Patents

Literature

30results about How to "Push in accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

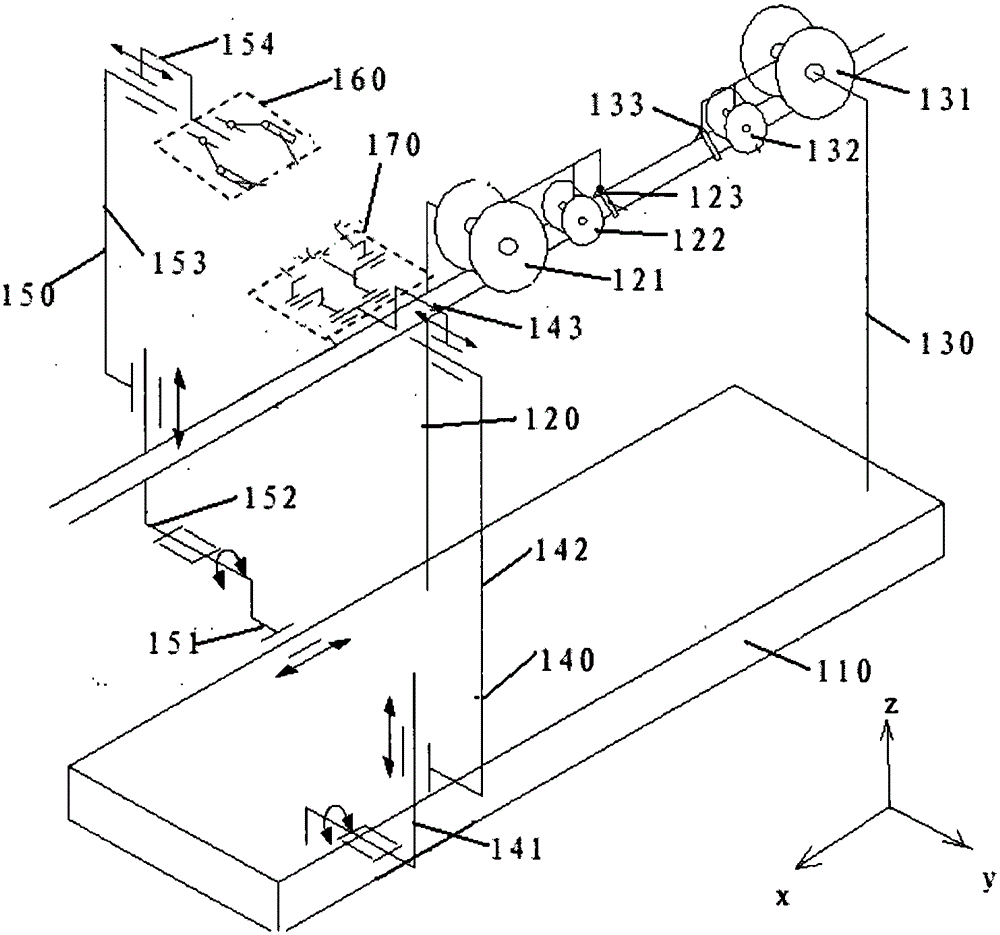

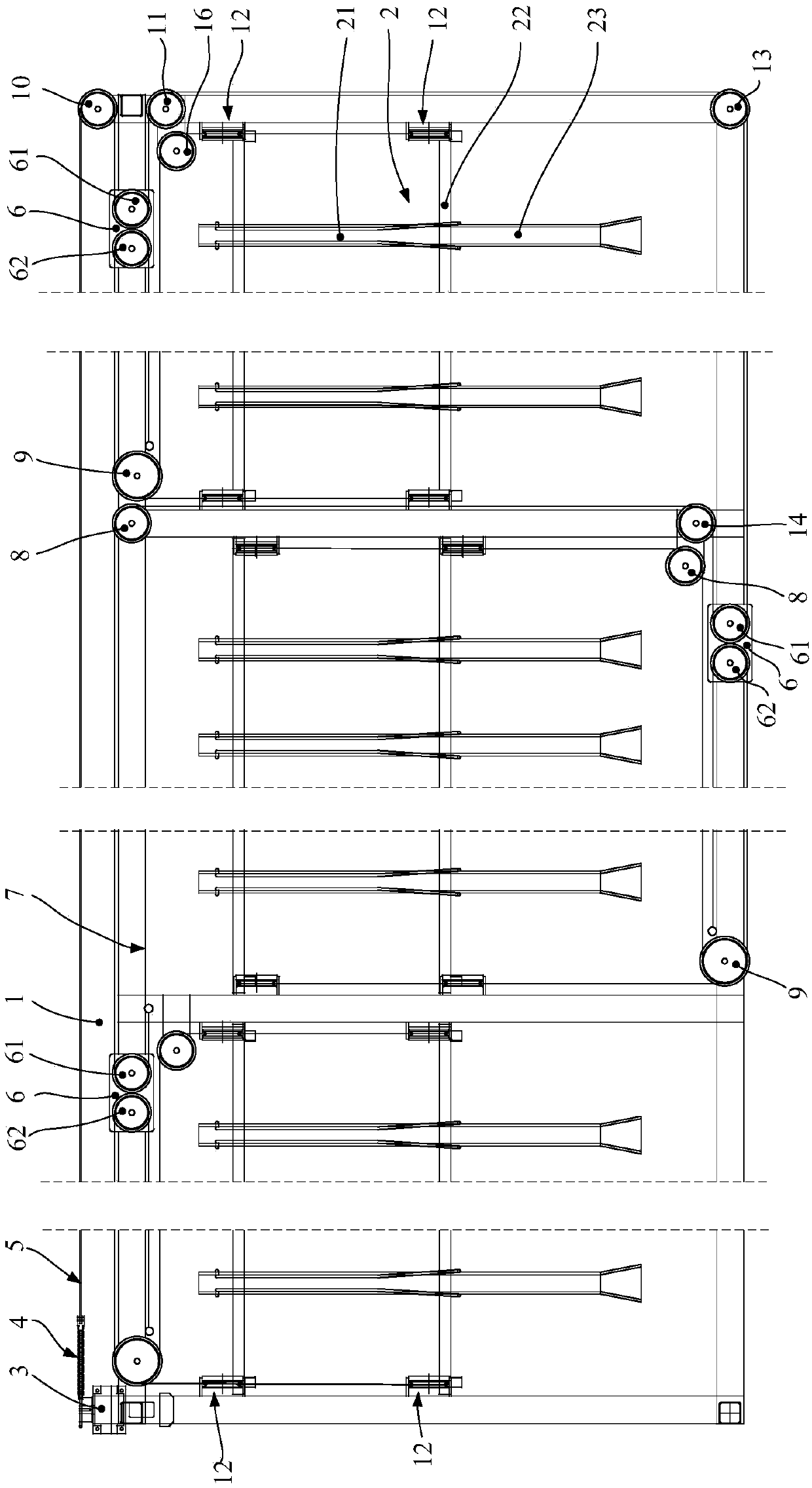

Automatic silkworm cocoon hole cutting machine and hole cutting method

ActiveCN104642270AUniform and reliable separationUniform and reliable movementAnimal husbandryEngineeringConveyor belt

