Microphone

A microphone and sound hole technology, applied in the field of microphones, can solve the problems of easy generation of echoes and whistling sounds, and mutual interference of microphones, and achieve the effect of preventing echoes and whistling sounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

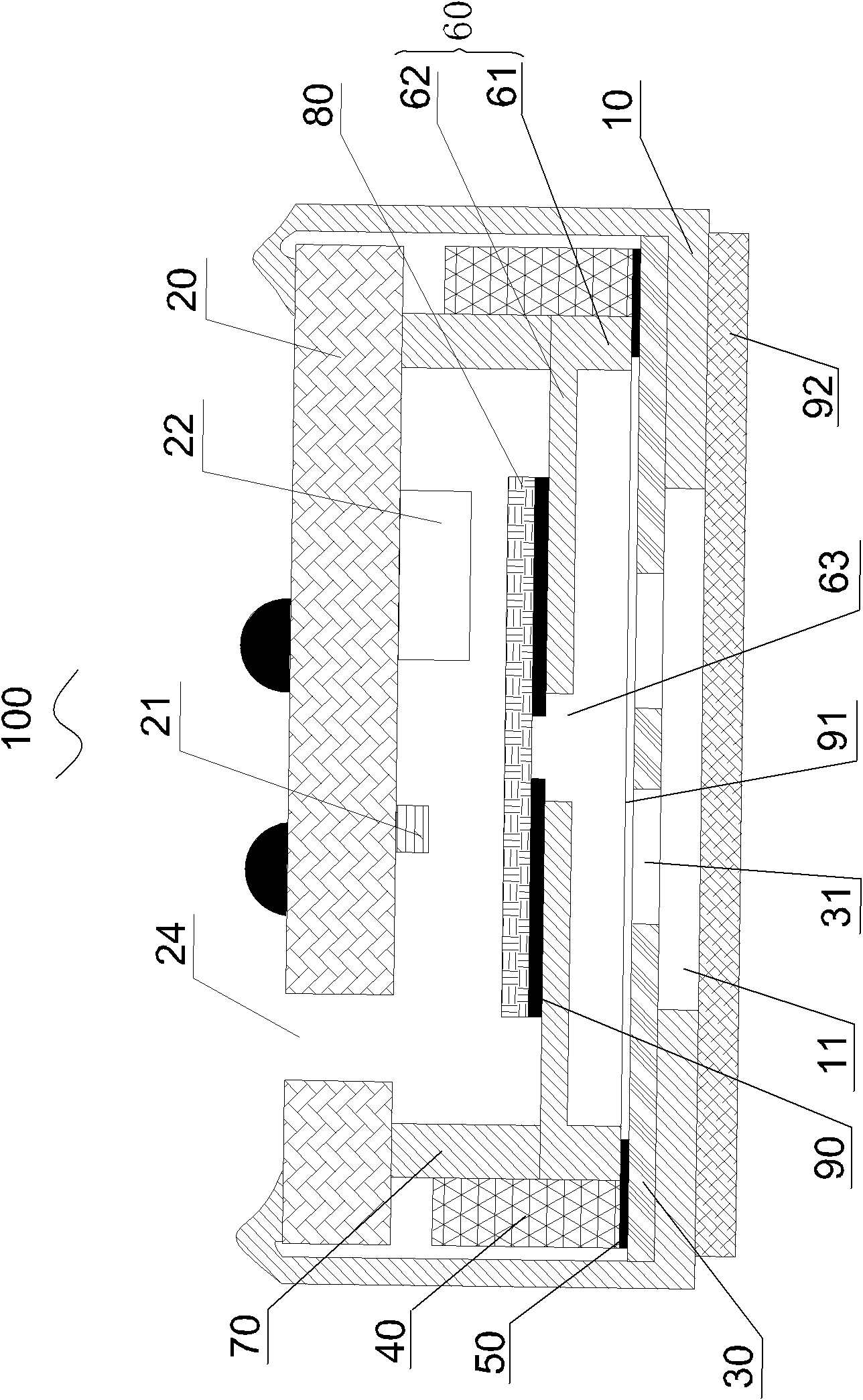

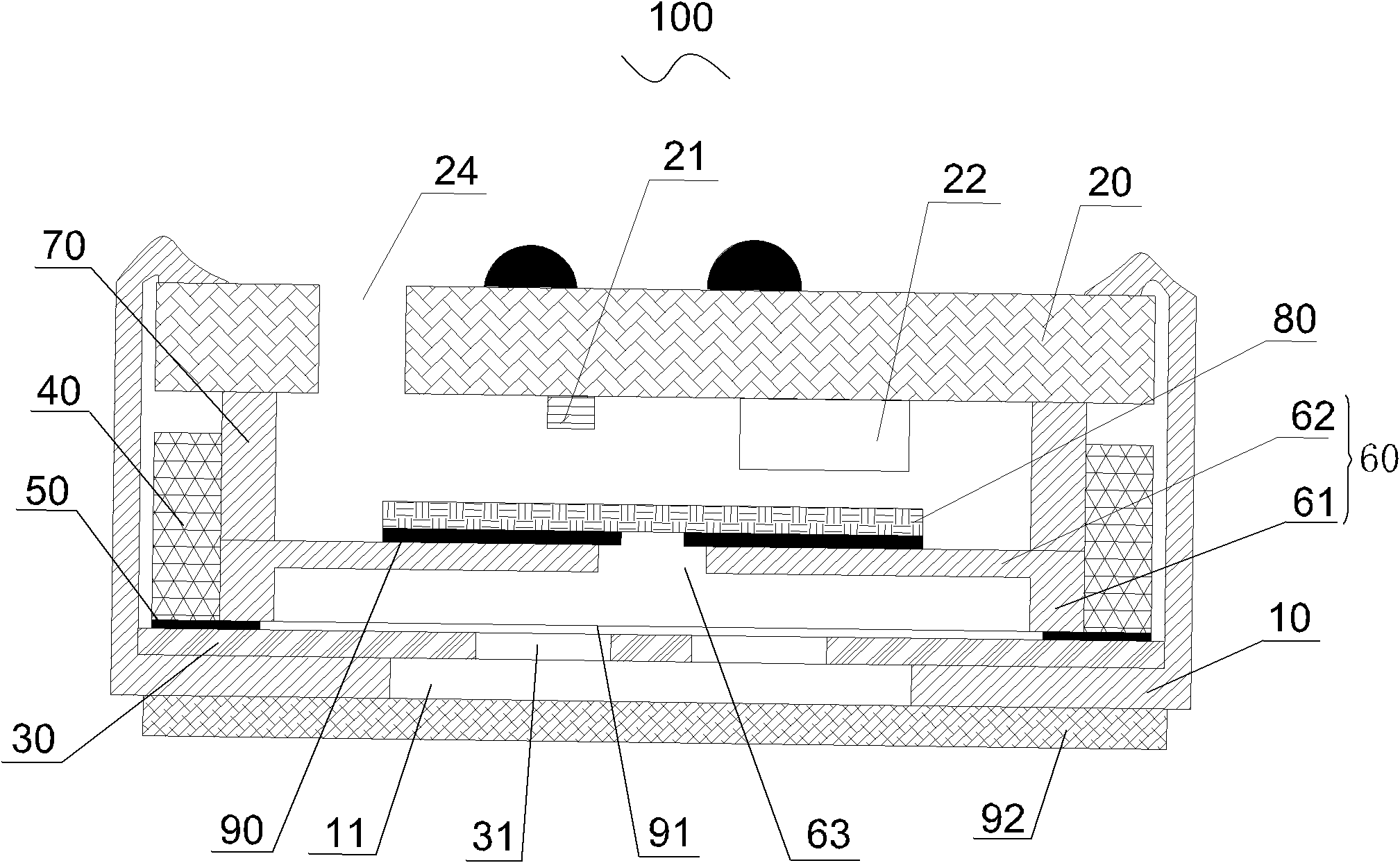

[0010] like figure 1 As shown, it is a schematic cross-sectional view of the microphone 100 in a preferred embodiment. The microphone 100 includes a hollow shell 10, a circuit board 20, a conductive back plate 30, a cavity 40, an insulating gasket 50, a lower copper ring 60, an upper copper ring 70, silk cloth 80, viscose 90, a diaphragm 91 and Dust cloth 92.

[0011] A front sound hole 11 is opened on the front wall of the housing 10 .

[0012] The circuit board 20 is disposed in the casing 10 and is close to the rear wall of the casing 10 . The circuit board 20 is provided with radio frequency capacitors 21, FET22 and other components. A rear sound inlet hole 24 is also provided on the circuit board 20 to realize the unidirectionality of sound.

[0013] The conductive back plate 30 is disposed in the housing 10 and located on the inner surface of the front wall of the housing 10 . A plurality of back pole sound entrance holes 31 are evenly opened on the conductive back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com