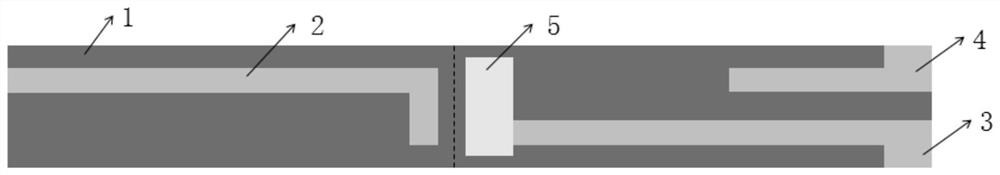

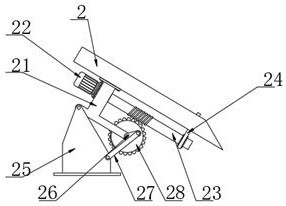

Infusion pipe conveying mechanism

ActiveCN105109945ASolve the problem of easy windingEasy to operateSupporting framesMechanical conveyorsButt jointEngineering

The invention discloses an infusion tube conveying mechanism. The infusion tube conveying mechanism comprises a loading mechanism and a storage mechanism in butt joint with the loading mechanism, the loading mechanism is used for feeding and conveying infusion tubes, and the storage mechanism is used for separating the infusion tubes conveyed from the loading mechanism to enable the infusion tubes to be arranged at preset intervals. The infusion tube conveying mechanism further comprises a loading mechanism limiting device which is arranged at the bottom of the loading mechanism and used for supporting the loading mechanism. According to the infusion tube conveying mechanism, separating operation and the like are carried out on the automatically-conveyed infusion tubes through a separating mechanism, and the problem that the tubes are likely to be wound is solved, so that subsequent packaging operation is more convenient. The butt joint mode of the ingeniously-designed separating mechanism and a loading trolley is adopted, so that the conveying process of the infusion tubes is smoother. The arrangement mode of a limiting mechanism is adopted in the design of the loading trolley, so that friction of trundles is avoided, and the service life of the loading mechanism is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

Fluorescent glass and preparation method and application thereof

The invention provides fluorescent glass and a preparation method and application thereof. Fluorescent powder is spherical non-aggregated fluorescent powder, so that higher optical performance is achieved, high-speed stirring is performed by only using a stirrer in the preparation process of the fluorescent glass, the stirring mixing time is short, the efficiency is high, treatment such as sieving, planar grinding, polishing and the like is not required, a processing technic is easier, the cost is lower, and the obtained fluorescent glass has higher light transmittance and high airtightness; and when the obtained fluorescent glass is applied to encapsulation of an LED (Light-Emitting Diode) chip, glass micro powder with higher airtightness, light transmittance and anti-ageing performance than silica gel or a transparent adhesive tape is coated on the chip, and the fluorescent glass is arranged on a glass micro powder layer on the chip with a dispensing method, so that the encapsulating operation is easier and more convenient, the airtightness and light transmittance is more excellent, and the radiating performance is high. The fluorescent glass is particularly suitable for encapsulating ultraviolet LEDs.

Owner:厦门市华海光电科技有限公司

LED packaging material, preparation method and application thereof

ActiveCN102442781AGood optical performanceShort mixing timeSemiconductor devicesLed packagingHigh pressure

The present invention discloses a LED packaging material, a preparation method and an application thereof. The LED packaging material comprises, by mass, 80-95% of glass micropowder and 5-20% of phosphor, wherein the phosphor is spherical non-aggregating phosphor. The preparation method comprises: adopting the glass micropowder and the phosphor as starting materials; stirring and mixing the glass micropowder, the phosphor and absolute alcohol to obtain composite powder body; filtering the composite powder body, and drying at a temperature of 100-150 DEG C to obtain the composite powder; placing the composite powder in a high temperature and high pressure grinding tool; adopting a continuous stamping and high temperature forming technology to treat the composite powder; and cooling to the room temperature to obtain the LED packaging material. The LED packaging material has characteristics of good light transmission rate, excellent air impermeability, and good heat dissipation performance so as to protect the use performance of the LED chip.

Owner:厦门市华海光电科技有限公司

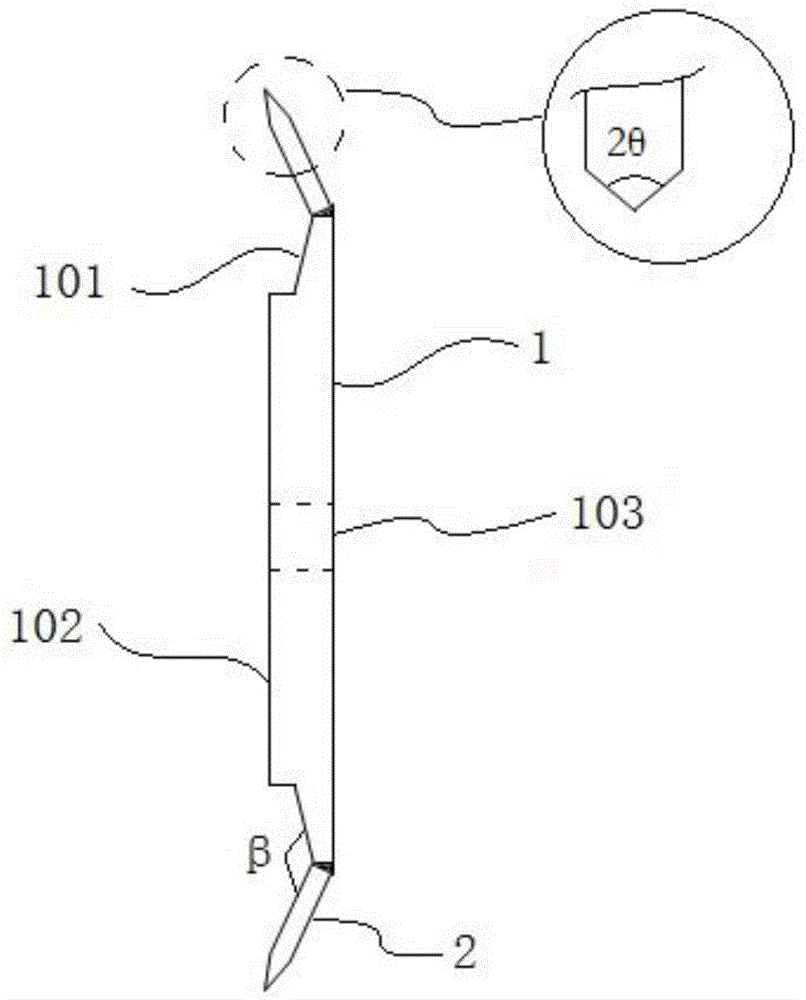

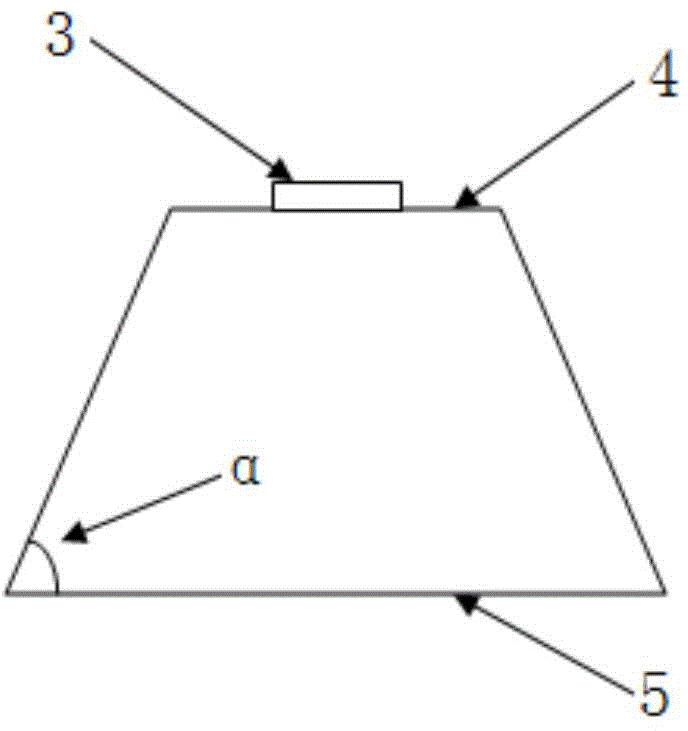

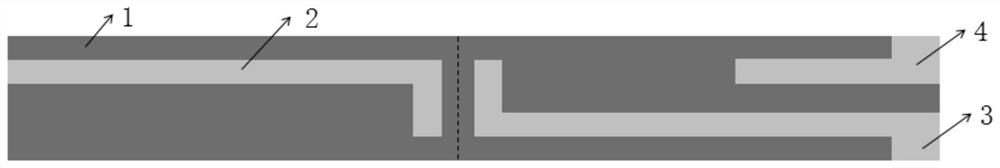

LED (light-emitting diode) chip cutting cutter with novel structure and LED chip cutting method

ActiveCN104476684AReduce cutting timeImprove cutting efficiencyFine working devicesSemiconductor devicesEngineeringSemiconductor

The invention discloses an LED (light-emitting diode) chip cutting cutter with a novel structure and an LED chip cutting method, which belong to the field of semiconductor device processing. The LED chip cutting cutter comprises a flange plate and a blade, wherein the flange plate is shaped like a disk, the center of the flange plate is provided with a flange bulge, the edge is provided with a flange transition, and the center of the flange bulge is provided with a mounting hole; the blade is shaped like a ring, and is fixed at the outer edge of the flange transition. The LED chip cutting cutter is highly stable under the condition of high-speed rotation, and is convenient to mount and dismount. By taking the cutting cutter as a cutting tool, the cutting method can be adopted to directly cut out chips with a trapeziform structure, cutting time is shortened, cutting efficiency is increased, and the cut chips are not damaged, and are high in luminous efficiency.

Owner:马鞍山太时芯光科技有限公司

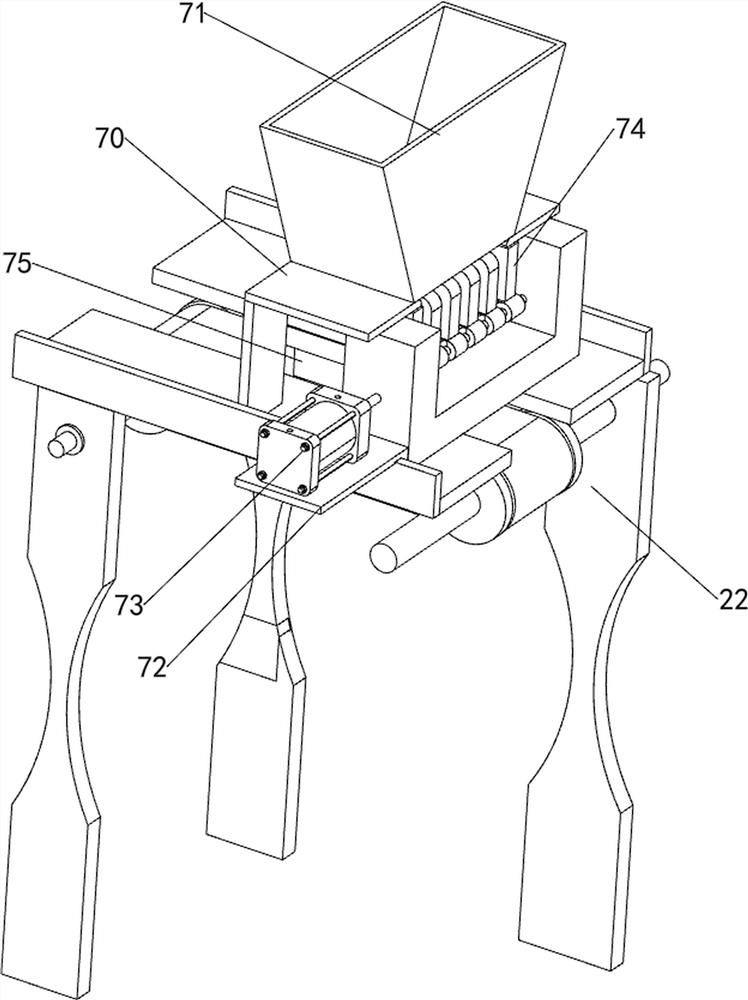

Bread production line and cutting mechanism thereof

ActiveCN107751275AImprove fitImprove guidanceDough dividingDough shaping and cutting apparatusProduction lineEngineering

The invention discloses a bread production line and a cutting mechanism thereof. According to the technical scheme, the bread production line is characterized by comprising a matching device, a stirring device, a fermentation tank, a forming device, a resting box and a baking oven which are sequentially arranged, wherein the cutting mechanism in the forming device comprises a mounting frame and cutters arranged on the mounting frame at intervals, the mounting frame comprises a cross rod, boxes corresponding to the cutters are arranged on the cross rod, slots allowing the cutters to penetrate out are formed in the bottoms of the boxes, and scraping plates abutting against side walls and cutting surfaces of the cutters are arranged in the boxes. By the aid of the scraping plates, the cutterscontinuously rotate in the flour cutting process, so that flour stick to the cutters can be scraped by the scraping plates continuously and left in the boxes, the flour cannot stick to the side wallsand the cutting surfaces of the cutters for a long time, and the following flour cutting process can be conducted well in order.

Owner:北京义利面包食品有限公司

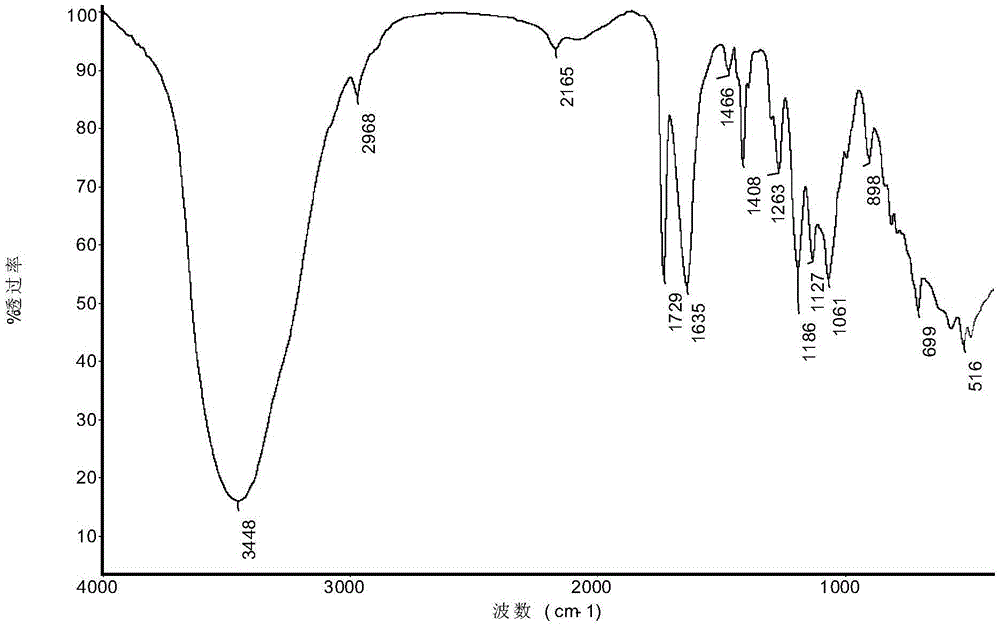

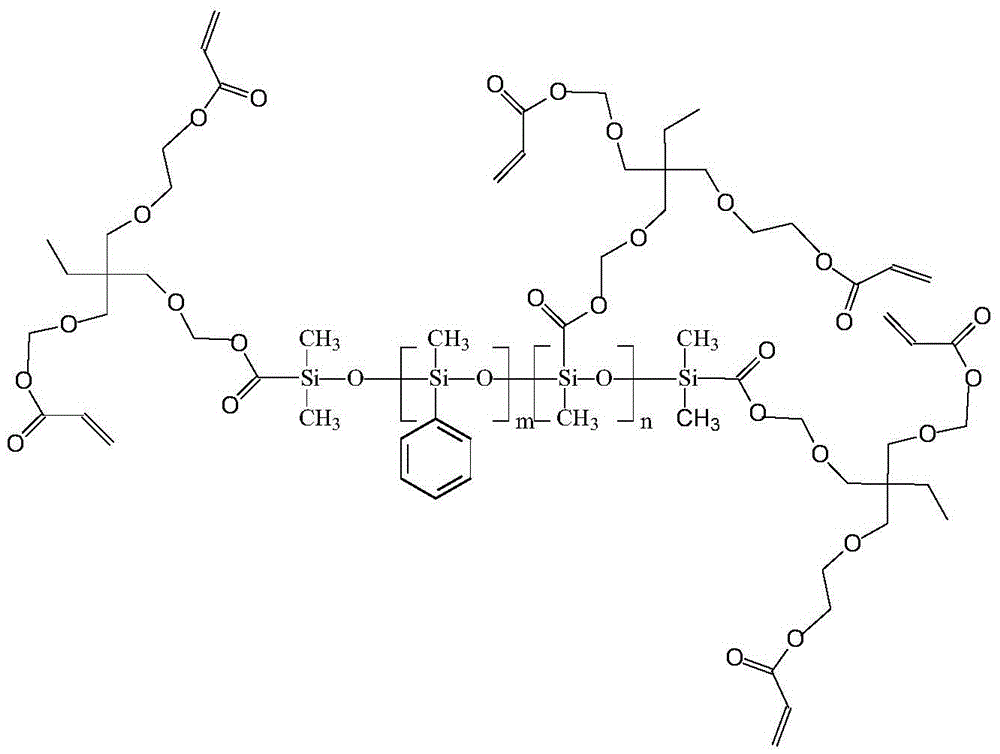

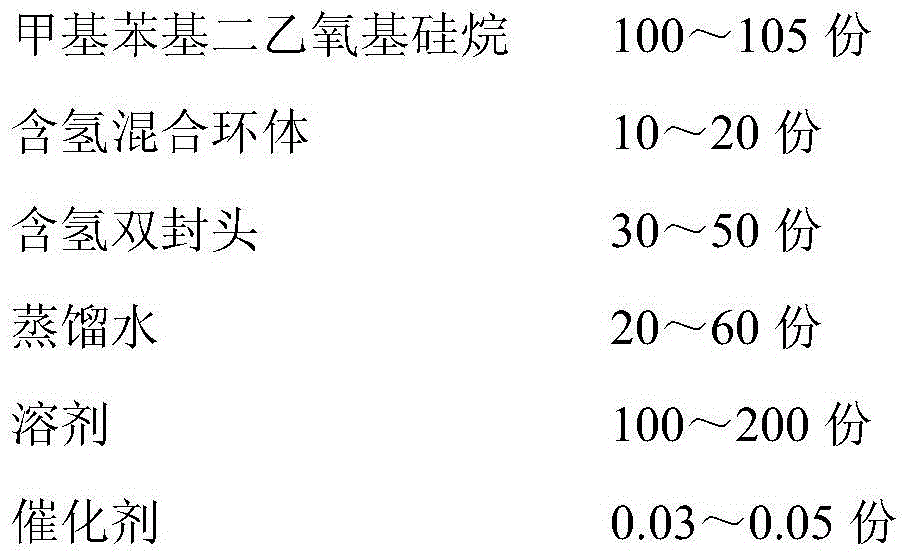

UV (ultraviolet) cured LED packaging adhesive resin and method for preparing same

The invention discloses UV (ultraviolet) cured LED packaging adhesive resin and a method for preparing the same. The method includes sequentially adding 100-105 parts of diethoxysilane, 10-20 parts of hydrogen-containing mixed rings, 30-50 parts of hydrogen-containing double-seal heads, 20-60 parts of distilled water, 100-200 parts of solvents and 0.03-0.05 part of catalysts into a container, carrying out constant-temperature reaction at the temperature of 60-90 DEG C, increasing the temperature until the temperature reaches 100-120 DEG C, carrying out constant-temperature reaction, treating reaction and carrying out post-treatment to obtain phenyl hydrogen-containing silicone oil; enabling the phenyl hydrogen-containing silicone oil and ethoxylation trimethylolpropane triacrylate to react to each other under the effect of the platinum catalysts to obtain the UV cured LED packaging adhesive resin. The UV cured LED packaging adhesive resin and the method have the advantages that the UV cured LED packaging adhesive resin is high in light transmittance, has a high refractive index and can be used in the field of LED packaging and the technical fields of industries of instruments, apparatuses, household appliances, machinery, automobiles, electronic and electrical appliances and the like.