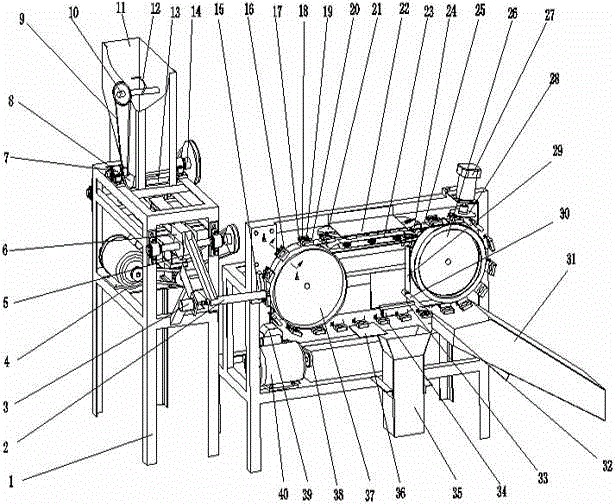

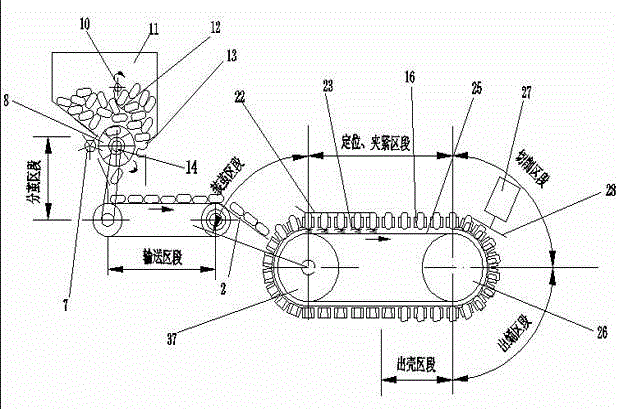

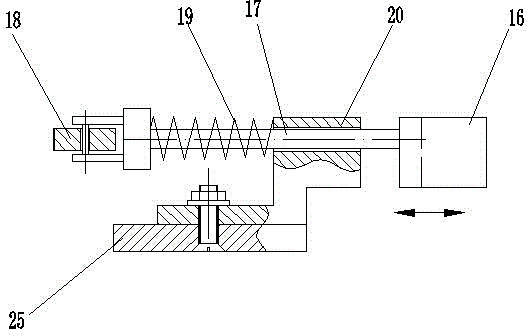

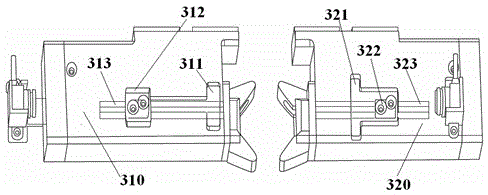

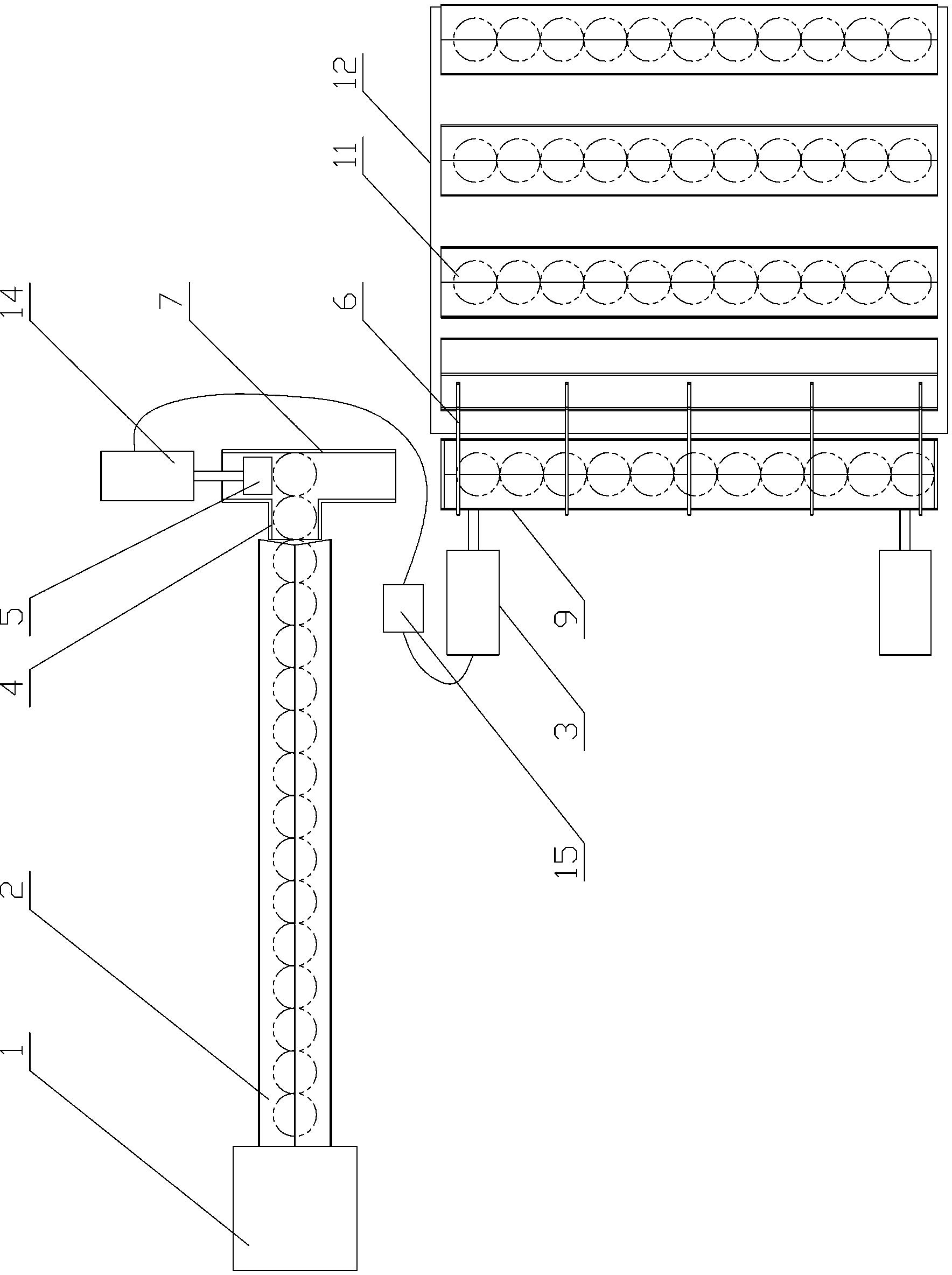

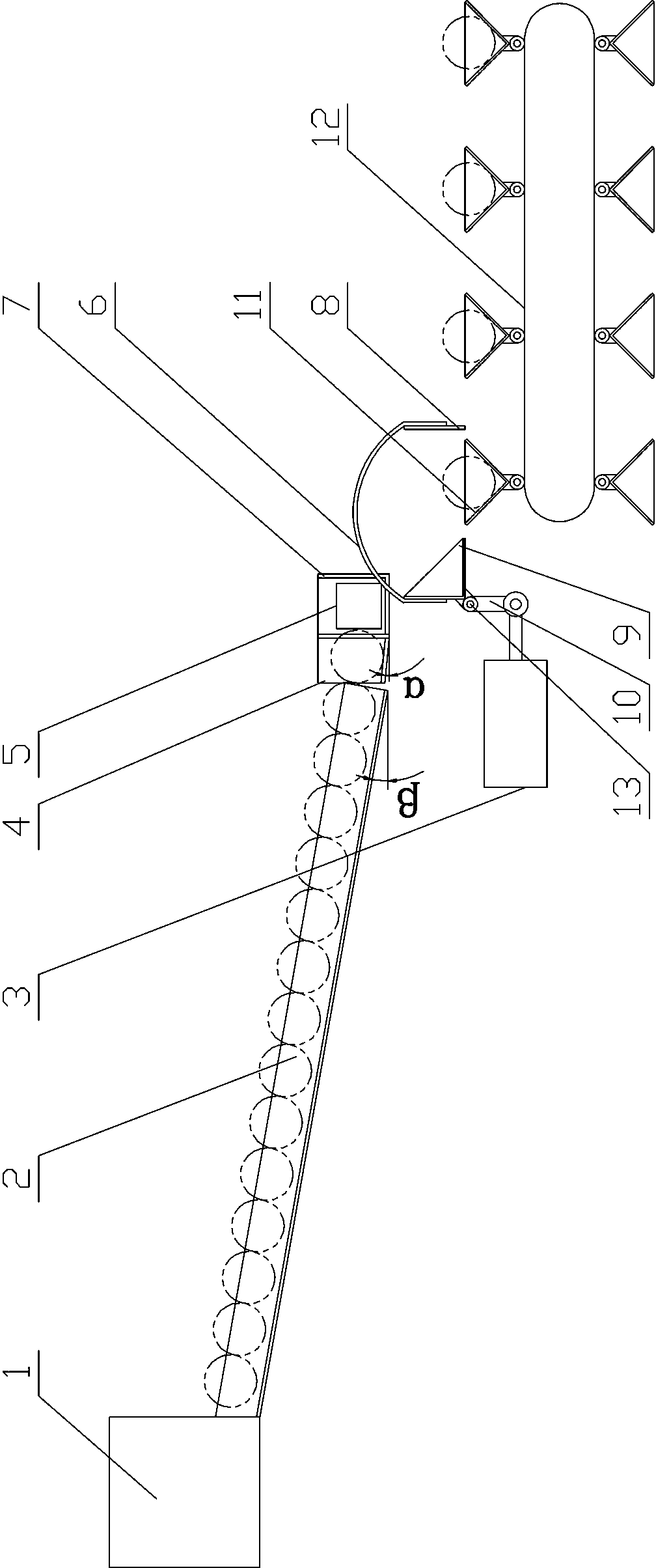

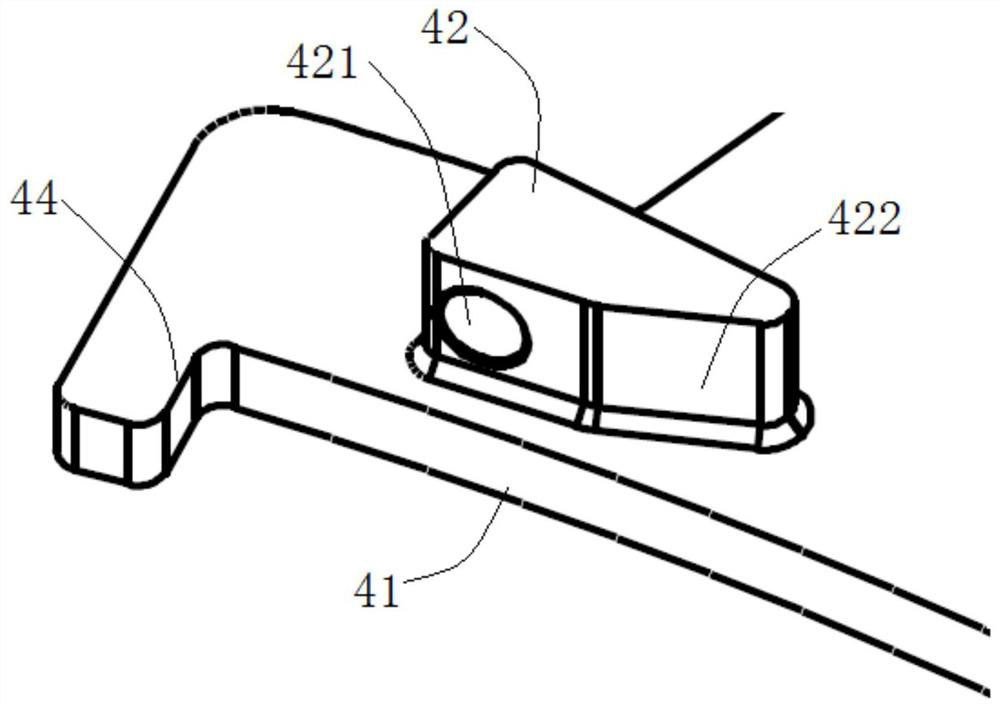

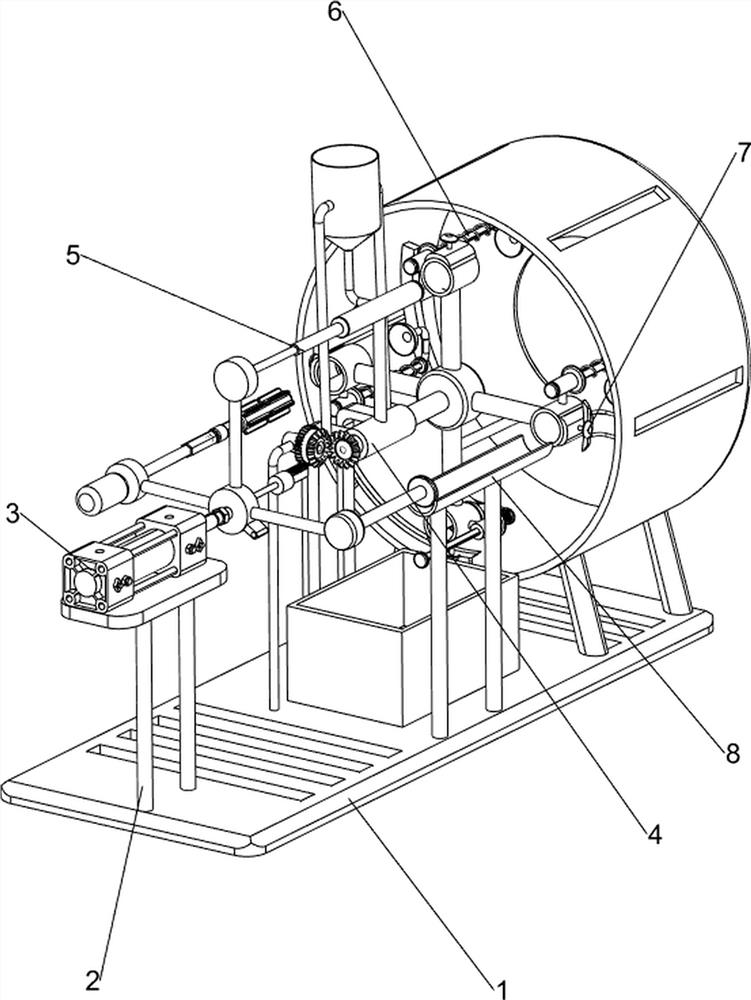

