Method for producing powder blood fat

A production method and blood lipid technology, applied in the field of additive manufacturing, can solve problems such as uneven product quality, increased drying, etc., and achieve the effects of high energy, solving oil backlog, and promoting growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

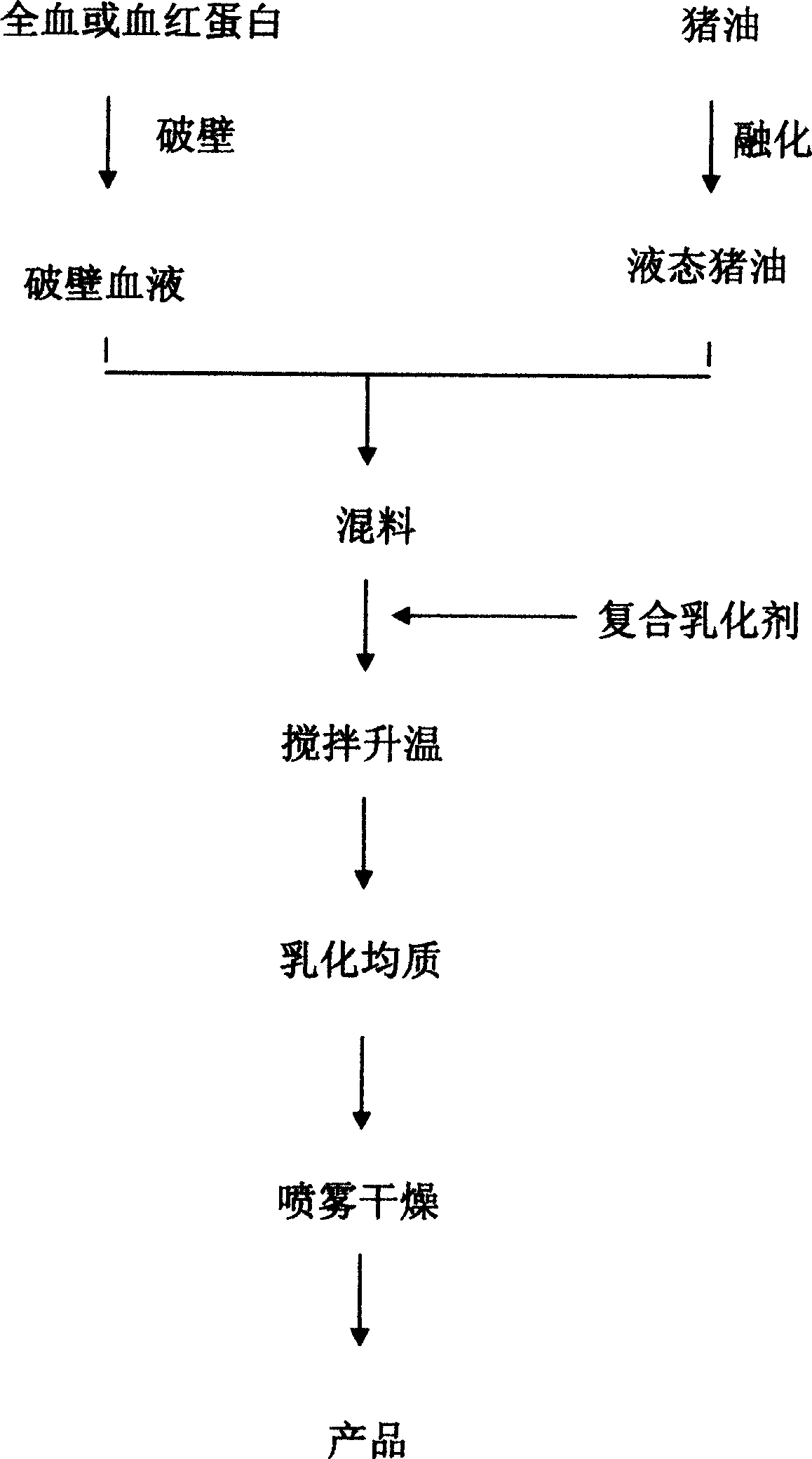

Image

Examples

Embodiment 1

[0028] Healthy pig blood was collected, and 0.35% trisodium citrate was added as an anticoagulant. Add 25% oil on dry matter and stir. Heat to 60°C, add a compound emulsifier (HLB value is 7.5) with an oil content of 2.6%, add a wall material of 12%, and keep warm for 10 minutes. Then homogeneously emulsify under 20Mpa, and then dry with a spray dryer, the inlet temperature is 180°C, and the outlet temperature is 70°C to obtain brown whole blood-powder blood lipid.

Embodiment 2

[0030] Broken whole blood-powder blood lipid was prepared by the method described in Example 1, the difference was that deionized water was added to break the wall according to the volume of whole blood at 1:1, and 15% oil of dry matter was added, and stirred. Heat to 56°C, add a compound emulsifier (HLB value is 6.5) with 2% oil content, add 9% wall material, and keep warm for 10 minutes. Then homogeneously emulsify under 20Mpa, and then dry with a spray dryer, the inlet temperature is 200°C, and the outlet temperature is 60°C to obtain brown whole blood-powder blood lipid.

Embodiment 3

[0032] Healthy anticoagulated pig whole blood was collected, separated by 10,000g centrifugal force, the hemoglobin in the lower layer was removed, mixed with 15% oil, and stirred. Heat to 56°C, add 2% emulsifier (HLB value is 9.5) of oil, add 9% wall material, and keep warm for 10 minutes. Then homogeneously emulsify at 20Mpa, and then dry with a spray dryer, the inlet temperature is 210°C, and the outlet temperature is 65°C to obtain brown-red hemoglobin-powder blood lipid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com