Owner:SHANGHAI INST OF TECH

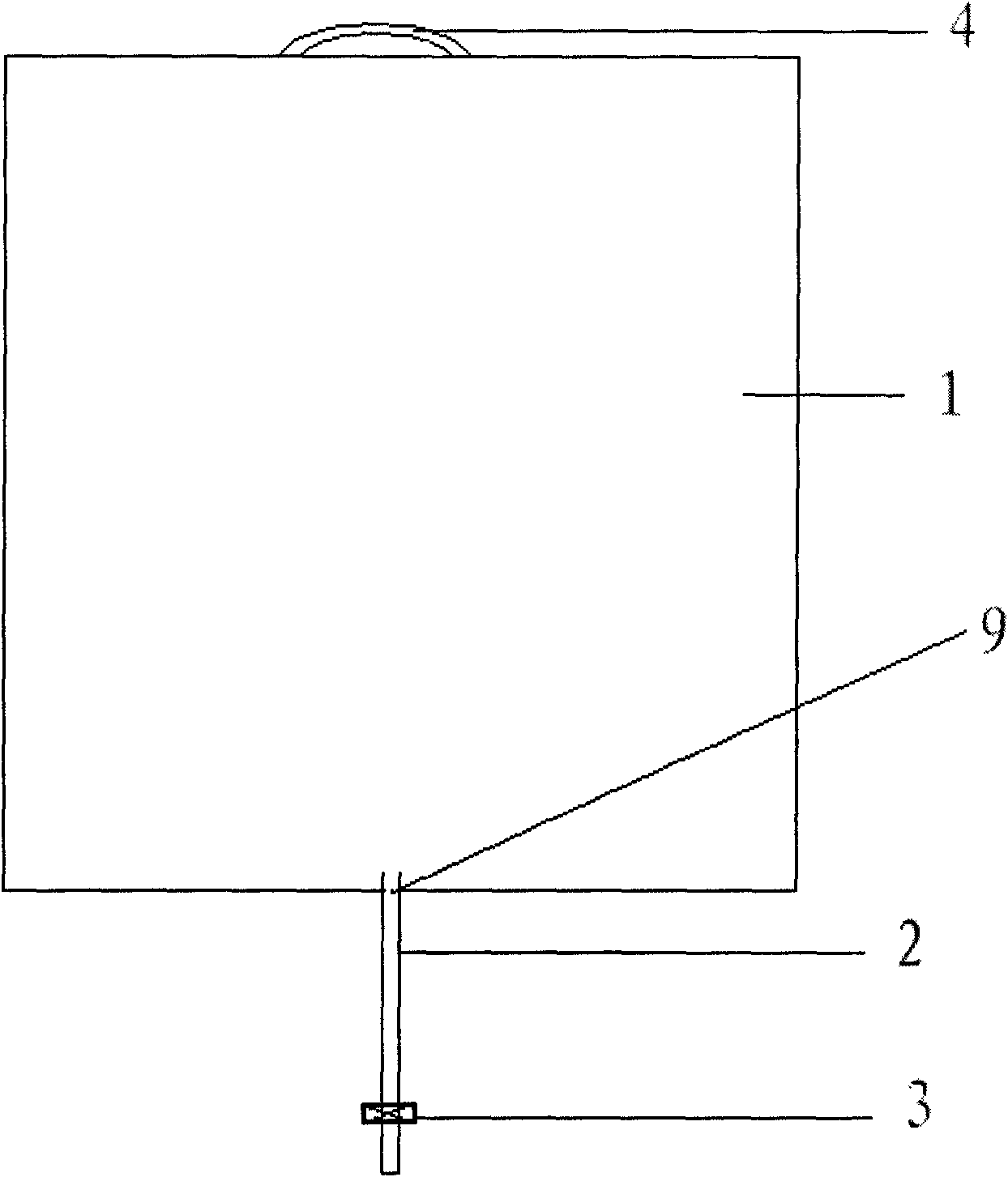

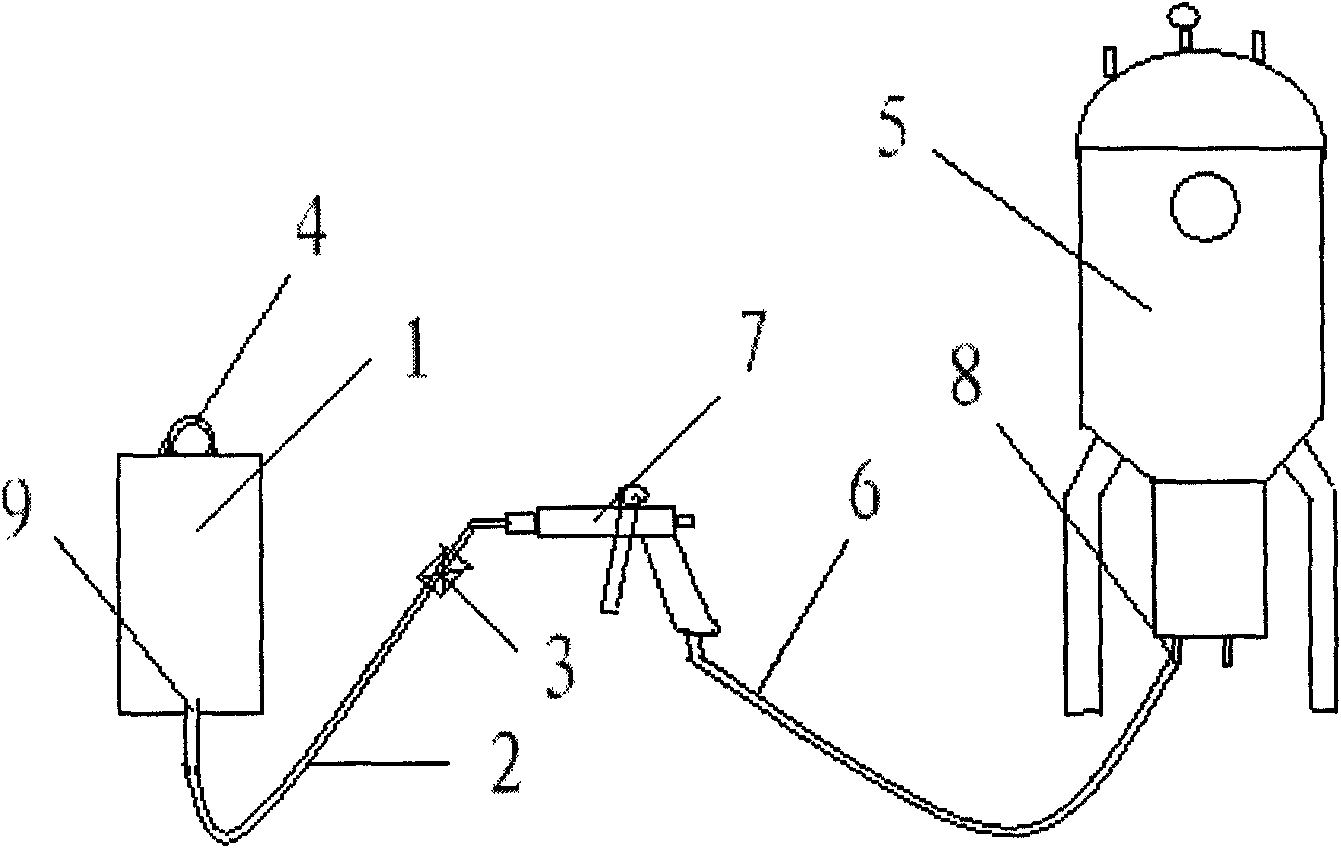

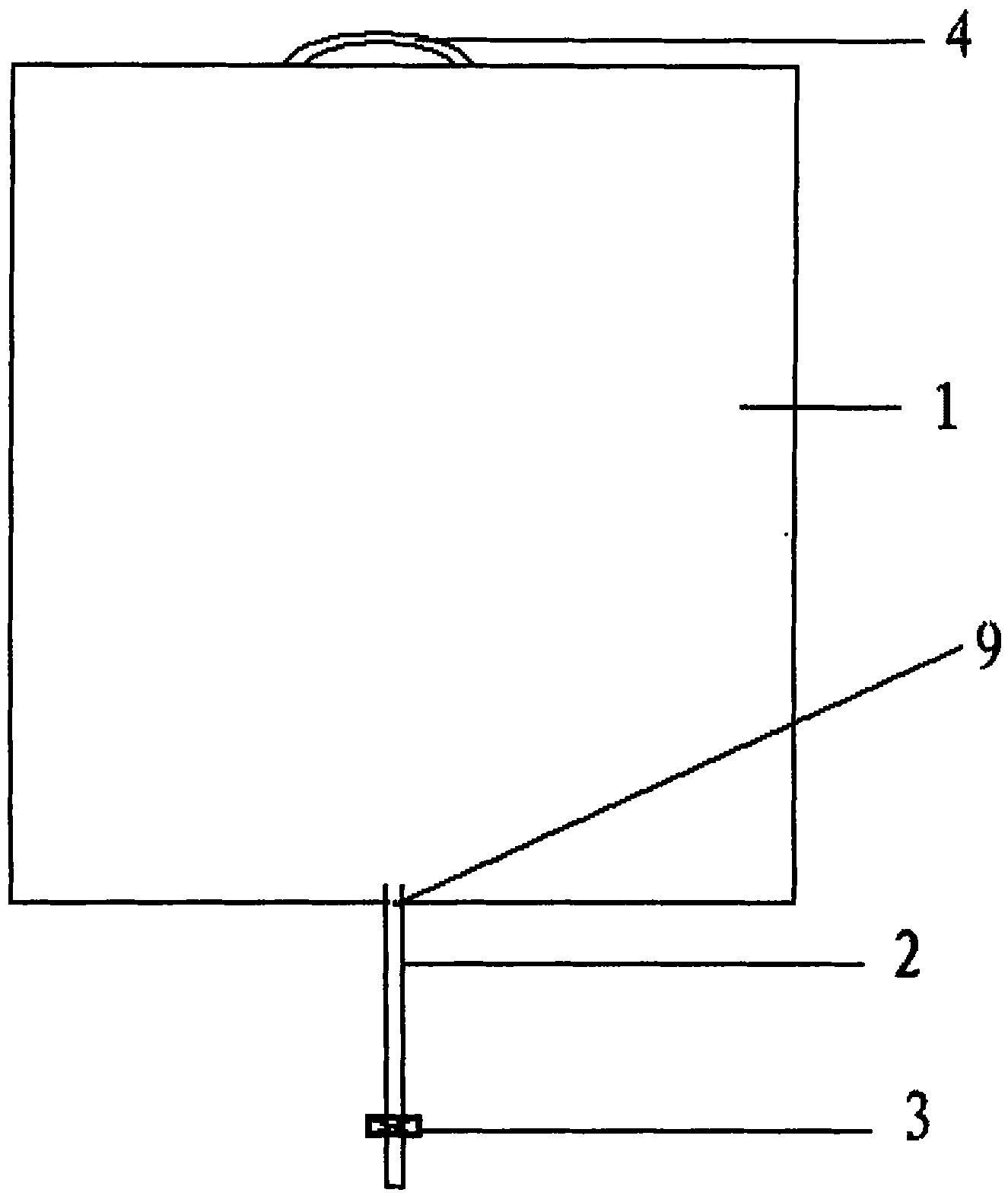

Edible mushroom liquid strain packaging bag device and application method thereof

The invention discloses an edible fungus liquid strain packaging bag device and an application method thereof. The lower bottom of the bag is provided with a bacterial liquid inlet and outlet, which is sealed and fixedly communicated with a conduit, and a liquid stop valve is installed at the lower end of the conduit; The upper end is provided with a hanging hole; application method: the high-pressure water gun is fixedly connected with the high-pressure conduit; Sterilized plastic bags. This invention makes up for the gap in the field of edible fungus liquid strains, and is a new product and application method that has never appeared in this technical field; the device of the present invention is used to package edible mushroom liquid strains, which has the advantages of simple and convenient packaging operation, low strain pollution It has the advantages of low yield and long storage time of strains, and the liquid strains are easy to transport, store and disperse after being packed in plastic bags.

Owner:谢日禄

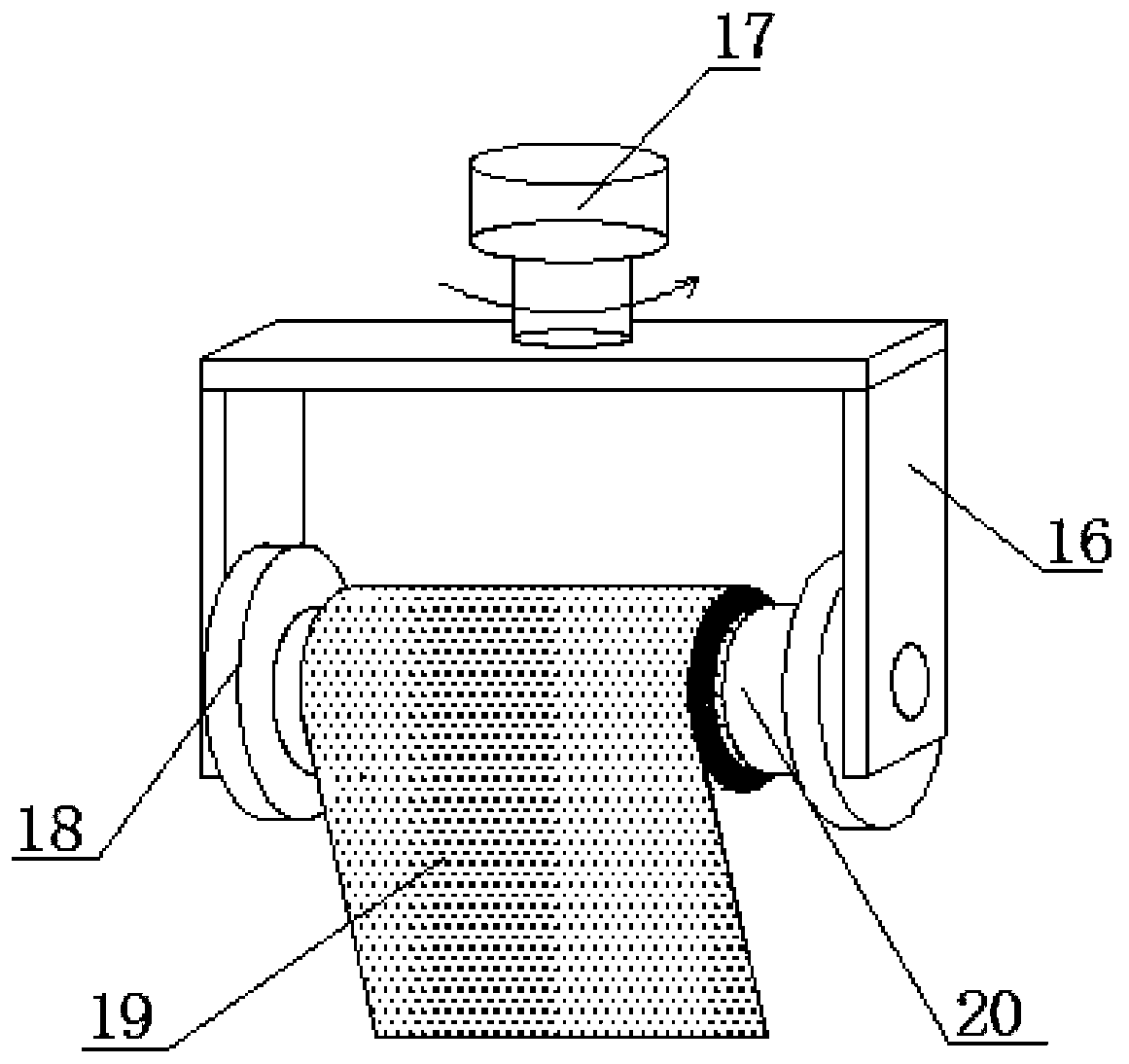

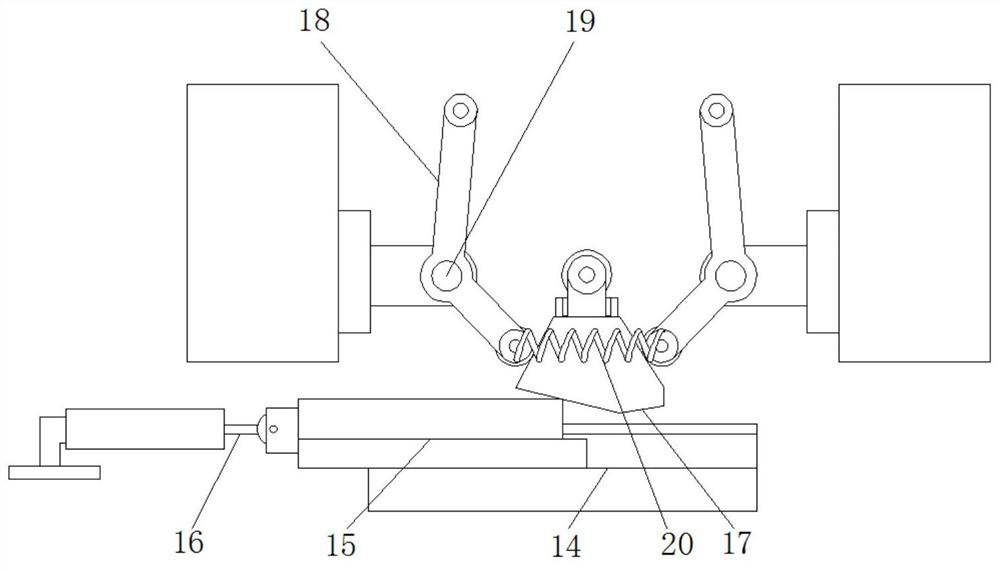

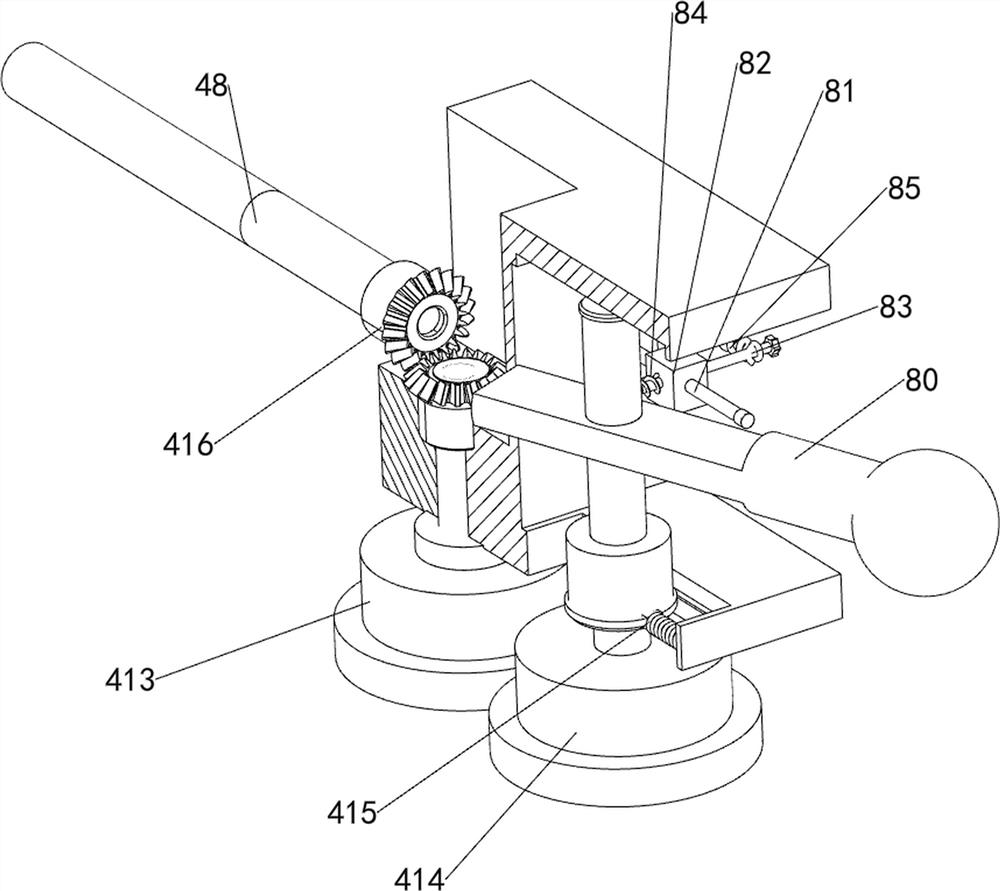

Auxiliary positioning device for product packaging

The invention relates to the technical field of product packaging and positioning, and discloses an auxiliary positioning device for product packaging. According to the device, a product or a packaging box with the product can be conveniently coated and packaged, the box filling and packaging operation can be conveniently carried out, an upper working table is used for carrying out film laminatingpackaging, a lower working table carries out box filling packaging, the packaging efficiency and the assembly line operation performance are improved, and meanwhile, a laminating roller of a laminating assembly can rotate, so that the laminating operation can be carried out in different directions, the convenience of laminating is improved, and the device is suitable for the packaging operation of a large-scale product, and in addition, the product can be rapidly clamped and positioned, and the film laminating operation can be conveniently carried out after positioning; and a telescopic length of a connecting rod can be adjusted through the clamping and fixing between a fixing holes and a fixing pin in a clamping mechanism, so that a clamping position of a positioning block can be adjusted, and the requirements for clamping and positioning of the packaging box or the products of different types can be met.

Owner:JIUJIANG UNIVERSITY

Copper plating method for ceramic substrate

ActiveCN110172717AImprove cleanlinessImprove bindingElectrolysis componentsCopper platingConductive materials

The invention provides a copper plating method for a ceramic substrate, and relates to the technical field of electrical copper plating. The method comprises the following steps of: S1, installing theceramic substrate on an installation hole of a first rack, wherein the first rack is made of a conductive material; S2, surface pretreatment; S3, electroplating copper firstly, obtaining an initial plating part; S4, cleaning; S5, transferring the initial plating part to a second rack from the first rack, wherein the second rack is formed by uniformly coating insulation materials on the surface apart from the contact part of the installation hole and a cathode rod; S6, surface pretreatment; S7, electroplating copper secondly, and obtaining a copper plated ceramic substrate; and S8, cleaning. The copper plating layer formed on the ceramic substrate by the above copper plating method has good uniformity, which is favorable for subsequent packaging operations and prolongs the service life ofa finished product.