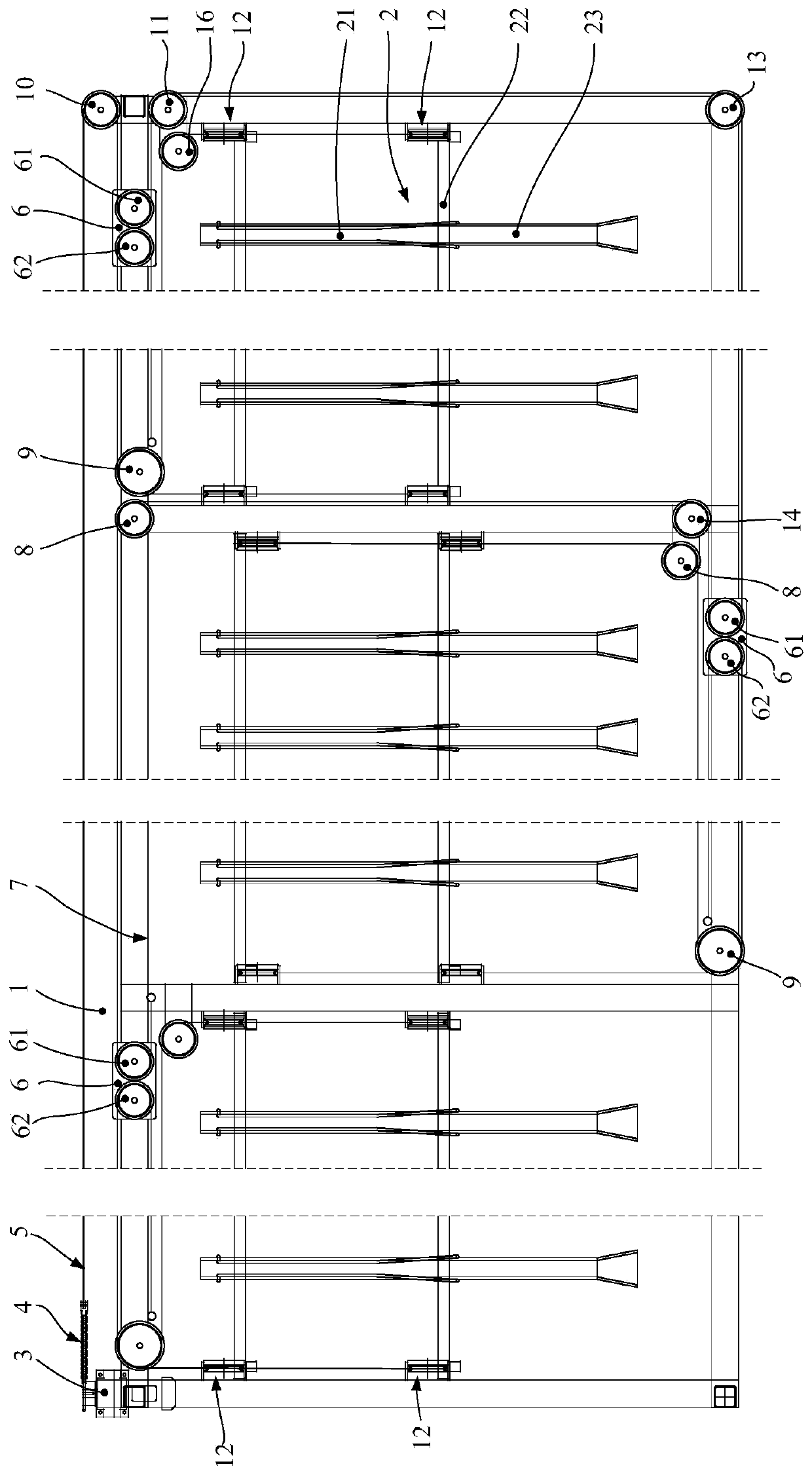

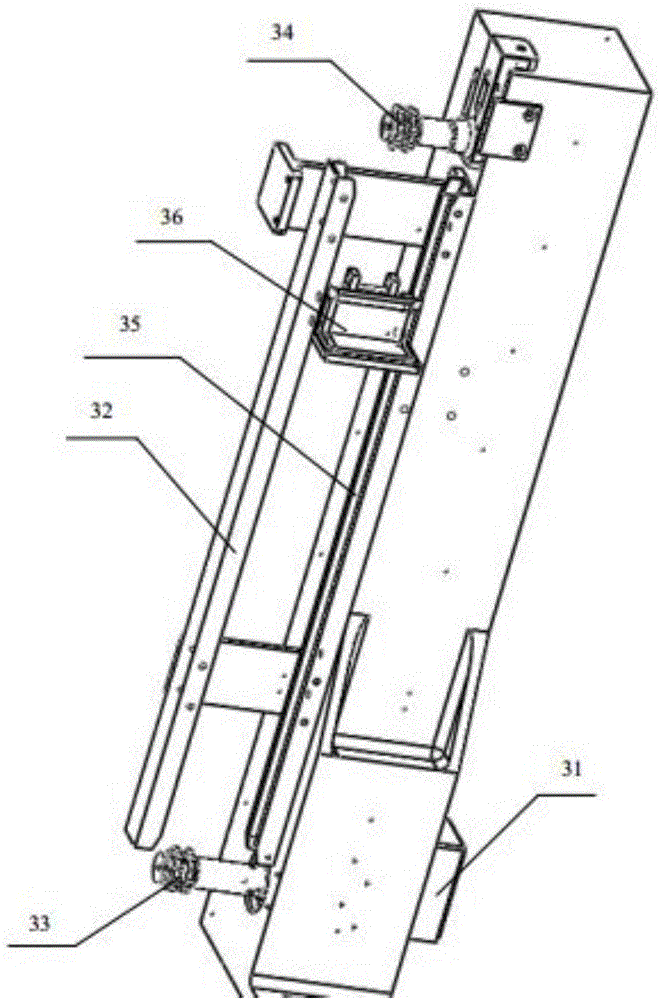

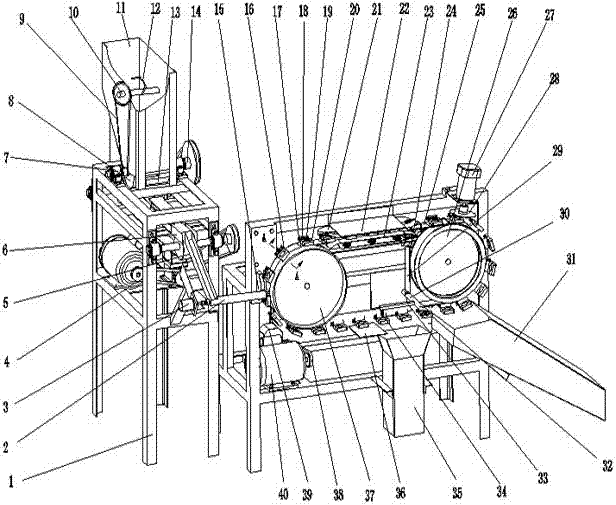

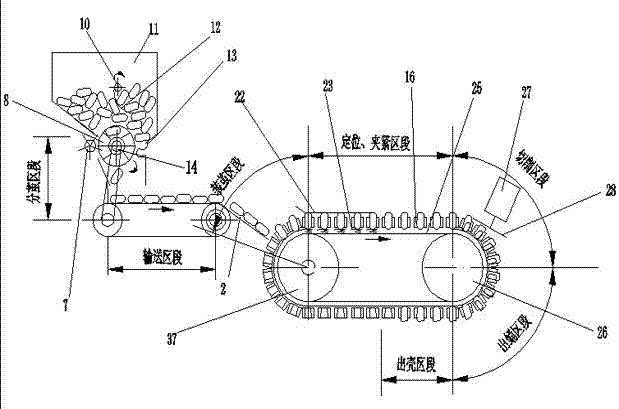

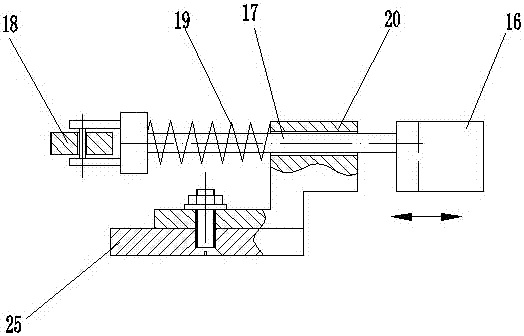

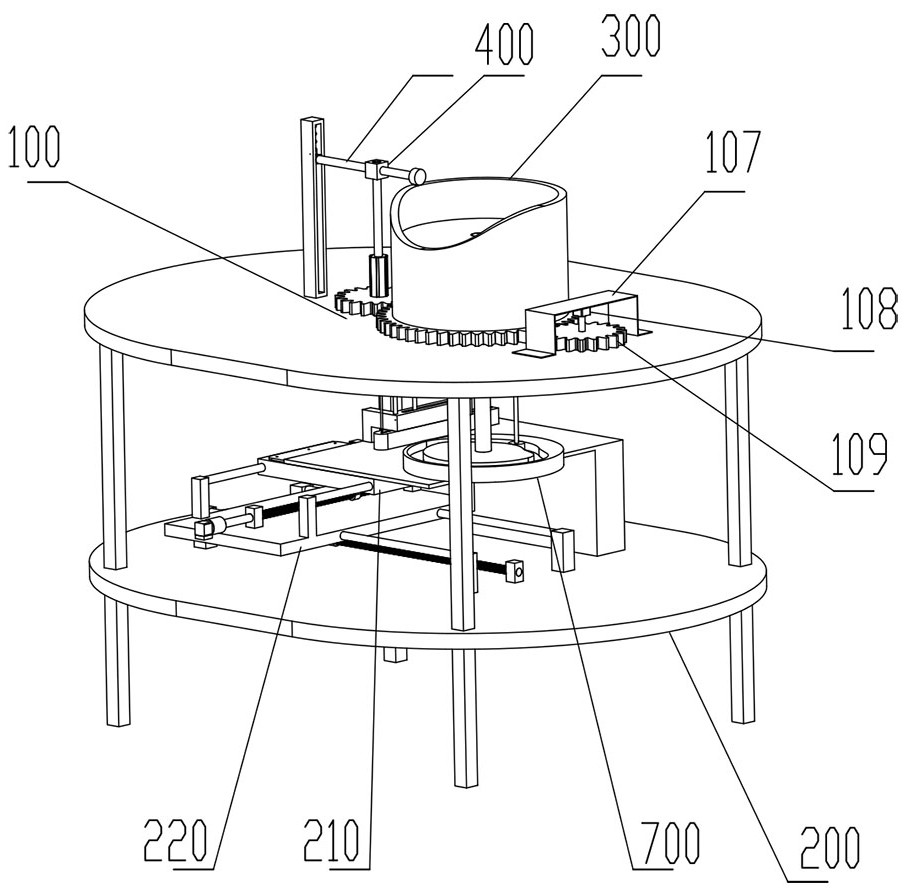

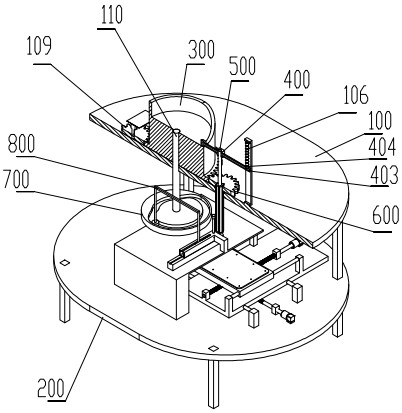

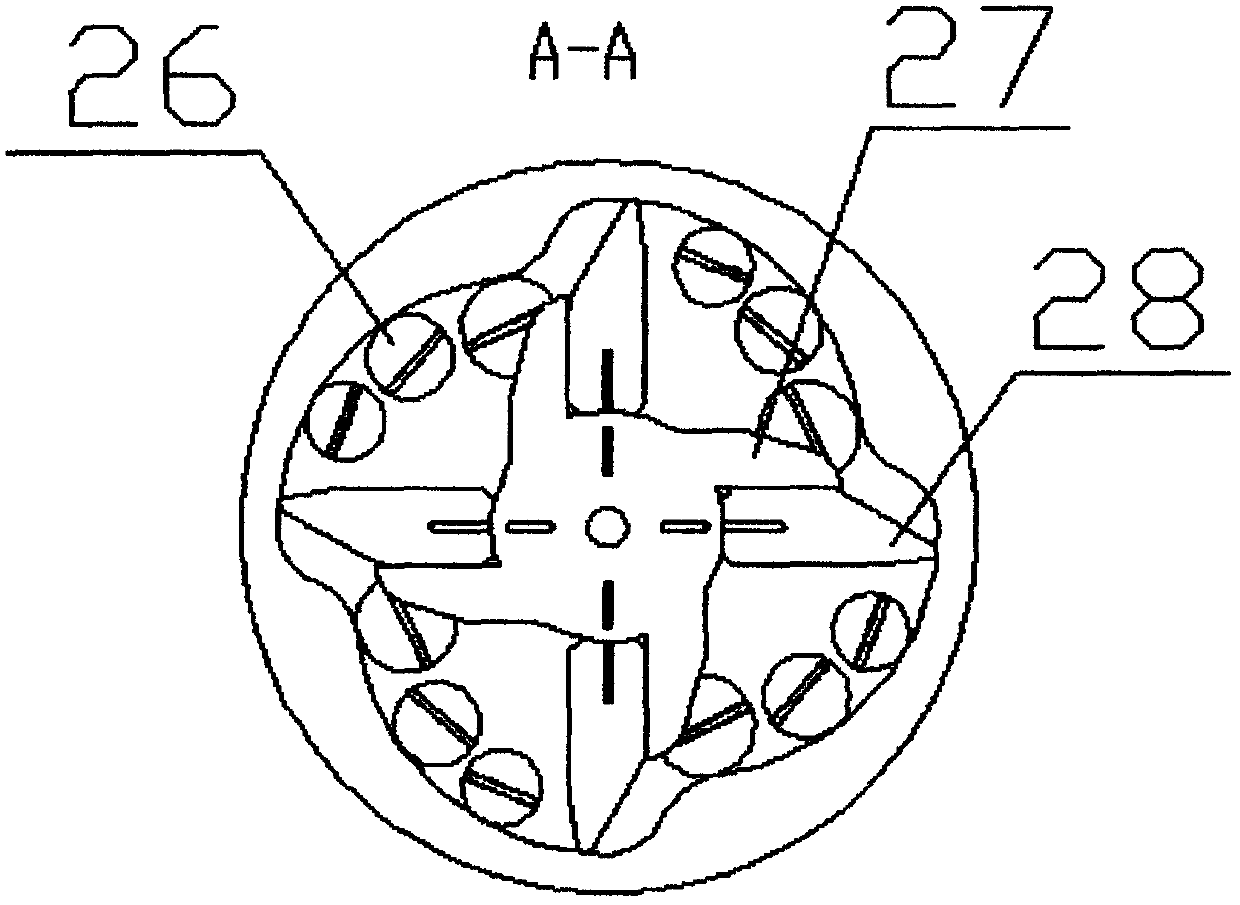

