Auxiliary positioning device for product packaging

An auxiliary positioning and product packaging technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of difficult and accurate assembly line packaging, difficult to achieve manual operation, and affect packaging efficiency, so as to reduce operating intensity and improve efficiency Compatible with assembly line performance and convenient lamination operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

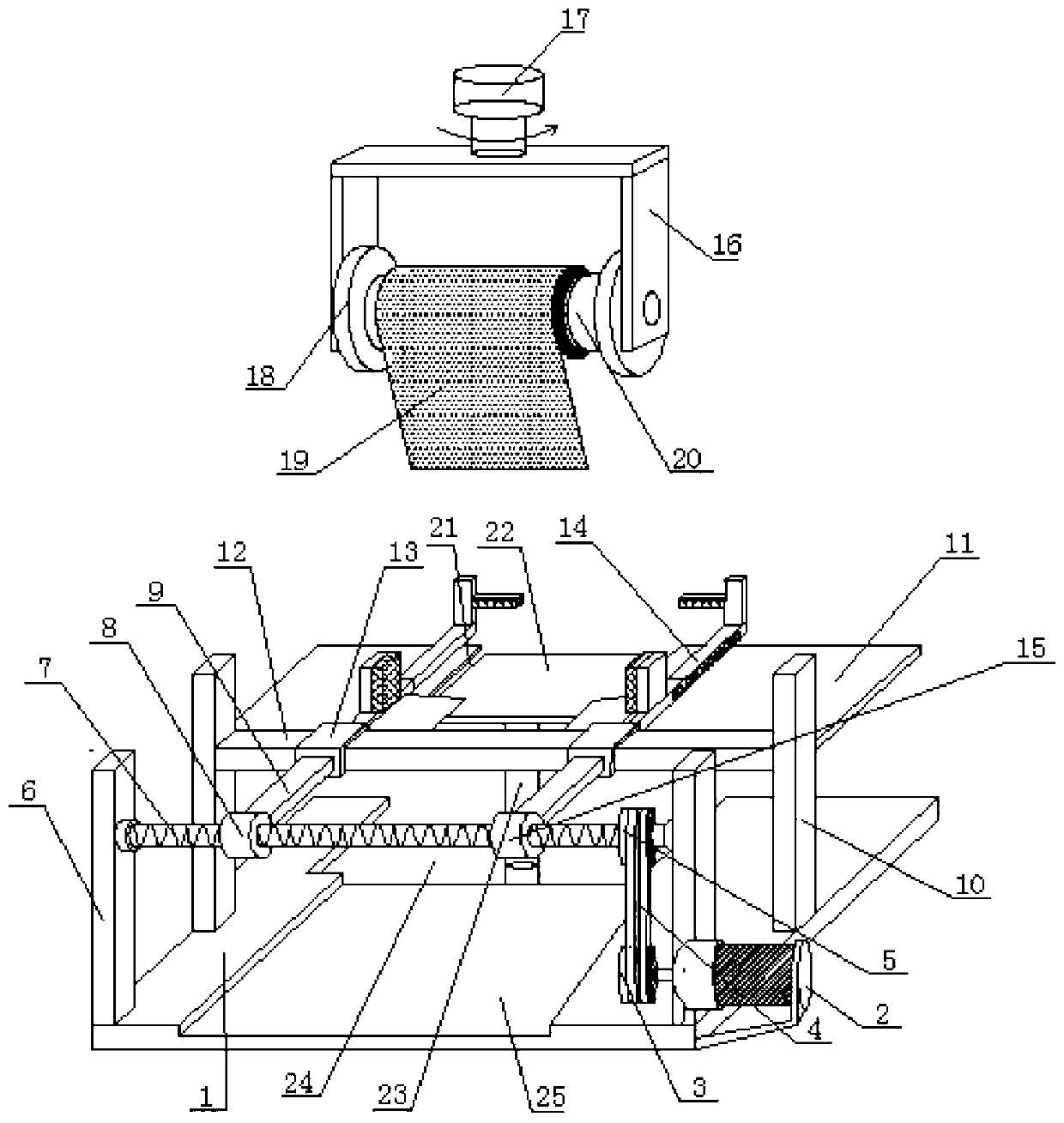

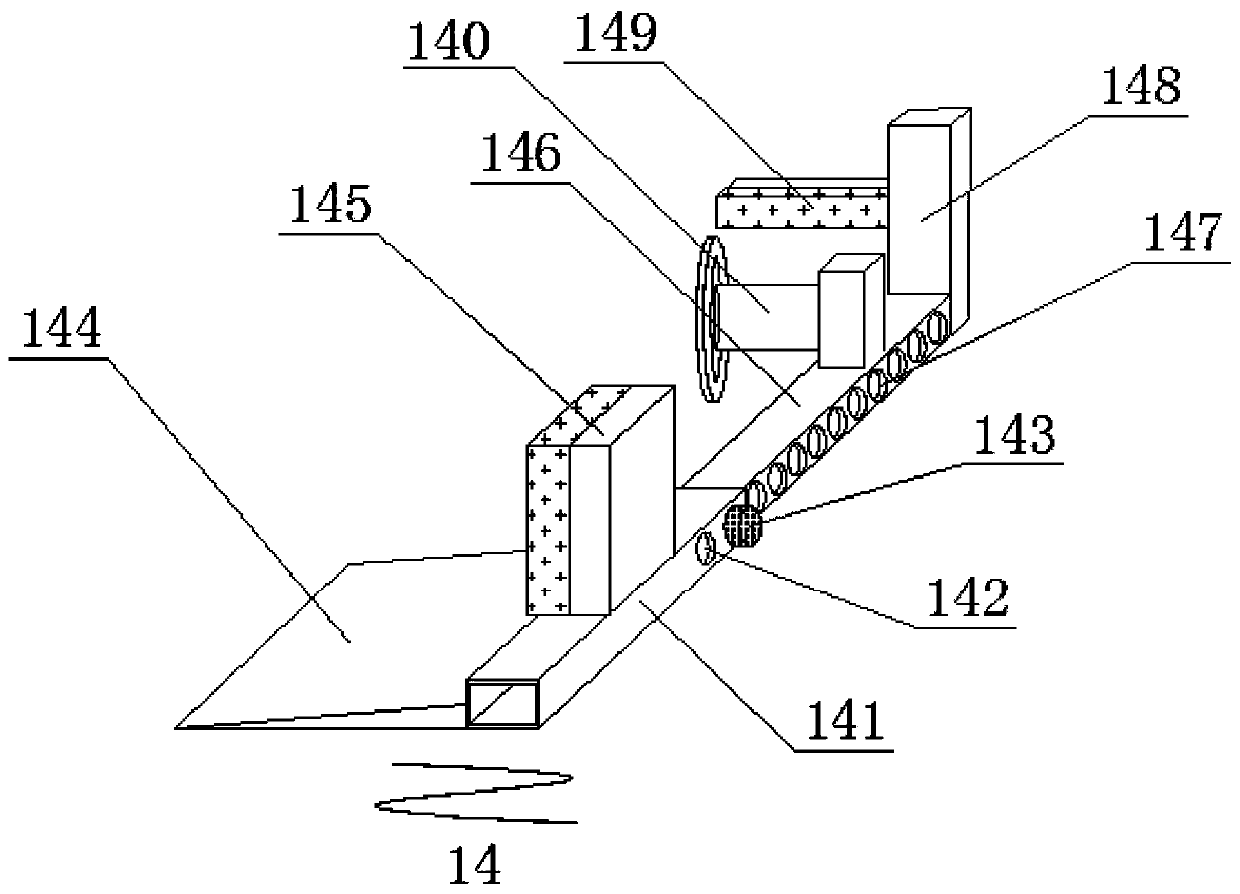