Owner:翔声科技(厦门)有限公司

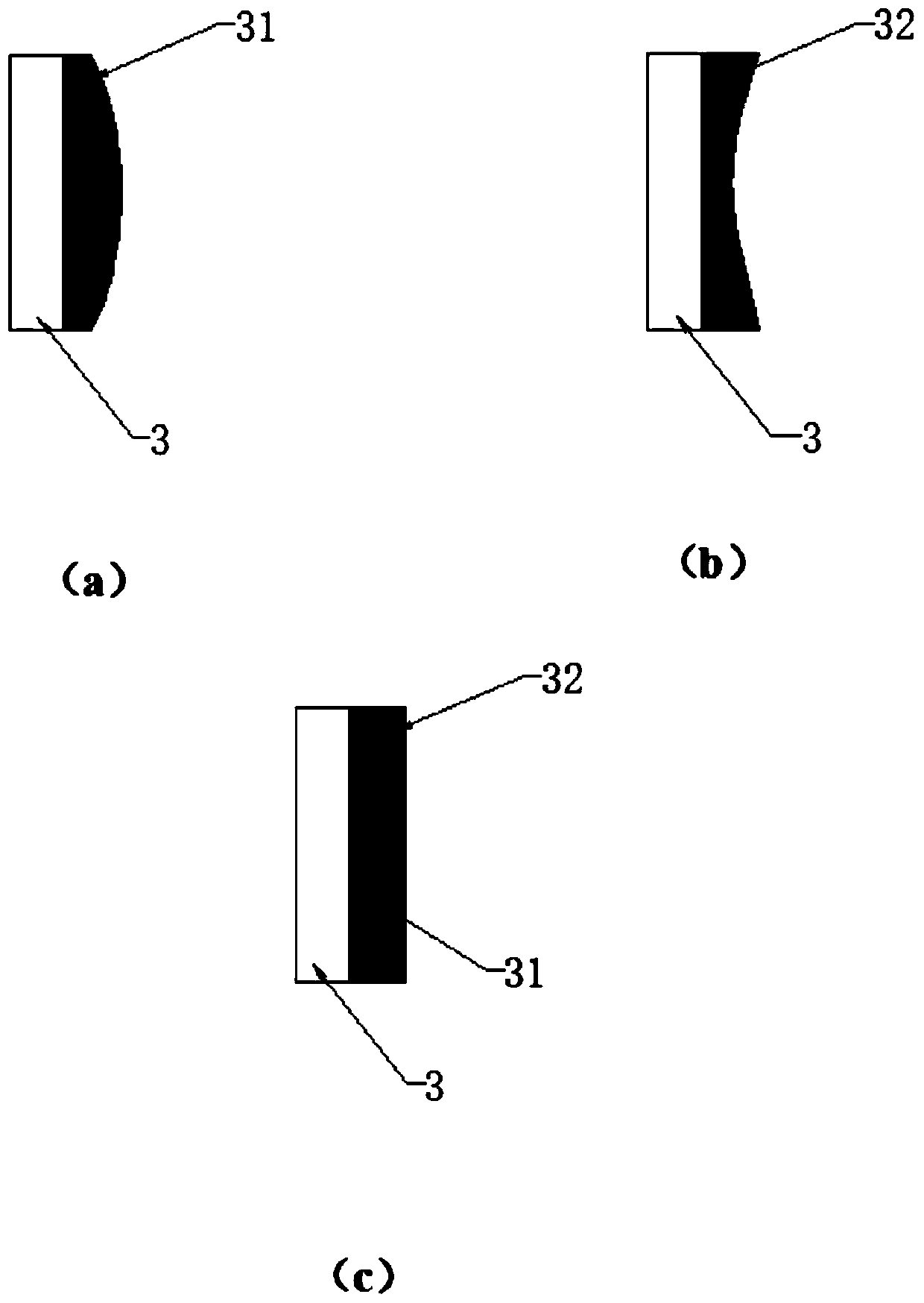

Heat radiating bracket for integrated packing of light emitting diode (LED) and preparation method thereof

InactiveCN102437270APackage structure is simpleEasy packing operationSemiconductor devicesHigh volume manufacturingInsulation layer

The invention provides a heat radiating bracket for integrated packing of light emitting diode (LED) and a preparation method thereof. The heat radiating bracket comprises an aluminum heat radiating substrate and a glue spotting hole which is arranged on the aluminum heat radiating substrate, wherein the bottom part of the glue spotting hole is provided with a crystal fixing hole, the surface of the aluminum heat radiating substrate is provided with an insulation layer, and an electrode is punched on the insulation layer on the inner wall of the glue spotting hole. The electrode is directly punched and fixed on the aluminum heat radiating substrate with the surface having the insulation layer, so not only can the heat radiating bracket is easy to prepare, is the performance reliable, and is the cost low, butr also the subsequent packing operation of the LED is simpler and more convenient, and the mass production can be realized.

Owner:SHAANXI UNIV OF SCI & TECH

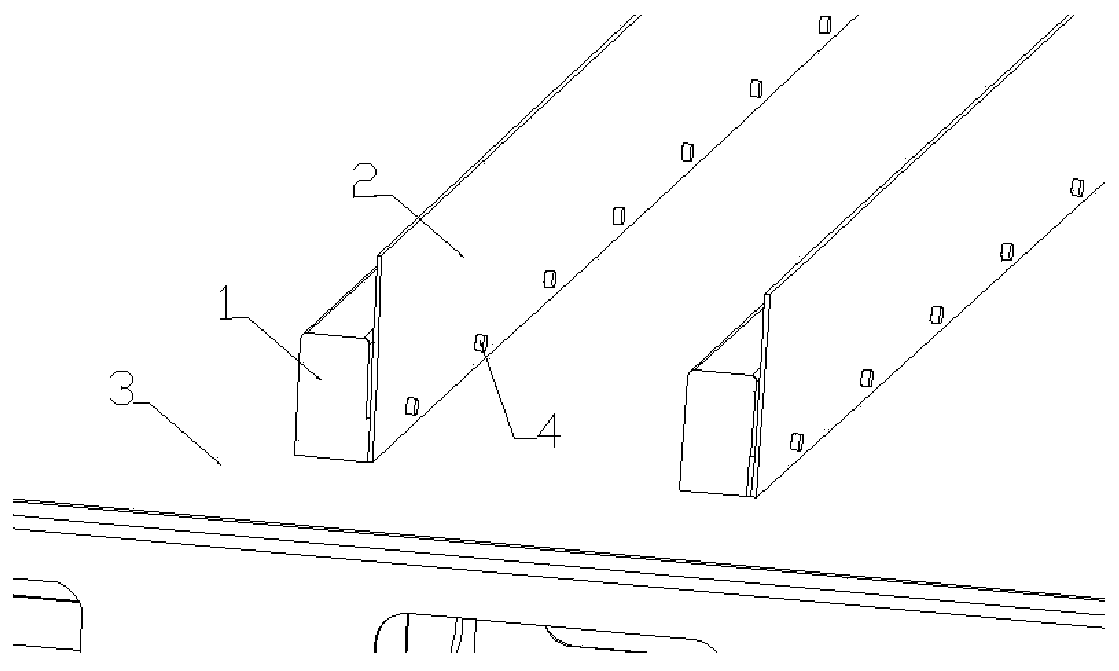

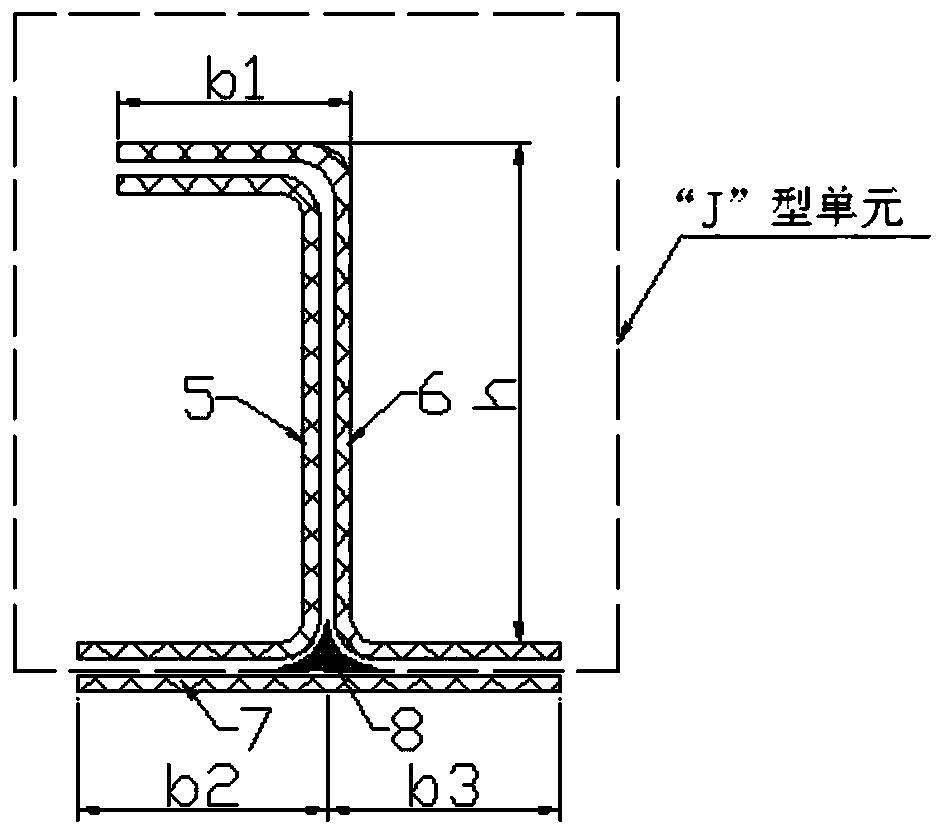

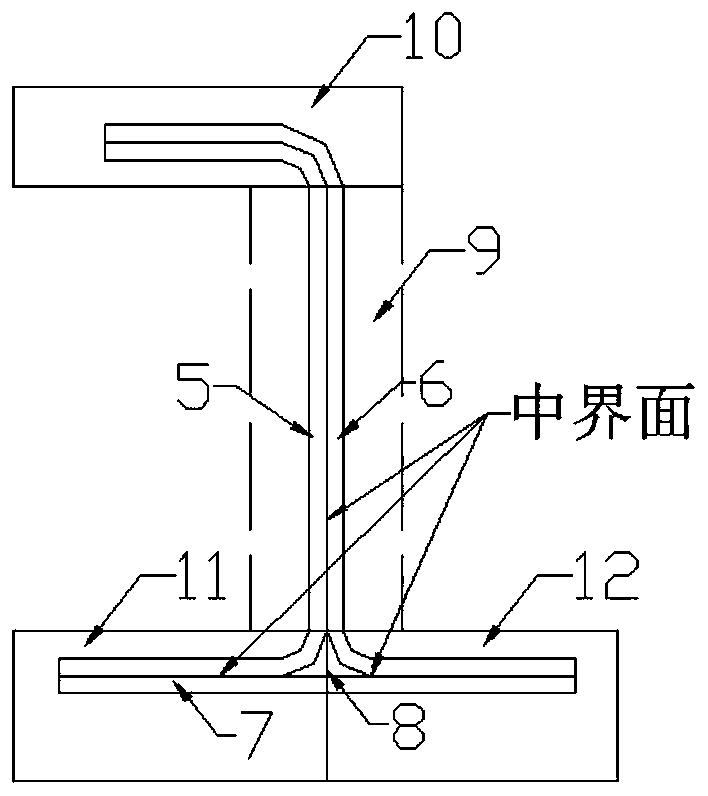

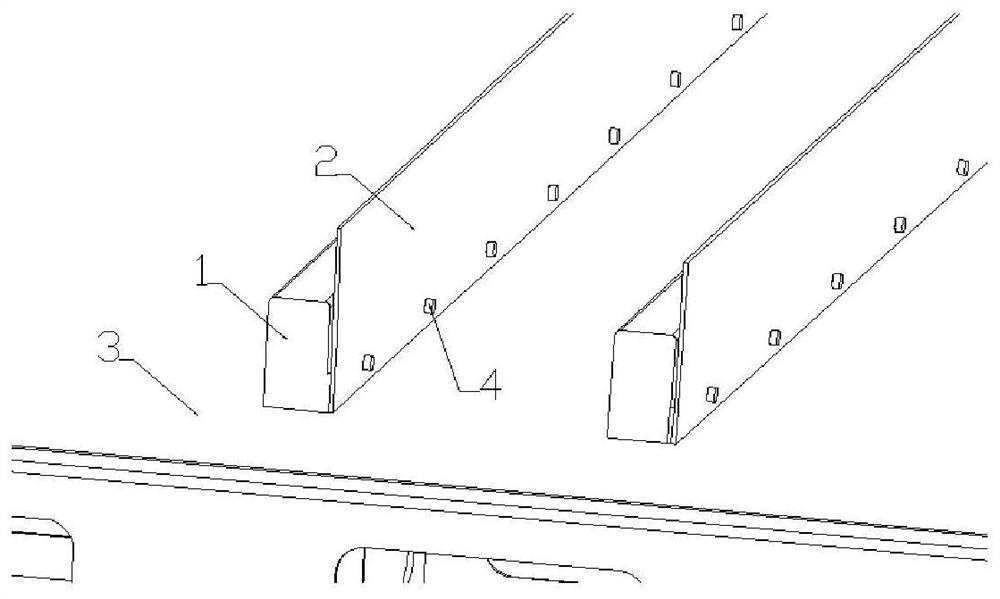

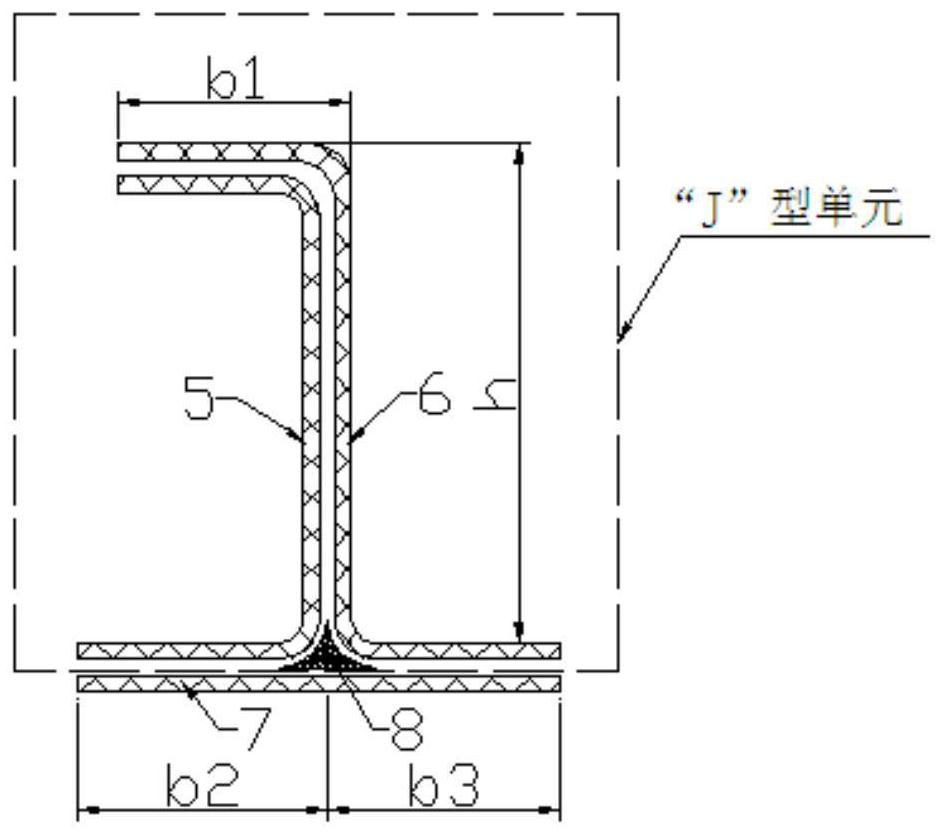

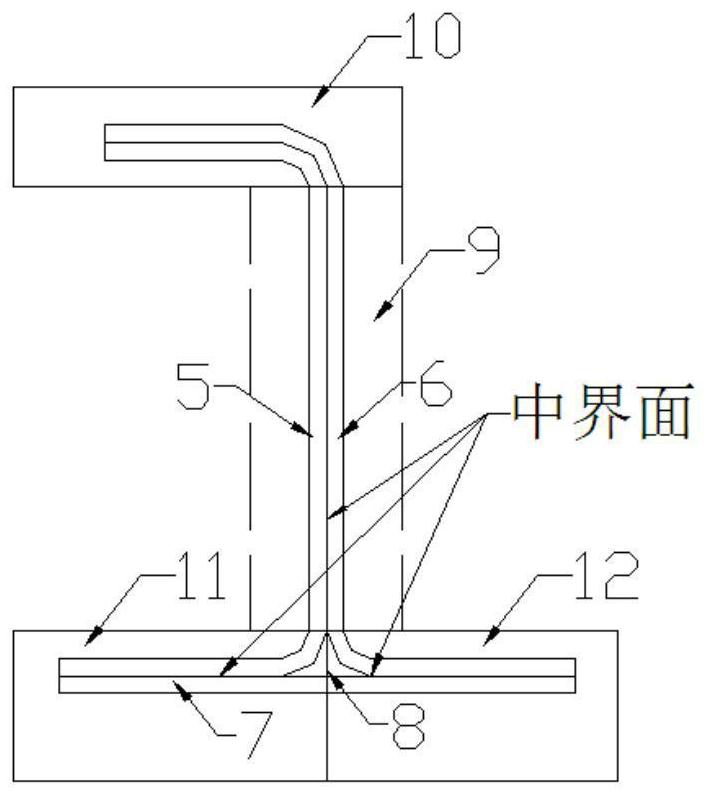

Preparation method of "J" type stiffened wall panel tackified preforms suitable for RFI technology

The invention belongs to the technical field of low-cost manufacturing of high-performance resin matrix composite materials, and provides a preparation method of "J" type stiffened wall panel tackified preforms suitable for an RFI technology. The preparation method comprises the steps that (a) a "J" type stiffened wall panel is decomposed according to structural features, and a "J" type long trusslayer unit is divided according to a technology separation surface; (b) a "J" type long truss preforming die is designed; (c) preforming of a "J" type long truss and a skin unit is carried out; (d) assembling, prepressing for shaping and positioning of the "J" type long truss, the skin unit and a forming mould form presetting type J" type stiffened wall panel tackified preforms; and (e) the presetting type "J" type stiffened wall panel tackified preforms are sewed and trimmed to prepare the "J" type stiffened wall panel tackified preforms. According to the preparation method of the "J" type stiffened wall panel tackified preforms suitable for the RFI technology, the final quality of the stiffened wall panel can be better guaranteed by controlling the accuracy of a profile and a position of the long truss in a preforming preparation process.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

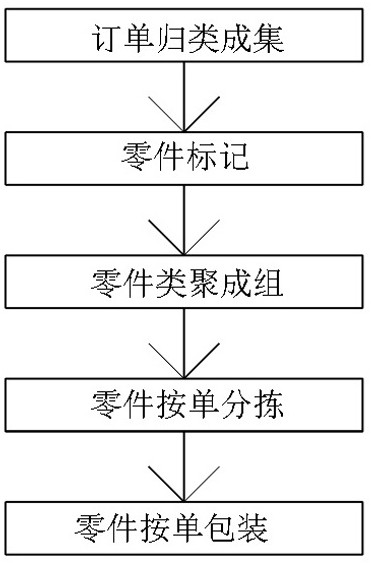

Order grouping processing method for personalized customized furniture

PendingCN113689094AHigh overlap rateIncrease profitResourcesCommerceProcess engineeringIndustrial engineering

The invention belongs to the technical field of furniture processing and system planning, and particularly relates to an order grouping processing method for personalized customized furniture. According to the multi-order personalized customized furniture production system, the order classification and gathering, part marking, part clustering and grouping, part sorting according to orders and part packaging according to orders are carried out in sequence, and the purpose that multi-order personalized customized furniture can be integrally and efficiently machined and produced is achieved. The method has the following advantages that 1, order products are divided into parts, the parts are produced in groups according to a plurality of division standards, and it is guaranteed that when the parts in the same group are produced, the stack cutting rate is high, the raw material plate utilization rate is high, and the overall production efficiency is high; 2, the processing cycles of the groups are reasonably matched, and the whole processing cycle of all orders is shortened; and 3, the overall planning of part grouping processing is reasonable and efficient, the subsequent sorting and packaging operation is simple and convenient, and finally finished orders are low in cost, high in quality and short in delivery time.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD +1

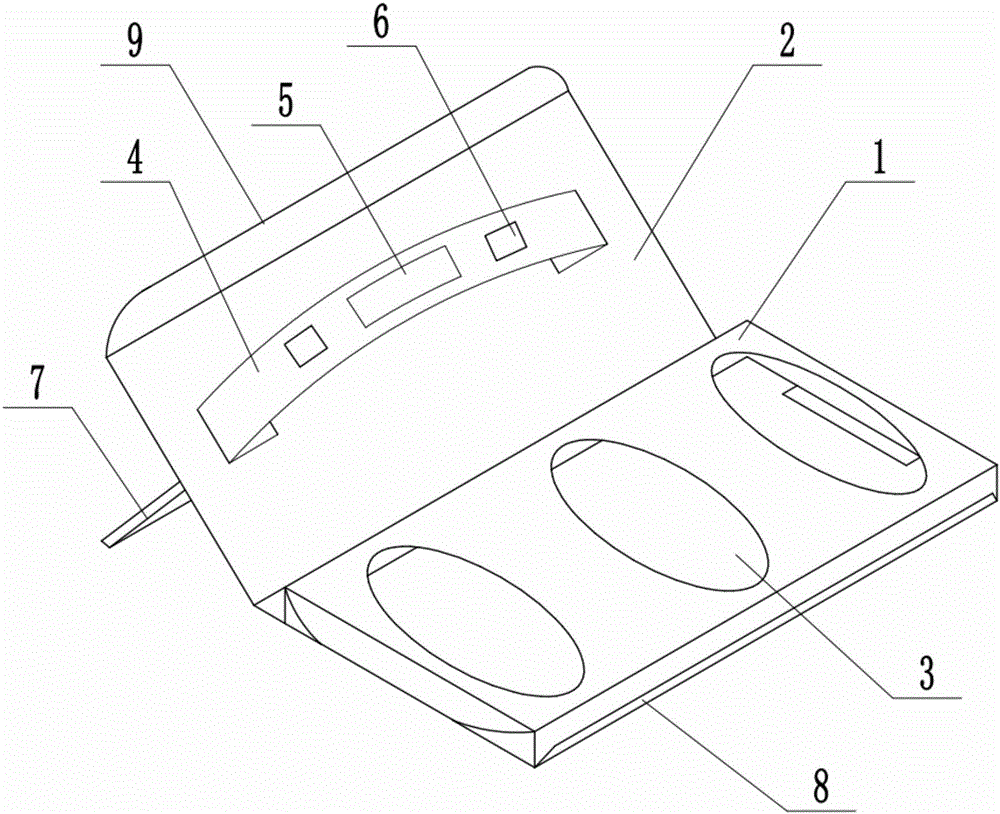

Display type packing box

The invention relates to a display type packing box comprising a flat box body and a box cover for sealing the box body, wherein a plurality of placement grooves are formed in the box body, a strip-shaped supporting plate is adhered on an inner side of the box cover, and a bar code and a two-dimensional code are arranged on the strip-shaped supporting plate; a groove is formed in an outer surface of the box cover, a supporting plate is adhered in the groove, and the supporting plate can rotate relative to the box cover; and an inclined slot is formed in a front side face of the box body, and the slot can accommodate the insertion of an insertion tongue on the box cover. The display type packing box provided by the invention has a simple structure, and compared with the traditional display type packing box, the display type packing box has the advantages of good display effect, good packing protectiveness, unique appearance, multifunction and simple and convenient packing operation.

