Prediction method of leakage rate of contact mechanical seal

A technology of mechanical seals and predictive methods, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as changes, leakage, backlog of spare parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

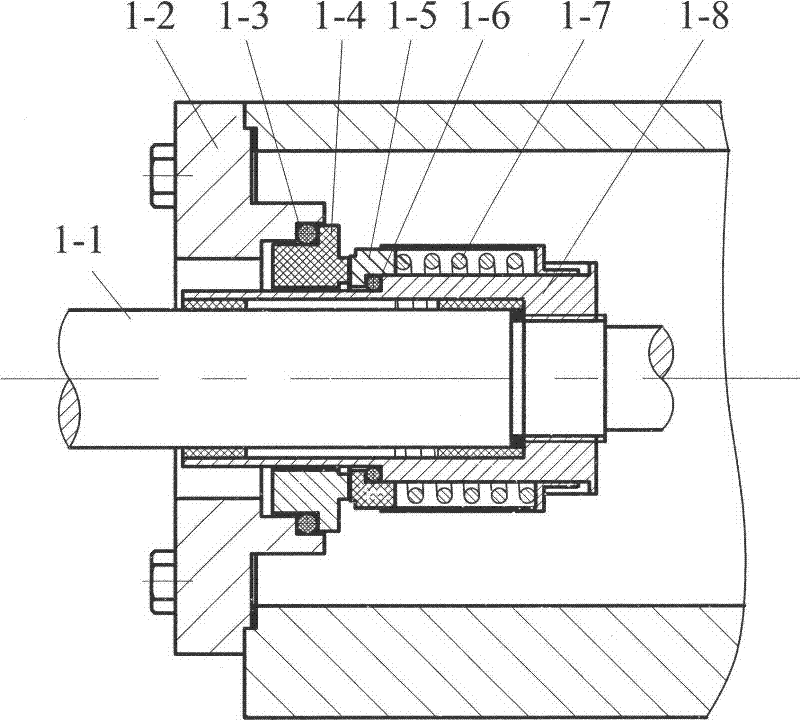

[0089] In order to further understand the content, characteristics and effects of the present invention, the following examples are cited hereby, and in conjunction with the attached Figure 14 The details are as follows:

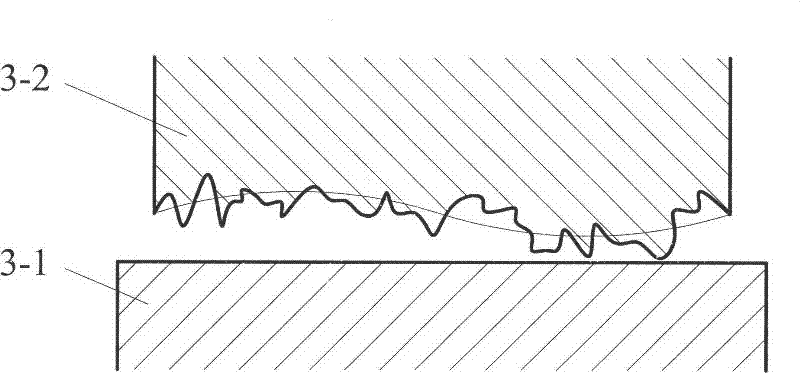

[0090] From the perspective of the contact mechanical seal structure, predicting the leakage rate of the contact mechanical seal needs to know the leakage rate of the main seal (between the end faces of the dynamic and static rings) and the leakage rate of the secondary seal (the O-ring of the dynamic ring and the contact surface, the O-ring of the static ring and the contact surface). between surfaces) leakage rate.

[0091] Through the experiment, the wear amount of the main seal interface of the dynamic and static rings of the mechanical seal, the law of the fractal parameters of the surface morphology changing with time, and the law of the elastic modulus of the O-rings for the moving and static rings changing with time.

[0092] (1) Leakage rate of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com