Trans-critical carbon dioxide combined cooling, heating and power comfort system based on double four-way reversing valves

A four-way reversing valve and comfort system technology, applied in the field of transcritical CO2 triple supply comfort system and its control, can solve the problems of increased energy consumption, inability to meet the requirements at the same time, affecting system efficiency, etc., to reduce the number and volume, improve Equipment utilization and the effect of improving system energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

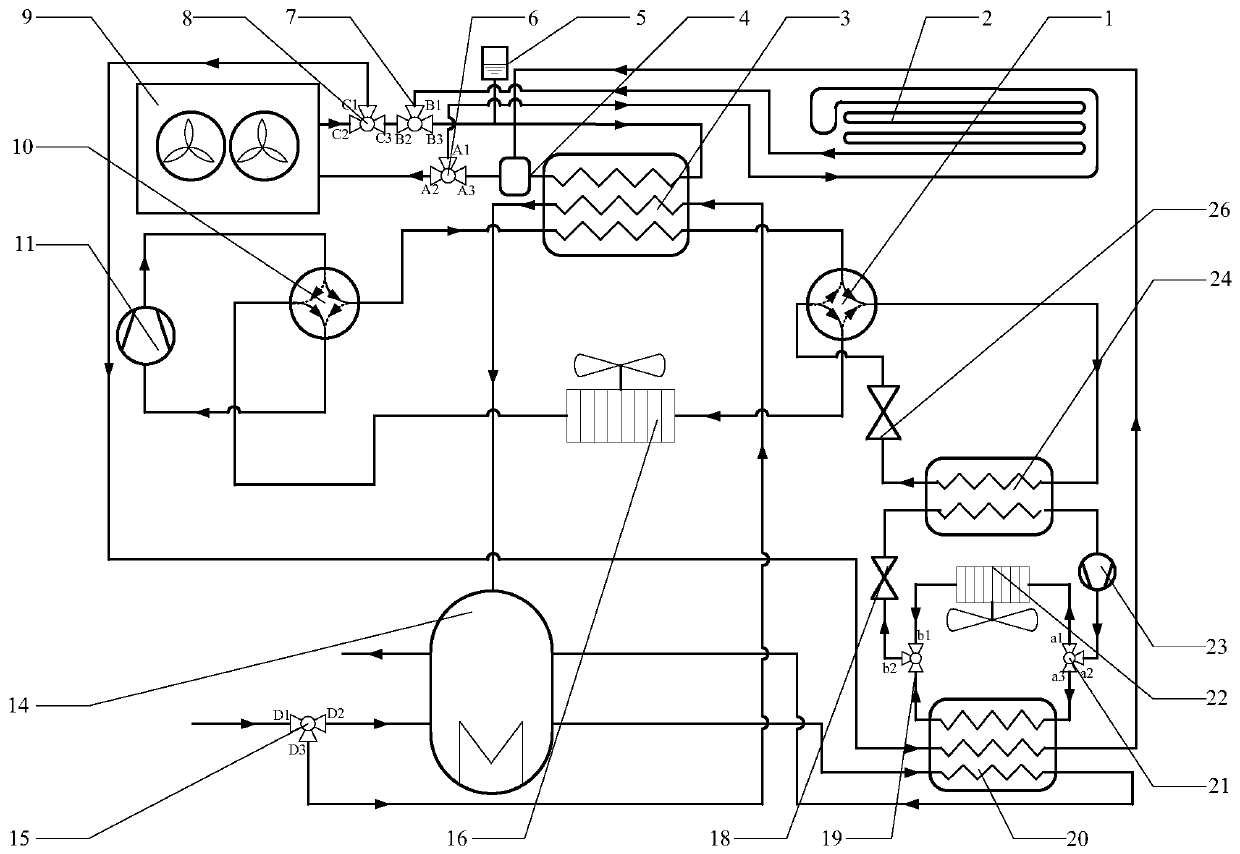

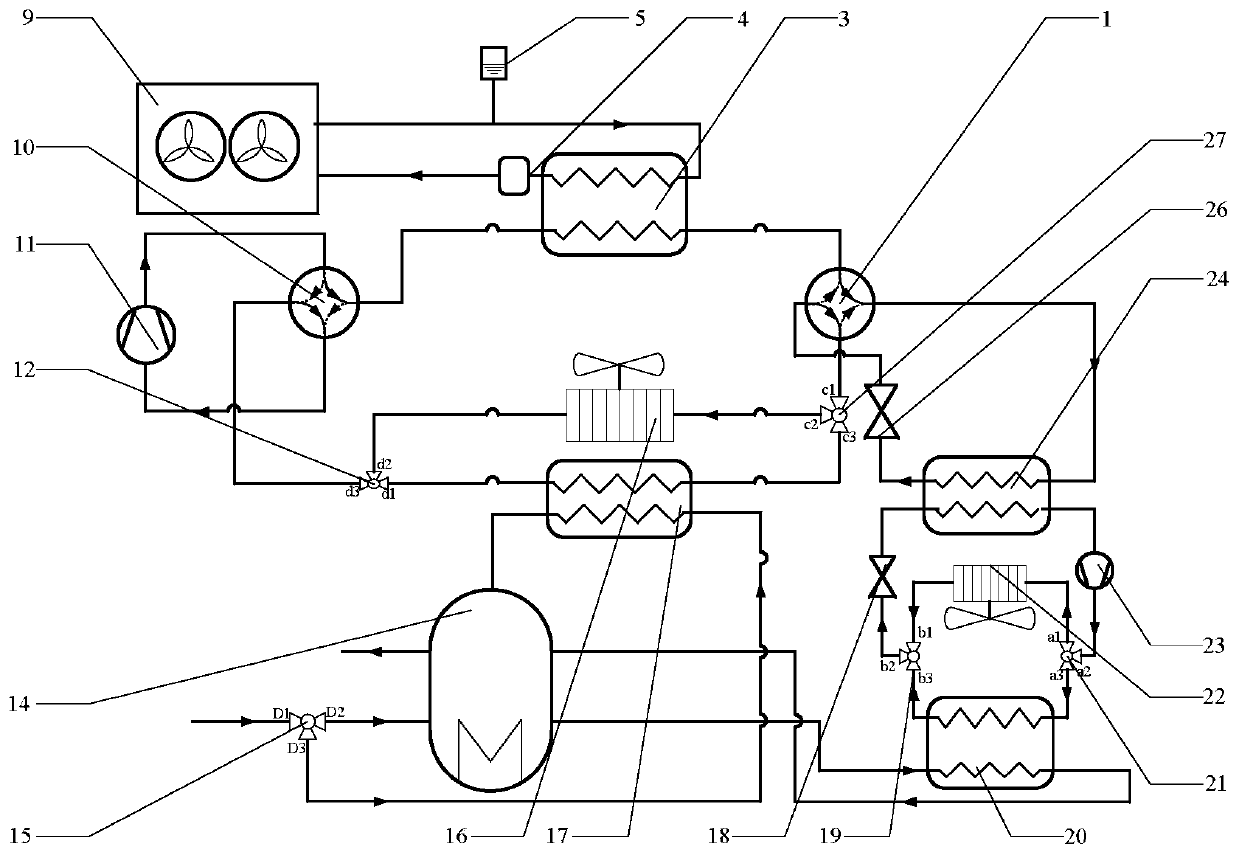

[0039] Step 1: Compressor 2 23 sucks low-temperature and low-pressure non-azeotropic refrigerant gas at the outlet of cooling evaporator 24, compresses it into high-temperature and high-pressure gas, and flows into condenser 20 through ports a2-a3 of three-way reversing valve a21 , heat exchange with water in the condenser 20 to achieve condensation, and then flow into the throttle valve-18 through the b3-b2 port of the three-way reversing valve b19 to throttle and reduce pressure, and become a gas-liquid two-phase state, and then evaporate through cooling After the device 24 evaporates and absorbs heat, it becomes superheated gas and enters the second compressor 23 to complete the auxiliary cycle.