Owner:WUXI ZHONGHUAN PACKAGING

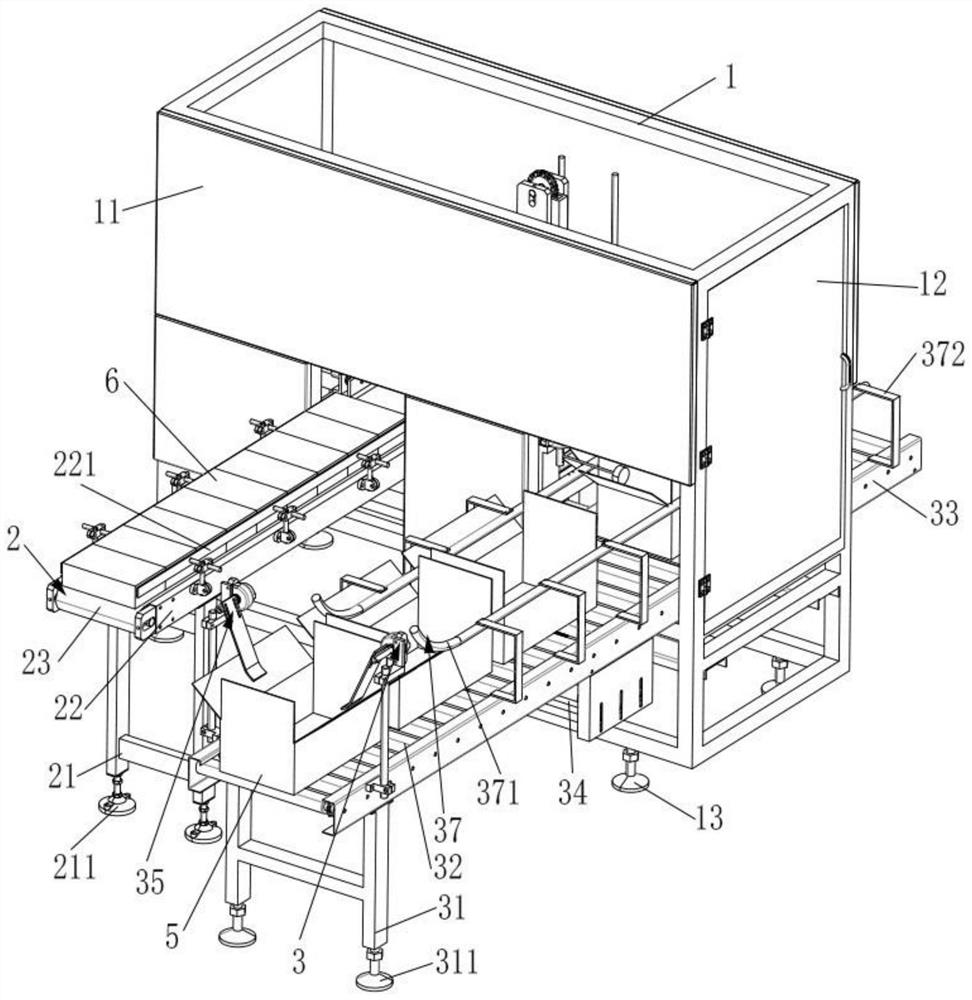

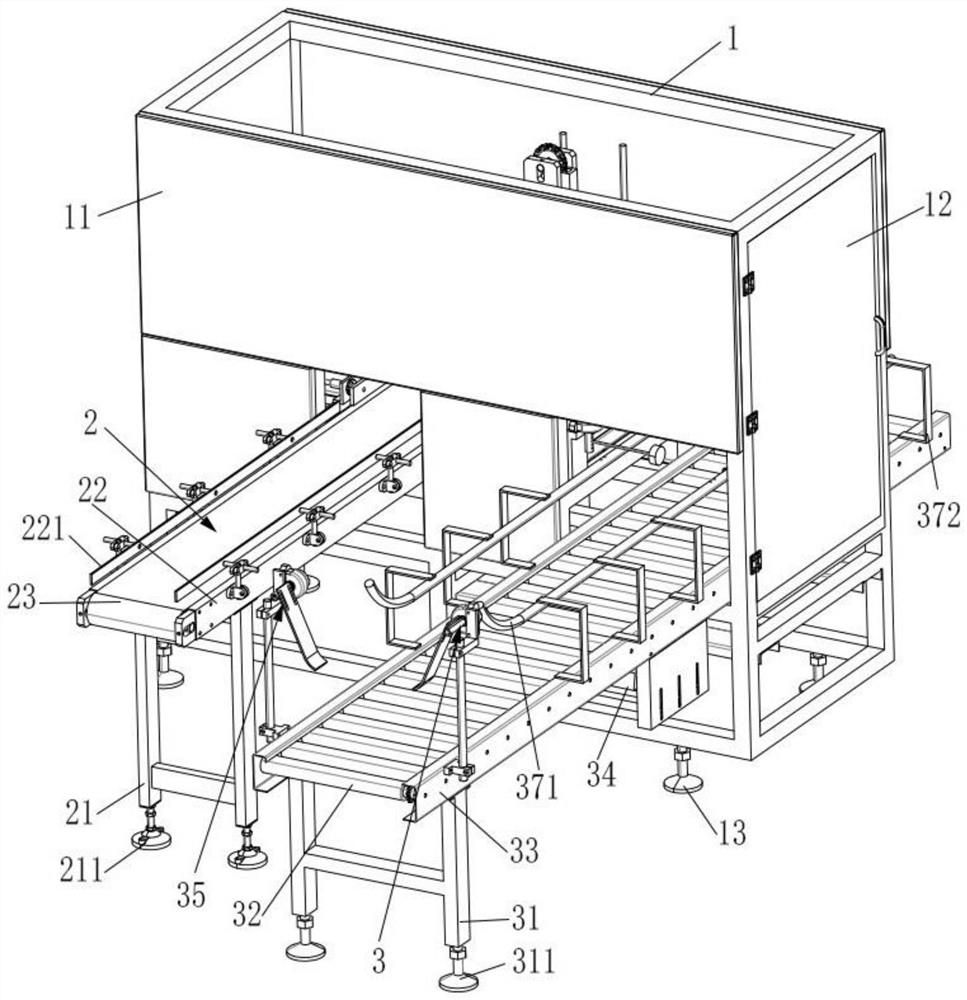

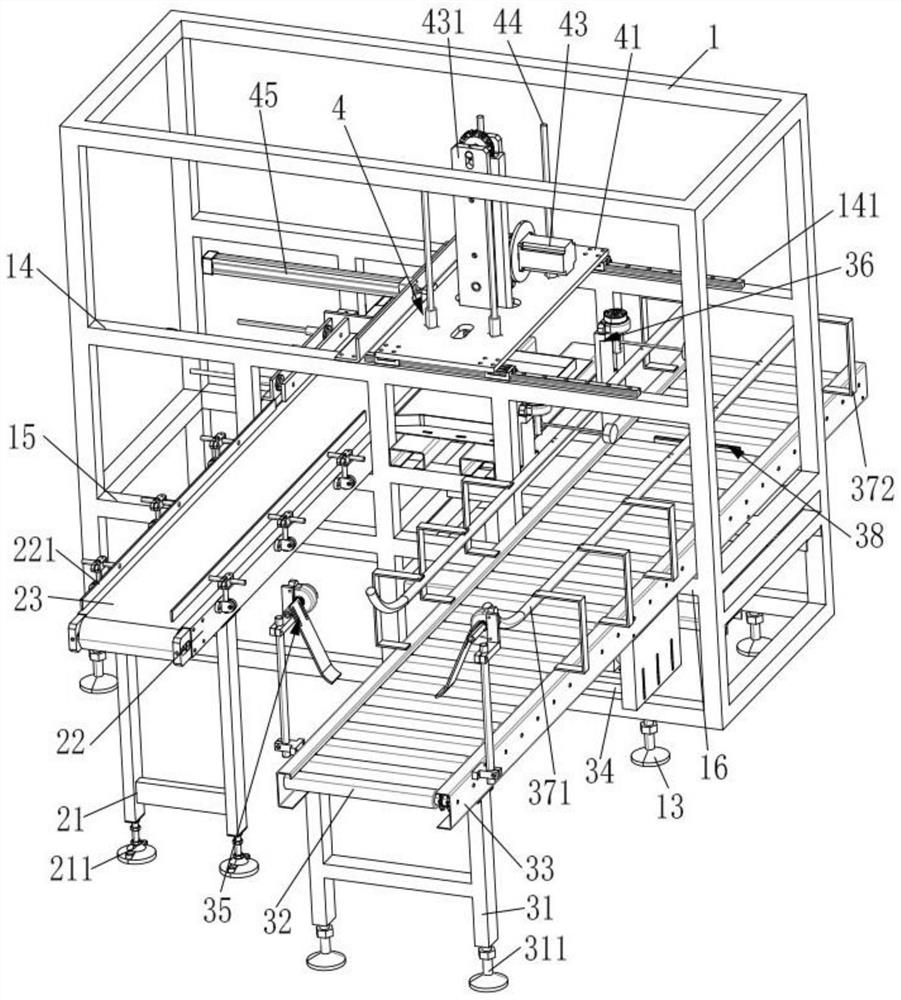

Box opening and boxing integrated automatic production line and working method thereof

PendingCN113232934ASimple working methodSimple structurePackagingManufacturing lineIndustrial engineering

The invention provides a box opening and boxing integrated automatic production line and a working method thereof, and belongs to the technical field of packaging equipment. The integrated automatic production line comprises a rack, a feeding component for conveying products, a box opening component for opening a packaging box cover, and a material taking component, and the feeding component is partially arranged in the rack through a second fixing beam; the box opening component is partially arranged in the rack through a third fixing beam, and the material taking component is arranged in the rack through a first fixing beam; a guide rail is arranged on the first fixing beam, and the material taking component is connected with the guide rail slidably; and the feeding component and the box opening component are arranged in parallel, and the material taking component is arranged above the feeding component and the box opening component. According to the box opening and boxing integrated automatic production line, automatic equipment is adopted, and packaging boxes can be automatically opened; the products can be automatically boxed, and the labor cost can be effectively saved; and the packaging efficiency of the products is improved.

Owner:江苏群昌智能科技有限公司

Fruit mesh bag bagging device with bagging anti-falling structure

InactiveCN112537487APrevent extrusion etc.Improve the protective effectWrapper twisting/gatheringPackaging fruits/vegetablesAgricultural engineeringStructural engineering

Owner:深圳市路码智能科技有限公司

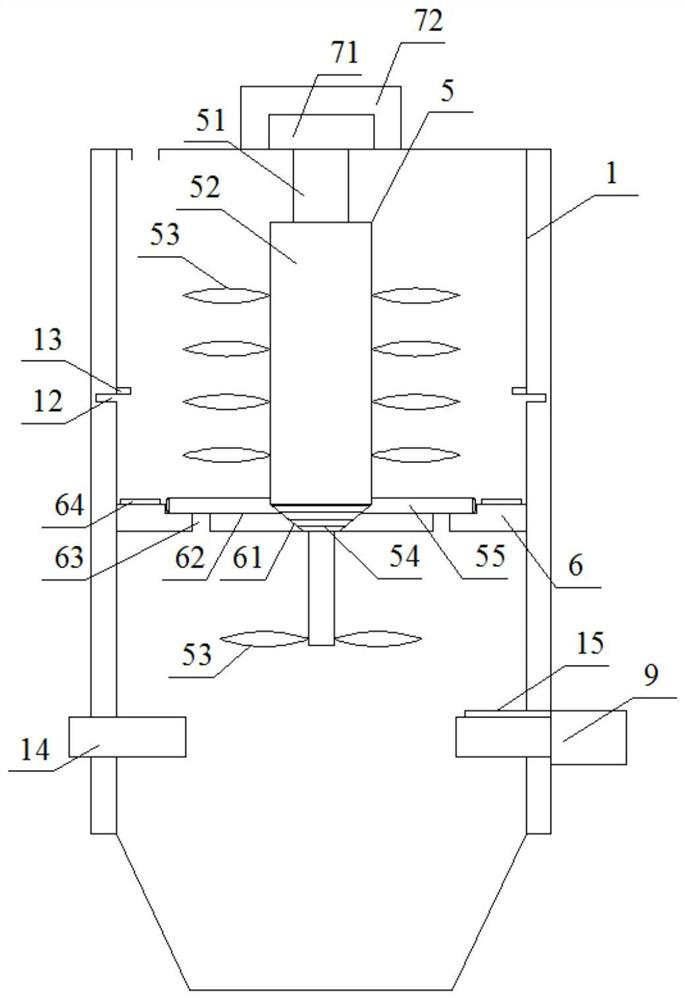

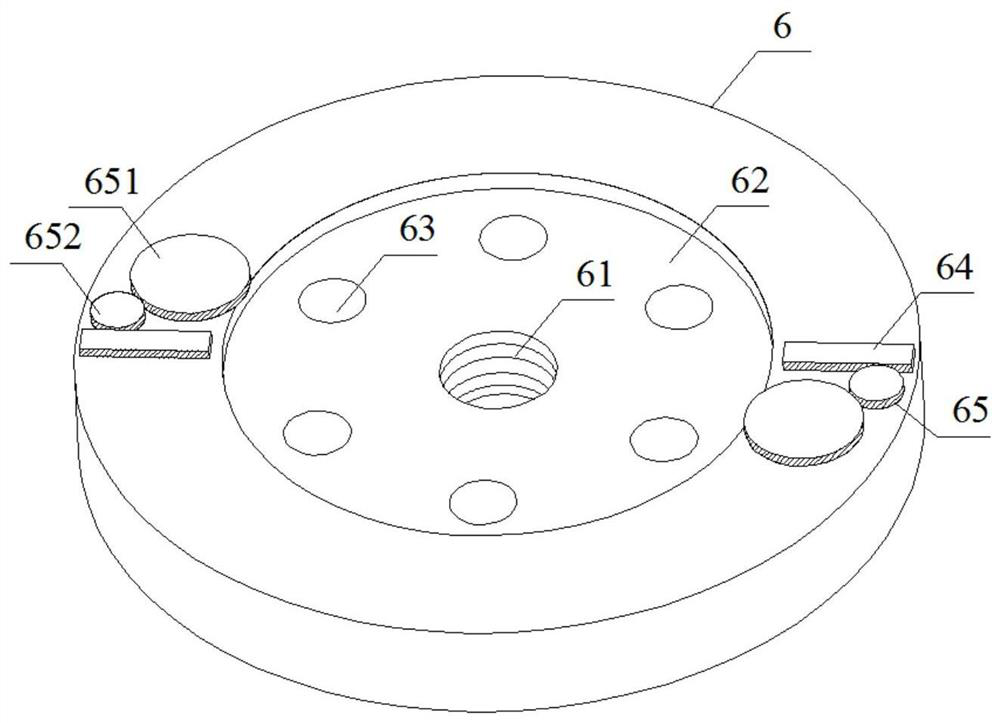

Method and device for producing rubber adhesive

ActiveCN113403002AStrong adhesionStrong water and corrosion resistanceShaking/oscillating/vibrating mixersRotary stirring mixersOligoesterLight cure

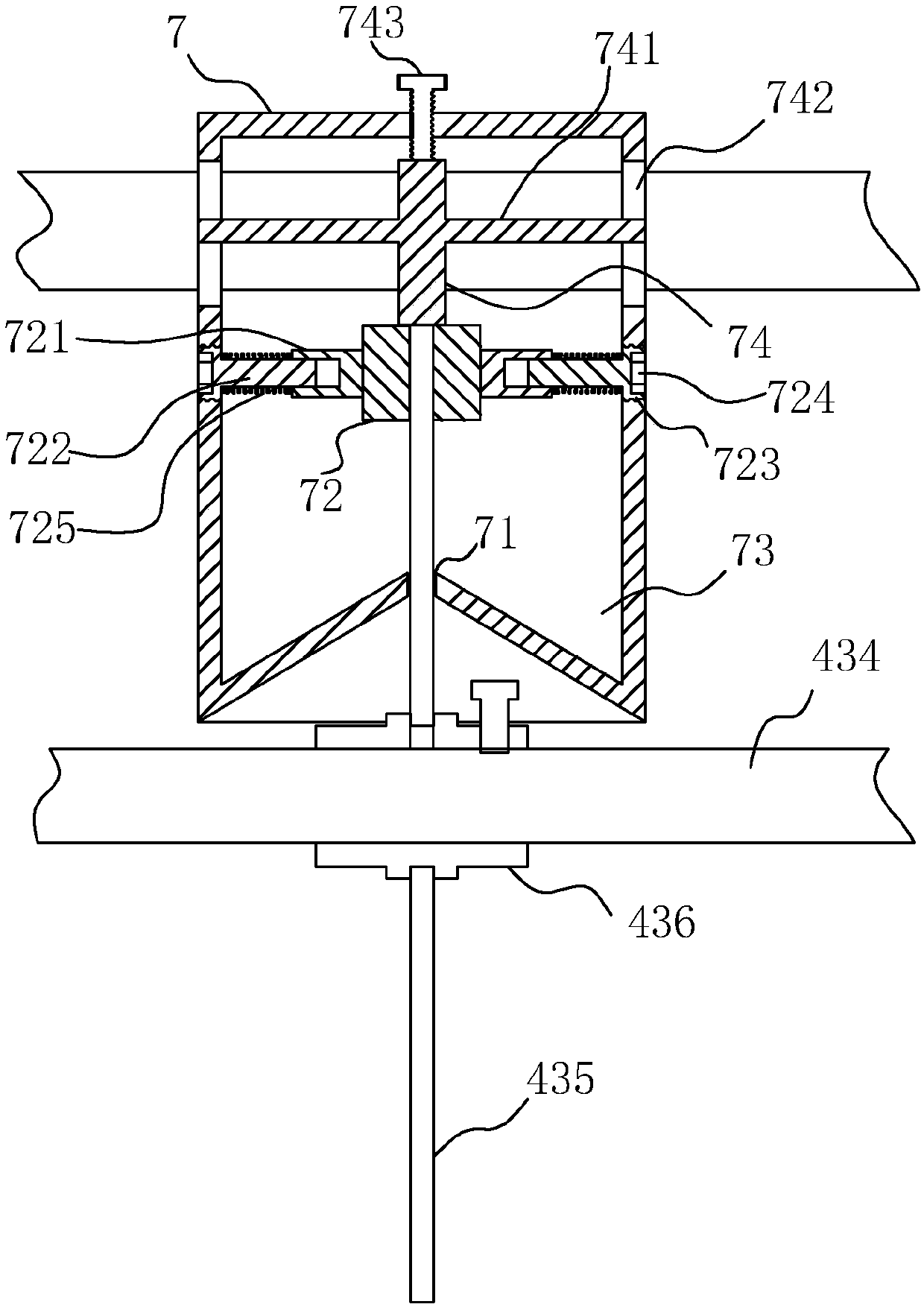

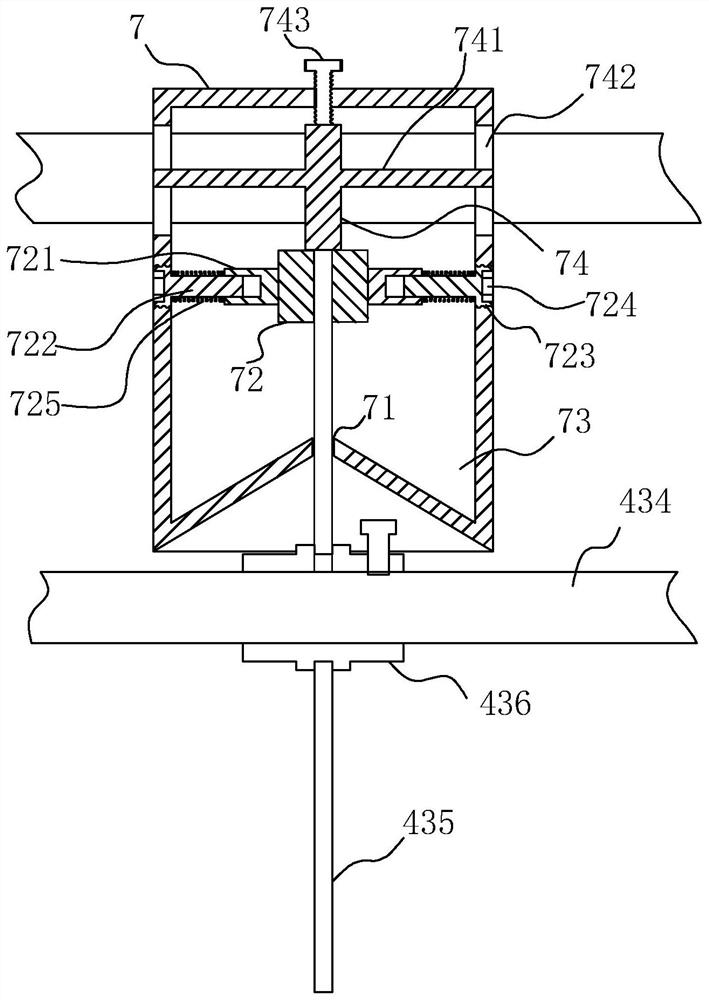

The invention discloses a method and a device for producing a rubber adhesive. The rubber adhesive is a dihydroxy-terminated polybutylbenzene liquid rubber adhesive, and the production method comprises the following steps: S1, synthesizing a lithium initiator; S2, conducting polymerization reaction: weighing 2 parts by weight of styrene, 4.6-5 parts by weight of tetrahydrofuran, 1.1-1.3 parts by weight of butadiene and 0.015-0.03 part by weight of a lithium initiator, and conducting reacting to obtain a polymerization solution; S3, carrying out an end-capping reaction; S4, conducting post-processing; and S5, carrying out ultraviolet light curing. The production device comprises a stirring barrel, an ultraviolet irradiation bin, an ultraviolet generating device and a feeding device, and a stirring telescopic rod and a lifting plate are arranged in the stirring barrel. The rubber adhesive is high in adhesive force, water resistance and corrosion resistance, oligomer active short chains with activity at the two ends are generated, and therefore the rubber adhesive is good in heat resistance and impact resistance and good in stability, extrusion conveying of the rubber adhesive is completed through a telescopic stirring rod and a lifting plate, and subpackaging operation is convenient.

