Patents

Literature

39results about How to "Overcoming adhesions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

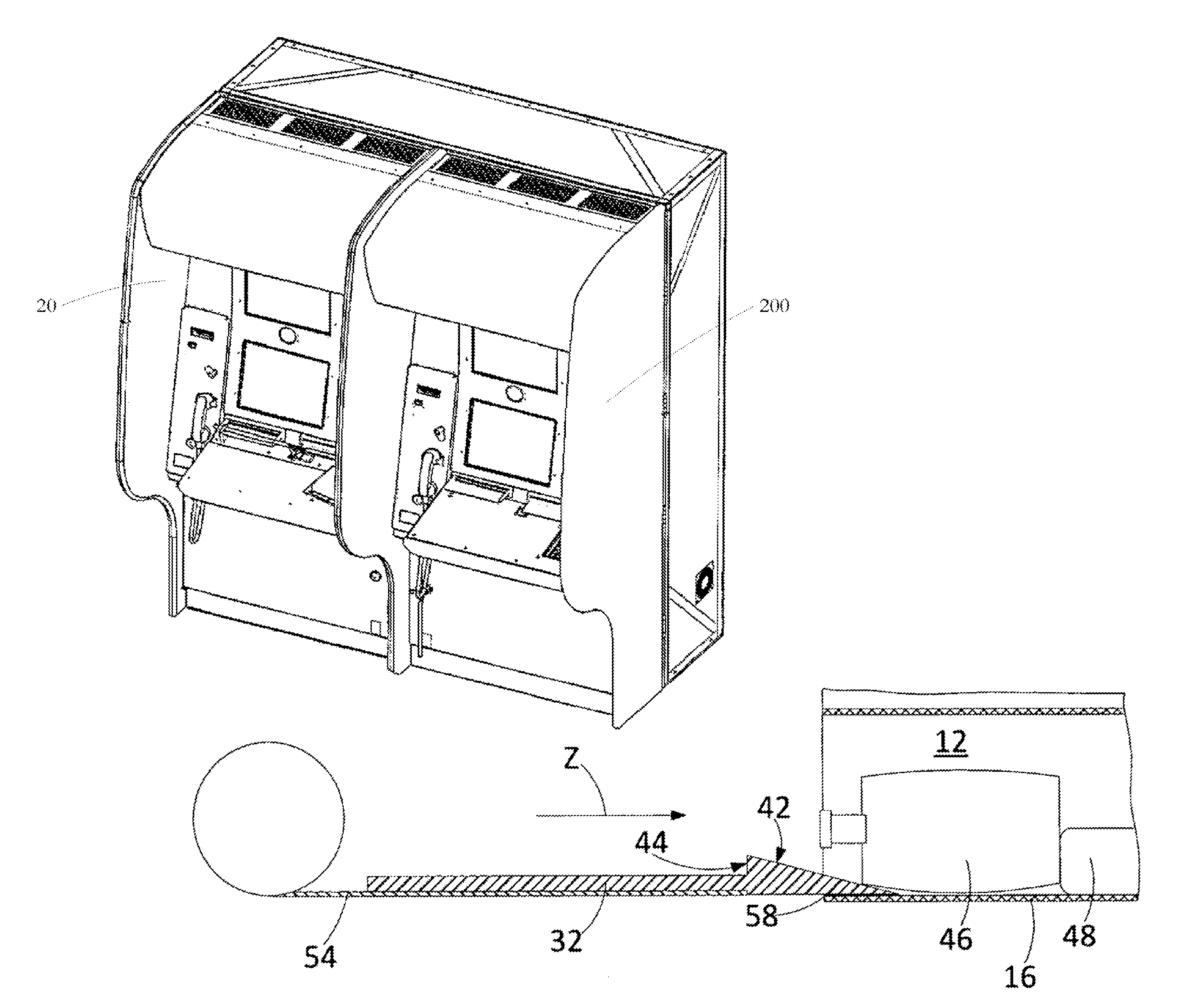

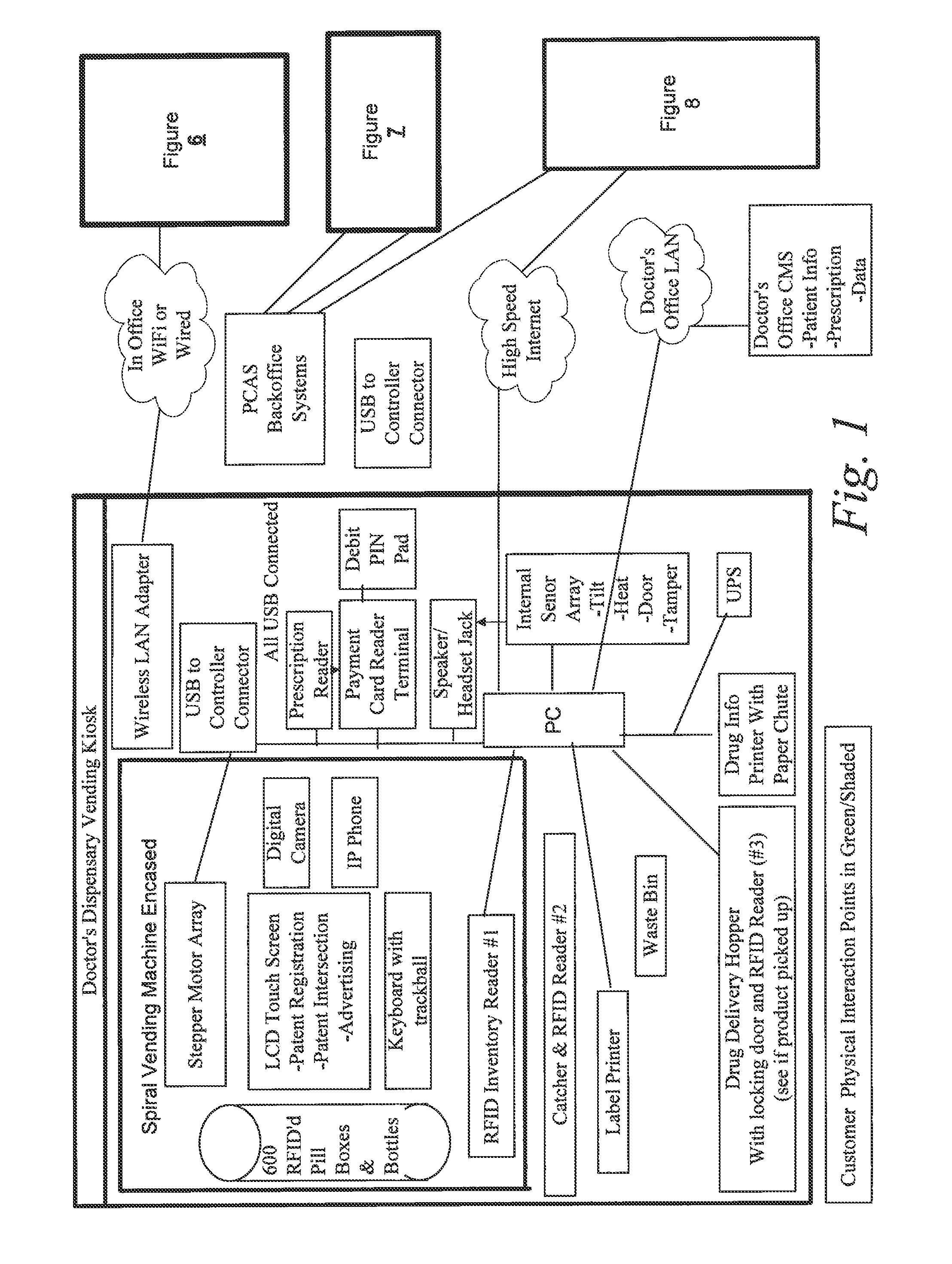

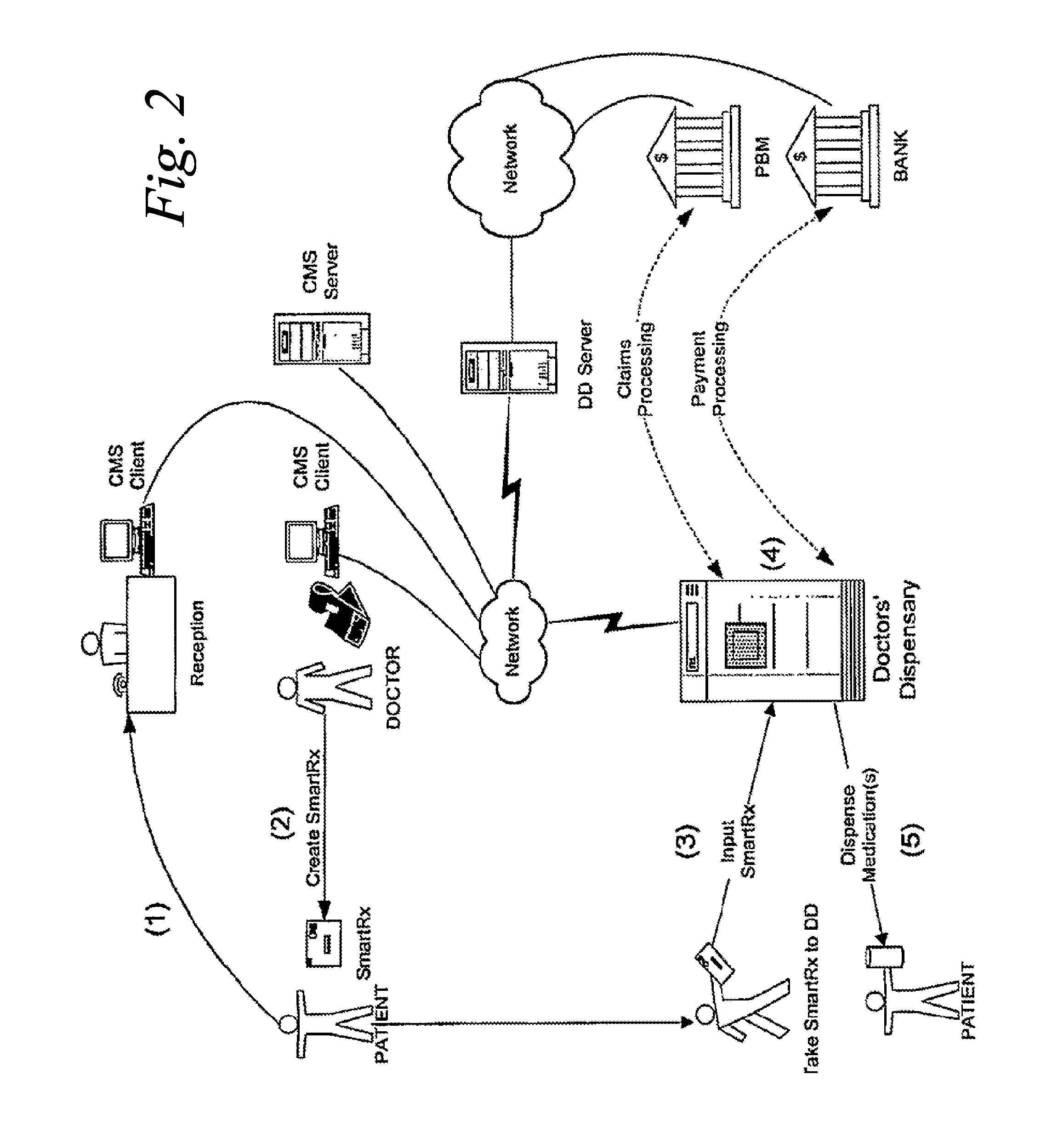

Vending machine for storage, labeling and dispensing of a container

ActiveUS8738177B2Low costPrevent heat-induced deterioration thereofLiquid surface applicatorsDrug and medicationsControl systemEngineering

A vending machine, in communication with a remote station, delivers a labeled container to a user from storage holding containers of different sizes and shapes and containing different products such as medicaments. A control system is operable to select a specific unlabeled container from among the other containers in storage, and to move the selected unlabeled container to a labeling module where a label is applied after the position of the label and / or the selected unlabeled container are / is adjusted so as to result in the label being applied at a desired position and angular orientation with respect to the selected unlabeled container. The control system is further operable to move the labeled container to a delivery zone accessible to the user.

