Automatic weighing and packaging device

A technology of packaging equipment and weight measurement, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of not being able to automatically pack and print the date of delivery, not being able to realize industrial automation, and low accuracy, so as to achieve moderate equipment cost and use Safe and reliable, stable and reliable data effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

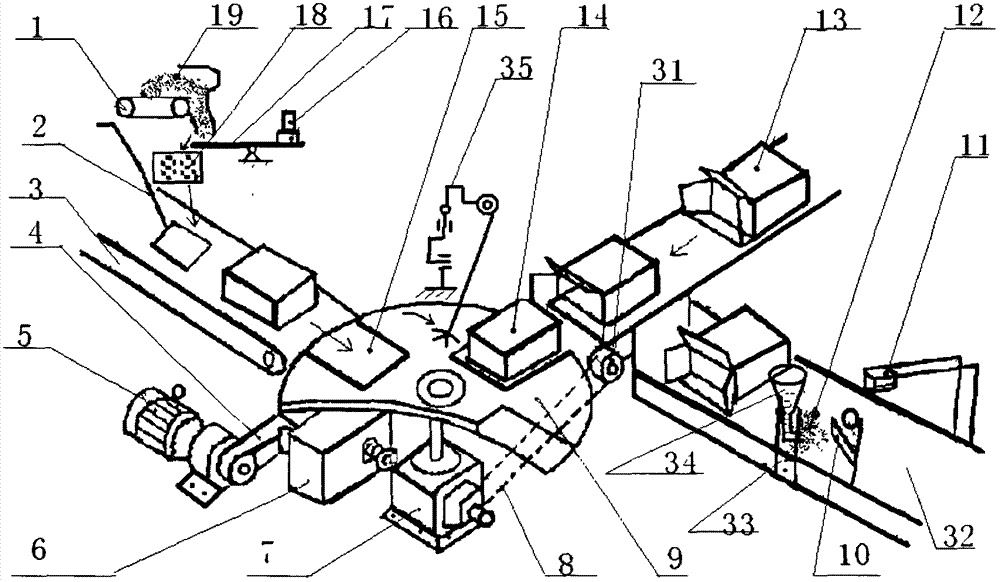

[0024] Such as figure 1 As shown, the present invention is mainly for weighing the bulk goods, and the bulk goods 19 are transferred to the bulk material conveyor belt 1 in advance, and after the bulk material conveyor belt 1 runs, the bulk material just falls on the photoelectric control scale 17 for weighing Heavy, the photoelectric control scale 17 is equipped with a standard counterweight weight 16, so that the weighing of the photoelectric control scale 17 can be serialized (the weight is serialized according to specific products, such as the weight is set to: 2.2 kg, 2.4 kg, 2.6 kg...) When the goods reach the preset weight, the goods will automatically slide down to the bag sealing machine 18 for automatic plastic bag packaging. The packaged plastic bag slides to the conveyor belt A3 through the ramp slideway 2, and the plastic bag or small package is transmitted to the cam indexer 7 through the conveyor belt A3. The cam indexer 7 is an indexing cycle indexer and the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com