Owner:JIANGSU GUOLI CHEM TECH

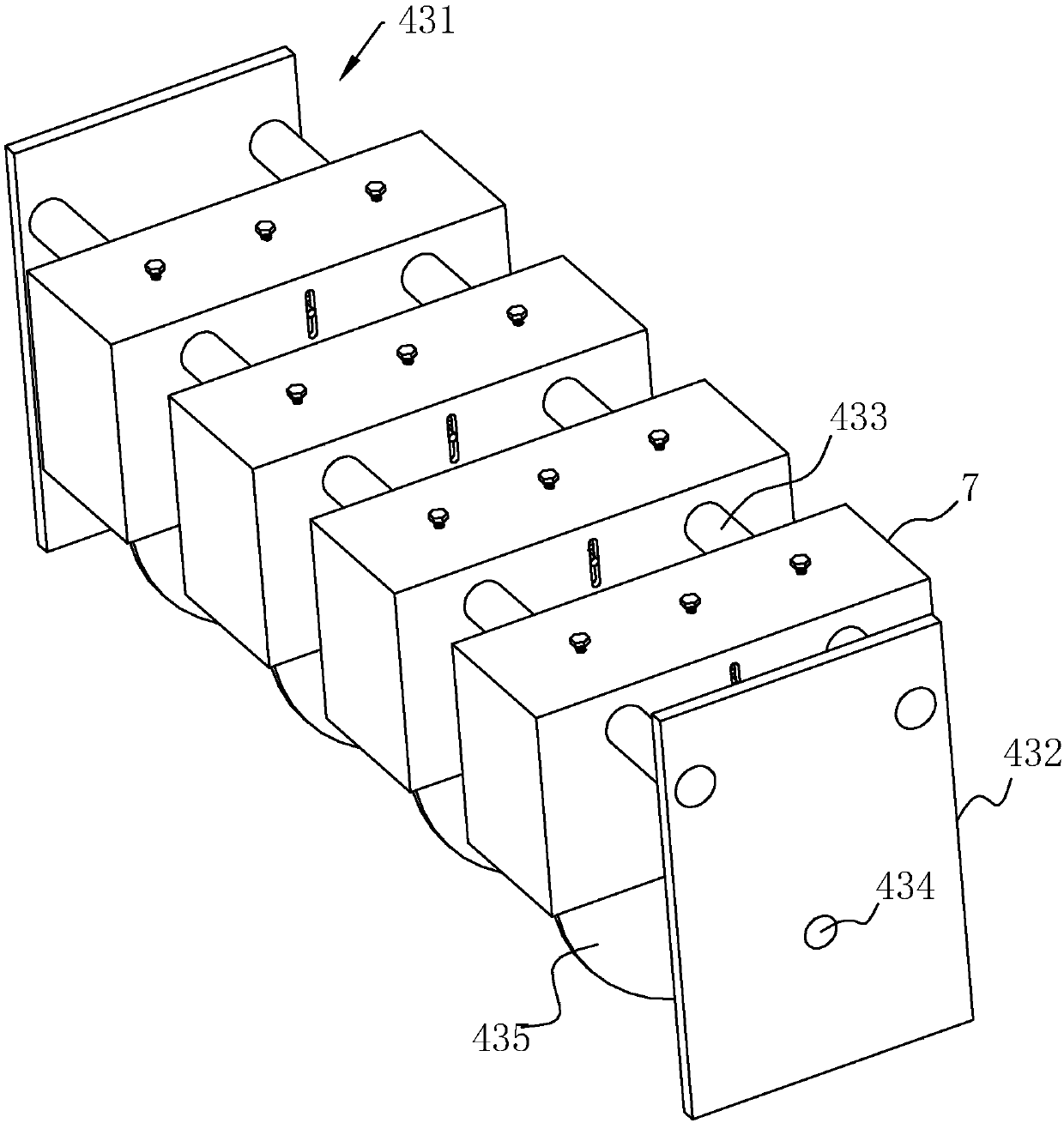

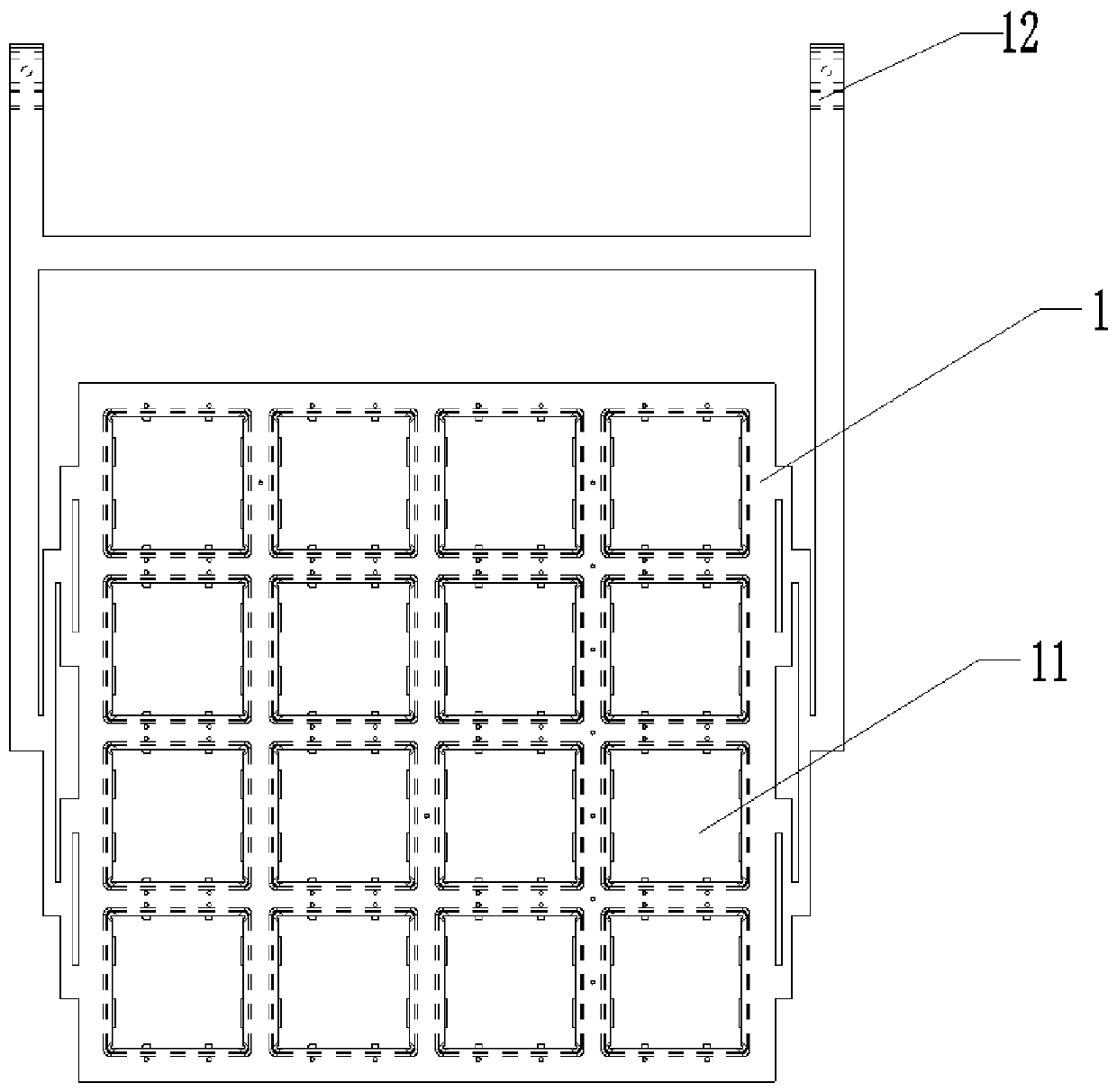

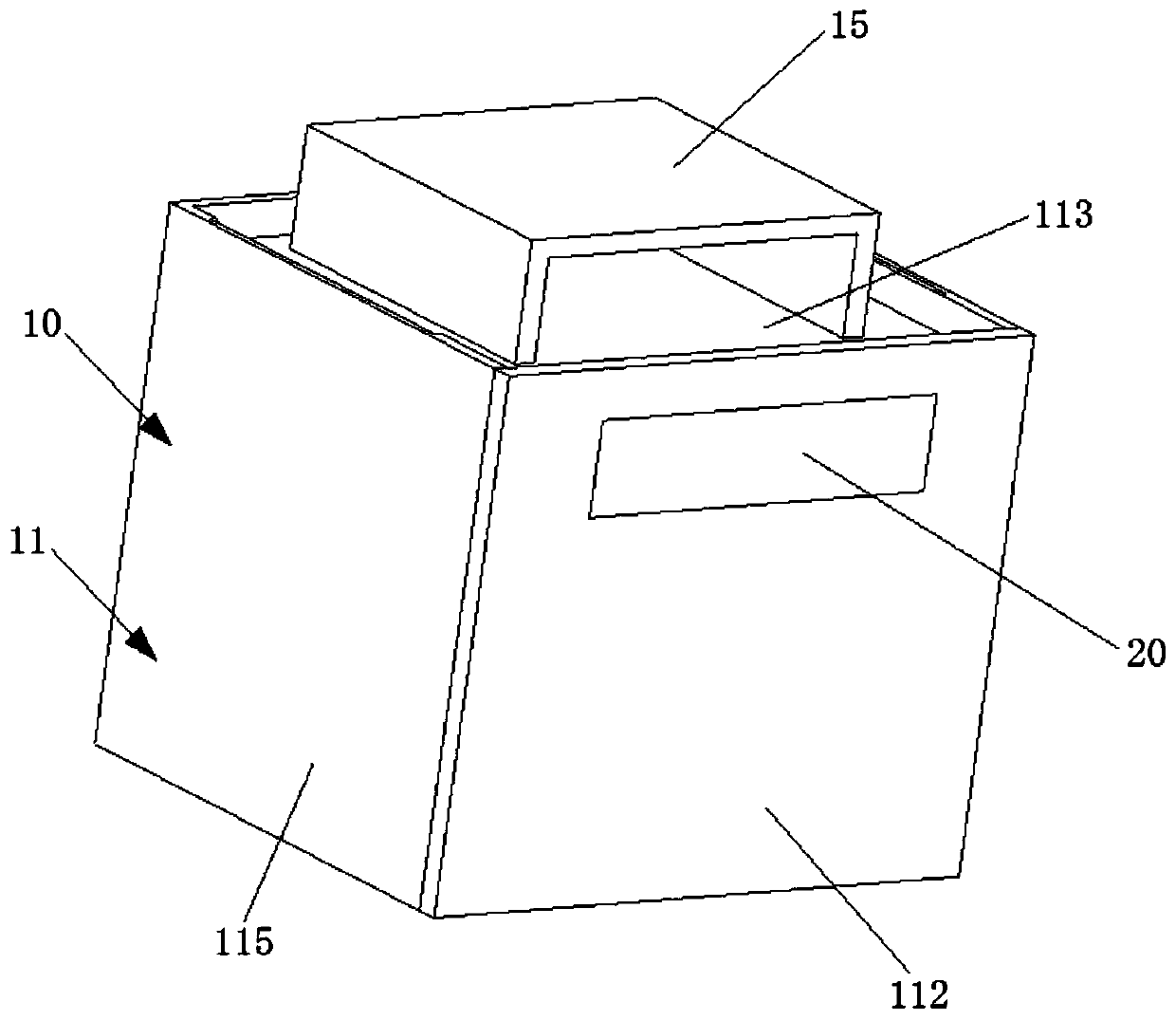

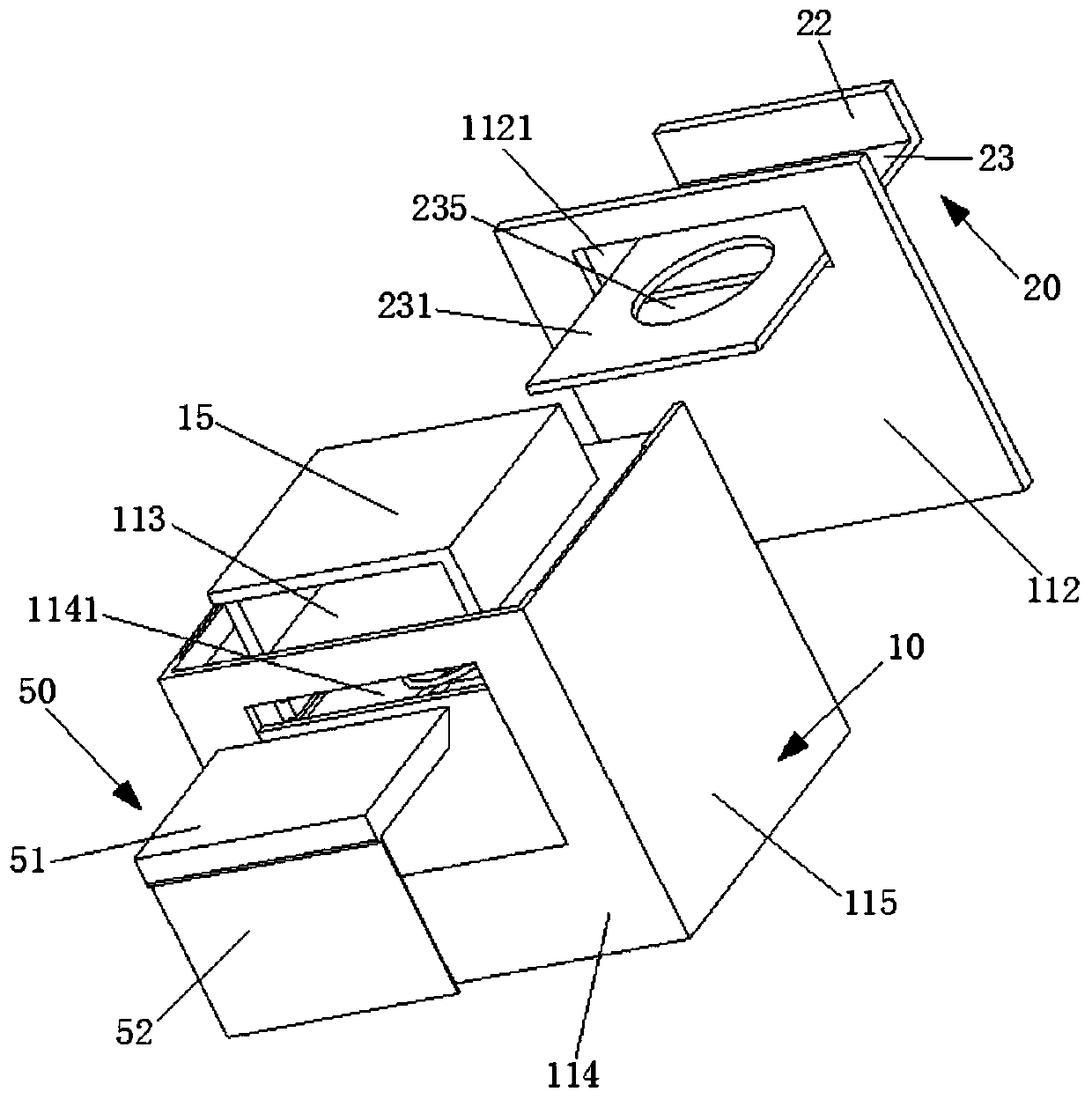

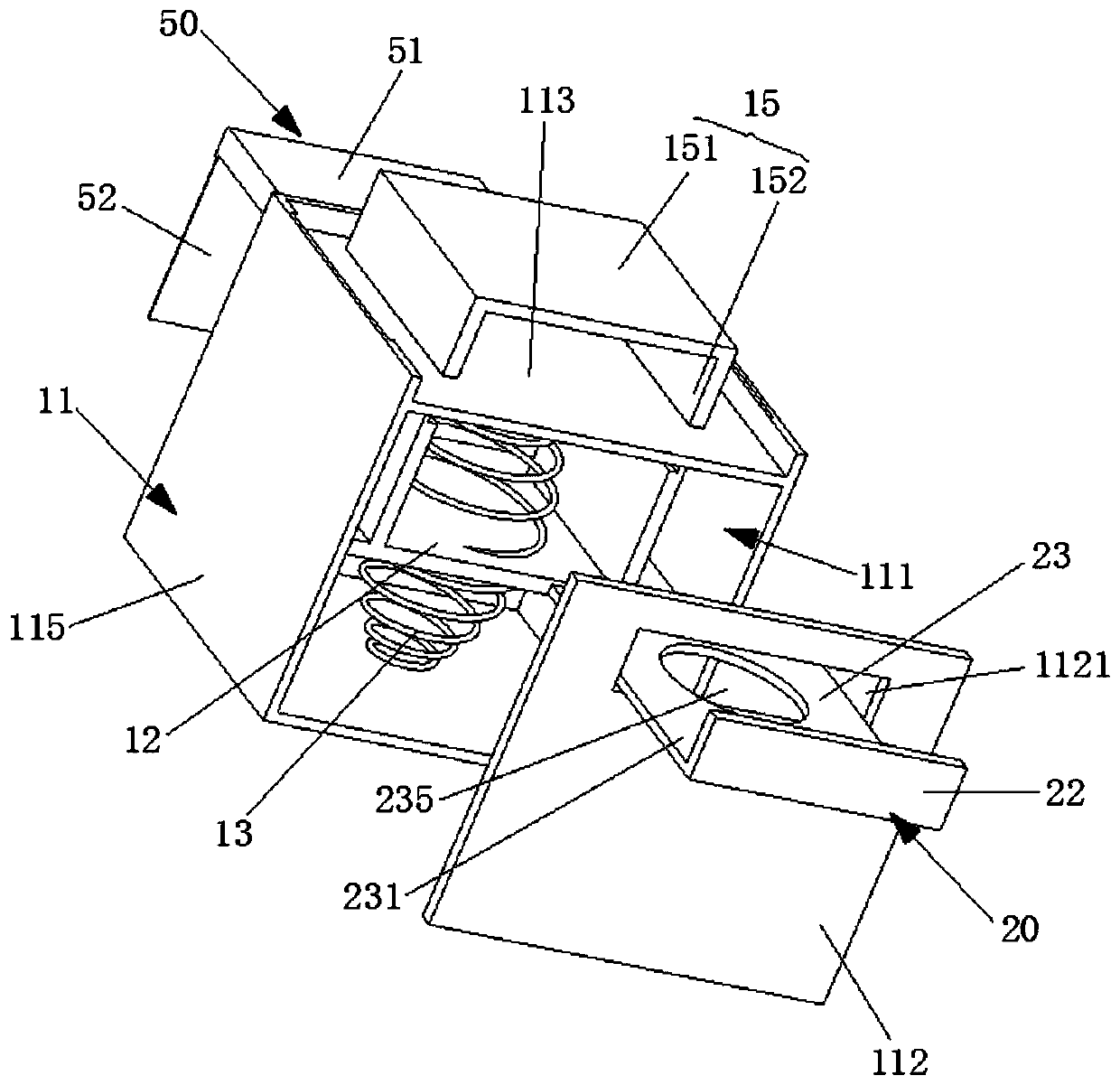

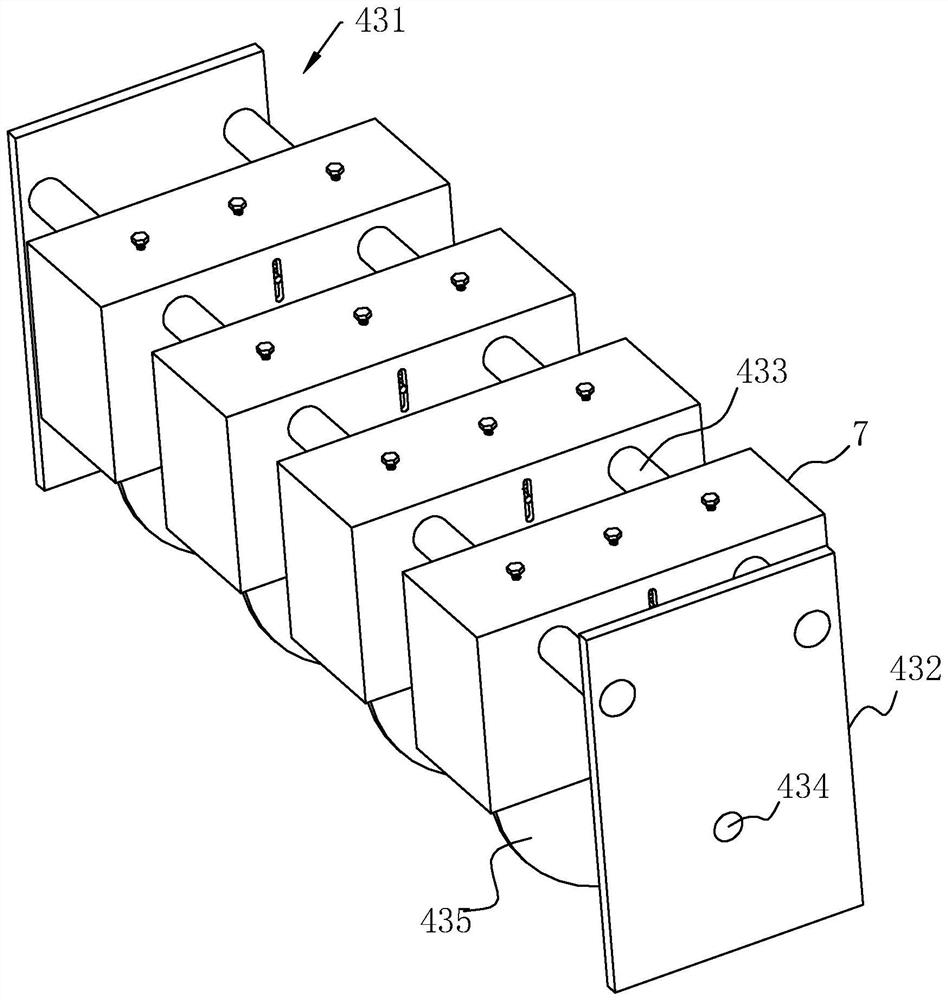

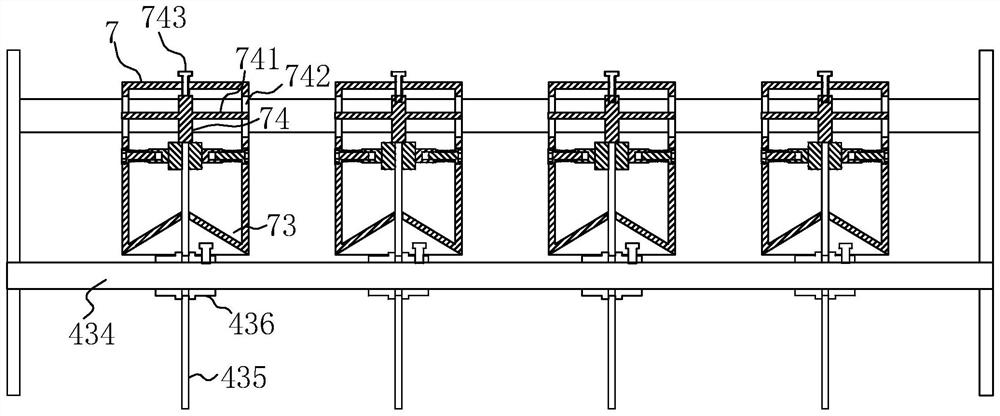

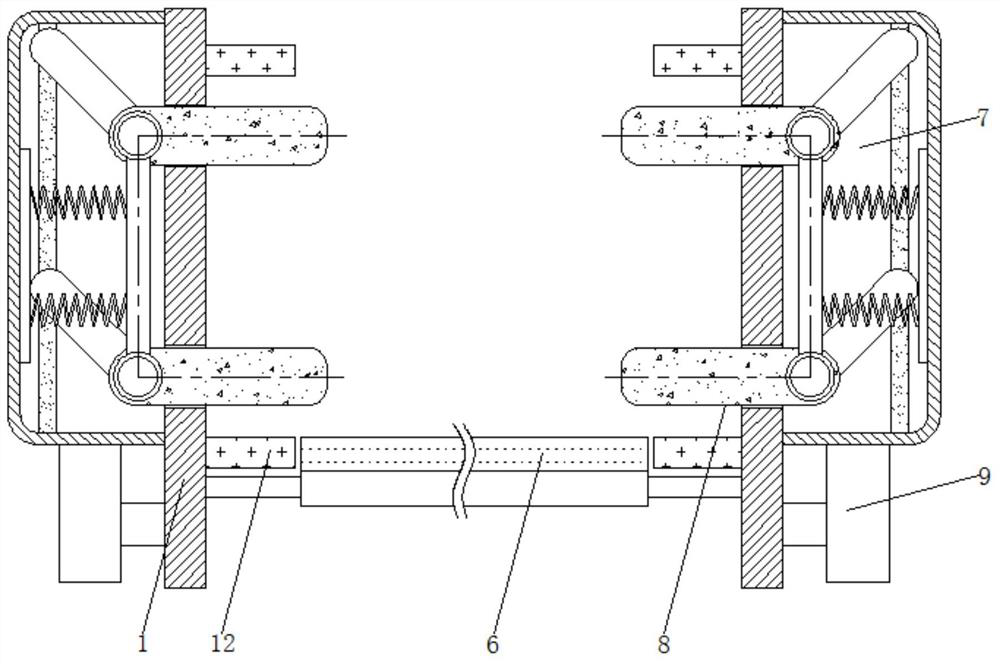

A push-type integrated circuit board packaging mechanism

ActiveCN110519958BUniform and stable packaging pressureEasy to replacePrinted circuit board receptaclesPlate pressureEngineering

The invention discloses a press type integrated circuit board packaging mechanism, and belongs to the technical field of integrated circuit board packaging. The press type integrated circuit board packaging mechanism comprises a packaging component and an insertion frame. The packaging component comprises a box body, a lifting plate, a pressure spring and a pressing frame. The box body is internally provided with an accommodating cavity. The lifting plate is slidably arranged in the accommodating cavity. The pressure spring is fixed on the lifting plate. The pressing frame penetrates through the box body to be connected with the lifting plate. A first through hole for insertion of the insertion frame is arranged on one side of the box body. The insertion frame is provided with an insertionplate. The insertion plate is movably inserted into the box body through the first through hole, and the insertion plate is located above the lifting plate and a clamping gap is formed between the insertion plate and the top of the accommodating cavity of the box body. The packaging pressure of the integrated circuit board is uniform and stable, the packaging fixation is stable and reliable, thestructural