Owner:MEDAVAIL

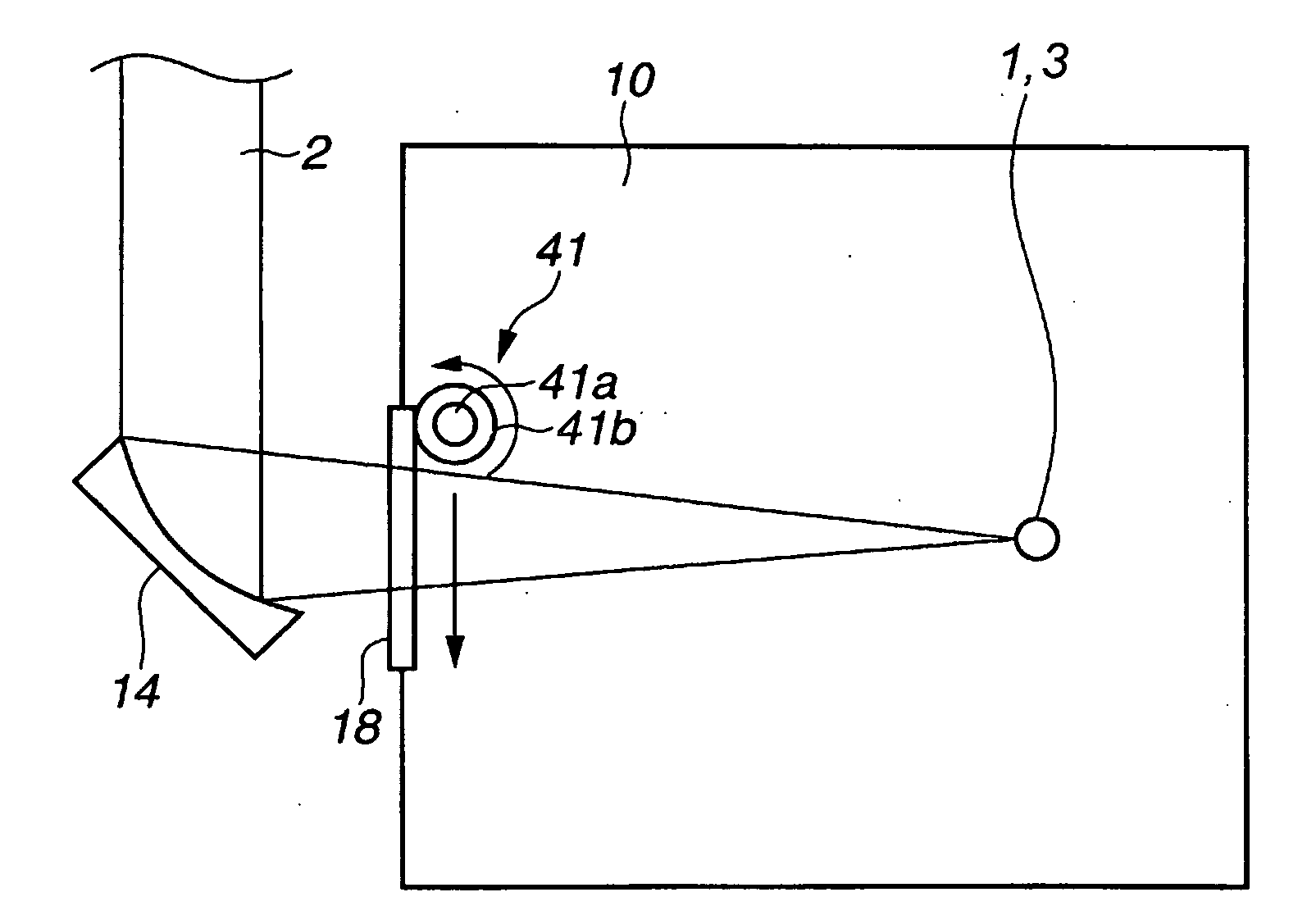

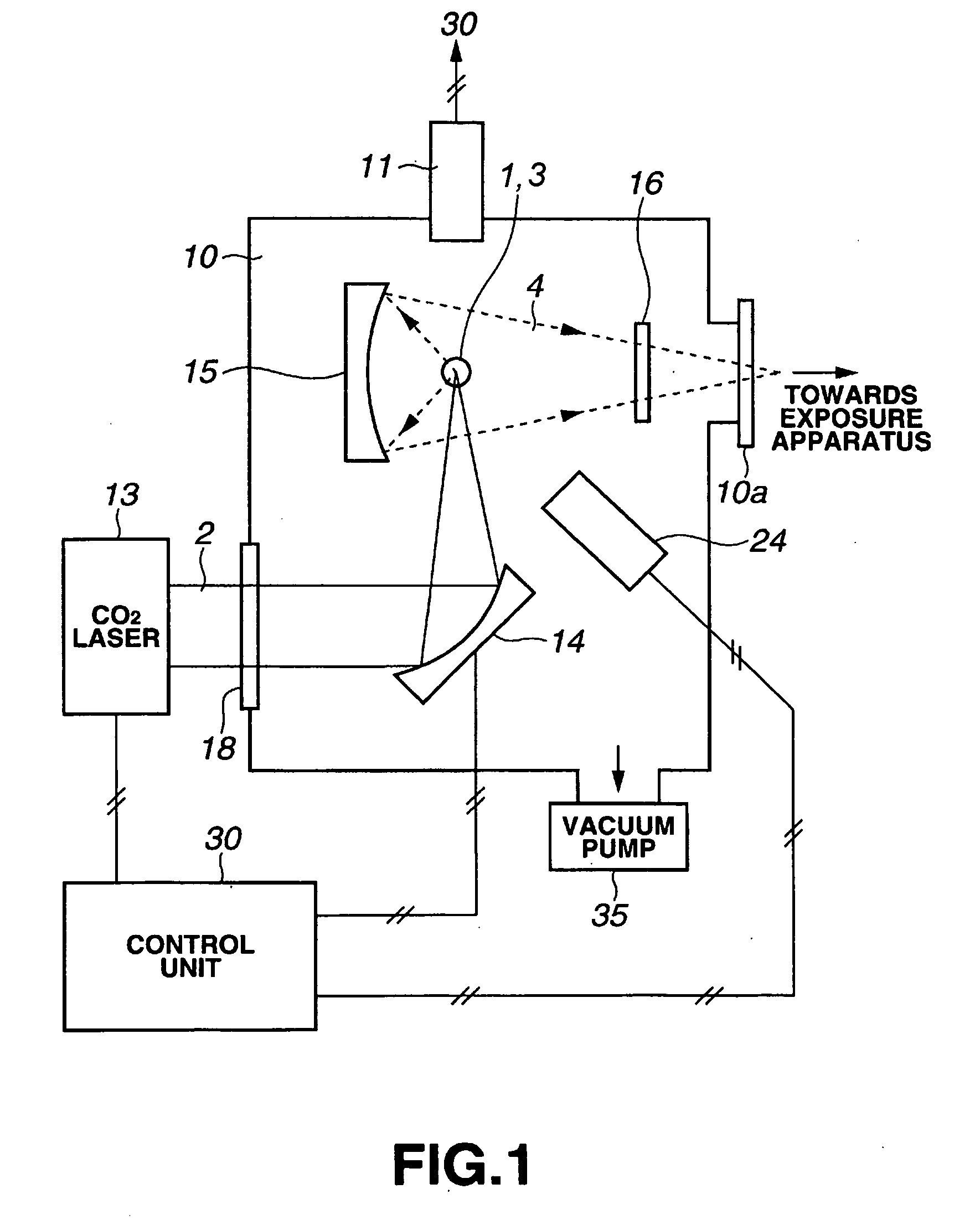

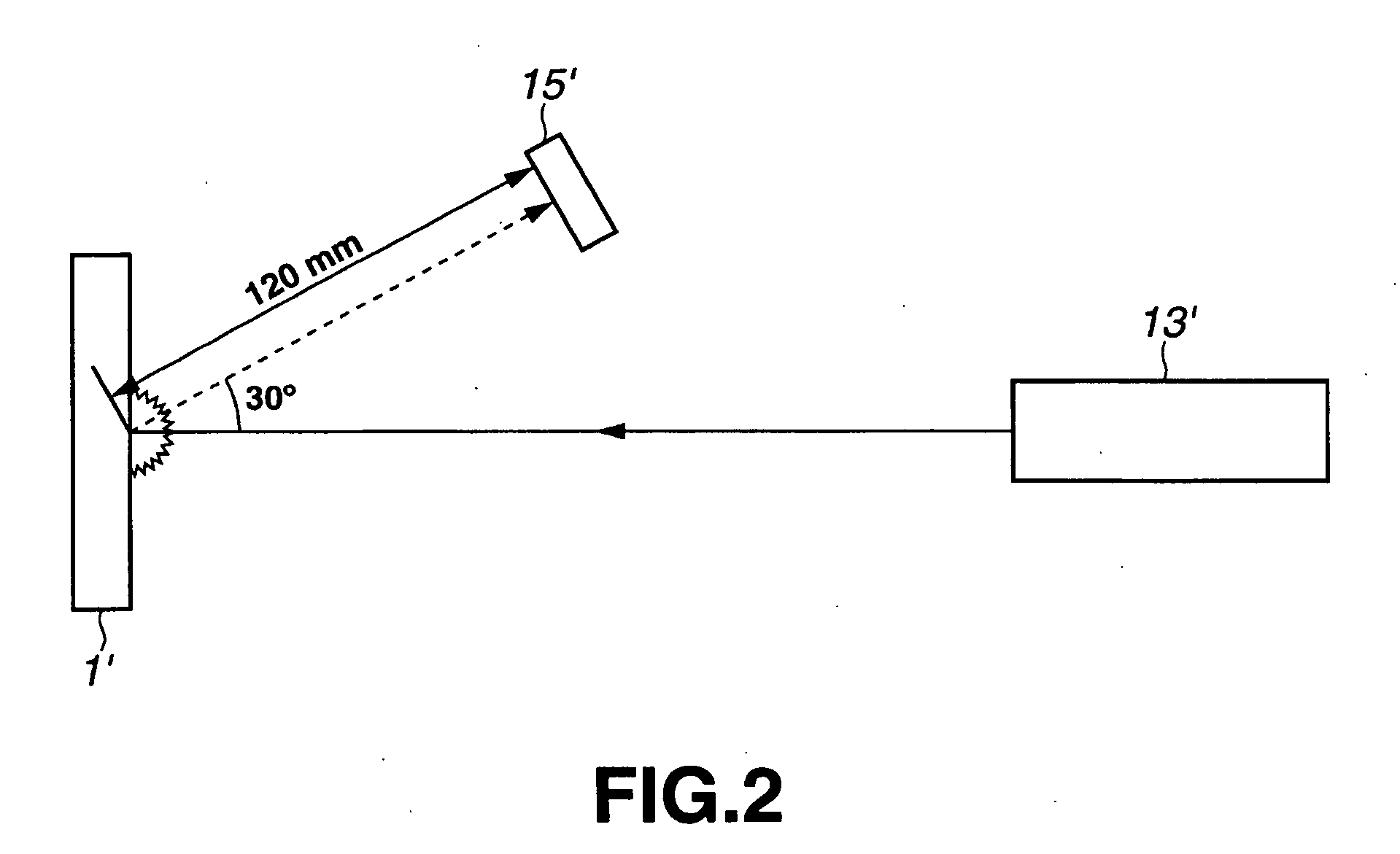

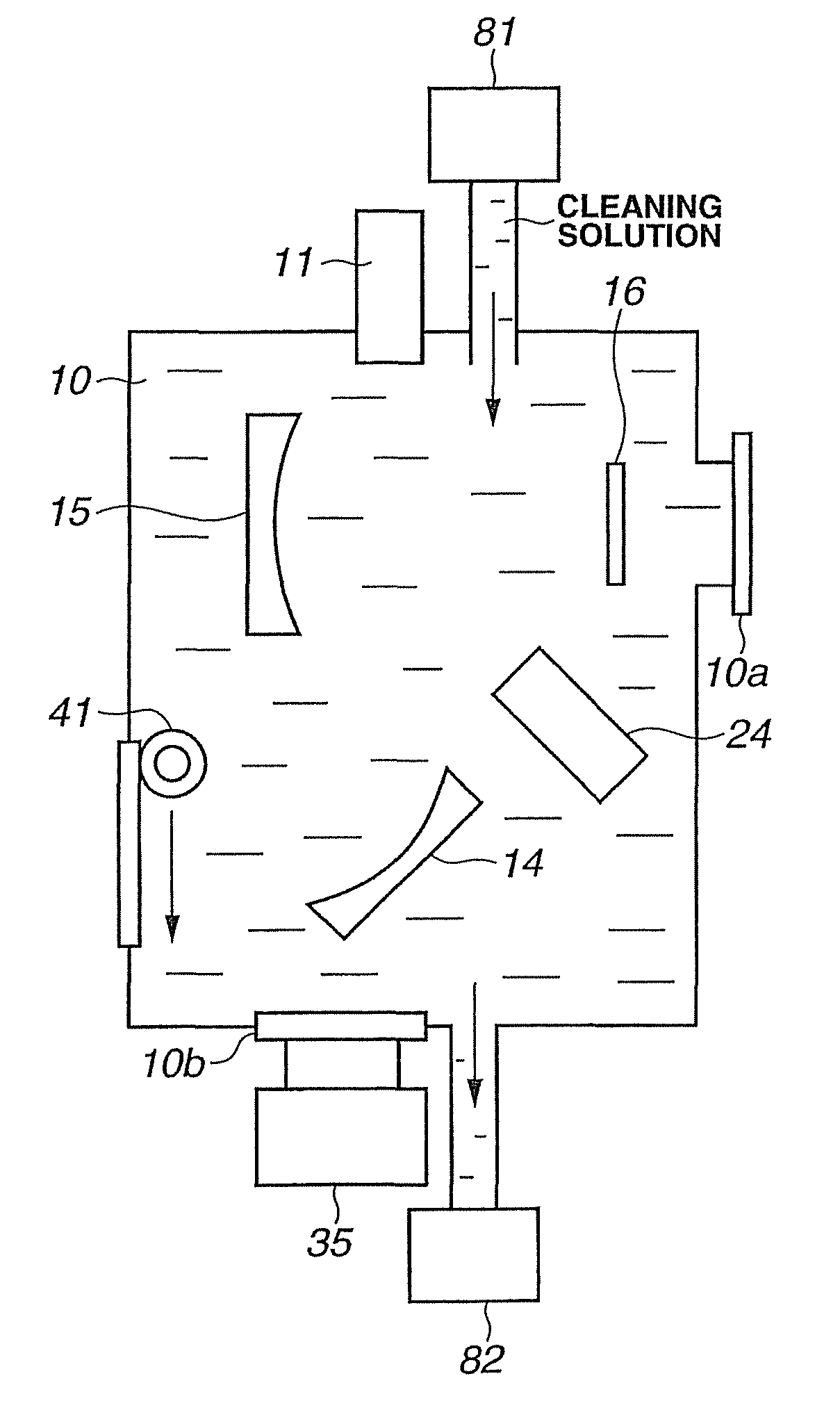

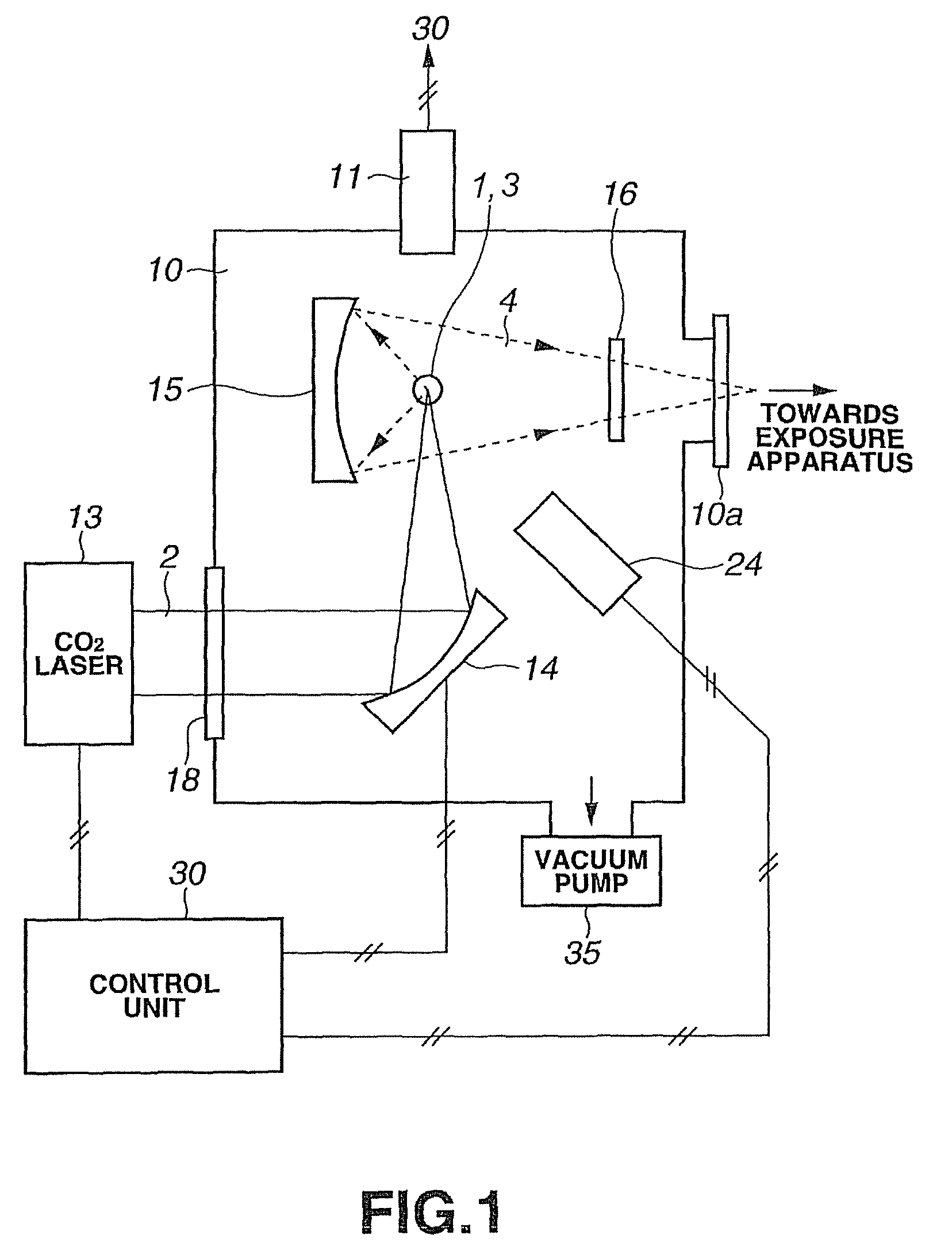

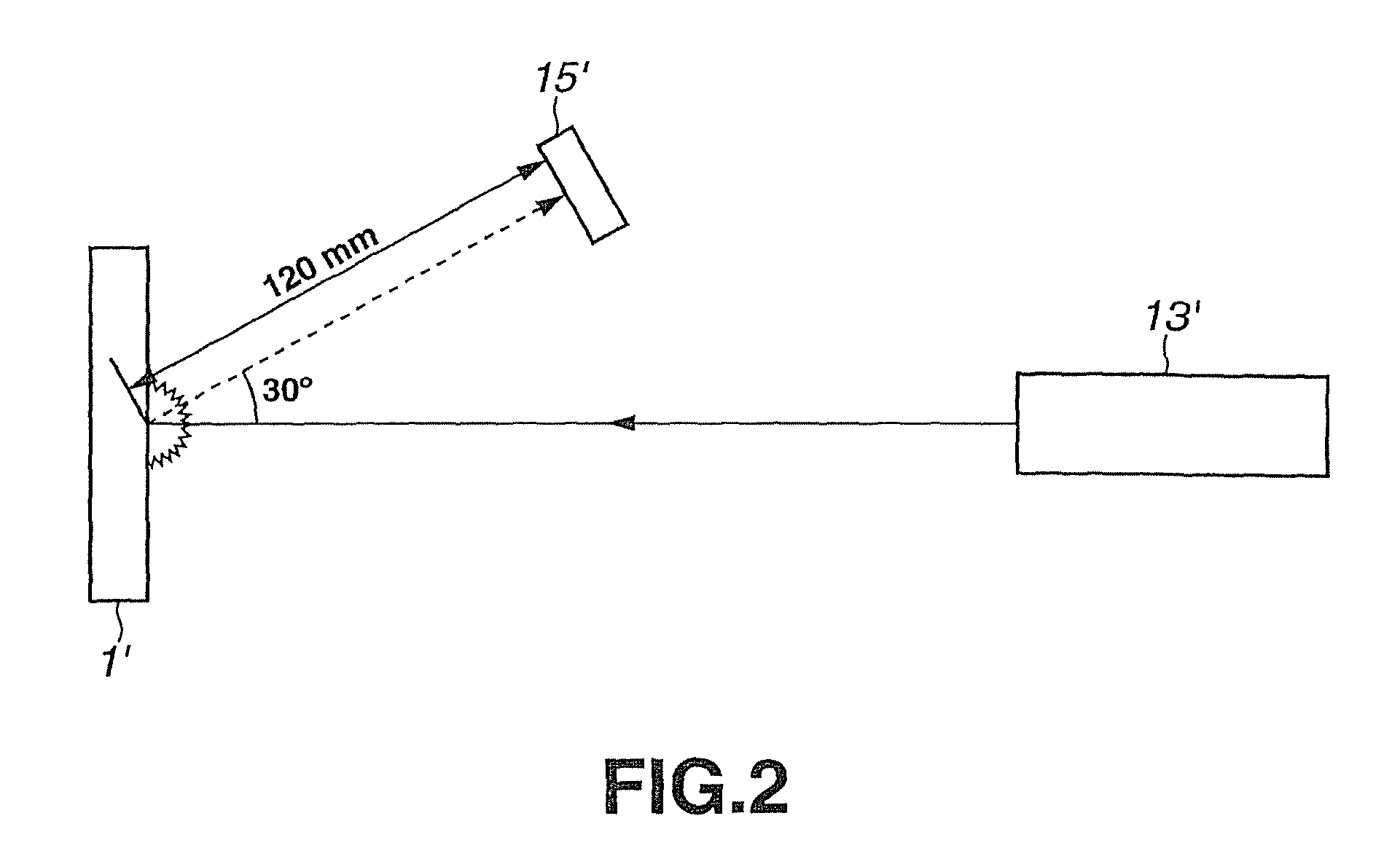

Method for cleaning optical element of EUV light source device and optical element cleaning device

ActiveUS20100025231A1Overcoming adhesionsAvoid stickingCellsVacuum evaporation coatingExtreme ultravioletLaser beams

A method for cleaning an optical element of an extreme ultraviolet light source device for removing, from the optical element in a chamber, scattered matter generated together with extreme ultraviolet light by plasma formed through laser beam excitation of a target in the chamber, the method which comprises: making the scattered matter generated by the plasma no larger than nanosize by using solid tin as the target and using a CO2 laser as an excitation source of the solid tin; and imparting, to the scattered matter no larger than the nanosize adhered to the optical element, an effect of overcoming the adherence of the scattered matter.

