A push-type integrated circuit board packaging mechanism

An integrated circuit board and integrated circuit technology, which is applied to the installation of printed circuit board sockets and support structures, can solve problems such as poor fixing stability of integrated circuit boards, high precision requirements for parts matching, and complex structural design, and achieve stable and reliable packaging and fixing , The packaging pressure is uniform and stable, and the production is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

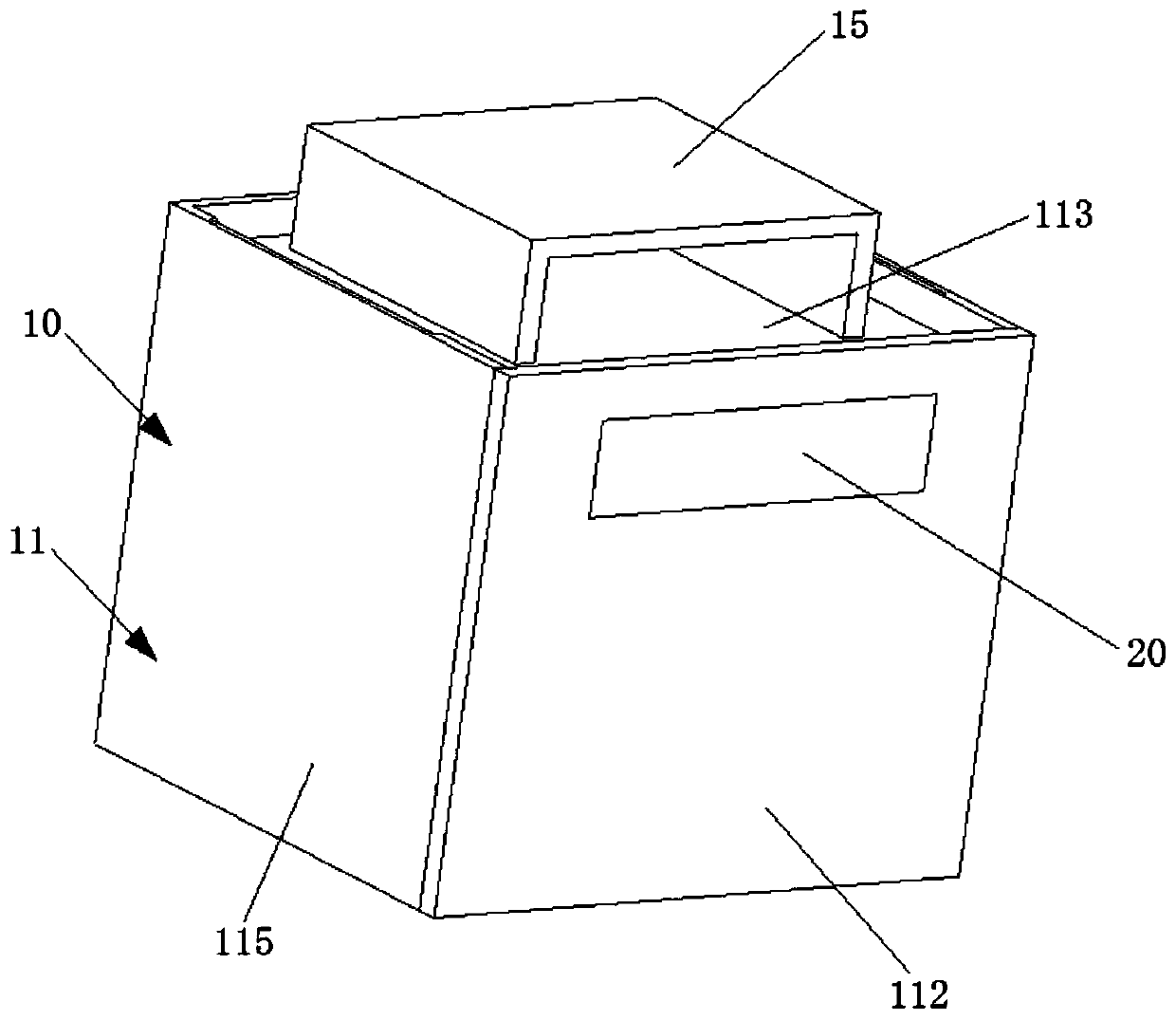

