Simple one-way breathing valve plate

A breathing valve, a simple technology, applied in safety valves, balance valves, valve devices, etc., can solve problems such as valve port adhesion, achieve the effect of overcoming valve port adhesion, achieving unidirectionality, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

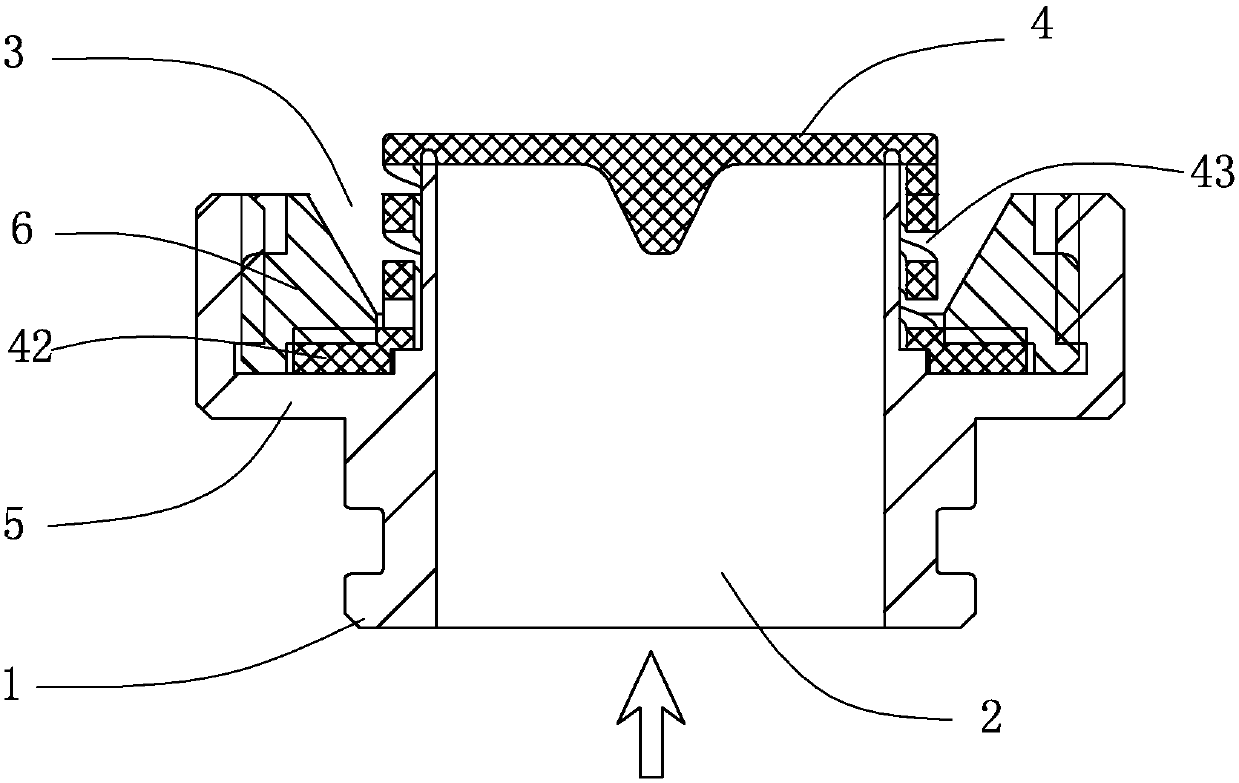

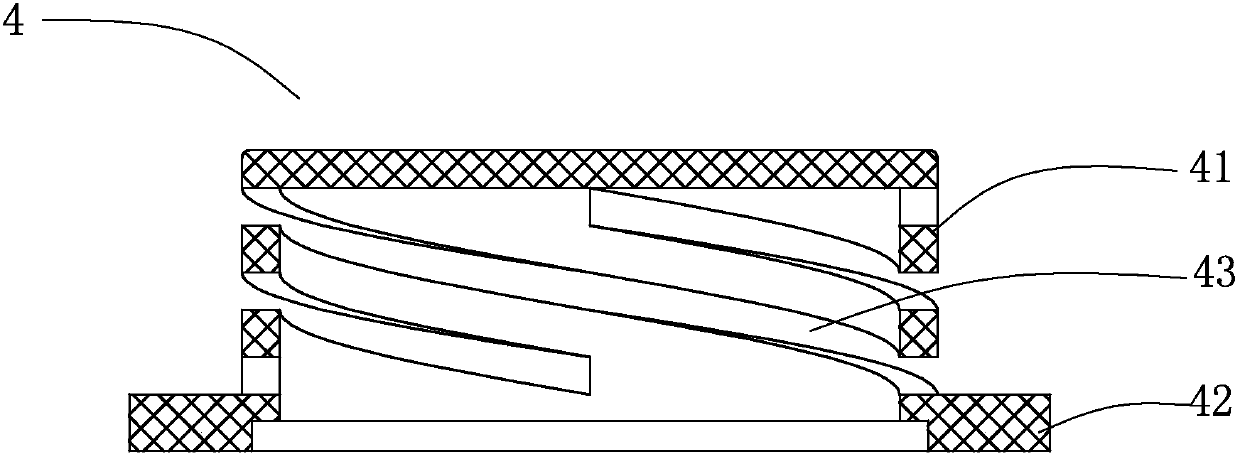

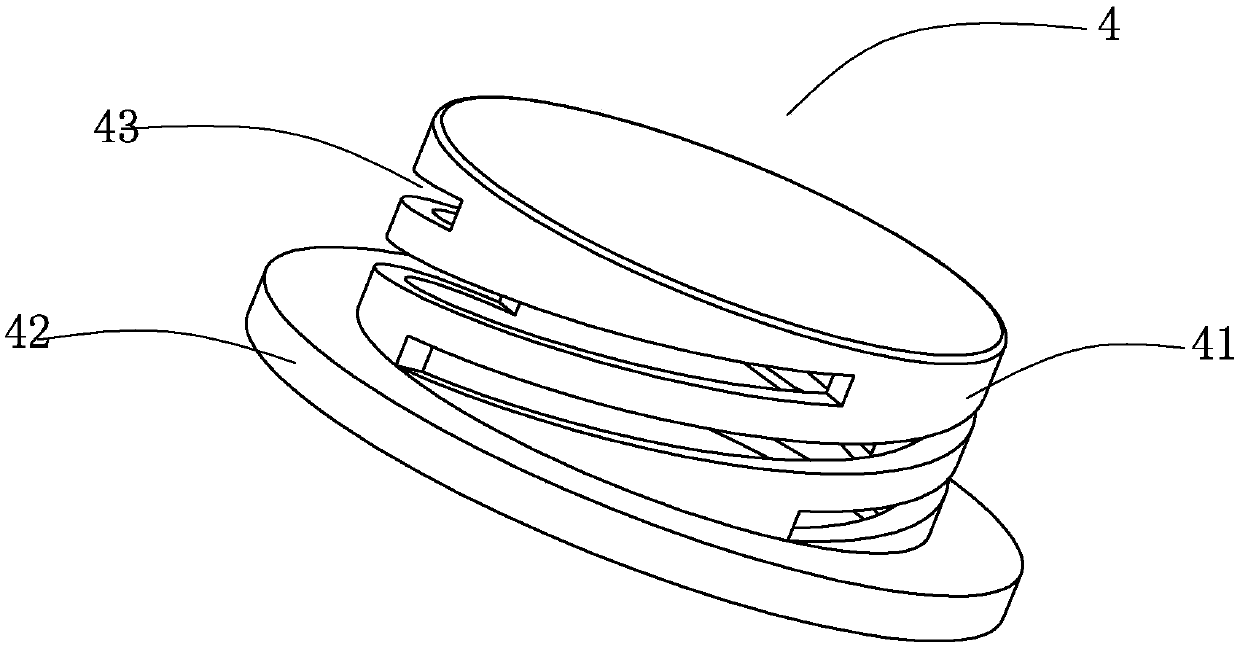

[0010] like figure 1 , figure 2 , image 3 As shown, a simple one-way breathing valve plate provided by the present invention includes a valve seat 1, the valve seat 1 is provided with a valve chamber 2 and a valve port 3, and the valve port 3 is provided with a valve plate 4; the valve plate 4 It includes a cylindrical body 41 with a sealed upper end and an open lower end. The periphery of the lower end opening of the cylindrical body 41 is provided with an annular flange 42 with a diameter larger than that of the cylindrical body. The wall of the cylindrical body is provided with a spiral Shaped air vent 43; the inner diameter of the valve port 3 of the valve seat 1 is larger than the inner diameter of the valve cavity 2, and an annular step 5 is formed at the connection between the valve port 3 and the valve cavity 2, and the annular flange of the valve plate 4 42 is located on the step 5, and an annular valve cover 6 is screwed to the inner wall of the valve port throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com