Shell and Tube Condenser and Air Conditioning System

A condenser and shell-and-tube technology, which is used in the field of shell-and-tube condensers and air conditioning systems, can solve the problems of liquid in the suction of the compressor, rising unit cost, and malfunction of the expansion valve, so as to increase the degree of turbulence, improve the replacement Thermal efficiency, thickness reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

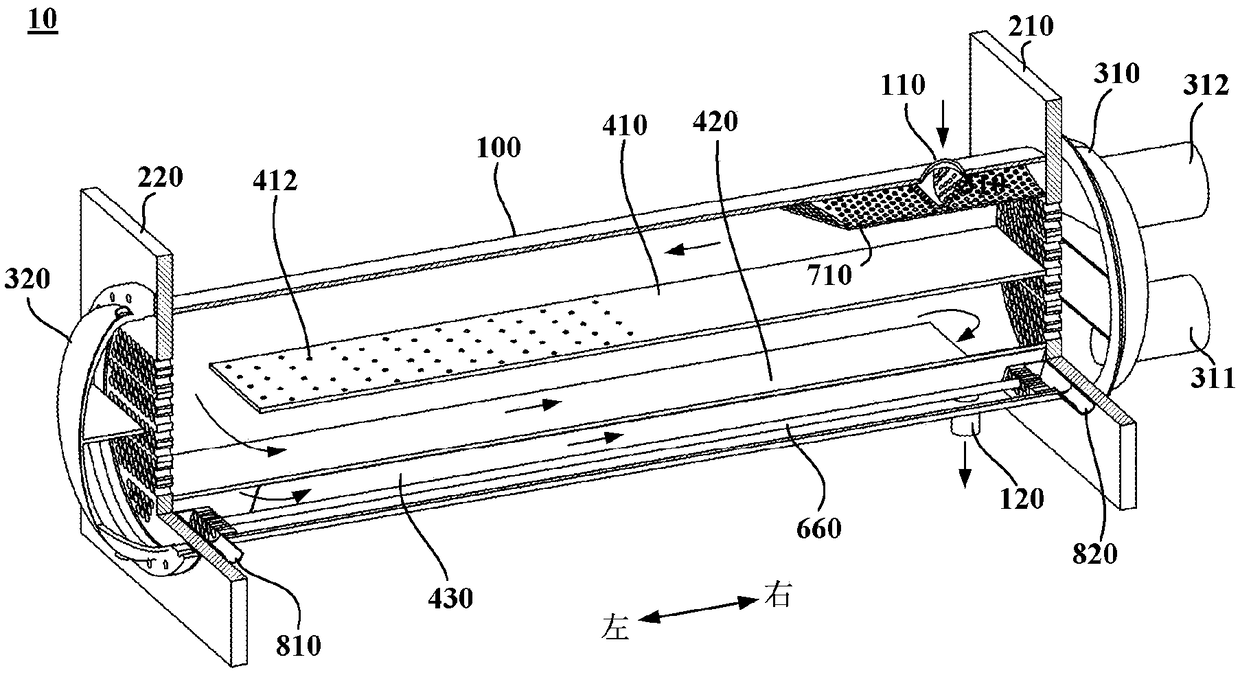

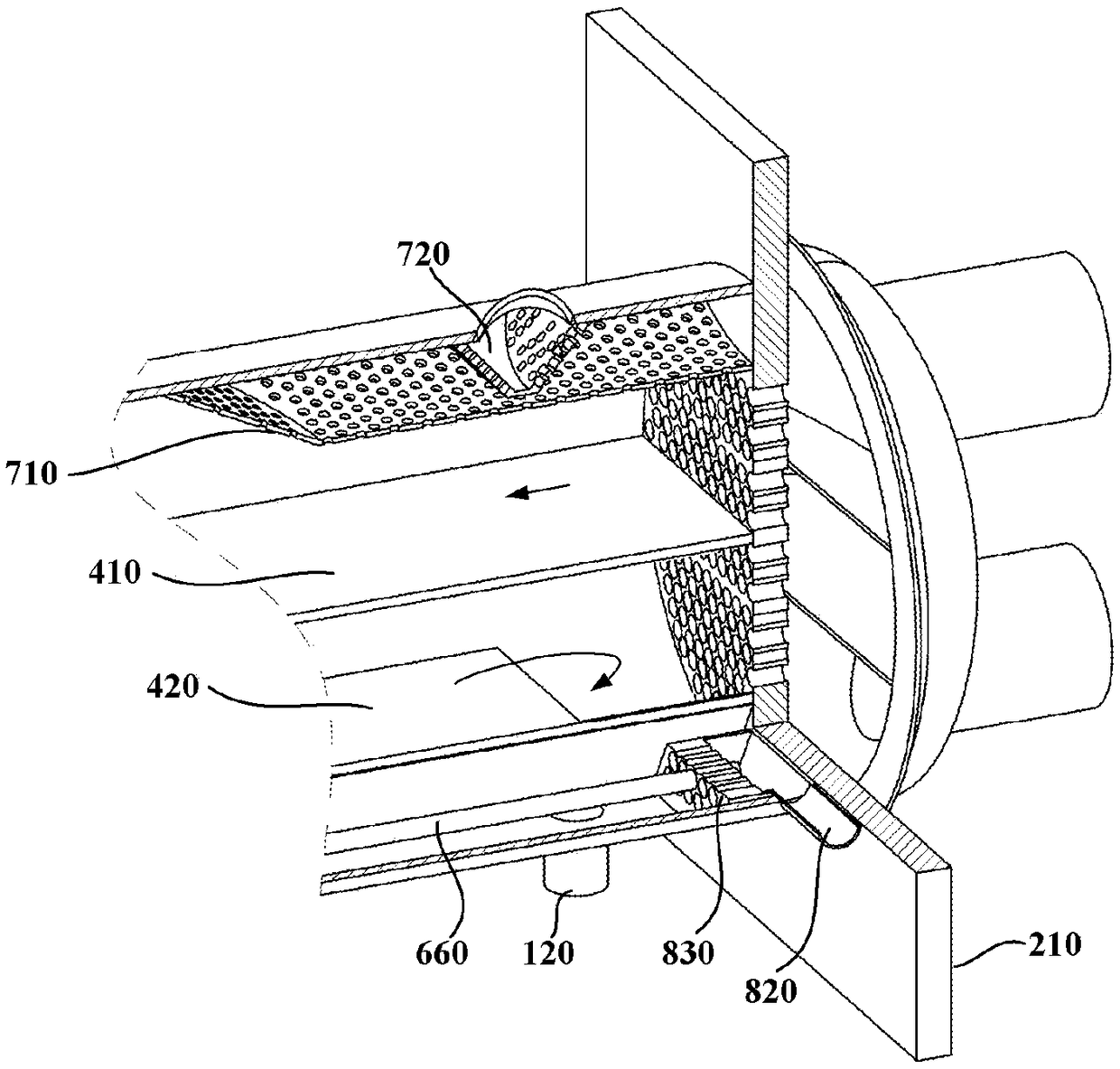

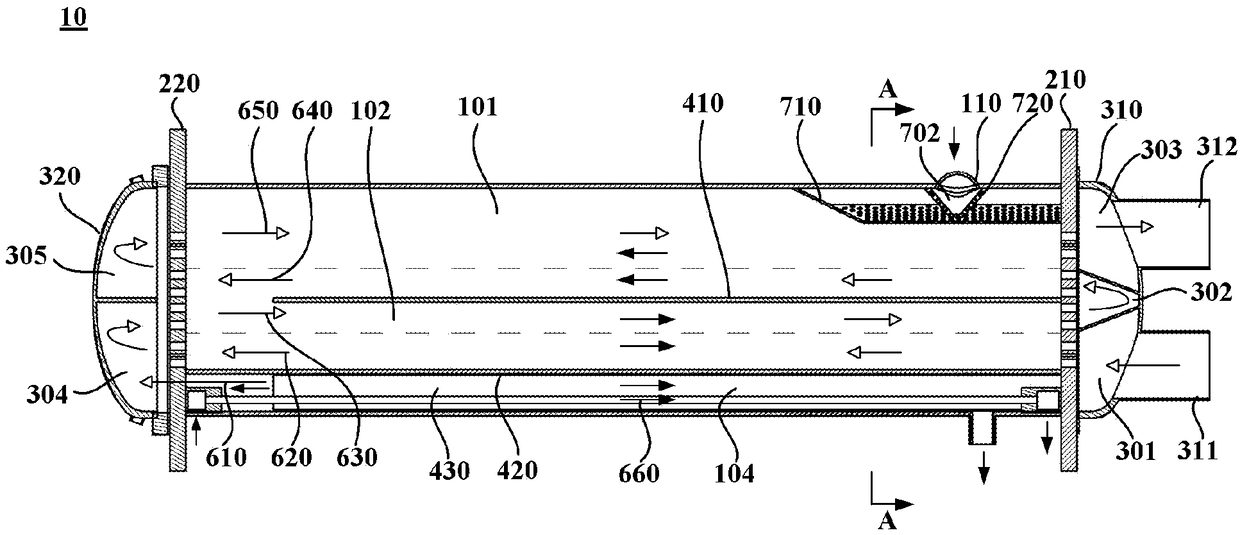

[0031] figure 1 It is a schematic three-dimensional sectional view of a shell-and-tube condenser according to an embodiment of the present invention; figure 2 yes figure 1 A partial enlarged view of the right structure of the shell-and-tube condenser; image 3 It is a plane sectional view of a shell-and-tube condenser according to an embodiment of the present invention; Figure 4 yes image 3 A-A sectional view of the shell-and-tube condenser shown. Such as figure 1 with figure 2 As shown, the embodiment of the present invention provides a shell and tube condenser, which is used in a vapor compression refrigeration cycle system. The shell-and-tube condenser 10 may generally include a shell 100 , a first tube sheet 210 and a second tube sheet 220 , a first tube box 310 and a second tube box 320 , and a heat exchange tube bundle. Wherein, the casing 100 is provided with a condensate inlet 110 for communicating with the exhaust port of the compressor, and a condensate ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com