Owner:GIGAPHOTON

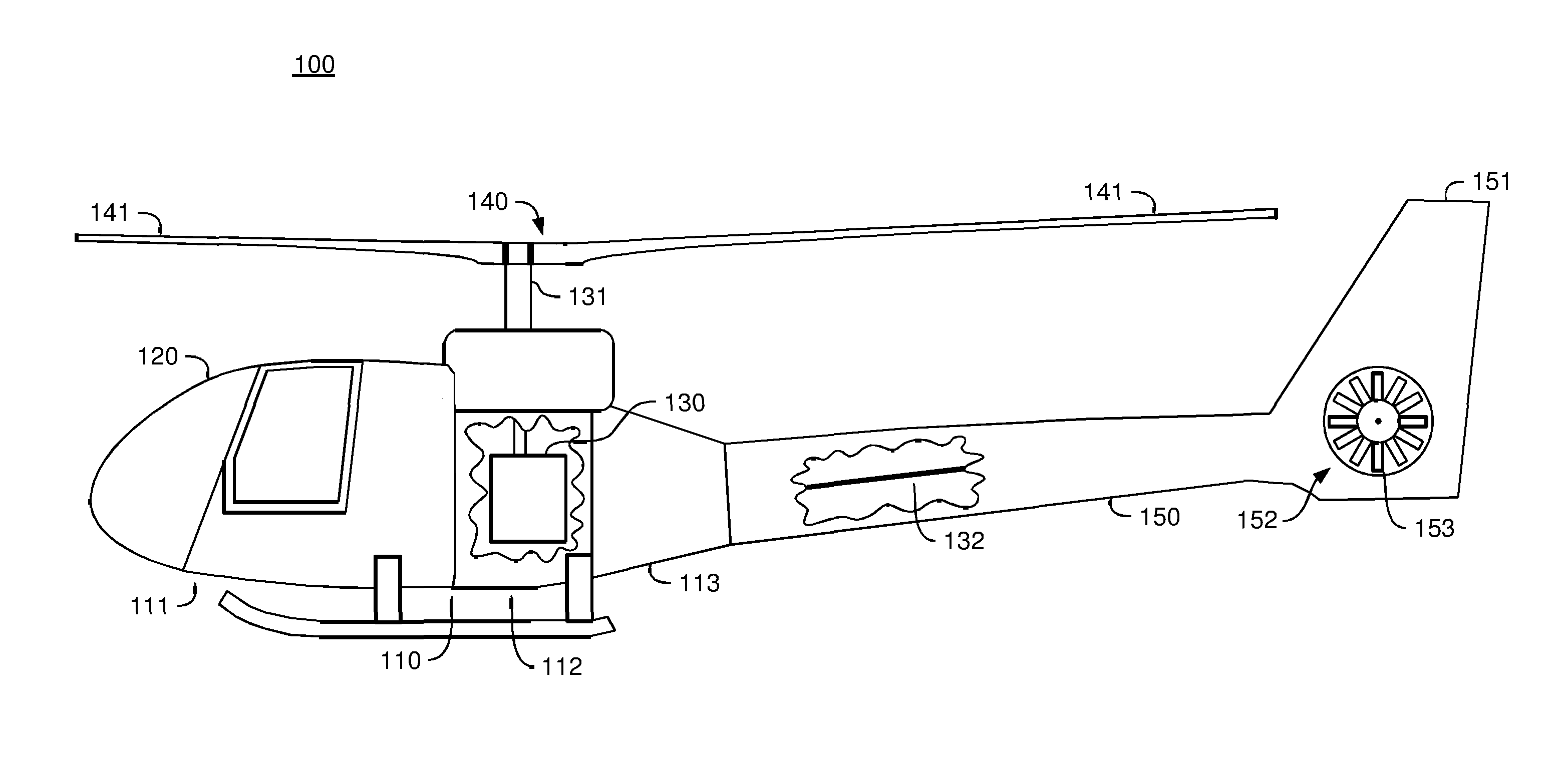

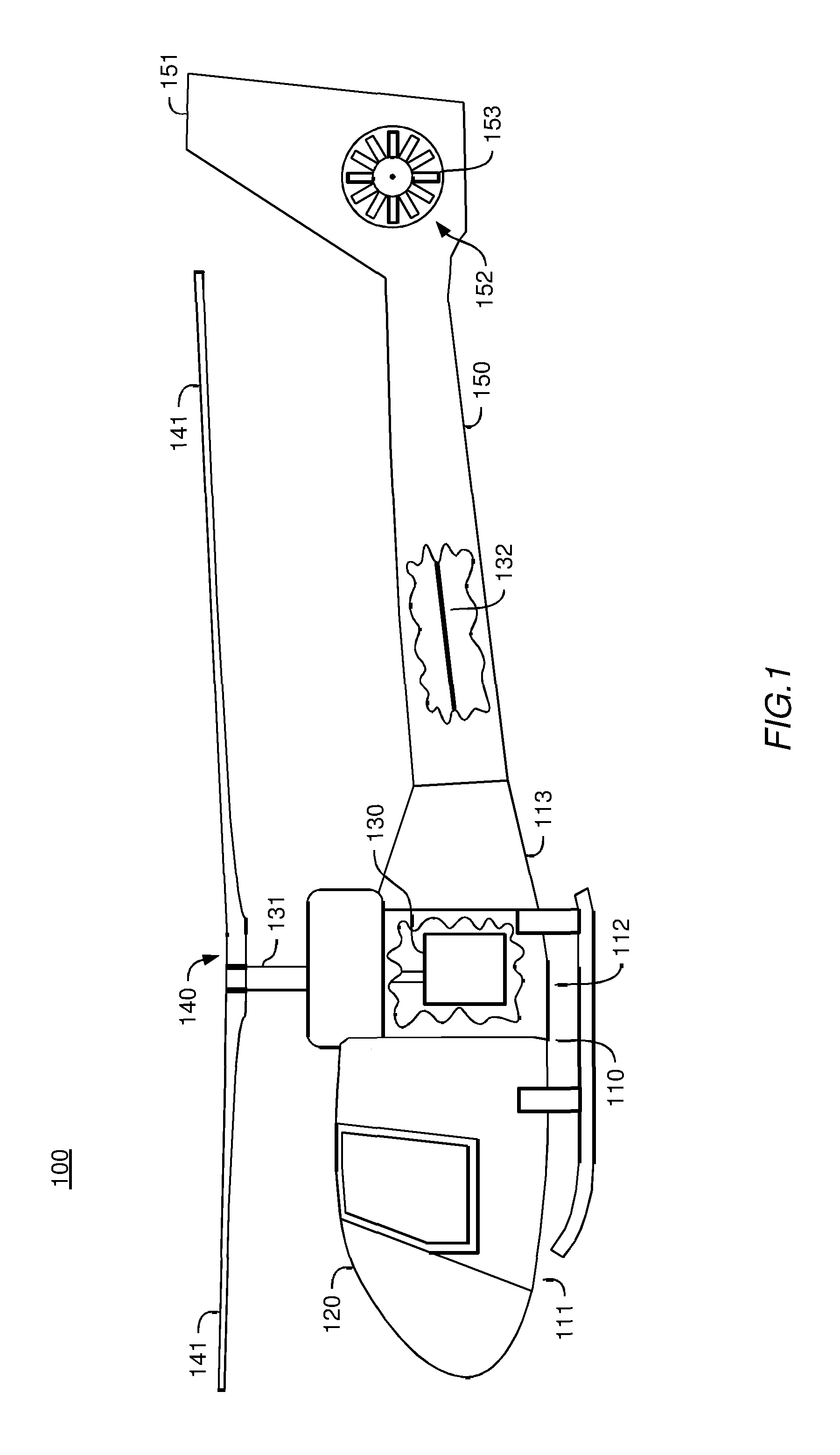

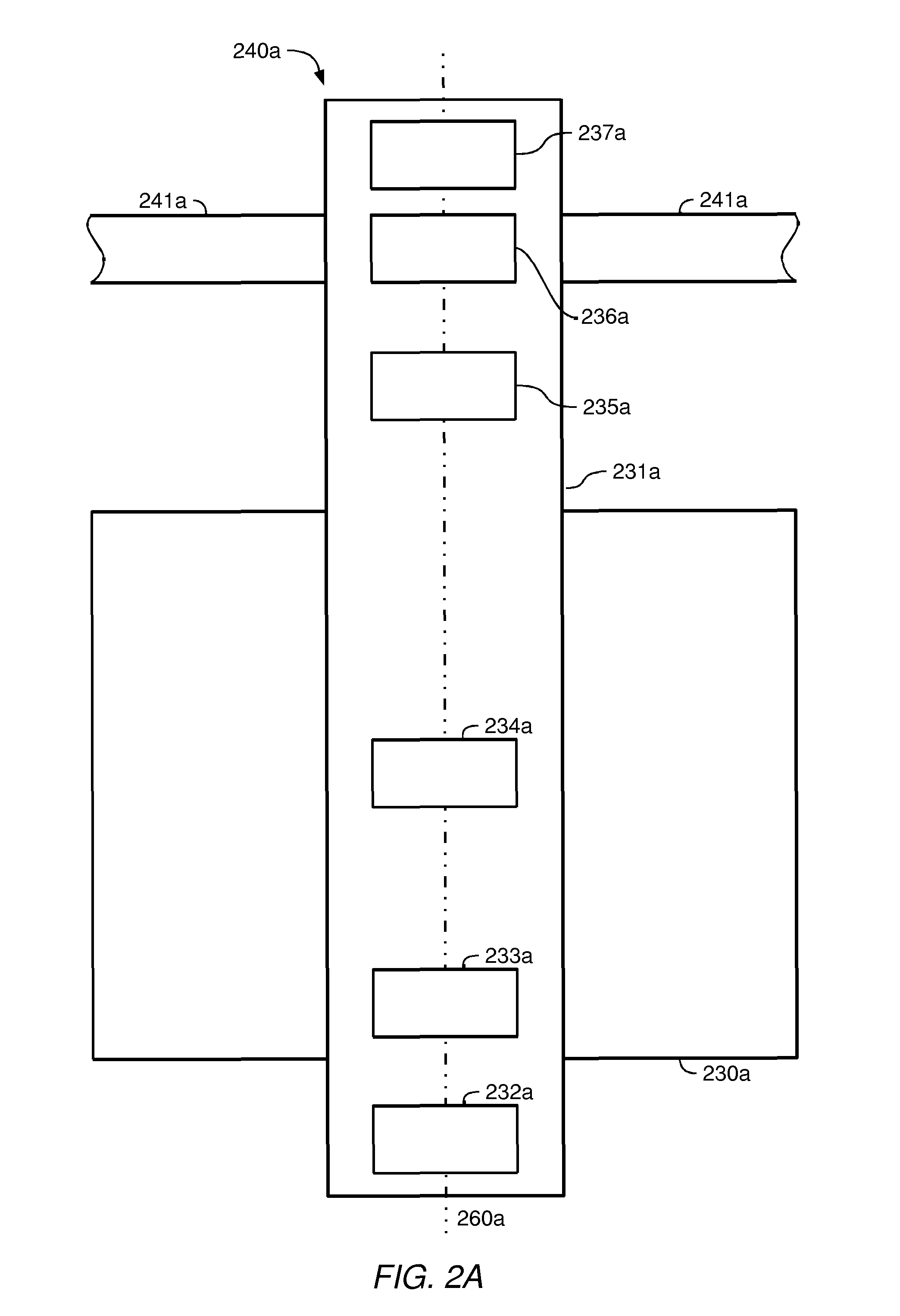

Method, apparatus and system for reducing vibration in a rotary system of an aircraft, such as a rotor of a helicopter

A method for reducing vibration in a rotary system (140; 240a; 240b; 340a; 340b) of an aircraft (100), for example an aeroplane or a rotorcraft, such as a helicopter, comprising balancing said rotary system (140; 240a; 240b; 340a; 340b), characterized by providing a substantially circular chamber (232a, 233a, 234b, 235a, 236a, 237a; 232b, 233b, 234b, 235b, 237b; 335a; 335b; 433a; 433b; 433c; 535a; 535b; 535c) having a fulcrumon an axis (260a; 260b; 360a; 360b; 460a; 460b; 460c; 560a; 560b; 560c) of a shaft (131; 231a; 231b; 331a; 331b; 431a; 431b; 431c; 531a; 531b; 531c) of said rotary system (140; 240a; 240b; 340a; 340b) and being partially filled with an amount of a thixotropic balancing substance (338a; 338b; 438a; 438b; 438c; 538a; 538b; 538c). An apparatus, and a system, for reducing vibration in a rotary system (140; 240a; 240b; 340a; 340b) of an aircraft (100) according to the method.

