Small candle packaging equipment

A technology of packaging equipment and candles, which is applied in the field of packaging equipment, can solve the problems of low mechanization and scalds in manual packaging candles, and achieve the effects of avoiding scalds, improving work efficiency, and high mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

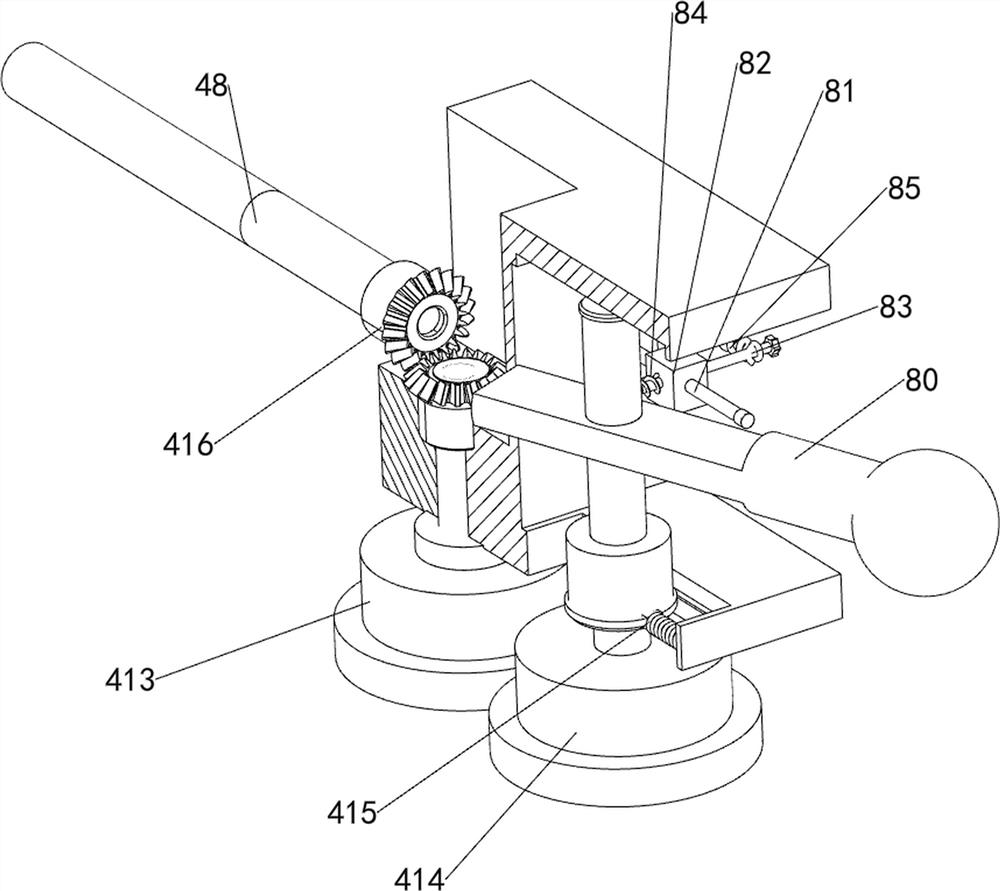

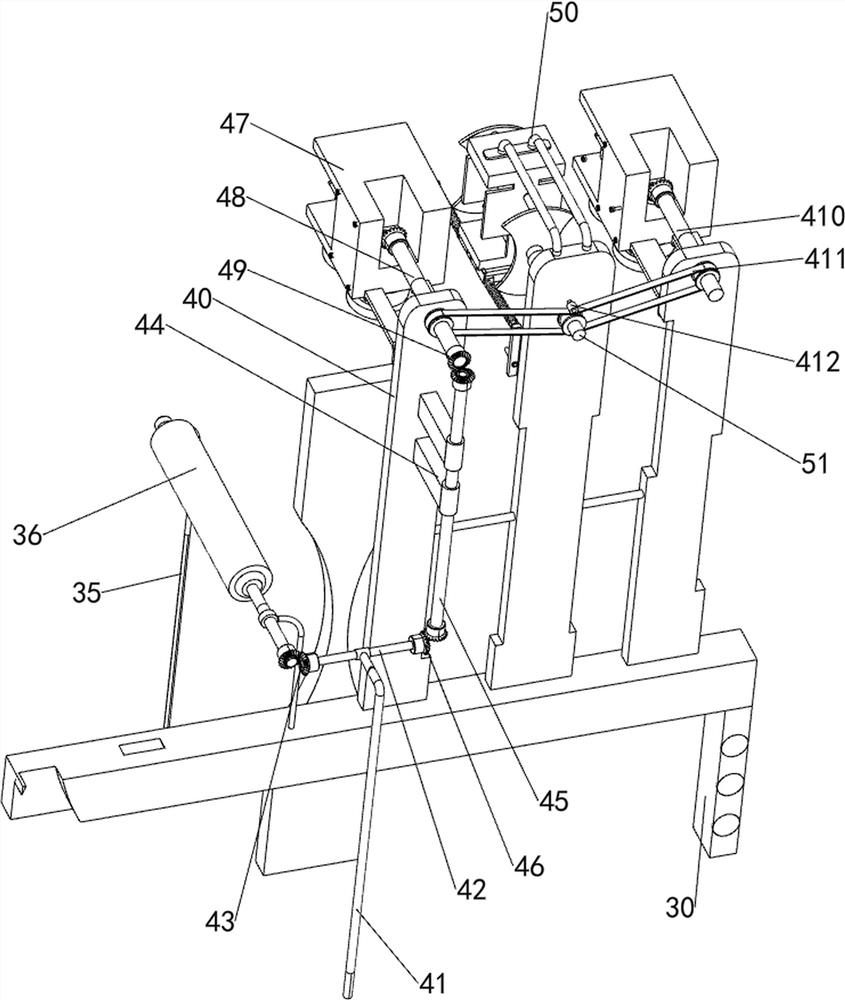

[0102] A small candle packaging equipment such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, it includes a bottom plate 1, a transmission mechanism 2, a film covering mechanism 3, a feeding mechanism 4 and a sealing mechanism 5. The top of the bottom plate 1 is provided with a transmission mechanism 2, and the middle part of the top side of the bottom plate 1 is provided with a film covering mechanism 3. The top side of the bottom plate 1 is provided with a film covering mechanism 3. A feeding mechanism 4 is provided between the middle part and the laminating mechanism 3, and a sealing mechanism 5 is arranged on the feeding mechanism 4. The sealing mechanism 5 includes a second fixed block 50, a sixth transmission shaft 51, a rotating block 52, and a first electric heating block 53. , installation block 54 and the second spring 55, the top of a certain part of the feeding mechanism 4 is provided with a second fixed block 50, and the top...

