Method for fast indentifying linear defect of automobile panel

A linear defect, automotive technology, applied in the field of automotive panel quality inspection, can solve problems such as inability to identify linear defects, inability to capture characteristic signals, and disordered detection signals, achieving significant economic and social benefits, and promising application prospects. Extremely popular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] A method for quickly identifying linear defects in automotive panels, comprising the following steps:

[0038] 1) Sample treatment: Use silicon carbide sandpaper to polish the defective part of the defective sample, remove the surface zinc layer, and expose the iron base;

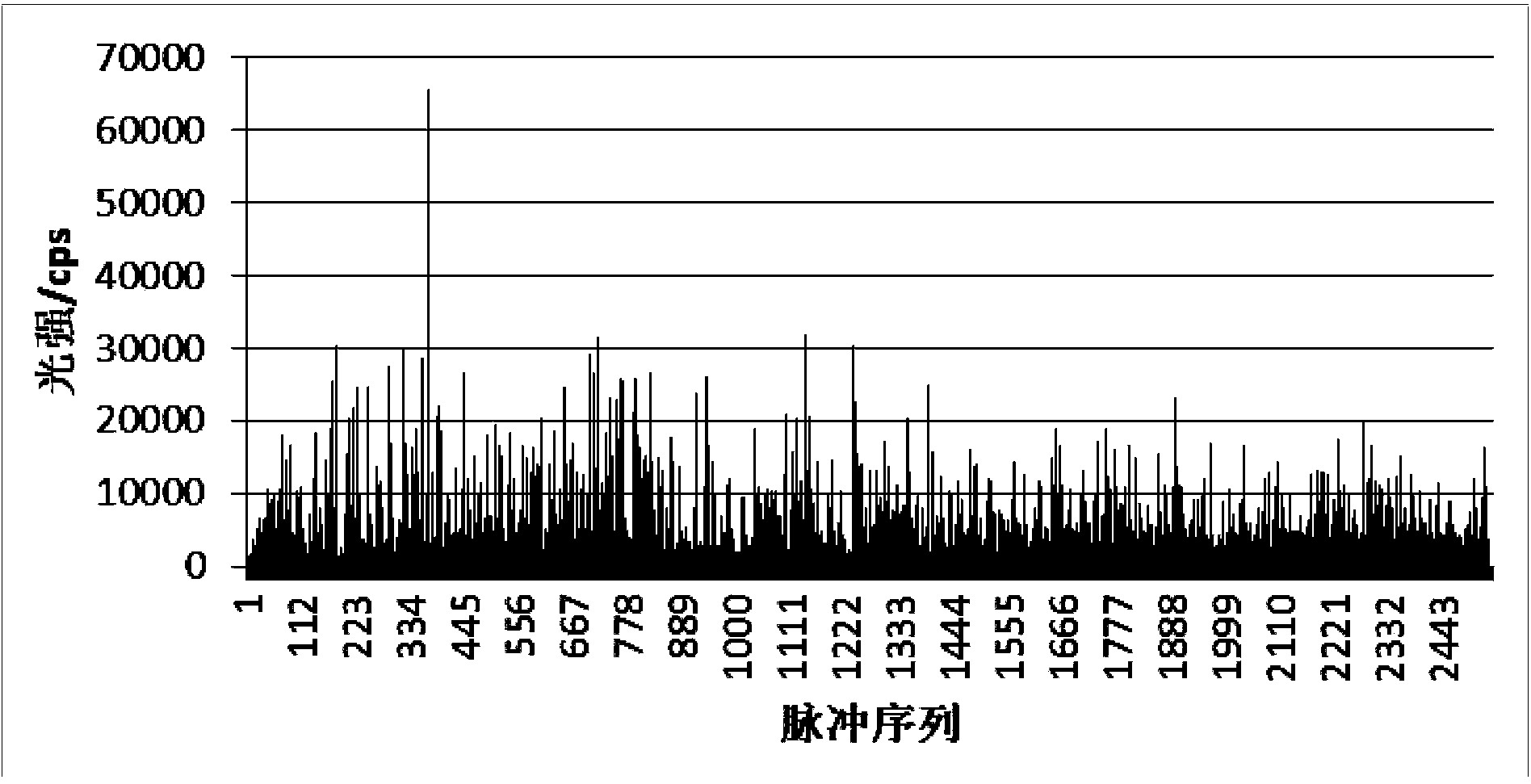

[0039] 2) Sample analysis: Analyze the sample on a spark spectrometer with single spark detection function, the analysis conditions are analysis gap 3mm, argon flushing time 3s, pre-discharge times 400 times, measurement 2000 times, spark pulse peak current 200A, normal area Stimulate 3 times, and stimulate at least 1 time for the defect in the abnormal area, and export the data after the analysis is completed;