Owner:PROF DR LARS BERTIL CARNEHAMMAR

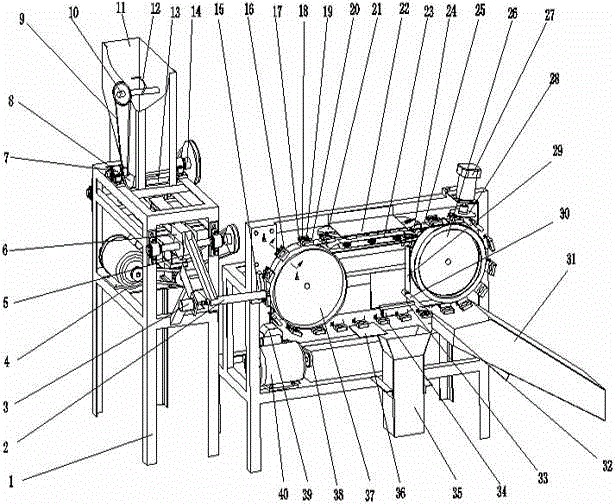

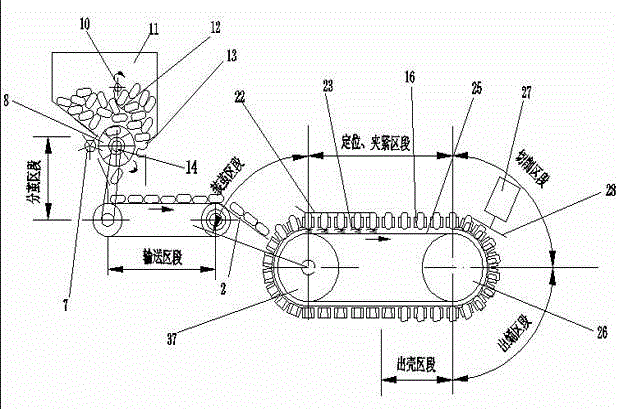

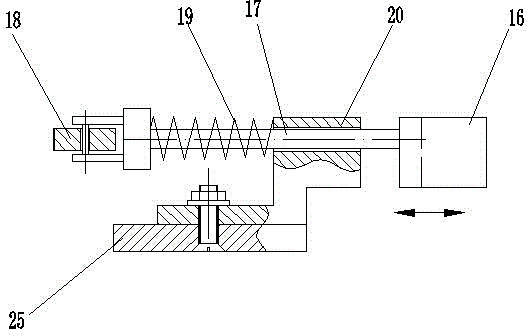

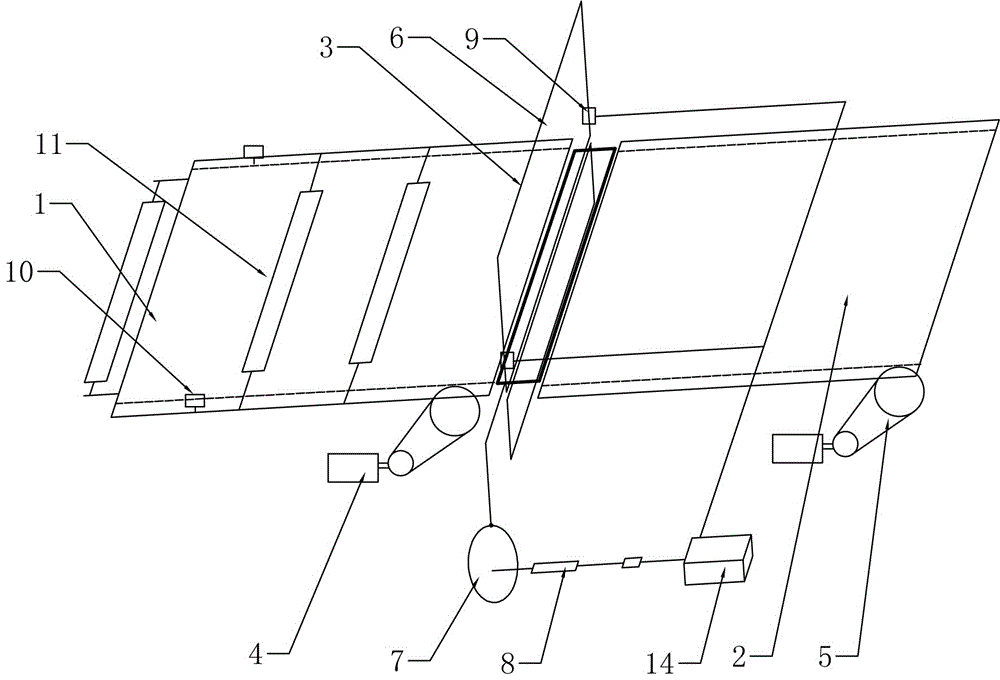

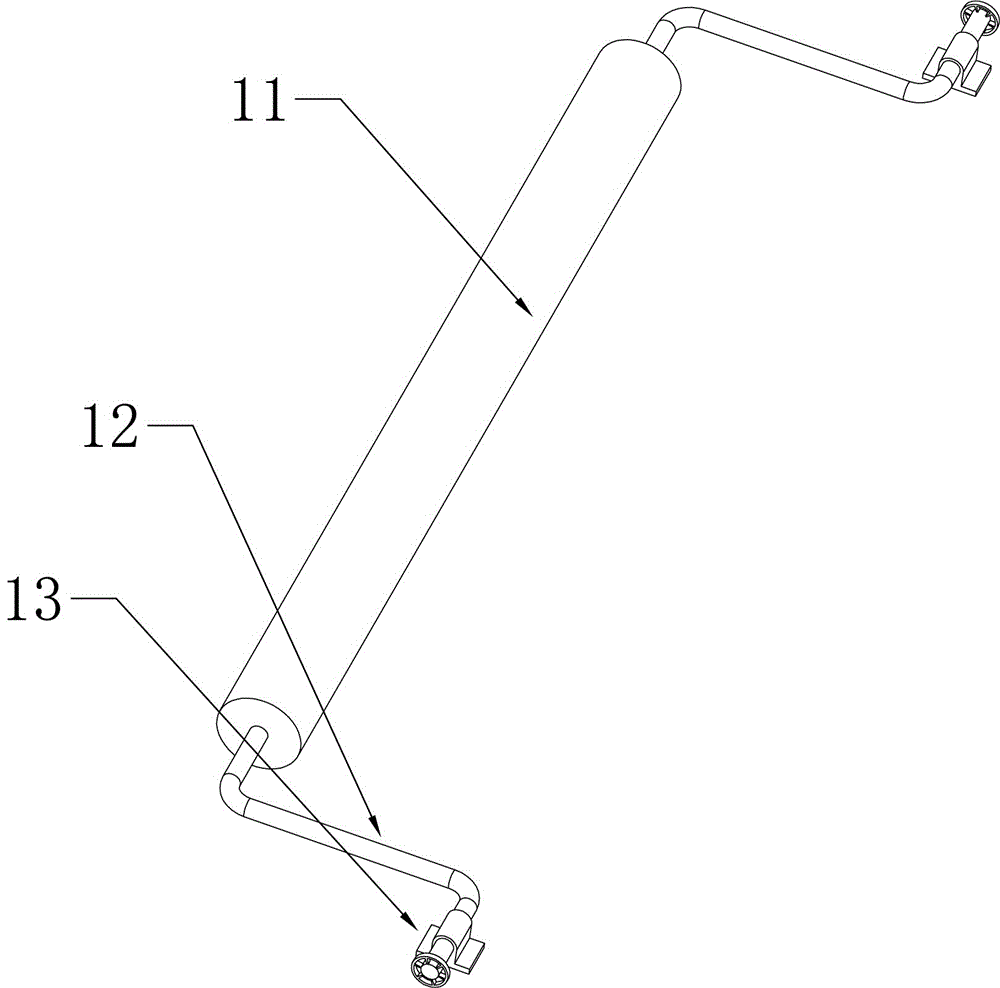

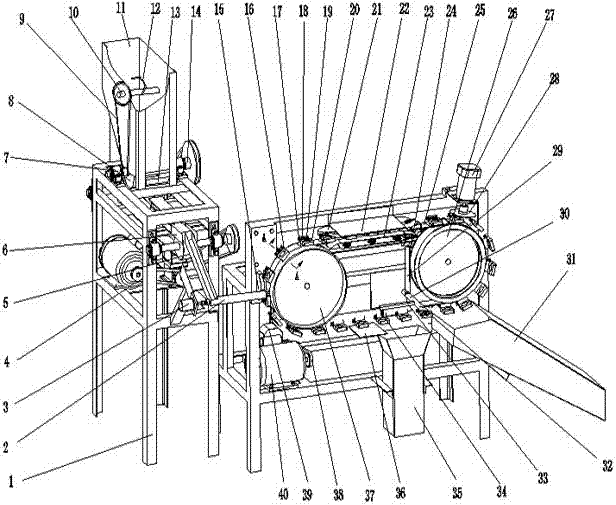

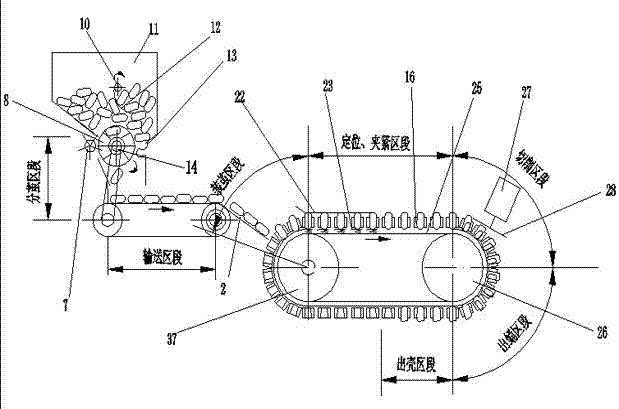

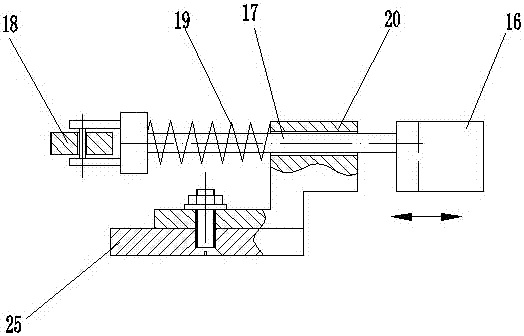

Automatic silkworm cocoon hole cutting machine and hole cutting method

ActiveCN104642270AUniform and reliable separationUniform and reliable movementAnimal husbandryEngineeringConveyor belt

The invention discloses an automatic silkworm cocoon hole cutting machine and a hole cutting method, the radial direction of a disk surface of a cocoon separating disk is provided with 2 rectangular slots that are symmetrical along the center of the cocoon separating disk, a horizontal cocoon conveying belt is positioned below the cocoon separating disk, the left end of the cocoon conveying belt is positioned under the cocoon separating disk, the right end of the cocoon conveying belt is tightly connected with the left end of a cocoon conveying passage, a cocoon pushing mechanism is arranged at an upper right position of the cocoon conveying passage, and a photosensitive sensor is installed on the cocoon pushing mechanism; a conveyor belt, an active roller wheel and a passive roller wheel are arranged on the right side of the cocoon conveying passage, a fixture component is fixedly connected on the conveyor belt, a positioning and clamping mechanism is arranged at a conveyor belt position between the active roller wheel and the passive roller wheel, a pushing plate that pushes the fixture to make the fixture open is positioned on the rear side of the positioning and clamping mechanism; a cutting mechanism is arranged at the upper right position of the passive roller wheel, and a cocoon shell separating mechanism is arranged on the left side of the passive roller wheel; batched and automatic hole cutting can be carried out on the silkworm cocoon of different sizes, silkworm chrysalis and cocoon shells can be separated automatically, the positioning is reliable, the cocoon for egg production can not be crushed or injured due to cutting, the cocoon cutting quality is good, and the efficiency is high.

Owner:JIANGSU UNIV OF SCI & TECH

Method for cleaning optical element of EUV light source device and optical element cleaning device

ActiveUS8256441B2Overcoming adhesionsAvoid stickingVacuum evaporation coatingPhotomechanical apparatusExtreme ultravioletLaser beams

A method for cleaning an optical element of an extreme ultraviolet light source device for removing, from the optical element in a chamber, scattered matter generated together with extreme ultraviolet light by plasma formed through laser beam excitation of a target in the chamber, the method which comprises: making the scattered matter generated by the plasma no larger than nanosize by using solid tin as the target and using a CO2 laser as an excitation source of the solid tin; and imparting, to the scattered matter no larger than the nanosize adhered to the optical element, an effect of overcoming the adherence of the scattered matter.

Owner:GIGAPHOTON

Heat-not-burn tobacco sheet and preparation method thereof

InactiveCN107692303AImprove suction qualityHigh tensile strengthTobacco preparationTobacco treatmentPectinaseMaillard reaction

The invention provides a heat-not-burn tobacco sheet and a preparation method thereof. The preparation method comprises: a) biologically treating tobacco under the action of microbes to obtain primarily biologically treated tobacco, wherein the microbes include bacillus and / or yeasts; b) mixing the primarily biologically treated tobacco with dried tangerine peel to obtain a mixture; c) subjectingthe mixture to water extraction and concentration, adding a compound enzyme preparation to perform biological treatment to obtain secondarily biologically treated concentrate, wherein the compound enzyme preparation includes two or more of cellulase, pectinase, proteinase and glucolase; d) mixing the secondarily biologically treated concentrate with a modifying agent to perform Maillard reaction to obtain a coating; 3) applying the coating to the surface of a tobacco sheet base, and drying to obtain the heat-not-burn tobacco sheet. The preparation method may provide improved tensile strength and bulkiness for the heat-not-burn tobacco sheet, adhesion rarely occurs, bad odors such as wood odor are basically removed, and the heat-not-burn tobacco sheet has the aroma of dried tangerine peel.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Automatic fixed-length cutting machine for rubber and cutting method

ActiveCN106584539ACutting length is accurateOvercoming adhesionsMetal working apparatusEngineeringRubber sheet

Provided is an automatic fixed-length cutting machine for rubber and a cutting method. The automatic fixed-length cutting machine mainly comprises a feeding conveyor belt, a discharging conveyor belt and a middle cutting mechanism. The feeding conveyor belt is driven by an independent feeding motor. The discharging conveyor belt is driven by an independent discharging motor. The cutting mechanism comprises a shearing blade. The shearing blade is driven by a cam and a rotary air cylinder. The feeding motor, the discharging motor and the rotary air cylinder are all controlled by a PLC to be started. According to the automatic fixed-length cutting machine for the rubber, by arranging the feeding conveyor belt, the discharging conveyor belt and the middle cutting mechanism, the PLC is used for control, and the technical problems that the cut length of rubber sheets is unstable, operation and adjustment are difficult in the continuous production process, and the yield of the rubber sheets is low are solved.

Owner:湖北华润科技有限公司

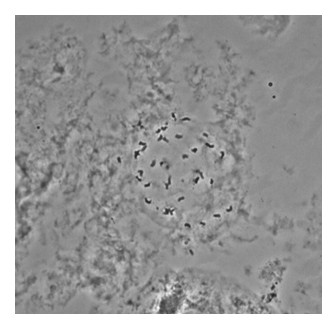

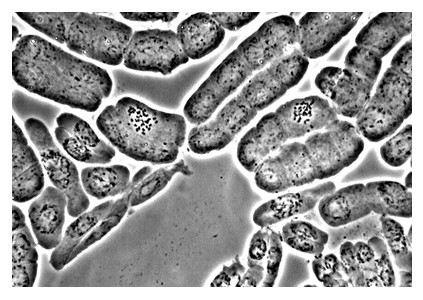

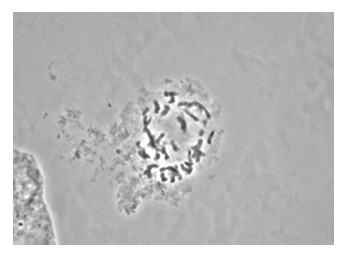

Method for sheeting peanut root tip cell chromosome in mitosis metaphase

InactiveCN102589943AChromosomal dispersionProduction is not idealPreparing sample for investigationBiotechnologyCell wall

The invention relates to a method for sheeting peanut root tip cell chromosome in the mitosis metaphase, which comprises the following steps that: a peanut root tip is selected, and paradichlorobenzene is utilized for soaking pretreatment; the root tip is put into carnoy stationary liquid for room temperature treatment; acetic acid is used for soaking, the root tip of a meristematic zone is cut and put on a glass slide, the center of a cover glass is tapped to disperse the cells, a cell wall is heated by fire for dissociating and softening, and a filter paper is used for removing the excess acetic acid; the cell which is in the mitosis metaphase and has smoothly dispersed chromosome is sheeted and refrigerated, the cover glass is removed, and the glass slide is dehydrated; and stain zoning or fluorescence in-situ hybridization are carried out. The obtained sheet has leveled cells and dispersed chromosome, and more cells are in the metaphase; and the acetic acid medium is used for direct compression, the reagent has small influence to the chromosome, so the method is easy to operate and control, has simple steps and high sheeting efficiency. The method is suitable to not only peanuts but also sesame, paddy, corns, soybeans, green beans or tomatoes and other various plants, and has good operability.