design is ingenious, the packaging device is simple and convenient to manufacture, the disassembly and assembly operation is flexible and convenient, the replacement of the integrated circuit board is convenient and the maintenance cost of the electronic product is reduced.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

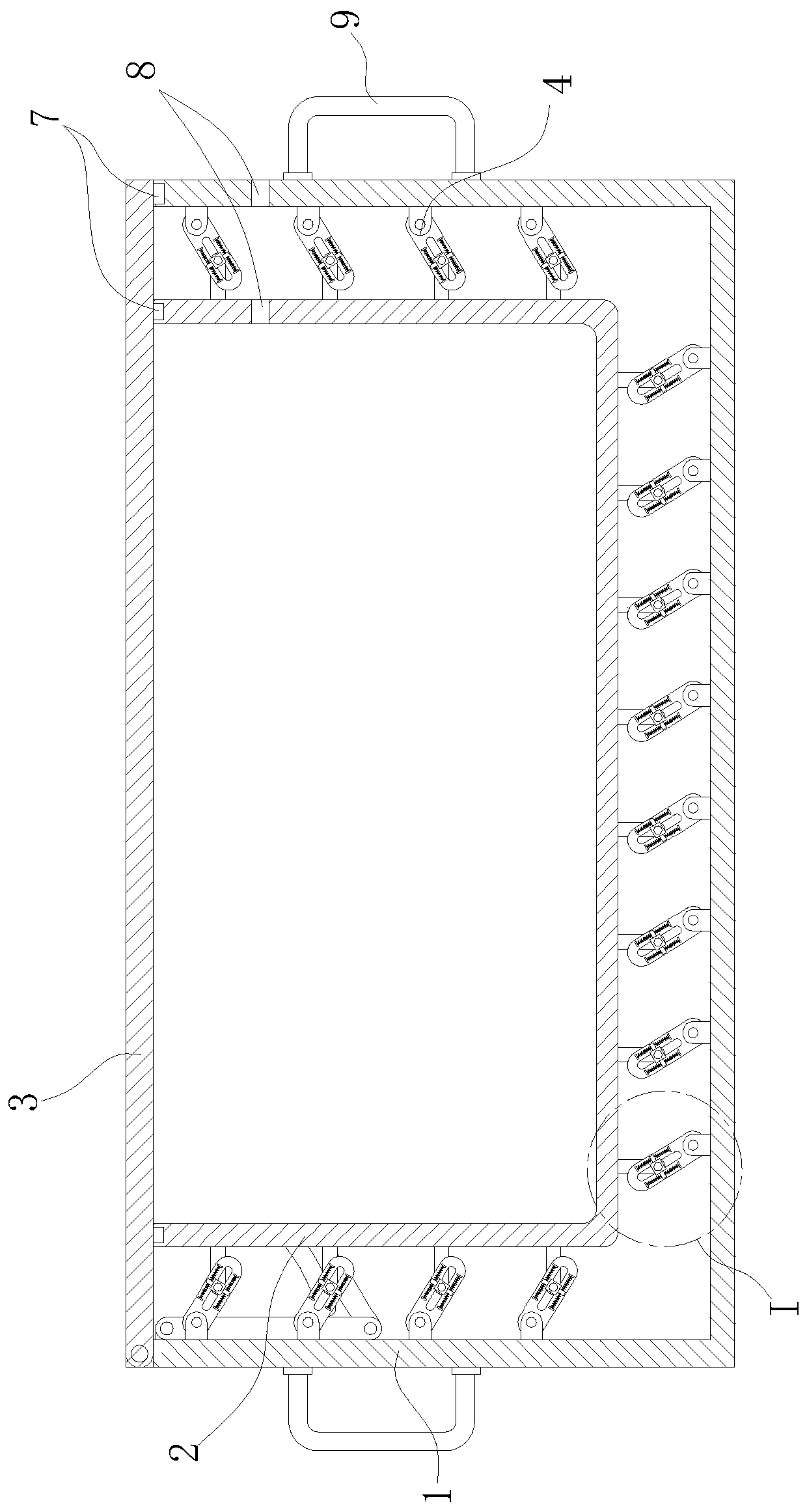

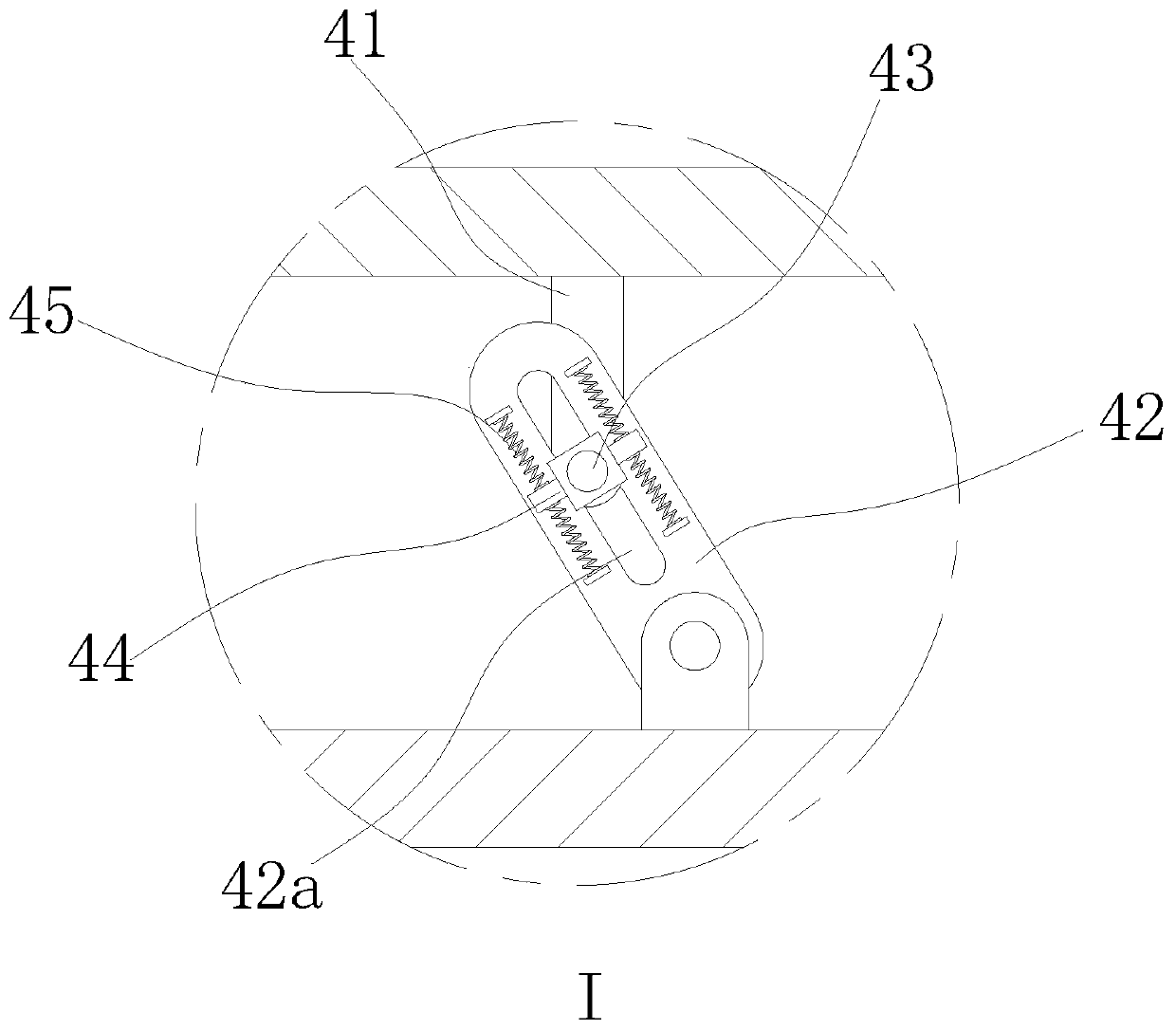

Box body device capable of all-round protection of new energy battery

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

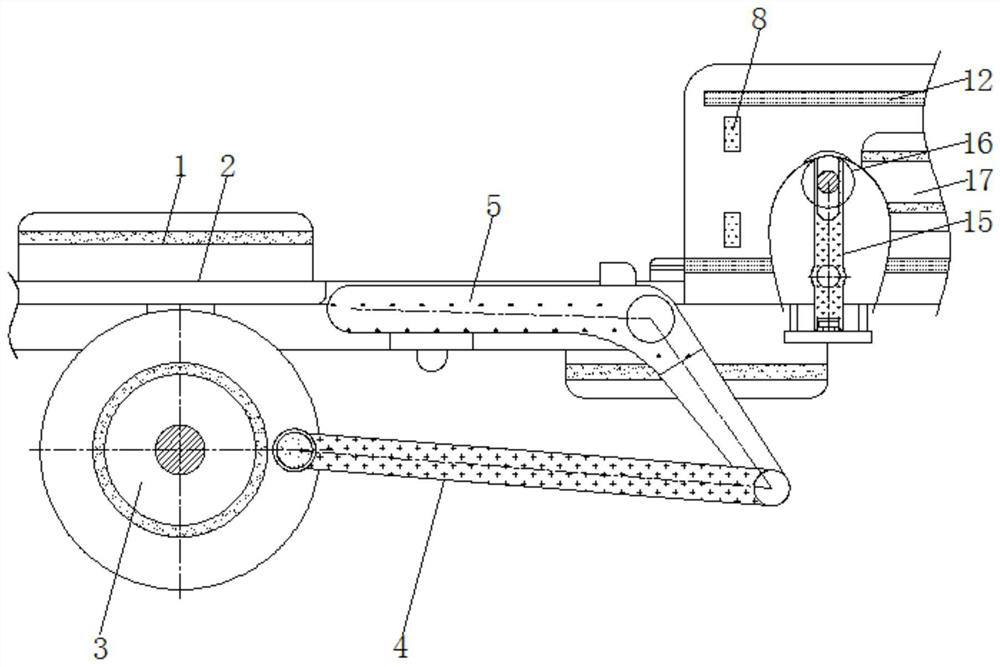

Small candle packaging equipment

ActiveCN113335678AHigh degree of mechanizationImprove work efficiencyWrapping material feeding apparatusConveyor wrappingCandlePlastic film

The invention relates to packaging equipment, in particular to small candle packaging equipment, and aims to solve the technical problem about how to provide the small candle packaging equipment which can feed, package and seal candles automatically and is high in safety. The small candle packaging equipment comprises a bottom plate, a conveying mechanism arranged at the top of the bottom plate, a film covering mechanism arranged in the middle of the top side of the bottom plate, a feeding mechanism arranged between the middle of the top side of the bottom plate and the film covering mechanism, and a sealing mechanism arranged on the feeding mechanism. Through cooperation of the conveying mechanism, the film covering mechanism, the feeding mechanism and the sealing mechanism, the candles and plastic films can be automatically conveyed, the candles are wrapped by the plastic films for sealing, the mechanical degree is high, and therefore the working efficiency of people can be improved.