Embodiment 2

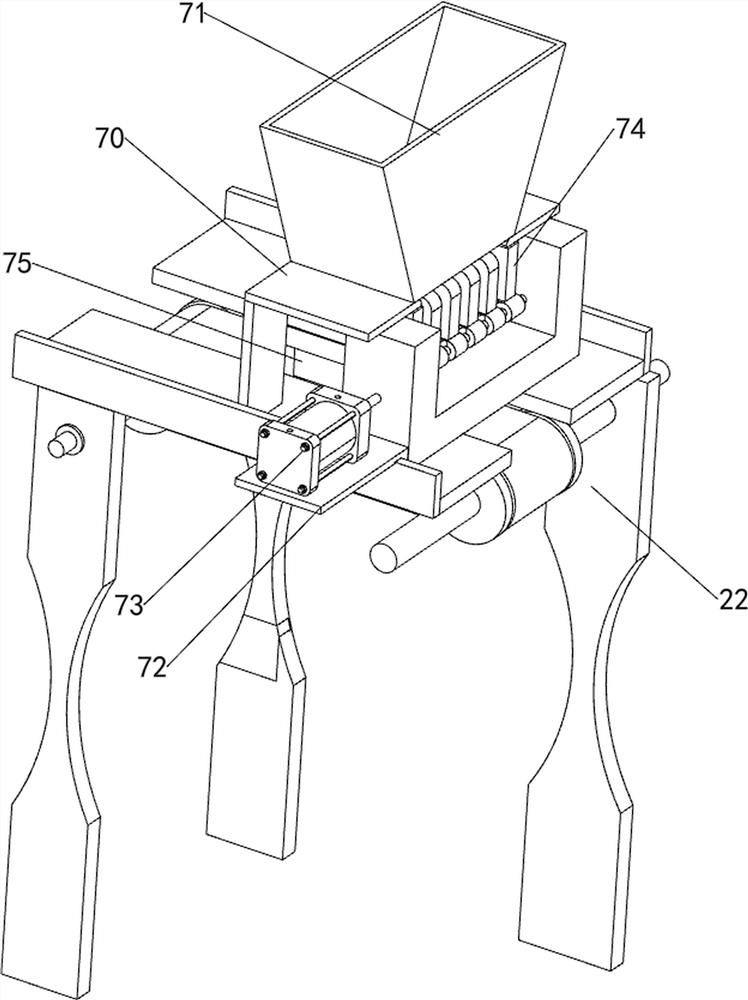

[0108] On the basis of Example 1, such as Figure 5 , Figure 7 and Figure 8 As shown, a cutting mechanism 6 is also included. The cutting mechanism 6 includes a sixth support rod 60, a rotating disk 61, a seventh belt 62, a connecting plate 63, a support seat 64 and a cutter 65. The sixth support rod 60, the upper part of the sixth support rod 60 is rotatably provided with a turntable 61, the seventh belt 62 is arranged between the turntable 61 and the rear side of the fifth transmission shaft 410, and the front side of the turntable 61 is rotatably provided with a connecting plate 63, A support seat 64 is provided between the left side of the top of the second support platform 25 , and a cutter 65 is slidably provided inside the support seat 64 , and the rear side of the cutter 65 is connected to the connecting plate 63 in a rotational manner.

[0109] After the candle is packaged by the first electric heating block 53, the second conveyor belt 29 will drive the packaged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com