Refrigerant circulatory system with undercooling function

A technology of refrigerant circulation system and cooling flow, which is applied in subcoolers, fluid circulation arrangements, refrigerators, etc., and can solve problems such as unstable gaps, heat absorption and gasification of cooling media, instability and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

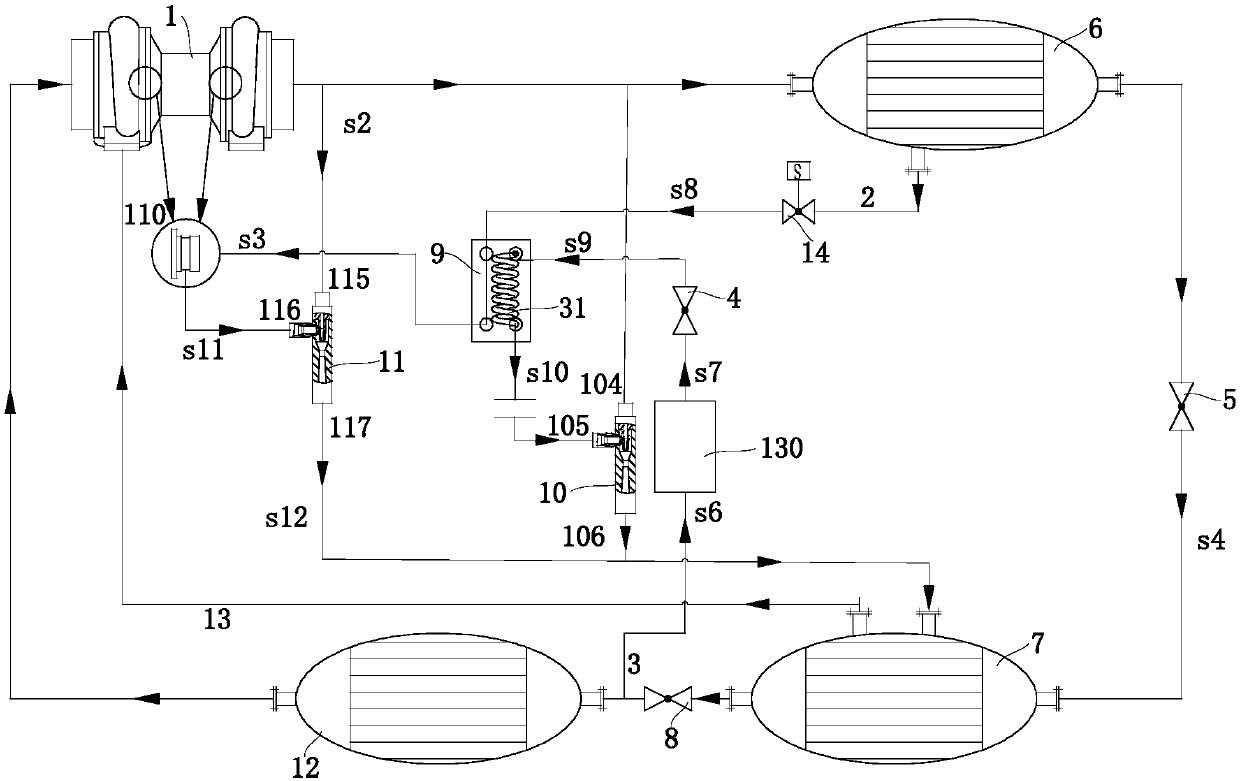

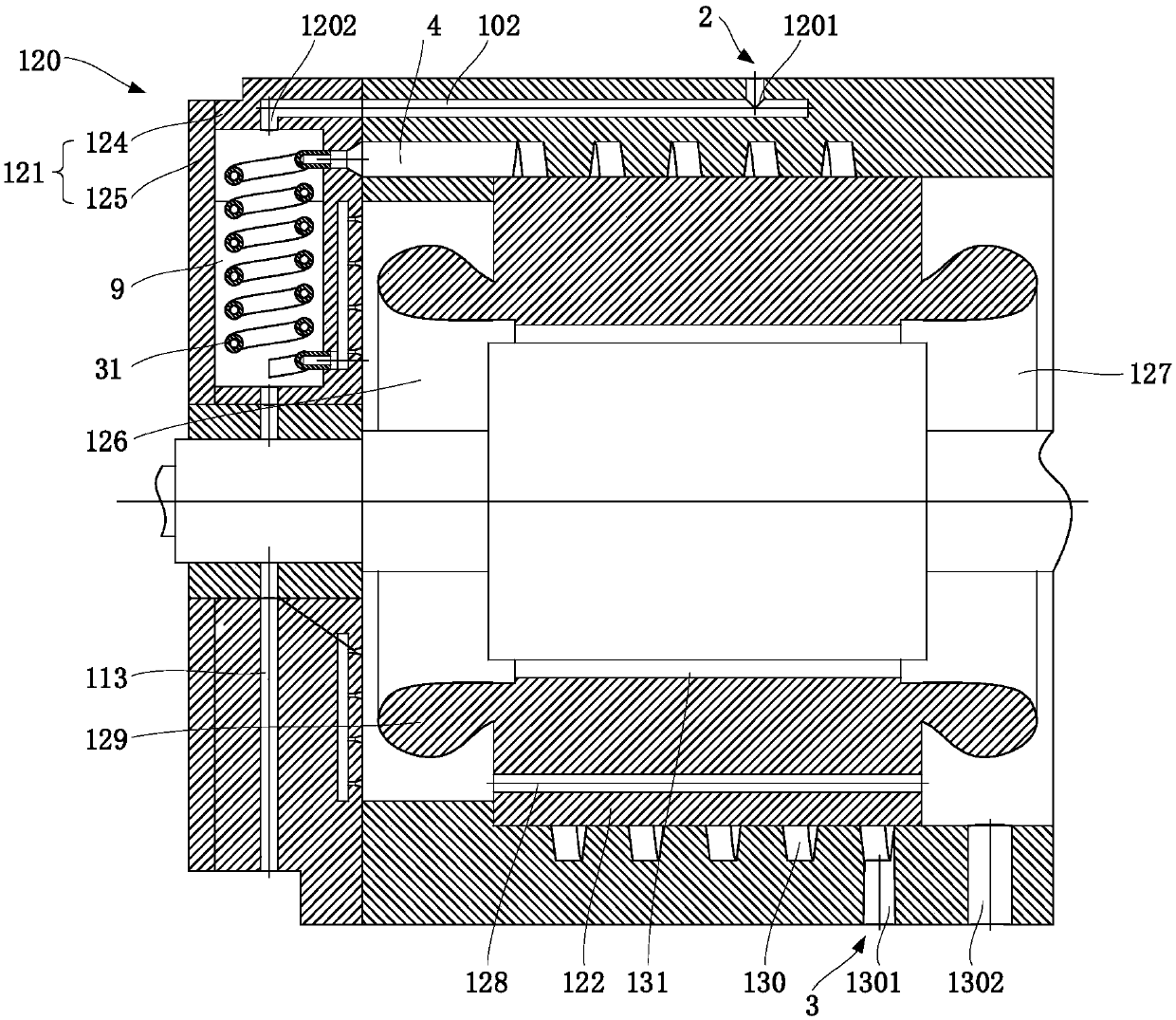

[0038] Combine below Figure 1 ~ Figure 2 The technical solution provided by the present invention is described in more detail.

[0039] see figure 1 and figure 2 , the present invention provides a refrigerant circulation system, including a compressor 1 , a drainage branch 2 and a cooling branch 3 . The compressor 1 includes a bearing 110 and a motor 120 . The drainage branch 2 is configured to cool the bearing 110 ; the cooling branch 3 exchanges heat with the drainage branch 2 for cooling the refrigerant in the drainage branch 2 ; the cooling branch 3 is also configured to cool the motor 120 .

[0040] The refrigerant used to cool the bearing 110 is, for example, a liquid refrigerant, which has a good cooling effect.

[0041] In some embodiments, the cooling branch 3 is configured to firstly cool the motor stator 122 and / or the motor rotor 123 of the motor 120 , and then cool the drain branch 2 . For example, the motor stator 122 is cooled first, and then the drainage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com