Automatic weighing and packaging system for hot melt colloidal particles

A technology of automatic weighing and packaging system, applied in the directions of packaging, transportation and packaging, the type of packaging items, etc., can solve problems such as heavy workload and adverse human health, and achieve the effect of convenient maintenance and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

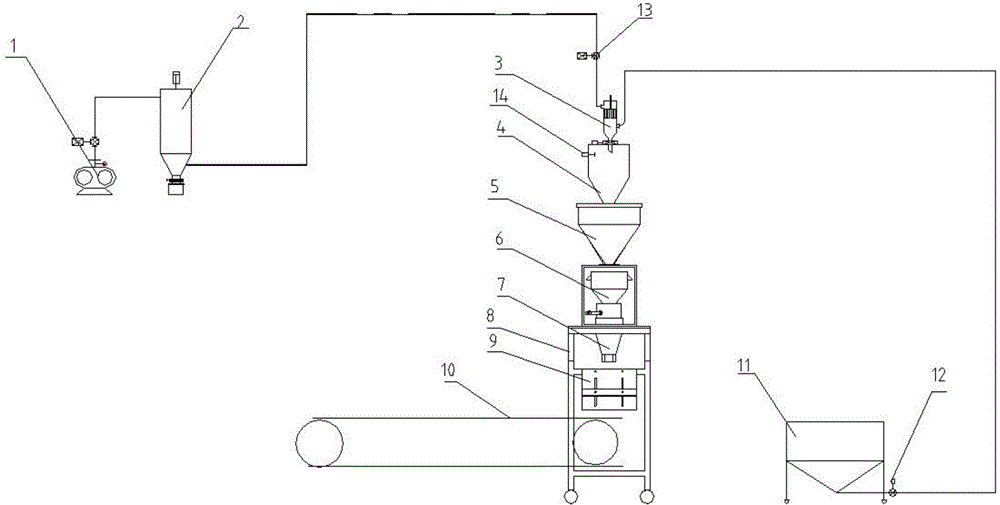

[0012] Its structure is shown in the figure: an automatic weighing and packaging system for hot-melt rubber particles, including a rubber particle conveying unit 1, which is connected to a filter 2 through a rubber particle conveying pipeline, and the filter 2 is connected to a vacuum through a pipeline The feeder 3, the other side of the vacuum feeder 3 is connected to the transition bin 11, the lower part of the vacuum feeder 3 is connected to the vacuum hopper 4, the lower part of the vacuum hopper 4 is connected to the metering bin 5, and the lower part of the metering bin 5 is connected to the weighing module 6 , the lower part of the weighing module 6 is connected to the sealing bag structure 7, the lower part of the sealing bag structure 7 is provided with a rotary bag dividing device 9, and the lower part of the rotating bag dividing device 9 is provided with a conveyor belt 10, the above-mentioned metering bin 5, weighing module 6, bag sealing structure 7. The rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com