Owner:南京市同亮科技有限公司

Flexible vibration sensor based on PVDF film and preparation method thereof

ActiveCN113497177AGood flexibilityImprove ductilitySubsonic/sonic/ultrasonic wave measurementUsing electrical meansThin membraneMechanical engineering

The invention relates to a flexible vibration sensor based on a PVDF film, and belongs to the technical field of sensing. The sensor provided by the invention has good flexibility and ductility, can be freely bent and even folded, is flexible and diverse in structural form, can be randomly arranged according to the requirements of the surface conditions of a measured object, can very conveniently detect the surface of a complex measured object, and the sensor can play an important role in the fields with irregular surfaces, such as biomedical treatment, bridges and the like. In addition, the invention also relates to a preparation method of the flexible vibration sensor based on the PVDF film, the method is flexible in applicable film size, the time for packaging the film into a device can be greatly shortened, meanwhile, the PVDF film cannot be damaged, and the method is compatible with the existing production process, and meanwhile, the packaging operation is convenient, the packaging time consumption is short, the packaging size is small, the response is sensitive and the like, the packaged PVDF device can well convert the received vibration signal into a charge signal, and the packaging method is suitable for large-scale popularization and application.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

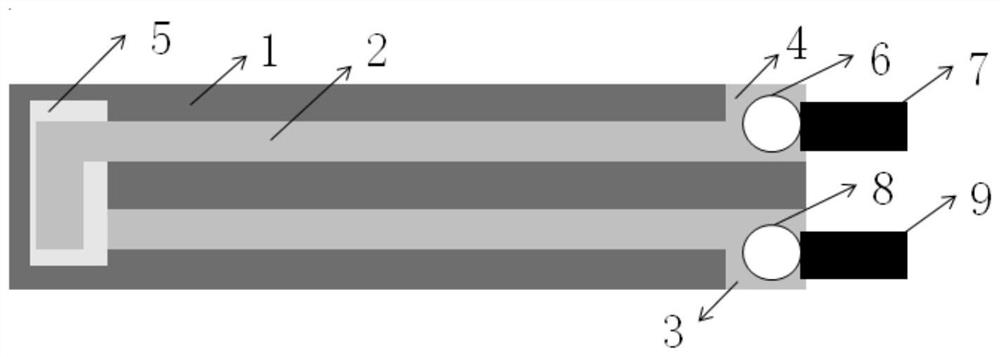

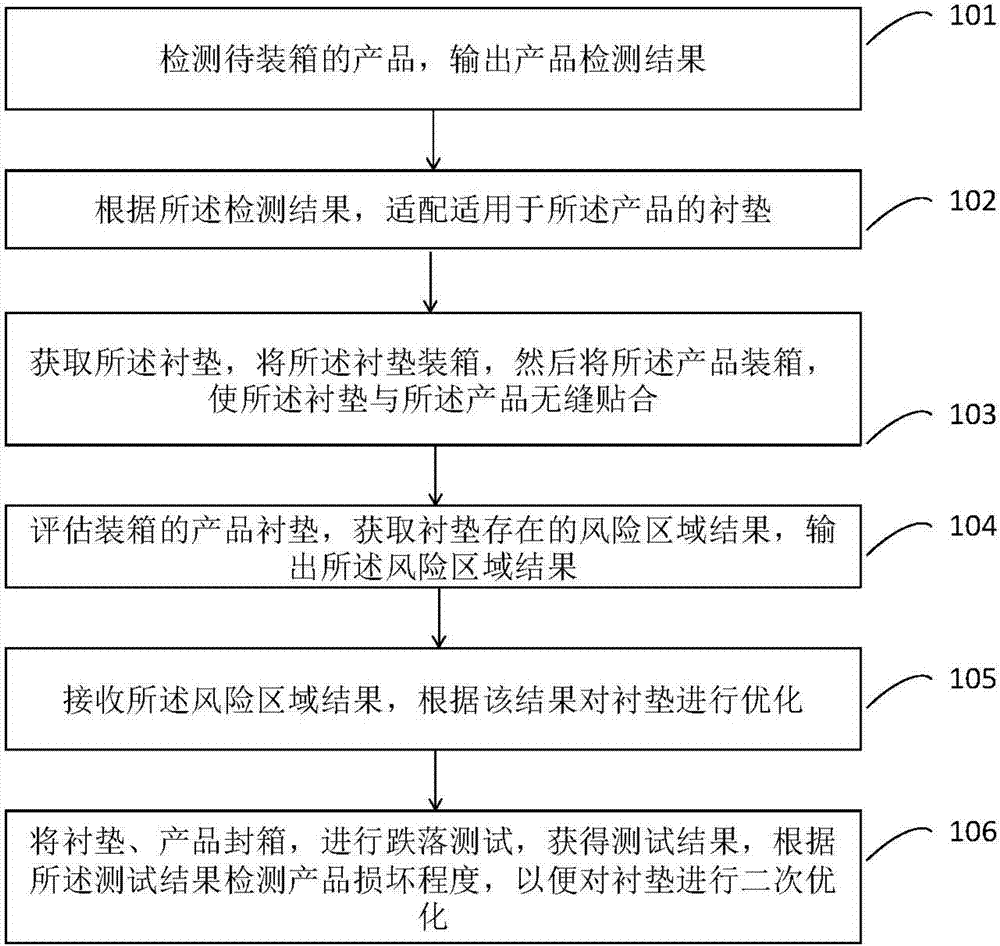

Method and system for verifying predicted risk of liner

InactiveCN107024333ADefect exposureEasy packing operationResourcesShock testingDrop testsDependability

The invention provides a method and a system for verifying the predicted risk of a liner. In view of the defect of the existing liner design by structural engineers, reliability engineers should evaluate the structural risk of liners before drop test of the liners. The fragile parts of a liner can be pointed out accurately before drop test, and the accuracy of prediction can be verified through test. Thus, the defects of products can be exposed more objectively through test, and packing operation can be improved. The quality of products is ensured. It is ensured that there will not be a large number of defective products after batch production.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

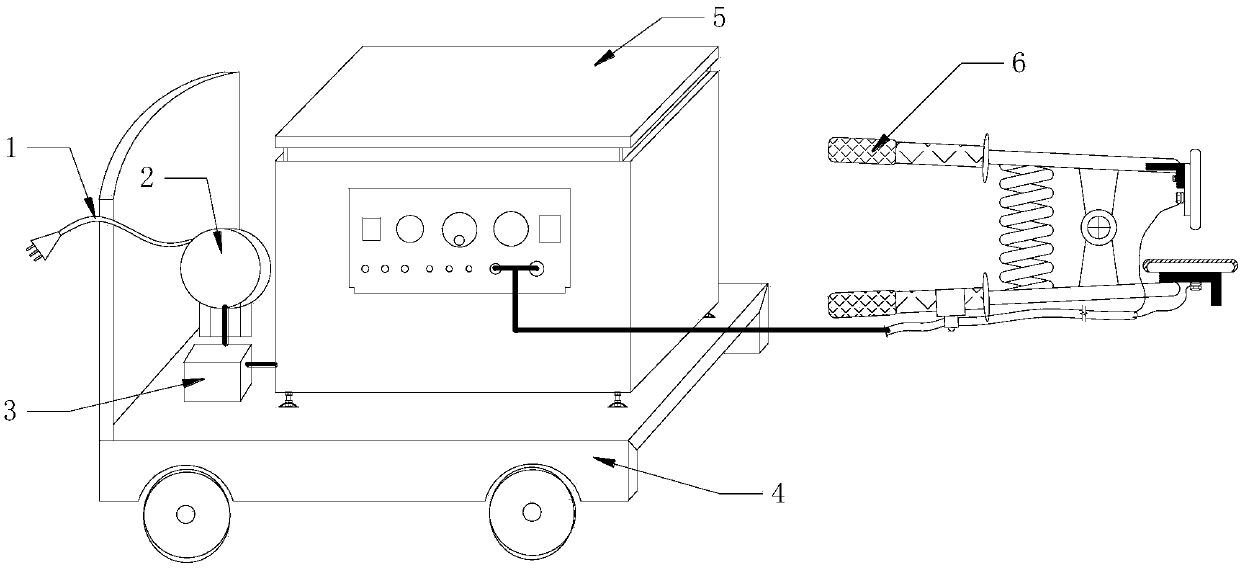

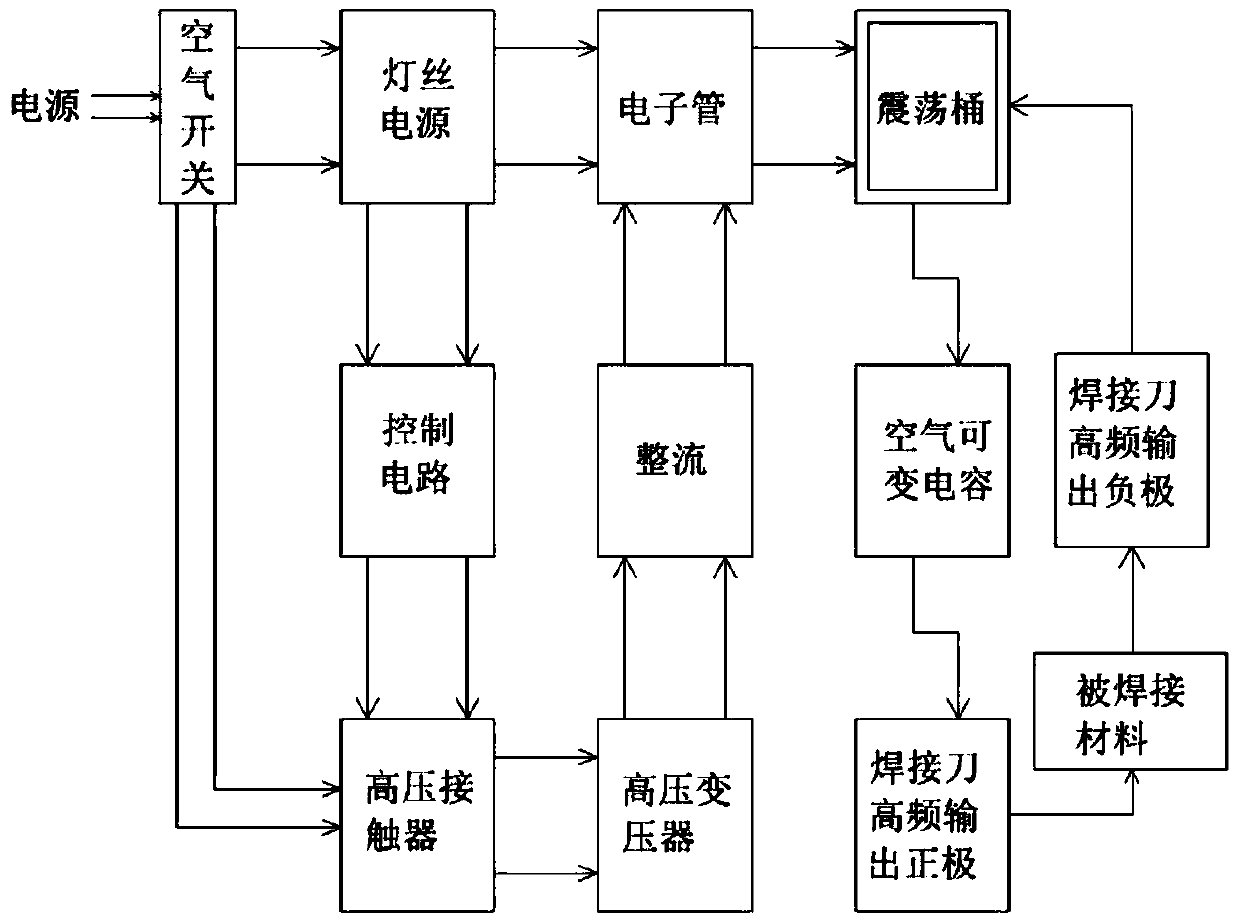

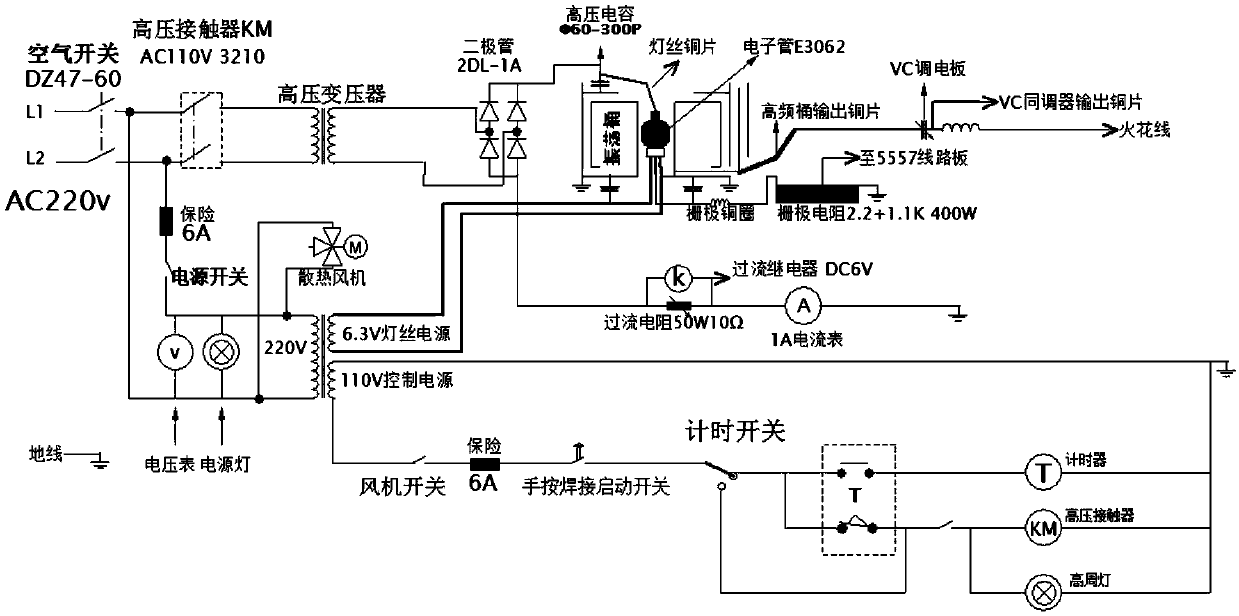

Movable seal welding device for tobacco outdoor storage outer covering

PendingCN109648860AMeets large-area sealing requirements for outdoor storageEasy to operateElectric wirePower supply voltage

The invention discloses a movable seal welding device for tobacco outdoor storage outer covering. The device comprises a power supply voltage stabilizer, a high-frequency welding main machine and a welding tool bit connected in sequence through electric wires; and a movable car is fixedly arranged at the bottom of the high-frequency welding main machine. The device is provided with the high-frequency welding main machine on the movable car; in actual operating process, equipment can be transferred to a related place for work through the movable car to meet large-area sealing requirements in tobacco outdoor storage; and the welding tool bit is connected with the high-frequency welding main machine through the electric wire, so that workers can directly hold a welding cutter connecting rod in hands for sealing a sealing cover in the operating process, and the operation is more convenient.

Owner:云南镁然科技有限公司 +1

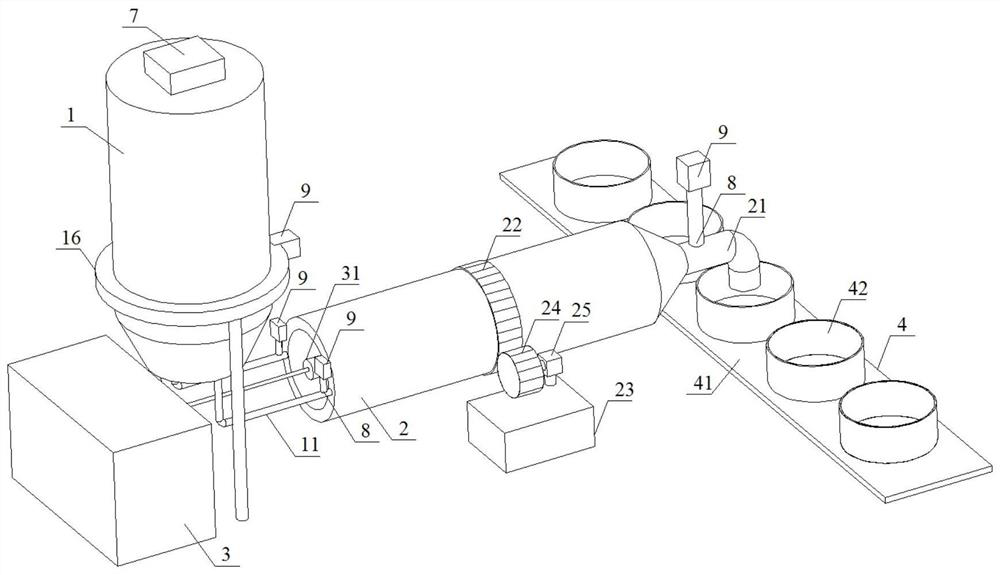

Efficient, rapid and small-size automatic packaging mechanical equipment

ActiveCN113859674AAutomatic inflationRealize automatic deliveryIndividual articlesEngineeringStructural engineering

The invention discloses efficient, rapid and small-size automatic packaging mechanical equipment, and particularly relates to the technical field of packaging machines. The efficient, rapid and small-size automatic packaging mechanical equipment comprises a main machine, a discharging table is arranged over the main machine, an intermittent discharging mechanism is arranged on one side of the discharging table, an air compressor is arranged at one end of the main machine, and a driving box is arranged at the end, away from the main machine, of the air compressor; a reel is arranged at the top end of the driving box, the outer surface of the reel is sleeved with an air column bag, and a bottom plate is arranged on one side of the main machine; and a limiting frame is arranged on the outer side wall of the side, close to the bottom plate, of the main machine, and a trigger switch is fixedly installed at the position, close to a base table, of the limiting frame. The whole equipment can achieve the automatic inflation and packaging process of the air column bag, is different from traditional manual inflation and packaging operation, is more efficient and rapider, is small in size, is suitable for being used in any use place, and meanwhile facilitates large-scale application and popularization of the air column bag in the express packaging field.

Owner:海南科技职业大学

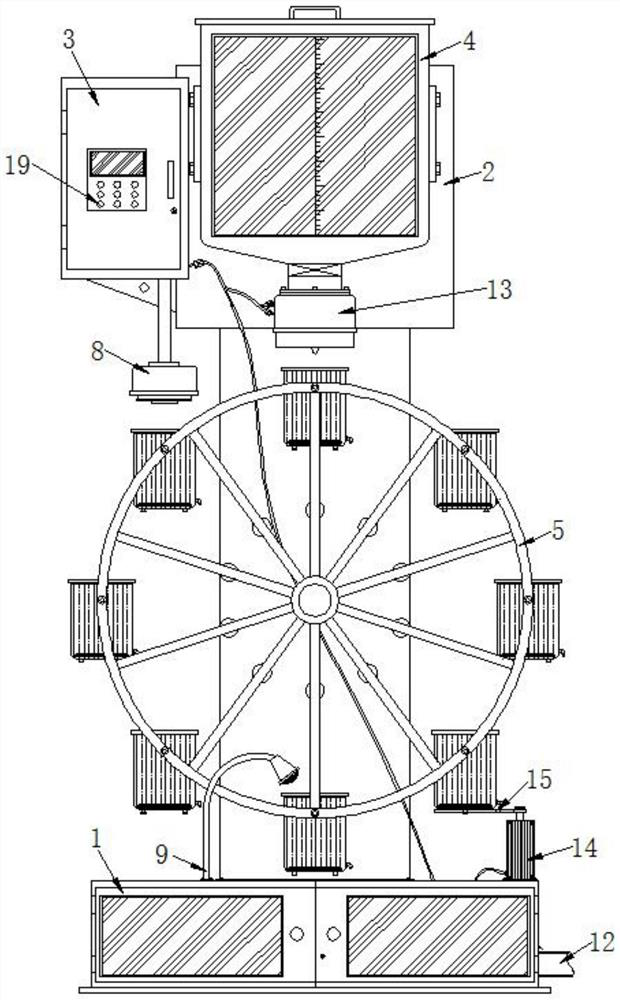

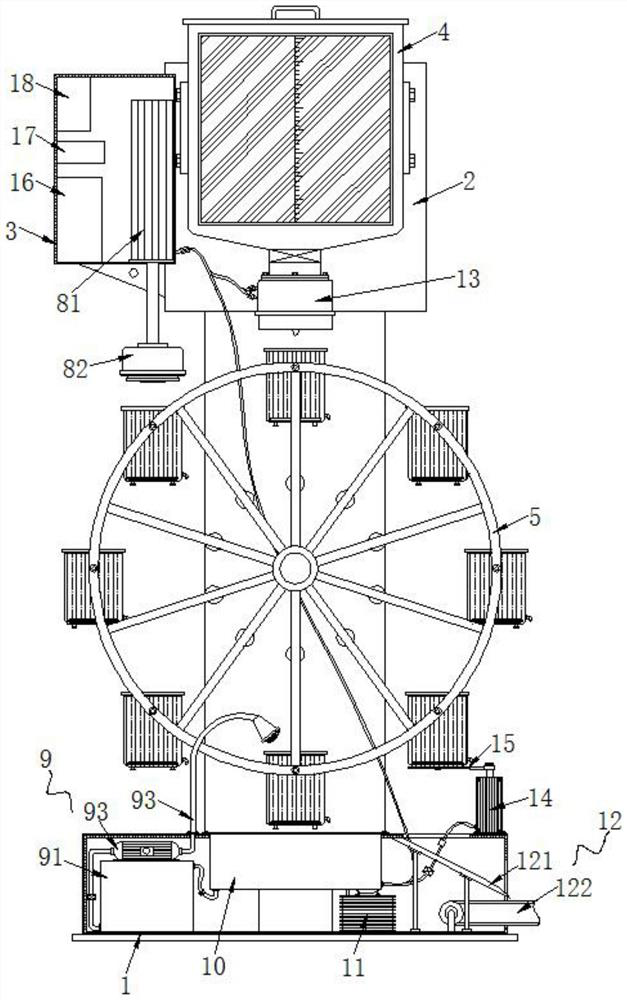

Packaging system for high polymer material production

InactiveCN111994389AIncrease productivityReduce manufacturing costMeasurement of fluid loss/gain rateWrapper twisting/gatheringElectric machineryMolecular materials

The invention discloses a packaging system for high polymer material production, and relates to the technical field of high polymer material production equipment. The packaging system comprises a bottom box and a mounting frame fixedly welded to the top of the bottom box; a control box and a metering tank are fixedly installed at the top of the front surface of the mounting frame through fixing parts in sequence from left to right; a circular conveying mechanism is arranged on the front surface of a mounting plate; a driving motor is fixedly installed at the top of the bottom box and located on the back surface of the mounting plate; and a driving belt wheel is fixedly installed on the outer surface of an output shaft of the driving motor. According to the packaging system for high polymermaterial production, bagging, sealing, air tightness detection, cleaning and automatic discharging can be combined into an integrated system for high polymer material packaging, a large amount of time of production personnel is not needed, and various production devices are adopted for carrying out air tightness detection and cleaning treatment on the packaging bag, so that the production efficiency of high polymer materials is greatly improved, the production cost is low, and the installation site is saved.

