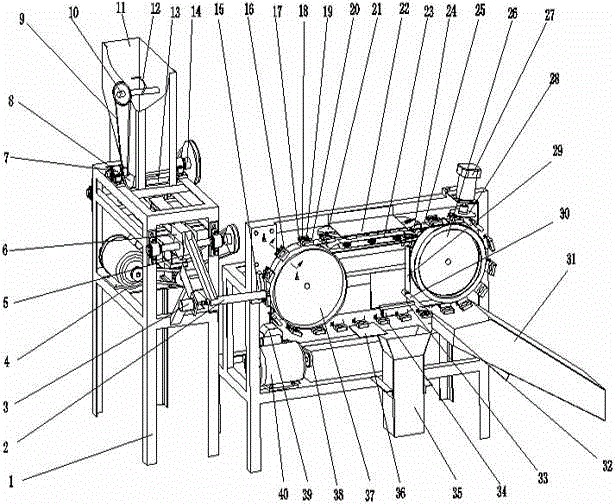

Automatic silkworm cocoon hole cutting machine and hole cutting method

A technology of silkworm cocoon and mouth cutting, applied in animal husbandry and other directions, can solve the problems such as not being well solved, unable to overcome cocoon silk adhesion, complex structure of the whole machine, etc. moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

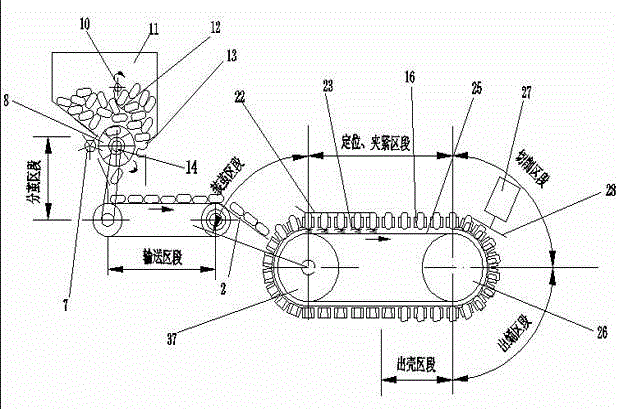

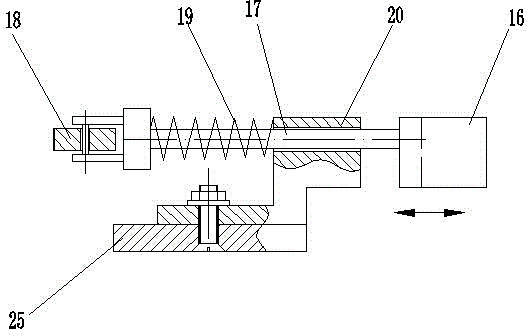

[0035] see figure 1 , 2 , 3, the present invention has a hopper 11, and the hopper 11 is on the upper left of the frame 1. Silkworm cocoons are placed in the hopper 11. A stirring shaft 10 is installed in the hopper 11, and three flexible stirring bars 12 are installed on the stirring shaft 10. The bottom of the hopper 11 is an opening, and directly below the bottom opening is a cocoon-distributing disk 8 , which is coaxially and fixedly sleeved on the rotating shaft 14 . In the lower left side of the frame 1, the cocoon-losing motor 4 is installed, and the cocoon-losing motor 4 is fixed on the frame 1. The cocoon transporting motor 4 is connected to the rotating shaft 14 through a belt pulley, and the cocoon transporting motor 4 drives the rotating shaft 14 to rotate so as to drive the cocoon dividing disk 8 to rotate. The cocoon transporting motor 4 is also connected to the stirring shaft 10 through another belt pulley to drive the stirring shaft 10 to rotate.

[0036] s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com