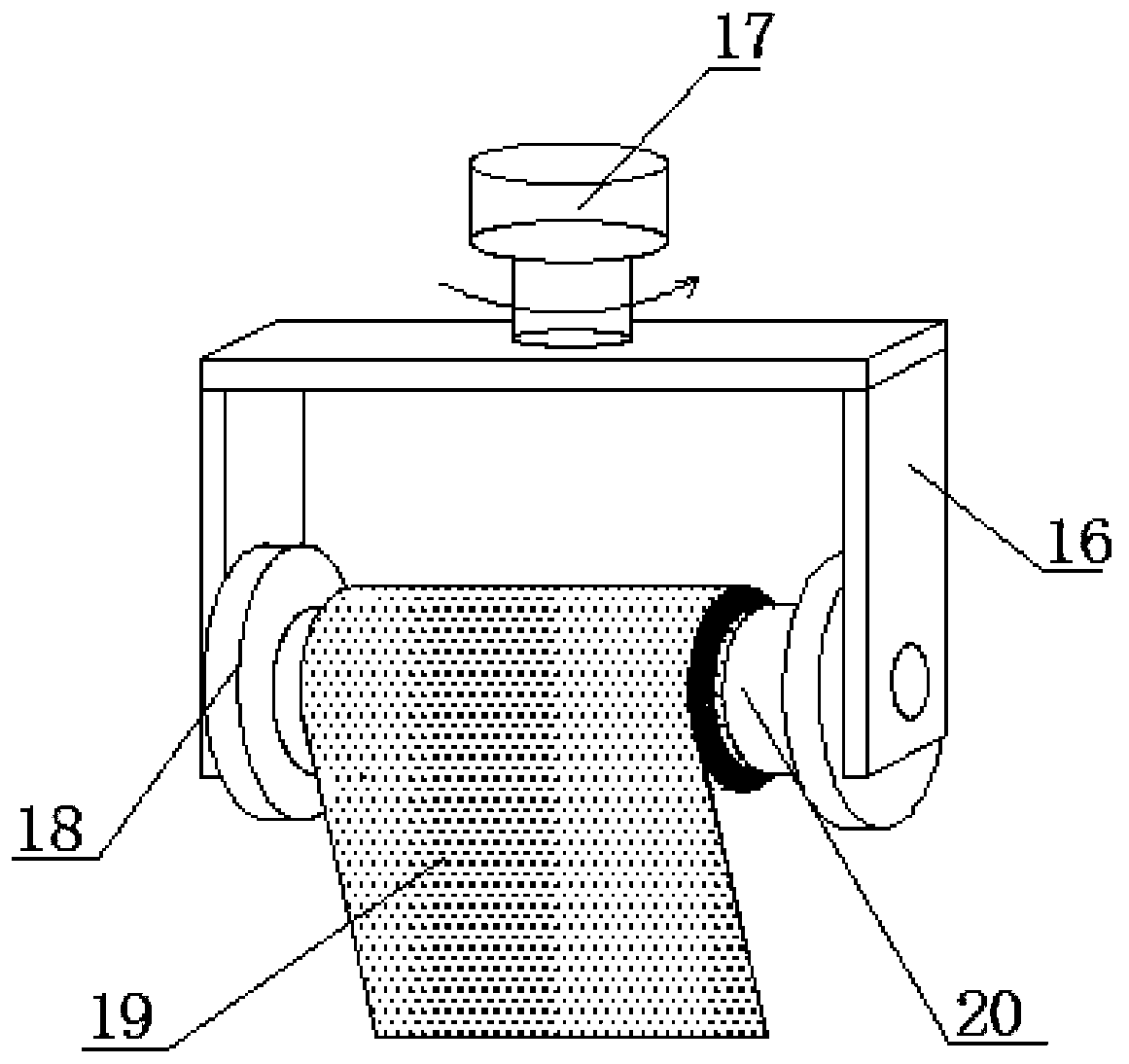

[0021] see Figure 1~3 , in an embodiment of the present invention, an auxiliary positioning device for product packaging, comprising a lower workbench 1, an upper workbench 11, a lifting workbench 22, a film covering assembly, a clamping mechanism, and a packaging box supply assembly, wherein the lower floor The top of the workbench is provided with the upper workbench 11, which is characterized in that the front side of the lower workbench 1 is provided with a lower work notch 24, and the upper workbench 11 is correspondingly provided with an upper work notch 21 , the lifting table can be lifted and positioned at the lower working slot and the upper working slot 21, and the upper working table is also provided with clamping and locating objects located on both sides of the upper working slot. The clamping mechanism, the above the upper workbench is provided with the film coating assembly, the rear side of the lower workbench is provided with a packaging box supply assembly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com