Owner:张凯华

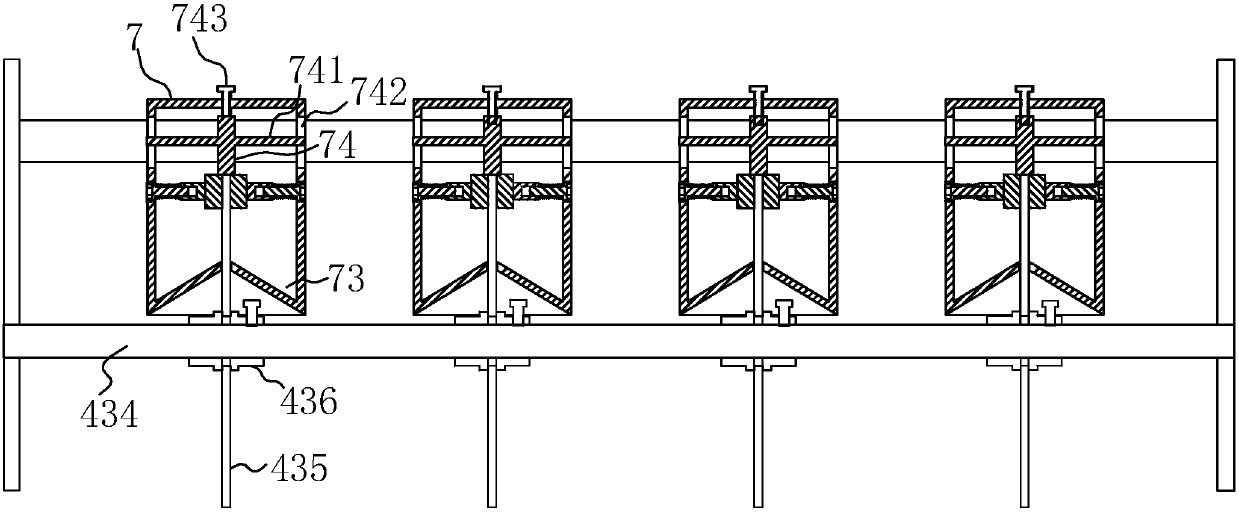

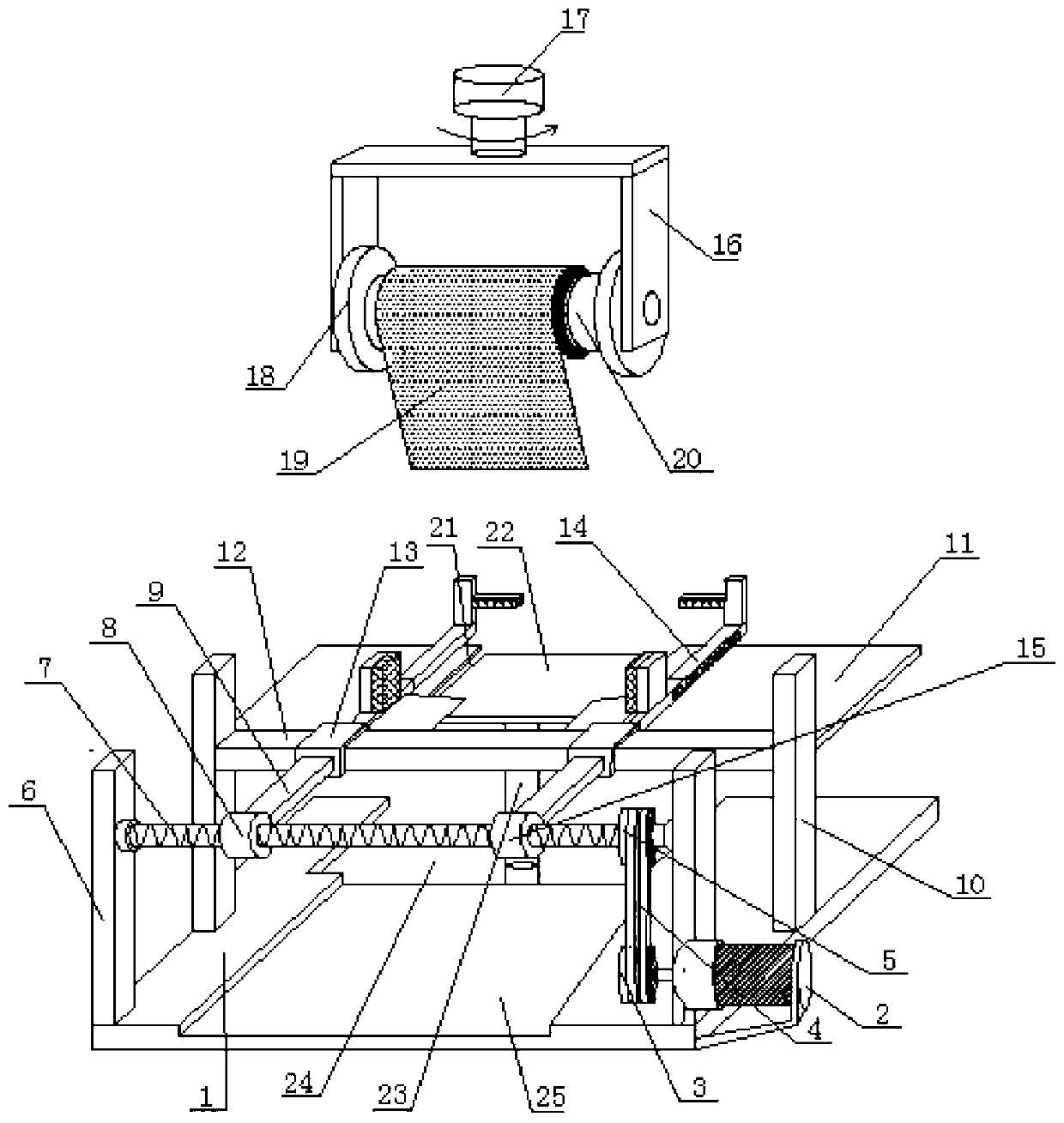

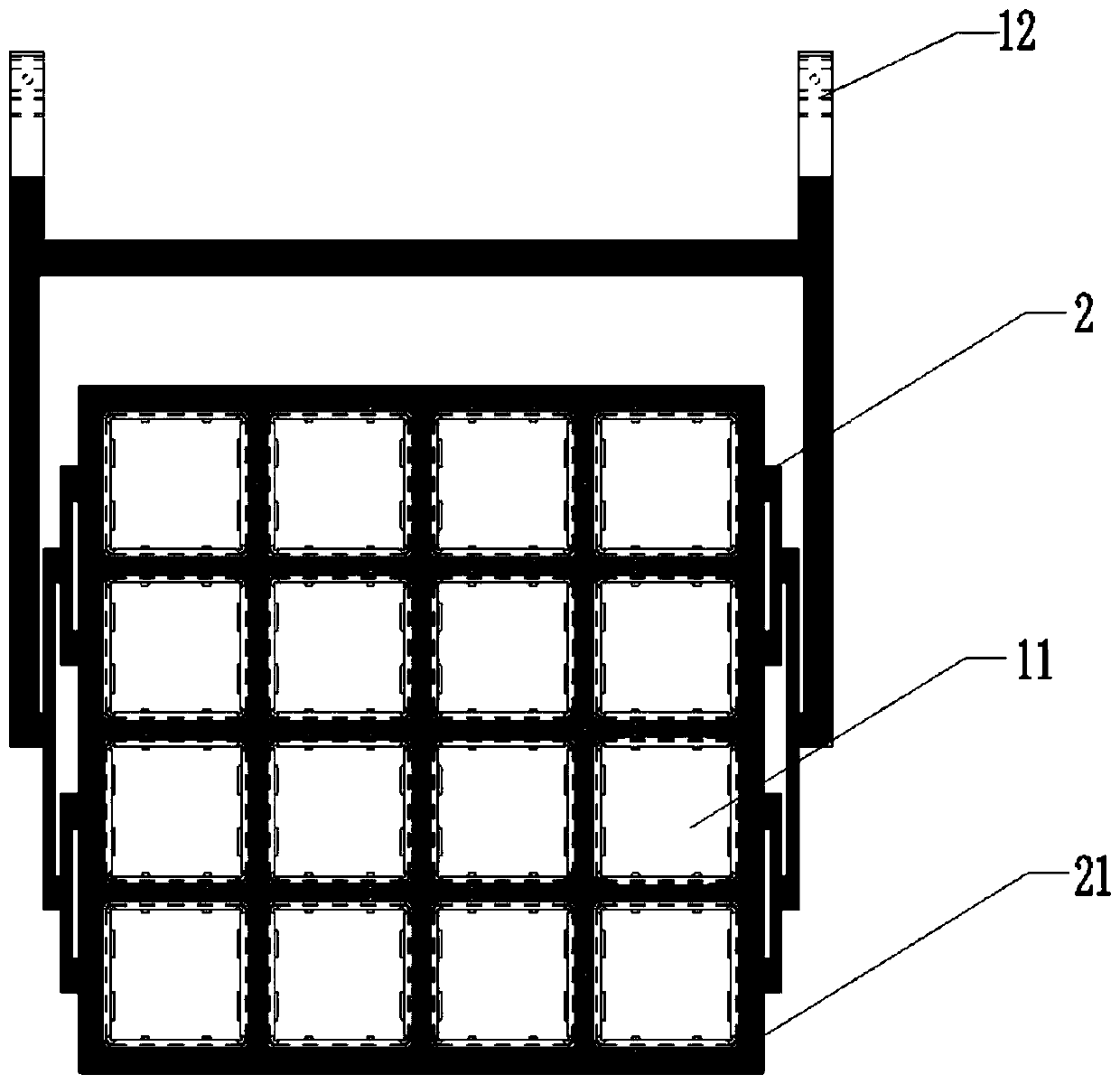

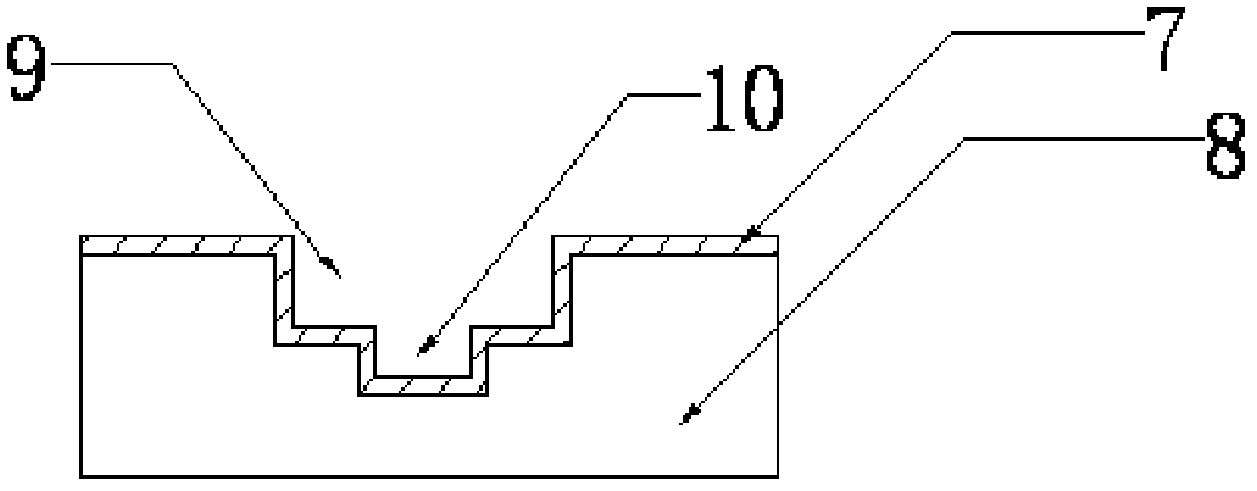

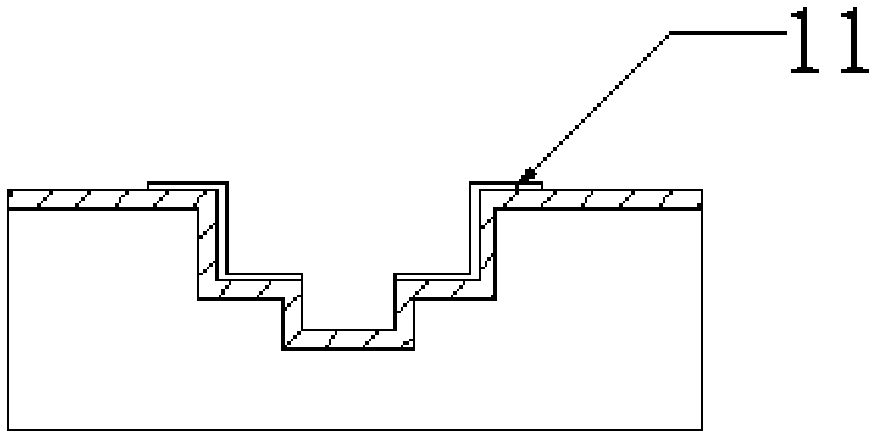

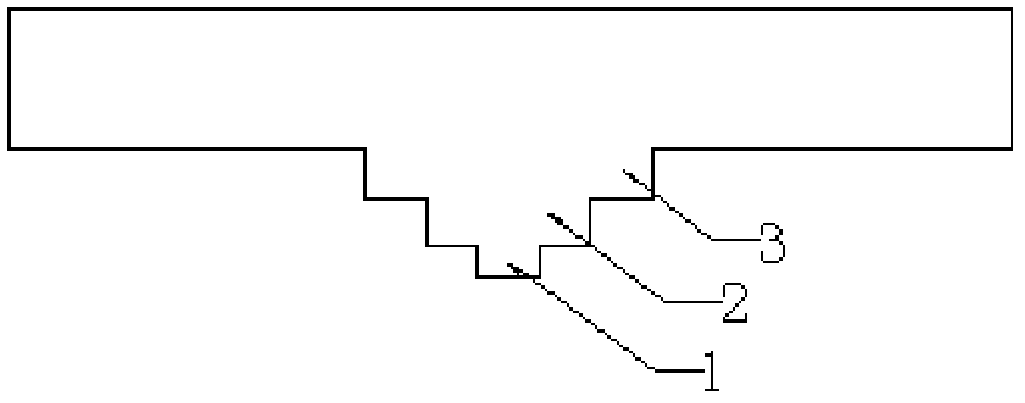

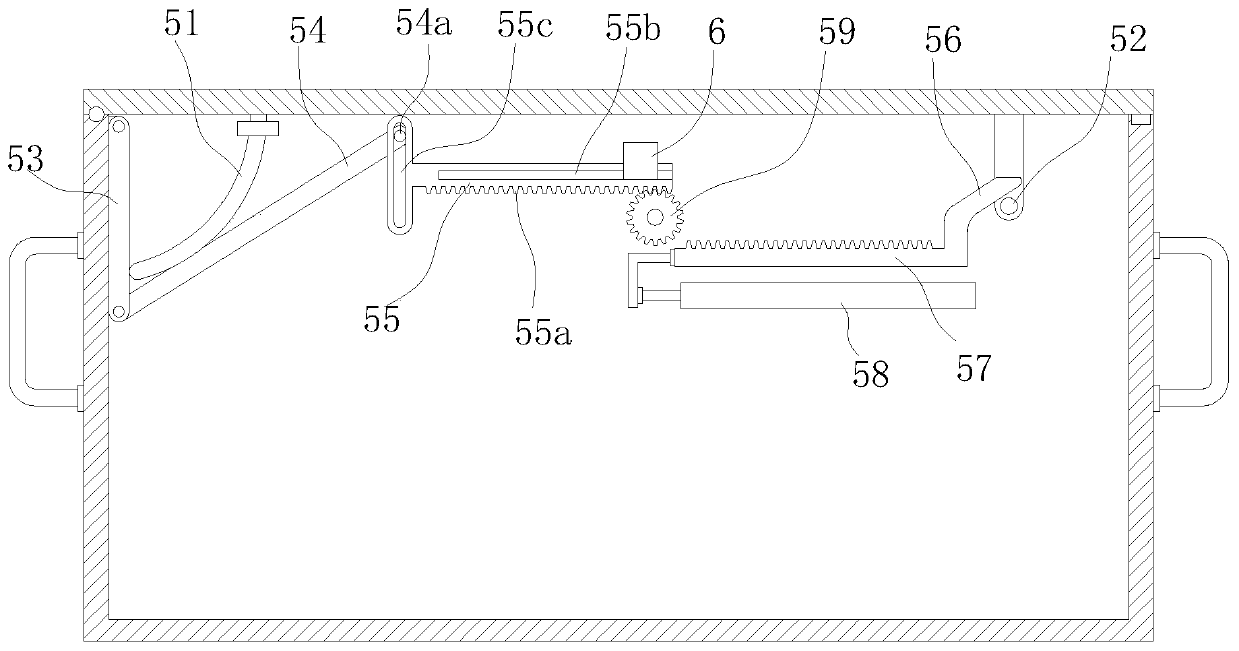

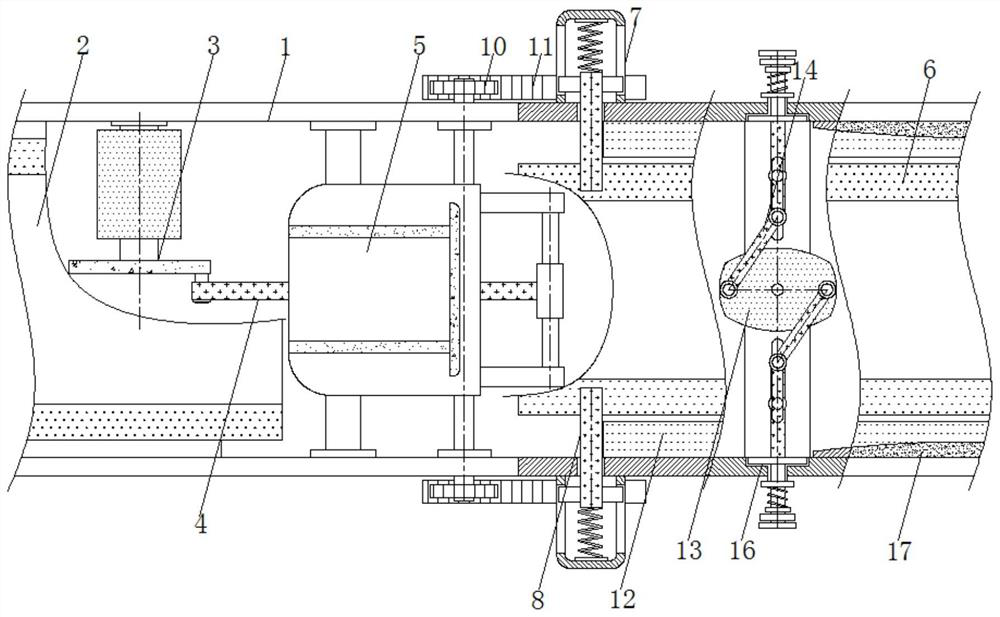

Automatic weighing and packaging device

The invention relates to an automatic weighing, packaging and printing device, and particularly relates to an automatic weighing and packaging device. The automatic weighing and packaging device comprises a conveying and weighing system, a cam indexing turntable transmission system, an empty box conveying system and a packaging, sealing and printing system. The automatic weighing and packaging device is characterized in that an output shaft of a cam indexer 7 is connected to the center of a turntable 9 in a general flat key connection manner, so that the cam indexer can drive the turntable to rotate conveniently; a coding machine 11 is arranged above a goods output track; and a glue containing hopper 34 is arranged on the side surface of a glue spreading sponge 12 which is arranged on an adjusting lever 33. The automatic weighing and packaging device is capable of substantially reducing the labor intensity of tedious work of manually weighing goods, packaging, printing data of production and the like, realizes automatic and continuous detection, ensures stability and reliability of weighing data, facilitates packaging operation, and is high in weighing speed and practicability.

Owner:宿迁柏特粮食设备有限公司

A bread production line and its dividing mechanism

ActiveCN107751275BImprove fitImprove guidanceDough dividingDough shaping and cutting apparatusEngineeringMechanical engineering

The invention discloses a bread production line and a cutting mechanism thereof. According to the technical scheme, the bread production line is characterized by comprising a matching device, a stirring device, a fermentation tank, a forming device, a resting box and a baking oven which are sequentially arranged, wherein the cutting mechanism in the forming device comprises a mounting frame and cutters arranged on the mounting frame at intervals, the mounting frame comprises a cross rod, boxes corresponding to the cutters are arranged on the cross rod, slots allowing the cutters to penetrate out are formed in the bottoms of the boxes, and scraping plates abutting against side walls and cutting surfaces of the cutters are arranged in the boxes. By the aid of the scraping plates, the cutterscontinuously rotate in the flour cutting process, so that flour stick to the cutters can be scraped by the scraping plates continuously and left in the boxes, the flour cannot stick to the side wallsand the cutting surfaces of the cutters for a long time, and the following flour cutting process can be conducted well in order.

Owner:北京义利面包食品有限公司

Device facilitating vertical overturning, conveying and adjusting of medicine boxes

The invention relates to the technical field of medical equipment, and discloses a device facilitating vertical overturning, conveying and adjusting of medicine boxes. The device comprises a machine body, an input device is arranged on the surface of the machine body, a driving disc is arranged in the machine body, a push rod is movably connected to the surface of the driving disc, and an overturning plate is arranged on the surface of the machine body. A conveying device is arranged on the side, away from the input device, of the overturning plate, a sliding seat is arranged on the side surface of the machine body, a limiting plate is arranged in the sliding seat, and an ejector rod is arranged on the lower surface of the sliding seat. According to the device facilitating vertical overturning, conveying and adjusting of the medicine boxes, through cooperative use of the input device and the overturning plate, cooperative use of the driving disc and the push rod, cooperative use of a gear and a toothed plate, cooperative use of the ejector rod and the sliding seat, and cooperative use of the sliding seat and the limiting plate, the medicine boxes can be automatically and vertically rotated and adjusted, the medicine boxes are not prone to rollover, the adjusting effect is good, and the medicine box adjusting operation efficiency is high.

Owner:赵小飞

A preparation method of "j" type reinforced wall panel preform suitable for rfi process

The invention belongs to the technical field of low-cost manufacturing of high-performance resin-based composite materials, and provides a method for preparing a "J"-shaped reinforced wall panel preform suitable for RFI technology, including: (a) decomposing the "J"-shaped panel according to structural features For reinforced wall panels, "J"-shaped stringer lay-up units are divided according to the process separation surface; (b) "J"-shaped stringer pre-forming mold design; (c) "J"-shaped stringer and skin unit pre-forming; (d) Assembly of "J"-shaped stringer, skin unit and forming mold, pre-pressing and shaping, and positioning to form a pre-formed "J"-shaped reinforced wall panel; (e) Pre-shaped "J"-shaped reinforced wall The panel preform is sewed and trimmed to prepare a "J"-shaped reinforced wall panel preform. The invention better guarantees the final quality of the reinforced wall plate by controlling the profile surface and the position accuracy of the stringer during the preforming preparation process.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com