Owner:HENAN ACAD OF AGRI SCI

Heat-not-burn tobacco sheet and preparation method thereof

InactiveCN107981401AHigh tensile strengthIncrease bulkTobacco preparationTobacco treatmentMaillard reactionMicroorganism

The invention provides a heat-not-burn tobacco sheet and a preparation method thereof. The preparation method comprises the steps that tobacco leaves are subjected to biological treatment under the action of microorganisms to obtain the primary biologically-treated tobacco leaves; the primary biologically-treated tobacco leaves and valerian are mixed to obtain a mixture; after the mixture is subjected to aqueous extraction and concentration, a compound enzyme preparation is added for biological treatment to obtain a secondary biologically-treated concentrated solution; the second biologically-treated concentrated solution and a modifier are mixed for Maillard reaction to obtain a coating medium; a tobacco sheet base is coated with the coating medium and dried to obtain the heat-not-burn tobacco sheet. By means of the preparation method, the tensile strength and the bulk of the heat-not-burn tobacco sheet can be improved, the heat-not-burn tobacco sheet is not likely to adhere, meanwhile, bad odor such as wood offensive odor is basically eliminated, and the heat-not-burn tobacco sheet has valerian fragrance.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Heat-not-burn tobacco sheet and preparation method thereof

InactiveCN107912802AImprove suction qualityHigh tensile strengthTobacco preparationTobacco treatmentMaillard reactionHeat not burn

The invention provides a heat-not-burn tobacco sheet and a preparation method thereof. The preparation method includes: subjecting tobacco leaves to biological treatment under the action of microorganisms to obtain primary biologically-treated tobacco leaves; mixing the primary biologically-treated tobacco leaves with agilawood to obtain a mixture; after aqueous extraction and concentration of themixture, adding a complex enzyme preparation for biological treatment to obtain secondary biologically-treated concentrated liquor; mixing the secondary biologically-treated concentrated liquor witha modifying agent to obtain a coating material through Maillard reaction; coating the surface of a tobacco sheet base with the coating material, and drying to obtain the heat-not-burn tobacco sheet. By adoption of the preparation method, tensile strength and bulkiness of the tobacco sheet can be improved while the tobacco sheet is less prone to adhesion, bad smells such as offensive wood odor arealmost eliminated, and an aroma of agilawood is achieved.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Heat-not-burn tobacco sheet and preparation method thereof

ActiveCN107981402AHigh tensile strengthIncrease bulkTobacco preparationTobacco treatmentIrritationHeat not burn

The invention provides a heat-not-burn tobacco sheet and a preparation method thereof. According to the preparation method, through a specific treatment process and specific treatment means in combination with multiple steps of biological treatment and specific medical plants, the tensile strength and the bulk of the heat-not-burn tobacco sheet can be improved, the heat-not-burn tobacco sheet is not likely to adhere, meanwhile, bad odor such as wood offensive odor is basically eliminated, the heat-not-burn tobacco sheet has specific fragrance of the medical plants and basically causes no irritation or burning sensation, and the tobacco fragrance is rich and soft.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Heat-not-burn tobacco sheets and preparing method thereof

InactiveCN107668766AHigh tensile strengthIncrease bulkTobacco preparationTobacco treatmentChemistryPectinase

The invention provides heat-not-burn tobacco sheets and a preparing method thereof. The preparing method comprises the steps of a, conducting biological treatment on tobacco leaves under the effect ofmicroorganisms to obtain primary biological treatment tobacco leaves, wherein the microorganisms comprise bacillus and / or saccharomycetes; b, mixing the primary biological treatment tobacco leaves with momordica grosvenori to obtain a mixture; c, conducting aqueous extract and concentration on the mixture, and afterwards adding a complex enzyme preparation into the mixture to conduct biological treatment to obtain a secondary biological treatment concentration solution, wherein the complex enzyme preparation comprises two or more of cellulase, pectinase, protease and glucolase; d, mixing thesecondary biological treatment concentration solution with a modifier to be subjected to a Maillard reaction to obtain a coating medium; e, coating the matrix surface of the tobacco sheets with the coating medium and drying the surface to obtain the heat-not-burn tobacco sheets. According to the preparing method of the heat-not-burn tobacco sheets, the tensile strength and bulk of the heat-not-burn tobacco sheets can be improved, and the heat-not-burn tobacco sheets are not easily adhesive; meanwhile, bad smell like woody mixed gas is fundamentally removed, and the heat-not-burn tobacco sheetshave the flavor of momordica grosvenori.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Reconstituted tobacco incombustible after being heated and preparation method thereof

InactiveCN107927890AHigh tensile strengthIncrease bulkTobacco preparationTobacco treatmentMaillard reactionEnzyme

The invention provides a reconstituted tobacco incombustible after being heated and a preparation method thereof. The preparation method comprises the steps that biological treatment is carried out ontobacco leaves under the action of microorganisms to obtain primary biological treatment tobacco leaves; the primary biological treatment tobacco leaves are mixed with tea leaves to obtain a mixture;water extraction and concentration are carried out on the mixture, and a complex enzyme preparation is added for biological treatment to obtain a secondary biological treatment concentrated solution;the secondary biological treatment concentrated solution is mixed with a modifier for a Maillard reaction to obtain a coating material; the surfaces of reconstituted tobacco bases are coated with thecoating material and dried to obtain the reconstituted tobacco incombustible after being heated. By means of the preparation method, the tensile strength and bulk of the reconstituted tobacco incombustible after being heated can be improved, and the reconstituted tobacco is not likely to adhere; meanwhile, the wood offensive odor and other bad smells are basically eliminated, and the reconstituted tobacco has the smell of the tea leaves.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Heat-not-burn tobacco sheet and preparation method thereof

The invention provides a heat-not-burn tobacco sheet and a preparation method thereof. The preparation method comprises: a) biologically treating tobacco under the action of microbes to obtain primarily biologically treated tobacco, wherein the microbes include bacillus and / or yeasts; b) mixing the primarily biologically treated tobacco with stem of noble dendrobium to obtain a mixture; c) subjecting the mixture to water extraction and concentration, adding a compound enzyme preparation to perform biological treatment to obtain secondarily biologically treated concentrate, wherein the compoundenzyme preparation includes two or more of cellulase, pectinase, proteinase and glucolase; d) mixing the secondarily biologically treated concentrate with a modifying agent to perform Maillard reaction to obtain a coating; 3) applying the coating to the surface of a tobacco sheet base, and drying to obtain the heat-not-burn tobacco sheet. The preparation method may provide improved tensile strength and bulkiness for the heat-not-burn tobacco sheet, adhesion rarely occurs, bad odors such as wood odor are basically removed, and the heat-not-burn tobacco sheet has the aroma of stem of noble dendrobium.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Reconstituted tobacco incombustible after being heated and preparation method thereof

InactiveCN107927889AHigh tensile strengthIncrease bulkTobacco preparationMaillard reactionMicroorganism

The invention provides a reconstituted tobacco incombustible after being heated and a preparation method thereof. The preparation method comprises the steps that biological treatment is carried out ontobacco leaves under the action of microorganisms to obtain primary biological treatment tobacco leaves; the primary biological treatment tobacco leaves are mixed with sarcandra glabra to obtain a mixture; water extraction and concentration are carried out on the mixture, and a complex enzyme preparation is added for biological treatment to obtain a secondary biological treatment concentrated solution; the secondary biological treatment concentrated solution is mixed with a modifier for a Maillard reaction to obtain a coating material; the surfaces of reconstituted tobacco bases are coated with the coating material and dried to obtain the reconstituted tobacco incombustible after being heated. By means of the preparation method, the tensile strength and bulk of the reconstituted tobacco incombustible after being heated can be improved, and the reconstituted tobacco is not likely to adhere; meanwhile, the wood offensive odor and other bad smells are basically eliminated, and the reconstituted tobacco has the smell of sarcandra glabra.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

