RFID (radio frequency identification device) label manufacturing equipment

A technology for RFID tags and manufacturing equipment, which is applied in the field of RFID tag manufacturing equipment, can solve problems such as difficult to guarantee the quality of sticking, low production efficiency, and high labor intensity, and achieve good practical value, fast production speed, and good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail, so that those skilled in the art understand:

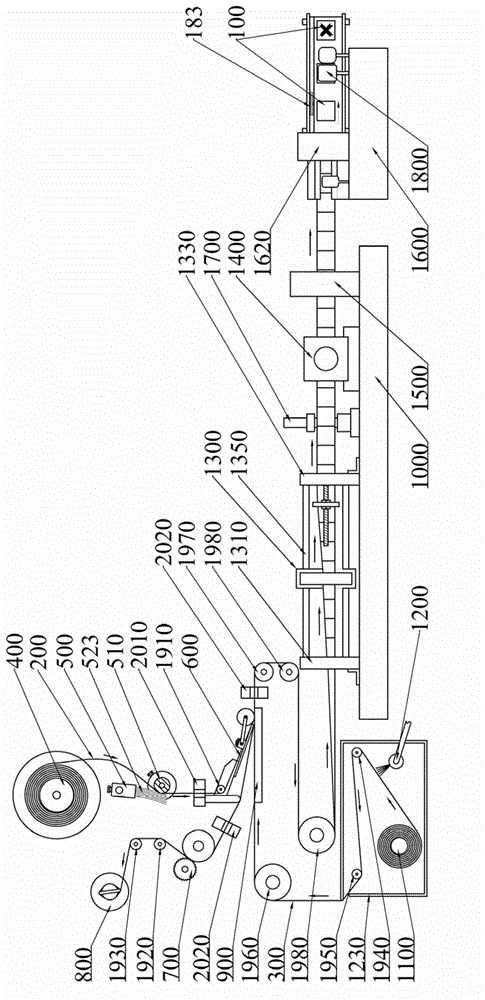

[0032] Such as Figure 1-11 As shown, the labels represent:

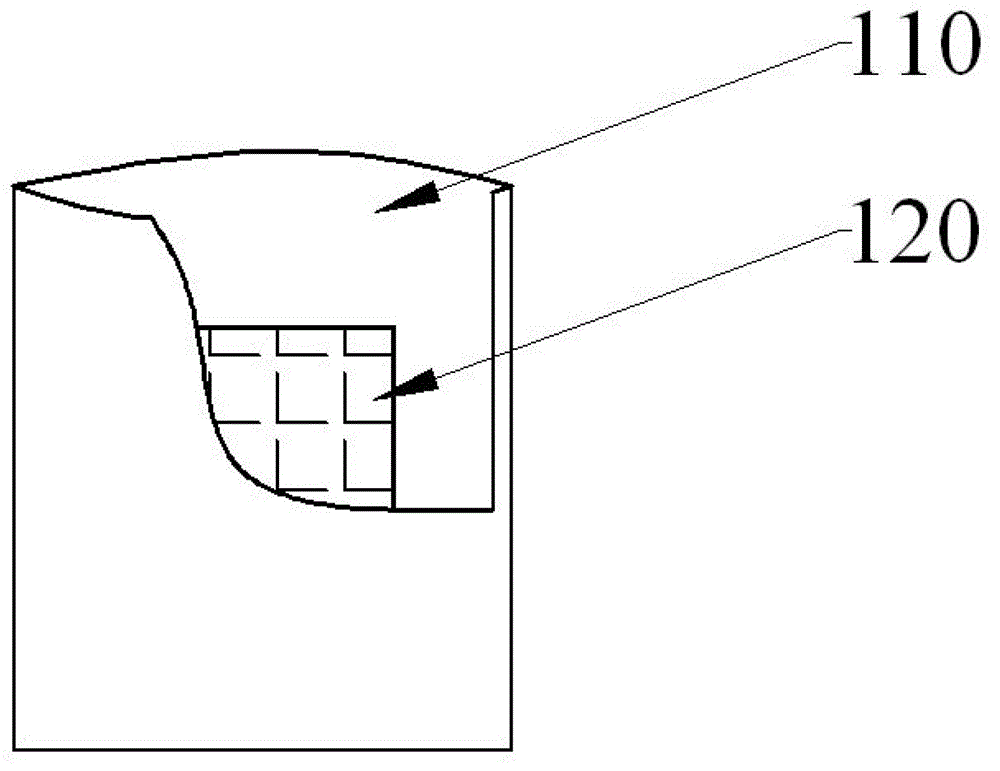

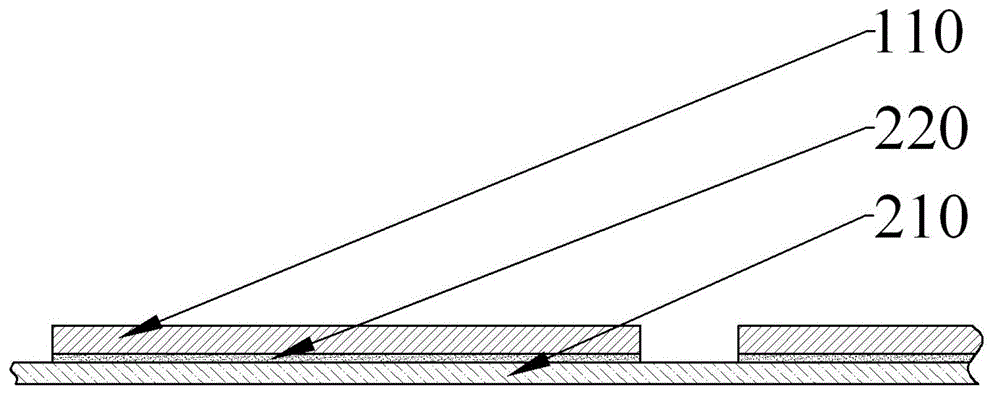

[0033] RFID label 100, RFID chip 110, label bag 120, self-adhesive label paper tape 200, release paper tape 210, self-adhesive layer 220, cloth tape 300,

[0034] Labeling system: tape unwinding wheel 400, tensioning device 500, passive roller 510, ring 511, set screw 512, pressing mechanism 520, shaft 521, rotating member 522, brush 523, set screw 524, composite Mechanism 600, peeling plate 610, labeling roller 620, support 621, connecting rod 622, spring 623, embossing device 700, embossing roller 701, pressure roller 702, paper tape winding wheel 800, flange 810, base plate 900 ;

[0035] Label bag forming system: frame 1000, tape unwinding wheel 1100, static electricity removal mechanism 1200, spray pipe 1210, water inlet pipe 1220, water retaining cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com