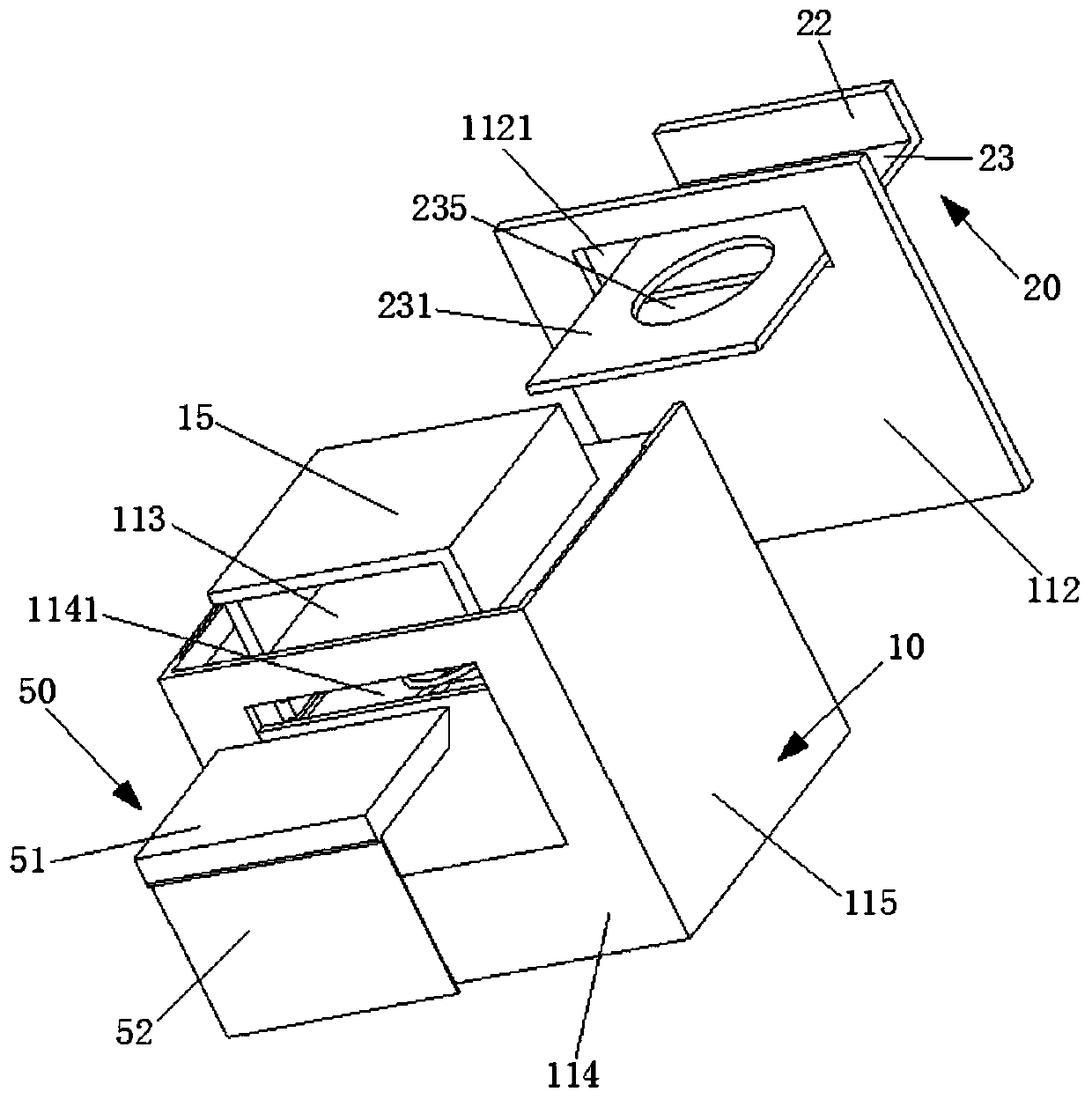

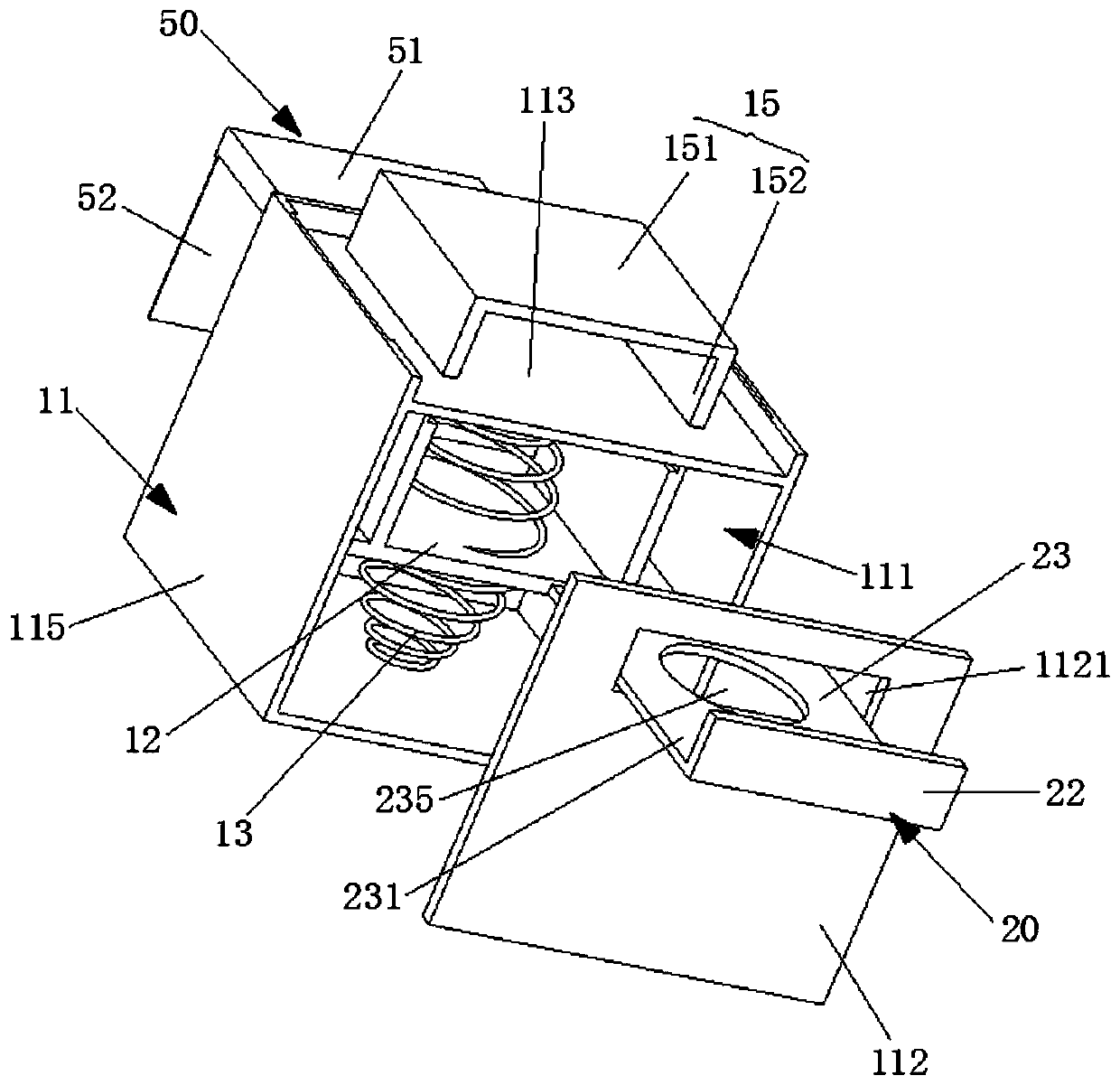

[0066] Such as Figure 1 to Figure 5As shown, a press-type integrated circuit board packaging mechanism in this embodiment includes a packaging assembly 10 and an insertion frame 20. The packaging assembly 10 includes a box body 11, a lifting plate 12, a pressure spring 13 and a pressing frame 15. The box body 11 adopts Rectangular box structure, surrounded by the first side plate 112, the second side plate 114, the third side plate 115, the fourth side plate 116, the top plate 113 and the bottom plate, the second side plate 114, the third side plate 115 , the fourth side plate 116, the top plate 113 and the bottom plate can be designed as an integrated structure, the first side plate 112 and the other side plates of the box body 11 adopt a split connection structure, and a rectangular box body is used to facilitate the layout of the packaging mechanism inside the box body. Convenient packaging of integrated circuit boards. There is a housing cavity 111 inside the box body 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com