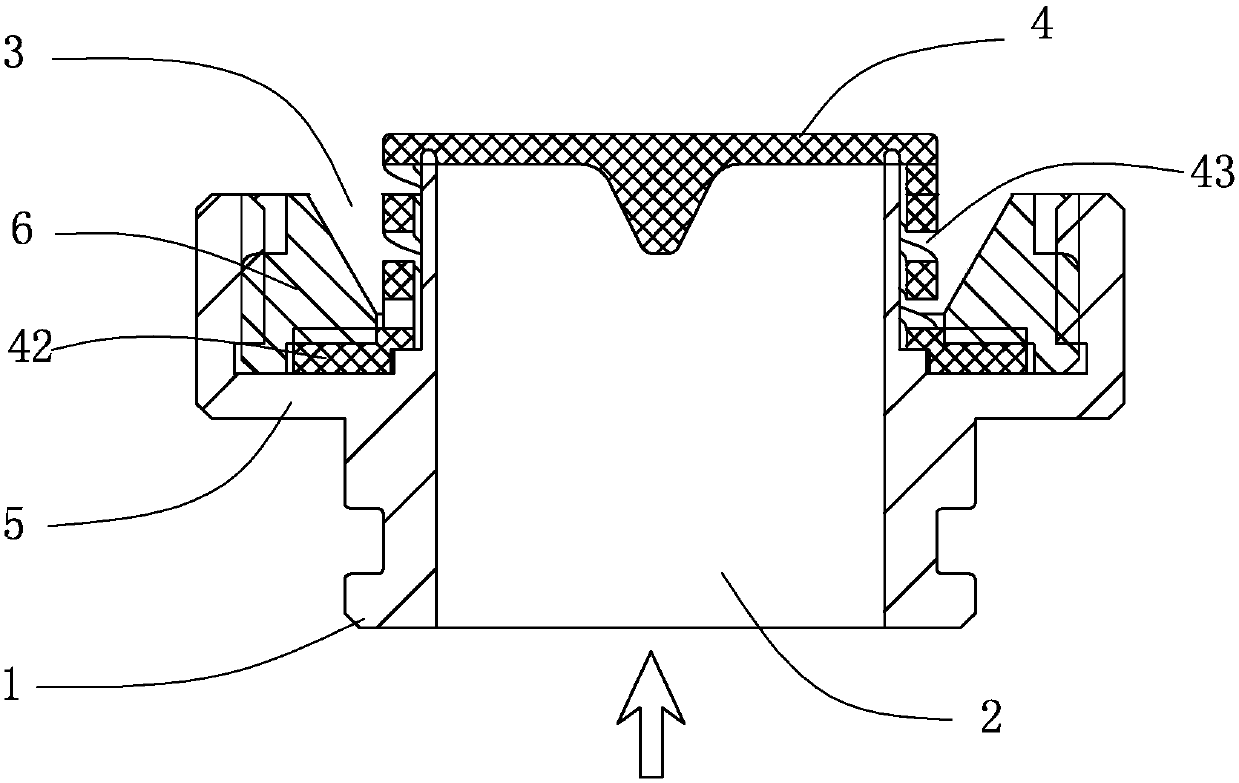

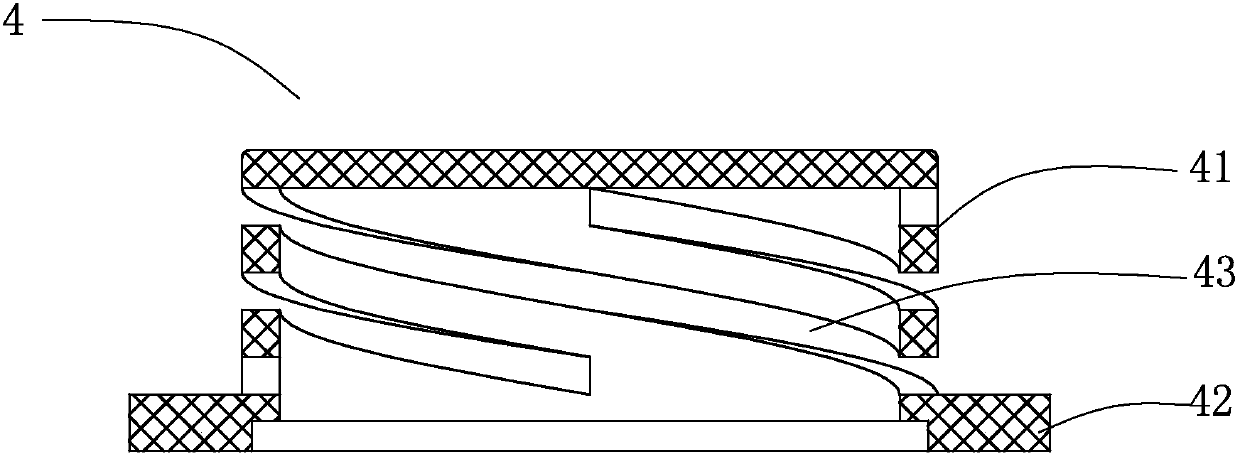

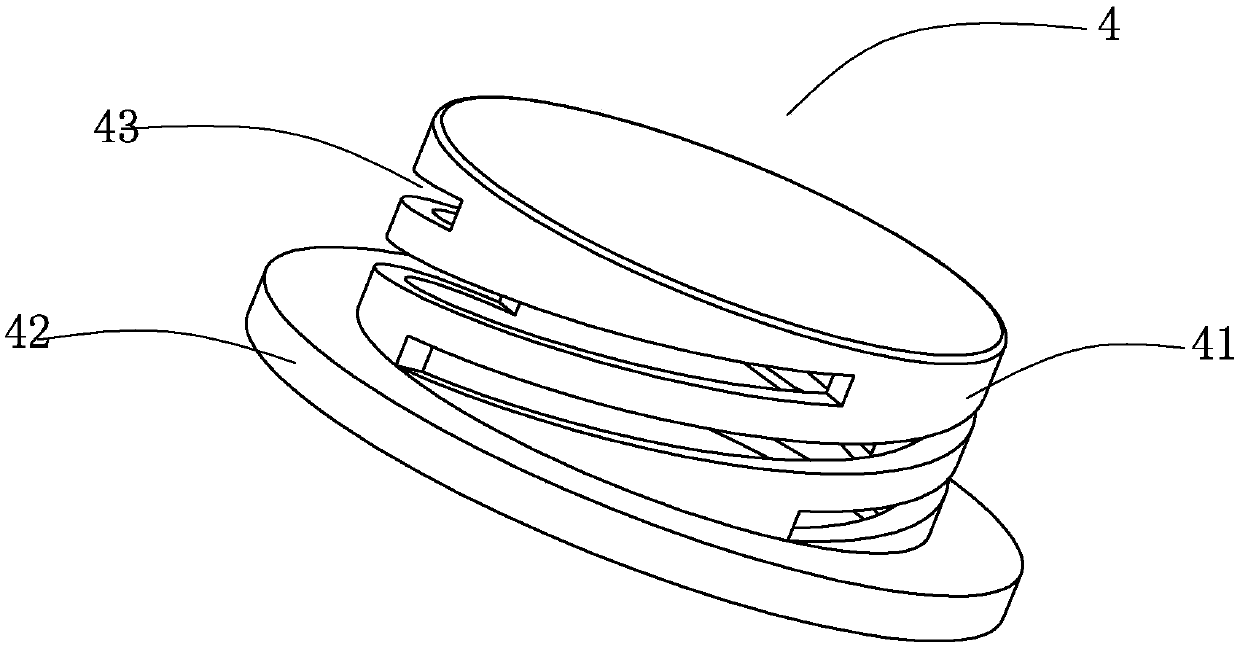

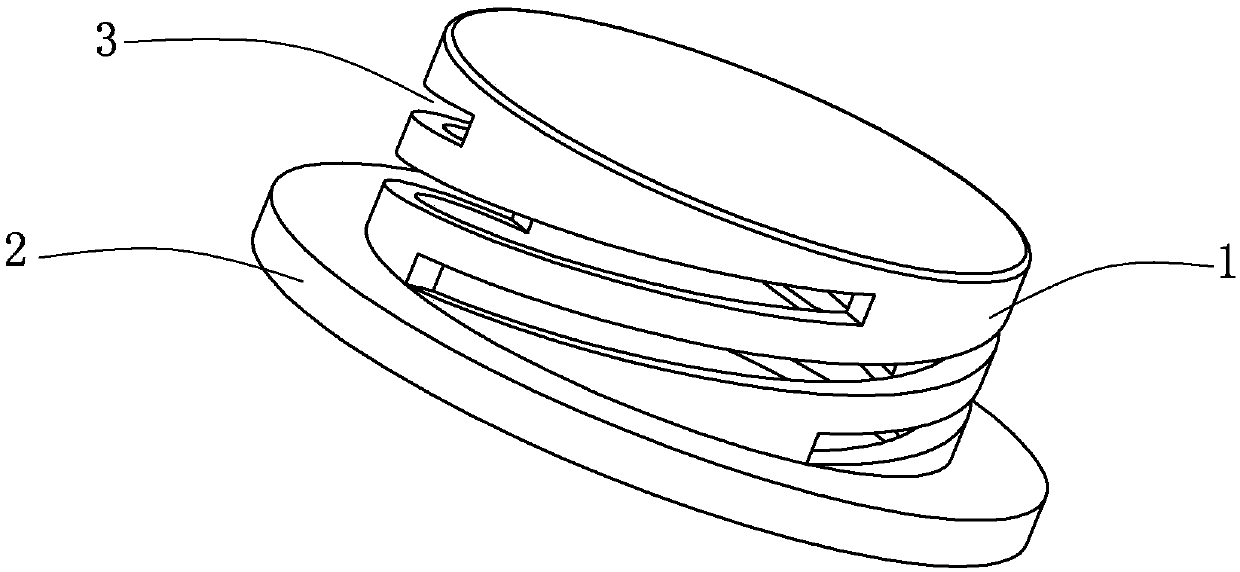

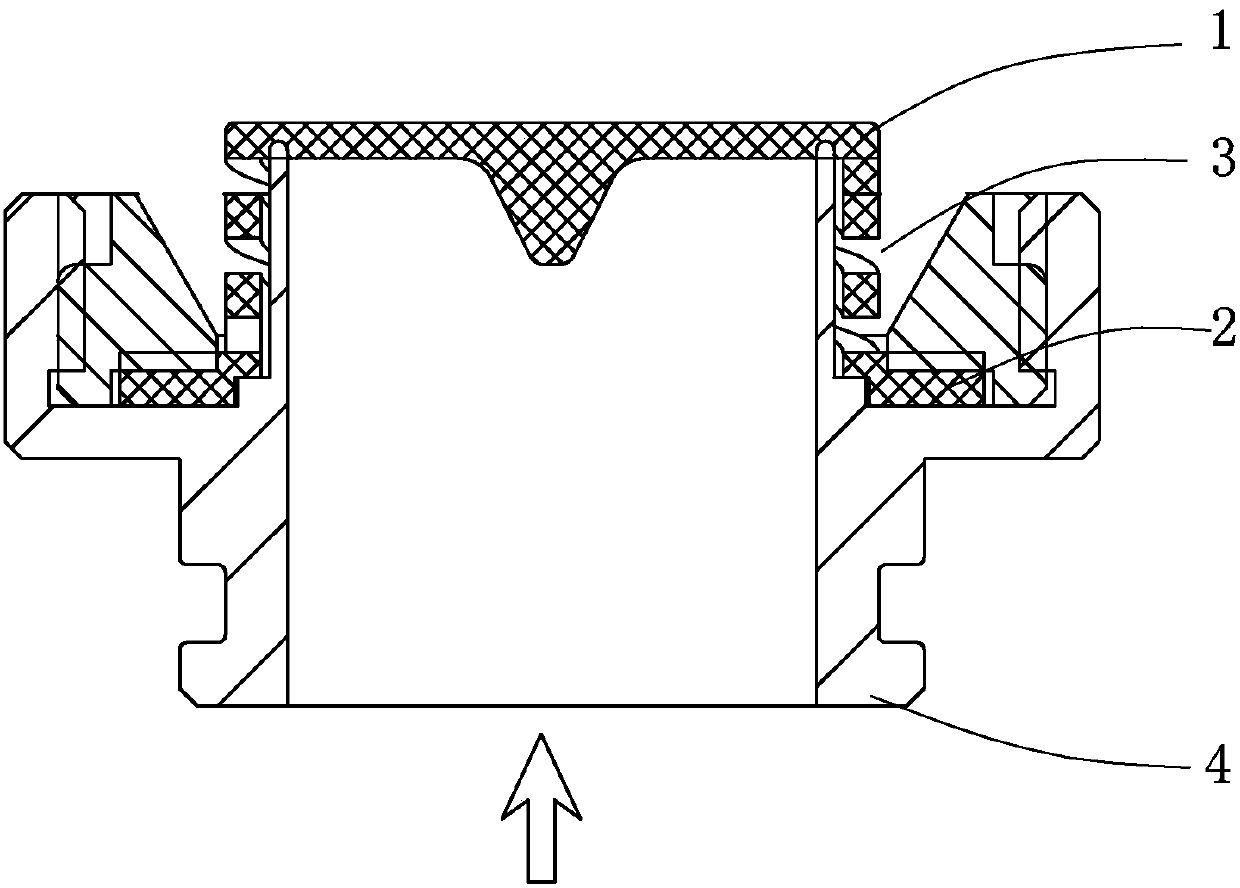

Simple one-way breathing valve plate

InactiveCN109780280AOvercoming adhesionsGuaranteed uniformityEqualizing valvesSafety valvesEngineeringFlange

The invention provides a simple one-way breathing valve plate. The valve plate comprises a valve seat. The valve seat is provided with a valve cavity and a valve port. A valve plate body is arranged in the valve port and comprises a cylinder with the upper end sealed and the lower end opened. A ring flange with the diameter greater than that of the cylinder is arranged on the periphery of an opening in the lower end of the cylinder. A spiral air vent is formed in the cylinder wall of the cylinder. The inner diameter of the valve port of the valve seat is greater than that of the valve cavity.A ring step is formed in the position where the valve port is connected with the valve cavity. The ring flange of the valve plate body is located on the step. A ring valve cover is in threaded connection with the inner wall of the valve port through threads and tightly presses the flange of the valve plate body to the step.

Owner:BEIJING AEROSPACE CHANGFENG CO LTD

A heat-not-burn tobacco sheet and its preparation method

ActiveCN107981402BHigh tensile strengthIncrease bulkTobacco preparationTobacco treatmentBiotechnologyNicotiana tabacum

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Heat-not-burn tobacco sheets and preparing method thereof

InactiveCN107668774AHigh tensile strengthIncrease bulkTobacco preparationTobacco devicesPectinaseFlavor

The invention provides heat-not-burn tobacco sheets and a preparing method thereof. The preparing method comprises the steps of a, conducting biological treatment on tobacco leaves under the effect ofmicroorganisms to obtain primary biological treatment tobacco leaves, wherein the microorganisms comprise bacillus and / or saccharomycetes; b, mixing the primary biological treatment tobacco leaves with astragalus membranaceus to obtain a mixture; c, conducting aqueous extract and concentration on the mixture, and afterwards adding a complex enzyme preparation into the mixture to conduct biological treatment to obtain a secondary biological treatment concentration solution, wherein the complex enzyme preparation comprises two or more of cellulase, pectinase, protease and glucolase; d, mixing the secondary biological treatment concentration solution with a modifier to be subjected to a Maillard reaction to obtain a coating medium; e, coating the matrix surface of the tobacco sheets with thecoating medium and drying the surface to obtain the heat-not-burn tobacco sheets. According to the preparing method of the heat-not-burn tobacco sheets, the tensile strength and bulkness of the heat-not-burn tobacco sheets can be improved, and the heat-not-burn tobacco sheets are not easily adhesive; meanwhile, bad smell like woody mixed gas is fundamentally removed, and the heat-not-burn tobaccosheets have the flavor of astragalus membranaceus.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Tobacco slices which do not combust when heated and preparing method of tobacco slices

InactiveCN107668764AHigh tensile strengthIncrease bulkTobacco preparationTobacco treatmentMaillard reactionPectinase

The invention provides tobacco slices which do not combust when heated and a preparing method of the tobacco slices. The preparing method comprise the steps of a, conducting biological treatment on tobacco leaves under the effect of microorganisms to obtain primary biological treatment tobacco leaves, wherein the microorganisms comprise bacillus and / or yeast; b, mixing the primary biological treatment tobacco leaves with eucommiae leaves to obtain a mixture; c, after conducting water extraction and concentration on the mixture, adding compound enzyme preparation to be subjected to biological treatment to obtain secondary biological treatment concentration liquid, wherein the compound enzyme preparation comprises two or more of cellulase, pectinase, protease and glucolase; d, mixing the secondary biological treatment concentration liquid with a modifier to be subjected to a Maillard reaction to obtain coating; e, coating the surface of a tobacco slice medium with the coating and keepingdry to obtain the tobacco slices which do not combust when heated. The preparing method can improve the tensile strength and the bulk of the tobacco slices which do not combust when heated, and the tobacco slices are not adhere with one another; meanwhile, smell of wood smell and the like is basically removed, and the tobacco slices have the fragrance of the eucommiae leaves.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Tobacco slices which do not combust when heated and preparing method of tobacco slices

