One-way ventilation valve for anesthesia respirator

A technology for one-way ventilation valves and ventilators, which is applied in the direction of control valves, valve devices, mechanical equipment, etc., and can solve problems such as valve port adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

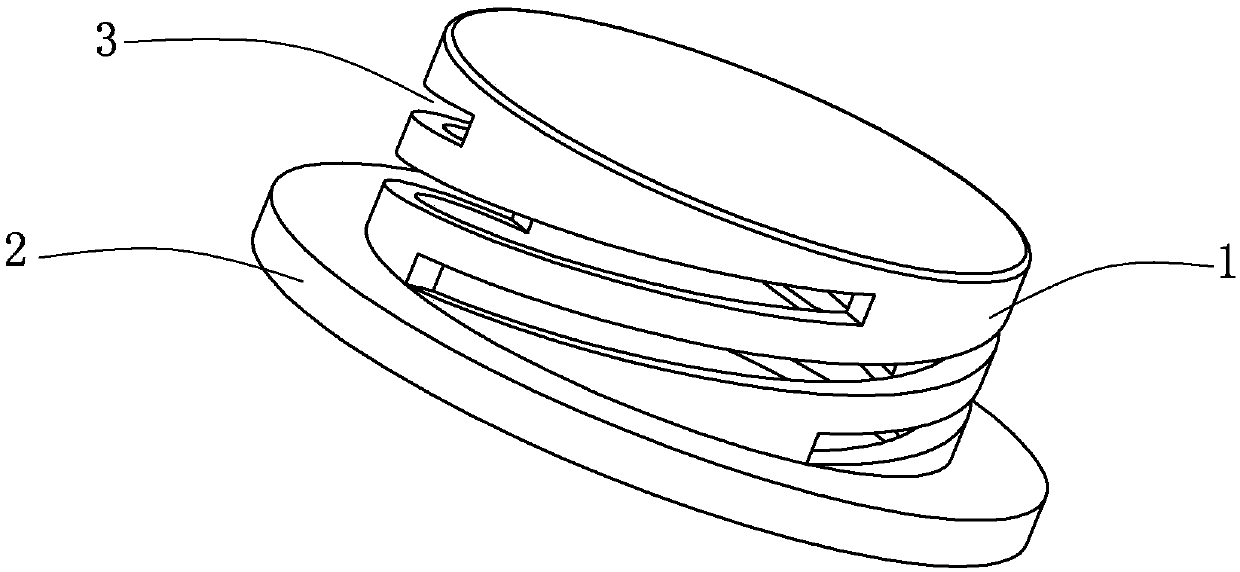

[0009] Such as figure 1 As shown, the present invention includes a valve plate, the valve plate includes a cylindrical body 1 with a sealed upper end and an open lower end, and an annular flange with a diameter larger than the diameter of the cylindrical body is provided on the periphery of the lower end opening of the cylindrical body 1 2. A spiral vent 3 is provided on the wall of the cylinder.

[0010] When the present invention is implemented, the overall structure of the valve plate is made of medical rubber, which has sufficient elasticity. When there is no ventilation, the air vent on the valve plate is in a naturally closed state.

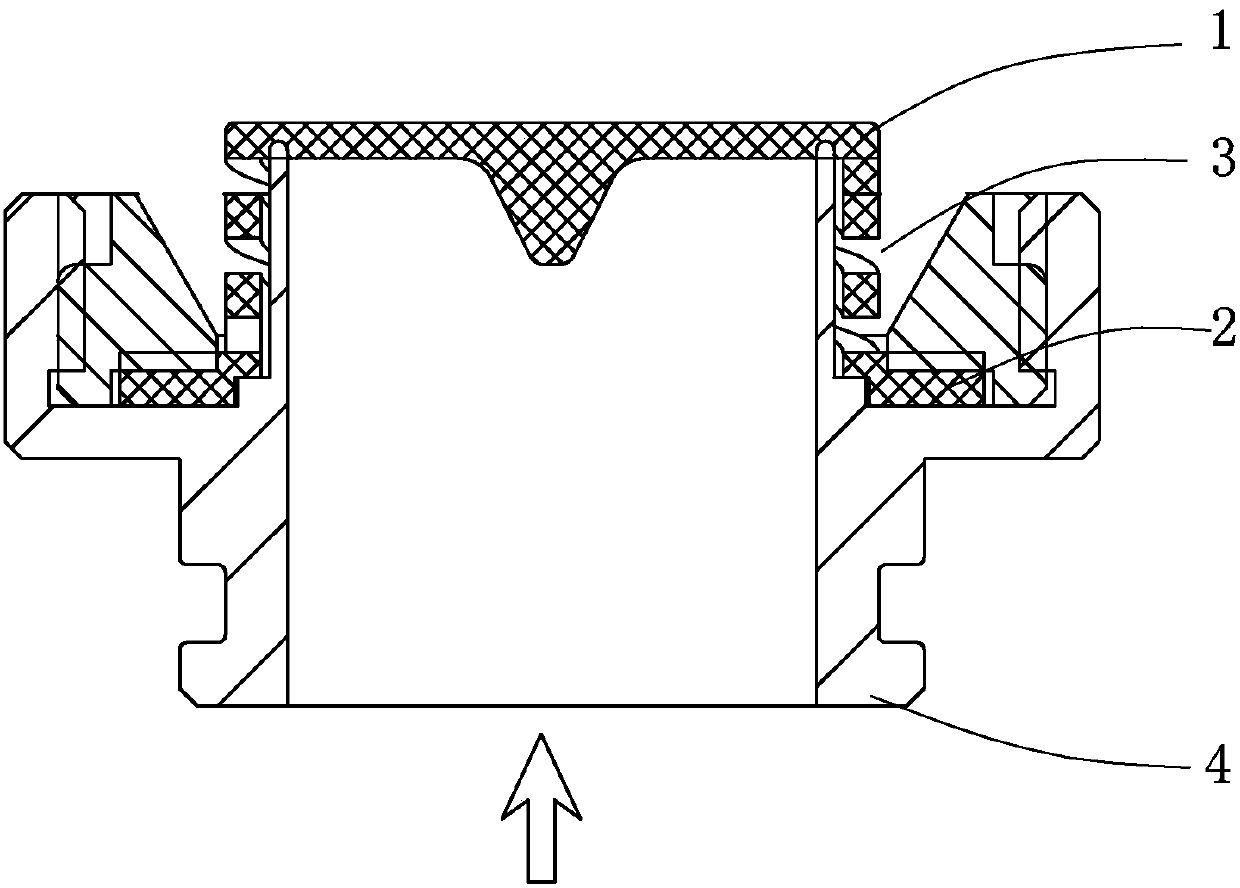

[0011] Such as figure 2 Shown, the present invention is installed on a valve seat 4 when in use, when along figure 1 When the direction of the middle arrow is positively ventilated, the airflow pushes the valve plate upwards, the cylinder of the valve plate stretches upwards, the air port 3 is opened, and the air flow passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com