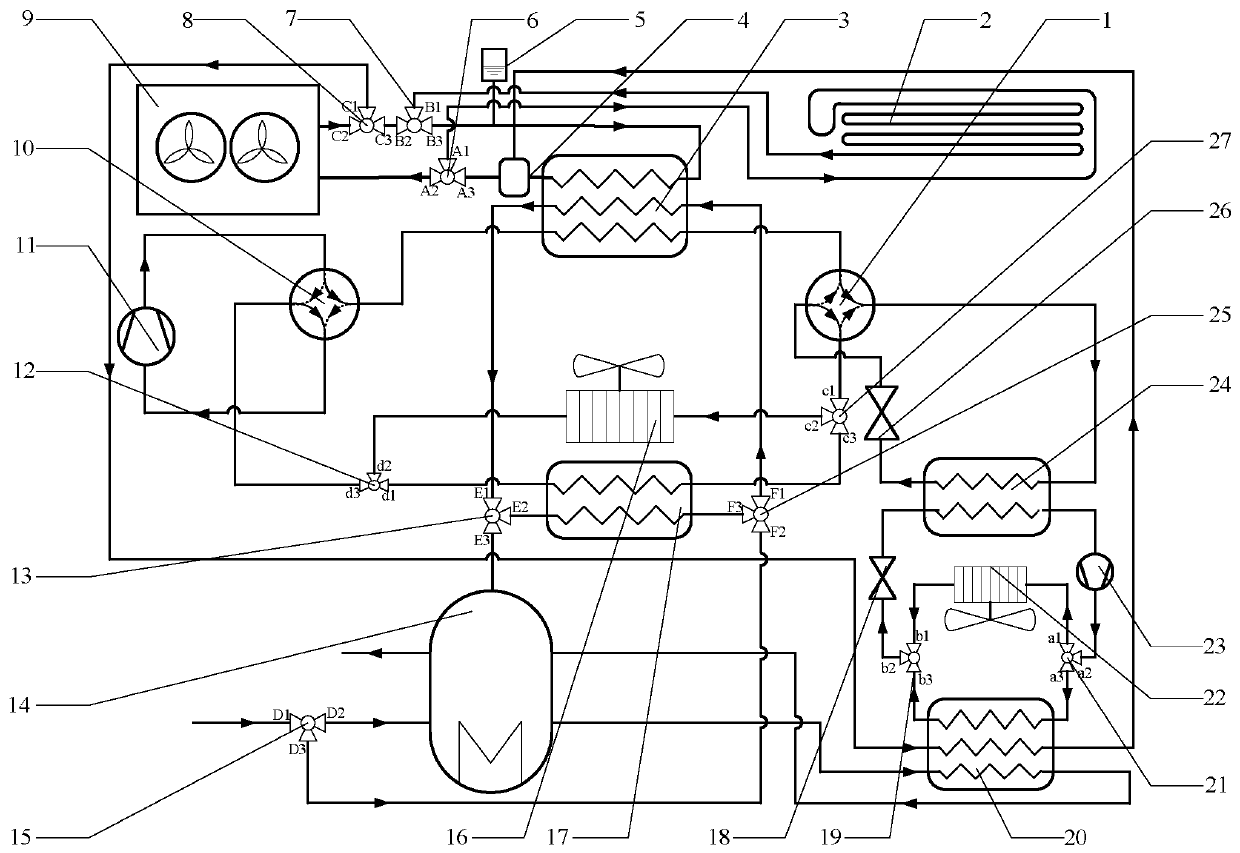

[0040] Step 2: Compressor-11 sucks the low-temperature and low-pressure CO at the outlet of finned tube finned tube heat exchanger-16 2 The gas is compressed into a high-temperature and high-pressure supercritical gas, flows through the pipeline shown by the solid line in the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com