InactiveCN107668765AHigh tensile strengthIncrease bulkTobacco preparationTobacco treatmentChemistryPectinase

The invention provides tobacco slices which do not combust when heated and a preparing method of the tobacco slices. The preparing method comprise the steps of a, conducting biological treatment on tobacco leaves under the effect of microorganisms to obtain primary biological treatment tobacco leaves, wherein the microorganisms comprise bacillus and / or yeast; b, mixing the primary biological treatment tobacco leaves with black tartary buckwheat to obtain a mixture; c, after conducting water extraction and concentration on the mixture, adding compound enzyme preparation to be subjected to biological treatment to obtain secondary biological treatment concentration liquid, wherein the compound enzyme preparation comprises two or more of cellulase, pectinase, protease and glucolase; d, mixingthe secondary biological treatment concentration liquid with a modifier to be subjected to a Maillard reaction to obtain coating; e, coating the surface of a tobacco slice medium with the coating andkeeping dry to obtain the tobacco slices which do not combust when heated. The preparing method can improve the tensile strength and the bulk of the tobacco slice, and the tobacco slices do not adherewith one another; meanwhile, bad smell of wood smell and the like is basically removed, and the tobacco slices have the fragrance of the black tartary buckwheat.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Heat-not-burn tobacco sheet and preparation method thereof

InactiveCN107692304AHigh tensile strengthIncrease bulkTobacco treatmentMaillard reactionHeat not burn

The invention provides a heat-not-burn tobacco sheet and a preparation method thereof. The preparation method comprises: biologically treating tobacco under the action of microbes to obtain primarilybiologically treated tobacco; mixing the primarily biologically treated tobacco with leaf of Omei Mountain bamboo to obtain a mixture; subjecting the mixture to water extraction and concentration, adding a compound enzyme preparation to perform biological treatment to obtain secondarily biologically treated concentrate; mixing the secondarily biologically treated concentrate with a modifying agentto perform Maillard reaction to obtain a coating; applying the coating to the surface of a tobacco sheet base, and drying to obtain the heat-not-burn tobacco sheet. The preparation method may provideimproved tensile strength and bulkiness for the heat-not-burn tobacco sheet, adhesion rarely occurs, bad odors such as wood odor are basically removed, and the heat-not-burn tobacco sheet has the aroma of the leaf of Omei Mountain bamboo.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Heat-not-burn tobacco sheets and preparing method thereof

InactiveCN107668775AImprove suction qualityHigh tensile strengthTobacco preparationTobacco devicesMaillard reactionFlavor

The invention provides heat-not-burn tobacco sheets and a preparing method thereof. The preparing method comprises the steps of a, conducting biological treatment on tobacco leaves under the effect ofmicroorganisms to obtain primary biological treatment tobacco leaves; b, mixing the primary biological treatment tobacco leaves with mints to obtain a mixture; c, conducting aqueous extract and concentration on the mixture, and afterwards adding a complex enzyme preparation into the mixture to conduct biological treatment to obtain a secondary biological treatment concentration solution; d, mixing the secondary biological treatment concentration solution with a modifier to be subjected to a Maillard reaction to obtain a coating medium; e, coating the matrix surface of the tobacco sheets withthe coating medium and drying the surface to obtain the heat-not-burn tobacco sheets. According to the preparing method of the heat-not-burn tobacco sheets, the tensile strength of the heat-not-burn tobacco sheets can be improved, and the heat-not-burn tobacco sheets are not easily adhesive and convenient to clean; meanwhile, bad smell like woody mixed gas is fundamentally removed, and the heat-not-burn tobacco sheets have the flavor of the mints.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Heat-not-burn tobacco sheet and preparation method thereof

InactiveCN107912801AHigh tensile strengthIncrease bulkTobacco preparationTobacco treatmentRHODIOLA ROSEA ROOTPectinase

The invention provides a heat-not-burn tobacco sheet and a preparation method thereof. The preparation method includes: a) subjecting tobacco leaves to biological treatment under the action of microorganisms to obtain primary biologically-treated tobacco leaves, wherein the microorganisms include bacillus and / or saccharomycetes; b) mixing the primary biologically-treated tobacco leaves with rhodiola rosea to obtain a mixture; c) after aqueous extraction and concentration of the mixture, adding a complex enzyme preparation for biological treatment to obtain secondary biologically-treated concentrated liquor, wherein the complex enzyme preparation comprises two or more of cellulase, pectinase, protease and glucolase; d) mixing the secondary biologically-treated concentrated liquor with a modifying agent to obtain a coating material through Maillard reaction; e) coating the surface of a tobacco sheet base with the coating material, and drying to obtain the heat-not-burn tobacco sheet. Byadoption of the preparation method, tensile strength and bulkiness of the tobacco sheet can be improved while the tobacco sheet is less prone to adhesion, bad smells such as offensive wood odor are almost eliminated, and an aroma of rhodiola rosea is achieved.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Heated-but-not-combusted tobacco sheet and preparing method thereof

InactiveCN107897999AHigh tensile strengthIncrease bulkTobacco preparationTobacco treatmentMaillard reactionEnzyme

The invention provides a heated-but-not-combusted tobacco sheet and a preparing method thereof. The method includes the steps of a, conducting biological treatment on tobacco leaves under the effect of microorganisms to obtain primary biological treatment tobacco leaves; b, mixing the primary biological treatment tobacco leaves with honeysuckle to obtain a mixture; c, conducting water extraction and condensation on the mixture, and then adding a complex enzyme preparation for biological treatment to obtain a secondary biological treatment concentrated solution; d, mixing the secondary biological treatment concentrated solution with a modifier to conduct a Maillard reaction to obtain a coating material; e, coating the surface of a tobacco sheet base with the coating material and then conducting drying to obtain the heated-but-not-combusted tobacco sheet. By means of the preparing method, the tensile strength and loose depth of the heated-but-not-combusted tobacco sheet can be improved,adhesion is not easy, meanwhile offensive wood odor and other bad smells are basically eliminated, and the tobacco sheet has honeysuckle aroma.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Reconstituted tobacco incombustible after being heated and preparation method thereof

The invention provides a heat-not-burn tobacco sheet and a preparation method thereof. The preparation method provided by the present invention comprises: biologically treating tobacco leaves under the action of microorganisms to obtain primary biologically treated tobacco leaves; mixing the primary biologically treated tobacco leaves with wild chrysanthemum to obtain a mixture; carrying out water extraction and concentration of the mixture, adding The compound enzyme preparation is biologically treated to obtain a secondary biological treatment concentrate; the secondary biological treatment concentrate is mixed with a modifier to perform a Maillard reaction to obtain a coating material; the coating material is coated on the tobacco The surface of the sheet base is dried to obtain a heat-not-burn tobacco sheet. The preparation method provided by the invention can improve the tensile strength and bulk of the heat-not-burn tobacco sheet, and is not easy to stick, and at the same time, it basically eliminates bad smells such as woody gas and the like, and has the fragrance of wild chrysanthemum.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

One-way ventilation valve for anesthesia respirator

The invention relates to a one-way ventilation valve for an anesthesia respirator. The one-way ventilation valve for the anesthesia respirator comprises a valve plate; the valve plate comprises a cylinder body with sealed upper end and opened lower end; an annular flange with a diameter larger than the diameter of the cylinder body is arranged on the peripheral edge of the opened lower end of thecylinder body; and a spiral ventilation port is formed in the cylinder wall of the cylinder body.

Owner:BEIJING AEROSPACE CHANGFENG CO LTD

Heat-not-burn tobacco sheet and preparation method thereof

InactiveCN107981403AHigh tensile strengthIncrease bulkTobacco preparationTobacco treatmentMicroorganismMaillard reaction

The invention provides a heat-not-burn tobacco sheet and a preparation method thereof. The preparation method comprises the steps that tobacco leaves are subjected to biological treatment under the action of microorganisms to obtain the primary biologically-treated tobacco leaves; the primary biologically-treated tobacco leaves and boxthorn leaves are mixed to obtain a mixture; after the mixture is subjected to aqueous extraction and concentration, a compound enzyme preparation is added for biological treatment to obtain a secondary biologically-treated concentrated solution; the second biologically-treated concentrated solution and a modifier are mixed for Maillard reaction to obtain a coating medium; a tobacco sheet base is coated with the coating medium and dried to obtain the heat-not-burn tobacco sheet. By means of the preparation method, the tensile strength and the bulk of the heat-not-burn tobacco sheet can be improved, the heat-not-burn tobacco sheet is not likely to adhere, meanwhile, bad odor such as wood offensive odor is basically eliminated, and the heat-not-burn tobacco sheet has fragrance of the boxthorn leaves.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

An automatic silkworm cocoon chipping machine and chipping method

ActiveCN104642270BUniform and reliable separationUniform and reliable movementAnimal husbandryCircular discEngineering

The invention discloses an automatic silkworm cocoon hole cutting machine and a hole cutting method, the radial direction of a disk surface of a cocoon separating disk is provided with 2 rectangular slots that are symmetrical along the center of the cocoon separating disk, a horizontal cocoon conveying belt is positioned below the cocoon separating disk, the left end of the cocoon conveying belt is positioned under the cocoon separating disk, the right end of the cocoon conveying belt is tightly connected with the left end of a cocoon conveying passage, a cocoon pushing mechanism is arranged at an upper right position of the cocoon conveying passage, and a photosensitive sensor is installed on the cocoon pushing mechanism; a conveyor belt, an active roller wheel and a passive roller wheel are arranged on the right side of the cocoon conveying passage, a fixture component is fixedly connected on the conveyor belt, a positioning and clamping mechanism is arranged at a conveyor belt position between the active roller wheel and the passive roller wheel, a pushing plate that pushes the fixture to make the fixture open is positioned on the rear side of the positioning and clamping mechanism; a cutting mechanism is arranged at the upper right position of the passive roller wheel, and a cocoon shell separating mechanism is arranged on the left side of the passive roller wheel; batched and automatic hole cutting can be carried out on the silkworm cocoon of different sizes, silkworm chrysalis and cocoon shells can be separated automatically, the positioning is reliable, the cocoon for egg production can not be crushed or injured due to cutting, the cocoon cutting quality is good, and the efficiency is high.

Owner:JIANGSU UNIV OF SCI & TECH

Preparation method of fluid core clamped chewy gelatinized confection

The invention discloses a preparation method of fluid core clamped chewy gelatinized confection. The main gelata of a wrapper of the fluid core clamped chewy gelatinized confection is gelatin. The preparation method comprises the following steps of crosslinking proteins, namely, immersing molded fluid core clamped chewy gelatinized confection into a transglutaminase aqueous solution for transglutaminase adsorption and crosslinking proteins. The preparation method provided by the invention comprises the protein crosslinking step, wherein the protein crosslinking refers to the fact that micromolecule proteins in the gelatin in the wrapper are crosslinked into macromolecule proteins by the transglutaminase aqueous solution, so that the melting point, the toughness and the mouthfeel of the wrapper of the confection are improved; the fluid core clamped chewy gelatinized confection is not prone to adhering and melting, and the confection product is soft in mouthfeel and is rich in resilience, cannot be affected by the external environment; the operation process is simple, convenient and efficient; the device cost is low, has extremely good popularization and using significance, and can generate great economic benefit.

Owner:HANSHAN NORMAL UNIV +1

Heated-but-not-combusted tobacco sheet and preparing method thereof

InactiveCN107897998AImprove suction qualityHigh tensile strengthTobacco preparationTobacco treatmentMaillard reactionPectinase

The invention provides a heated-but-not-combusted tobacco sheet and a preparing method thereof. The method includes the steps of a, conducting biological treatment on tobacco leaves under the effect of microorganisms to obtain primary biological treatment tobacco leaves, wherein the microorganisms include bacillus and / or saccharomycetes; b, mixing the primary biological treatment tobacco leaves with ginseng to obtain a mixture; c, conducting water extraction and condensation on the mixture, and then adding a complex enzyme preparation for biological treatment to obtain a secondary biological treatment concentrated solution, wherein the complex enzyme preparation includes two or more of cellulase, pectinase, protease and glucolase; d, mixing the secondary biological treatment concentrated solution with a modifier to conduct a Maillard reaction to obtain a coating material; e, coating the surface of a tobacco sheet base with the coating material and then conducting drying to obtain the heated-but-not-combusted tobacco sheet. By means of the preparing method, the tensile strength and loose depth of the heated-but-not-combusted tobacco sheet can be improved, adhesion is not easy, meanwhile offensive wood odor and other bad smells are basically eliminated, and the tobacco sheet has ginseng aroma.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com