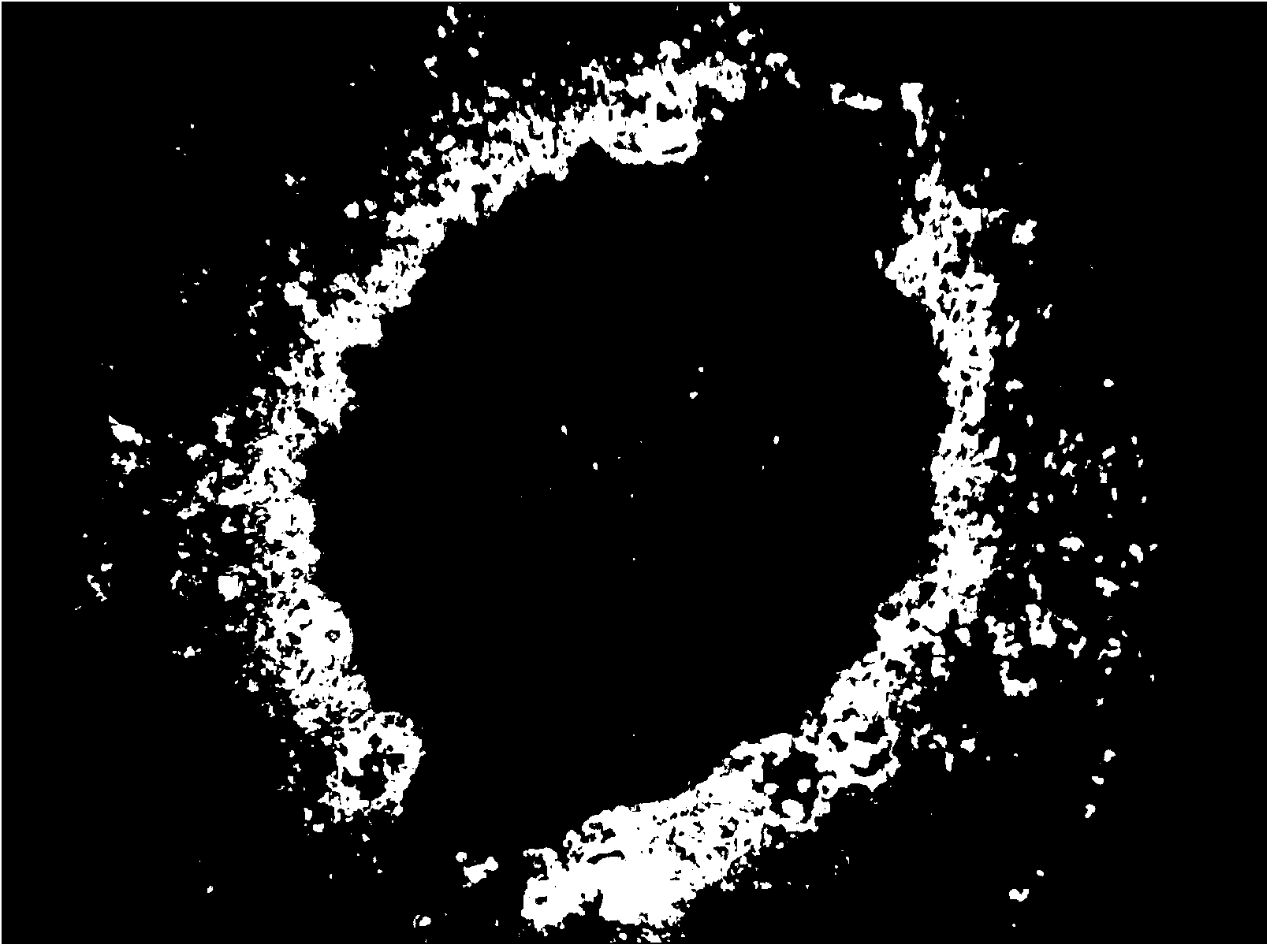

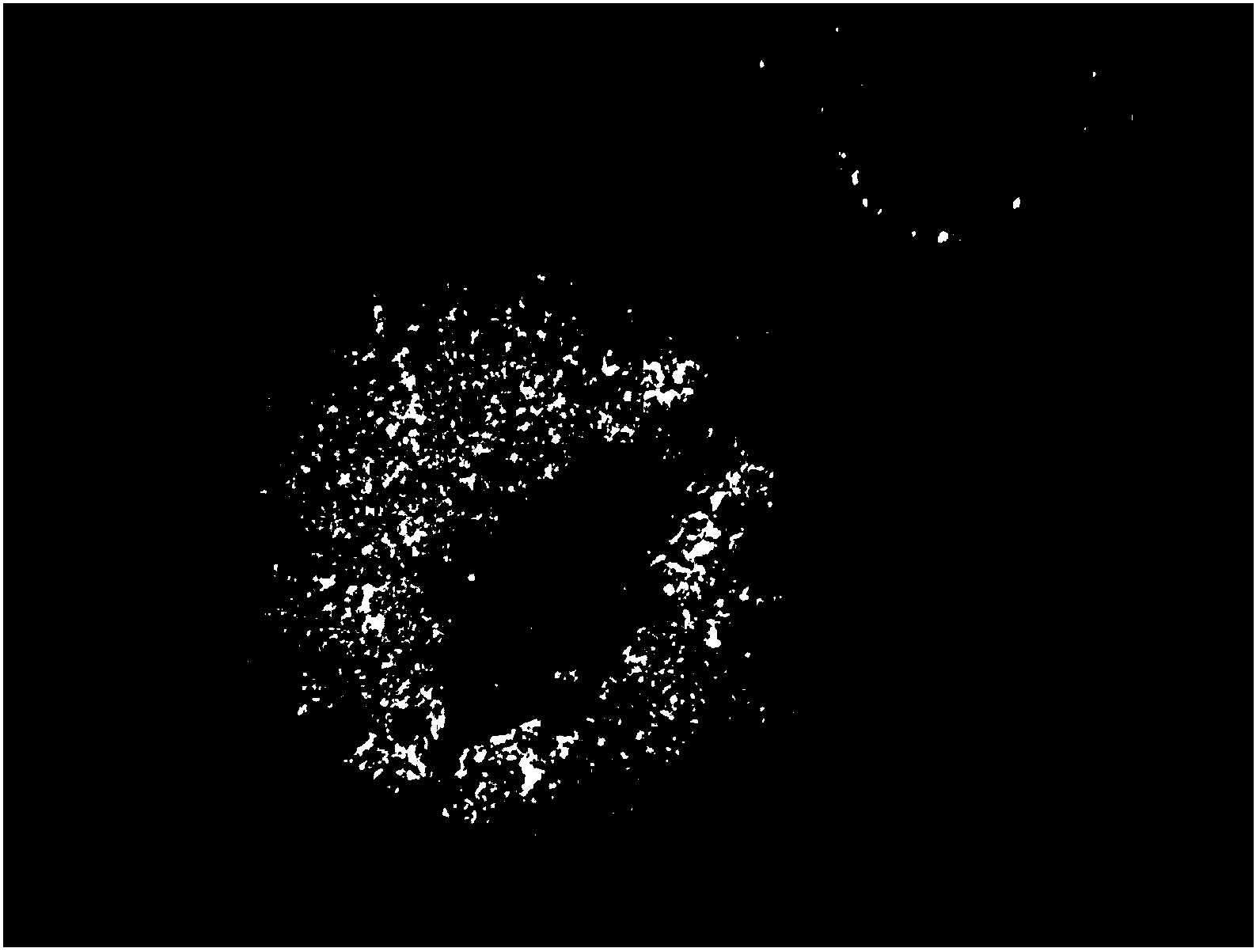

[0040] A stable discharge can be formed under the analysis conditions of the present invention, such as figure 2 As shown, the bright discharge area around the molten residue shows no difference in the appearance of the discharge from the defect-free area, and the phenomenon of iron-based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com