Order grouping processing method for personalized customized furniture

A processing method and order technology, applied in data processing applications, instruments, calculations, etc., can solve the problems of asynchronous production cycle of customized furniture parts, inefficiency of processing and production process, slowing down of production rhythm by parts b, etc., to achieve overall The effect of reasonable and efficient planning, high overall production efficiency and shortened processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

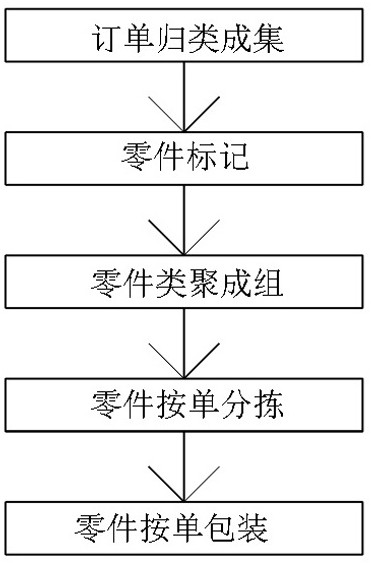

[0035] Example: as attached figure 1 As shown, an order grouping processing method for personalized customized furniture includes the following steps in sequence:

[0036] S1. Classify orders into sets: Divide all orders into 1 set, 2 sets, 3 sets, and finally M sets according to the types of furniture materials, to ensure that the main materials of all orders in a single set are the same, and then divide the All orders of the order are numbered and marked as 1, 2, 3 until N, so that the order numbered a-b is unique, where 1≤a≤M, 1≤b≤N;

[0037] S2. Part marking: mark all parts in the order a-b as a-b-1 to a-b-p, where p is an integer ≥ 1;

[0038] S3. Grouping of parts: group all parts of all orders according to any one or more reference indicators of the same process, same size, size matching, average area or average number of parts, so as to improve the internal production of each group Efficiency, balance the production speed between groups;

[0039] S4. Parts sorting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com