The invention discloses an automatic silkworm cocoon hole cutting machine and a hole cutting method, the radial direction of a disk surface of a cocoon separating disk is provided with 2 rectangular slots that are symmetrical along the center of the cocoon separating disk, a horizontal cocoon conveying belt is positioned below the cocoon separating disk, the left end of the cocoon conveying belt is positioned under the cocoon separating disk, the right end of the cocoon conveying belt is tightly connected with the left end of a cocoon conveying passage, a cocoon pushing mechanism is arranged at an upper right position of the cocoon conveying passage, and a photosensitive sensor is installed on the cocoon pushing mechanism; a conveyor belt, an active roller wheel and a passive roller wheel are arranged on the right side of the cocoon conveying passage, a fixture component is fixedly connected on the conveyor belt, a positioning and clamping mechanism is arranged at a conveyor belt position between the active roller wheel and the passive roller wheel, a pushing plate that pushes the fixture to make the fixture open is positioned on the rear side of the positioning and clamping mechanism; a cutting mechanism is arranged at the upper right position of the passive roller wheel, and a cocoon shell separating mechanism is arranged on the left side of the passive roller wheel; batched and automatic hole cutting can be carried out on the silkworm cocoon of different sizes, silkworm chrysalis and cocoon shells can be separated automatically, the positioning is reliable, the cocoon for egg production can not be crushed or injured due to cutting, the cocoon cutting quality is good, and the efficiency is high.

Owner:JIANGSU UNIV OF SCI & TECH

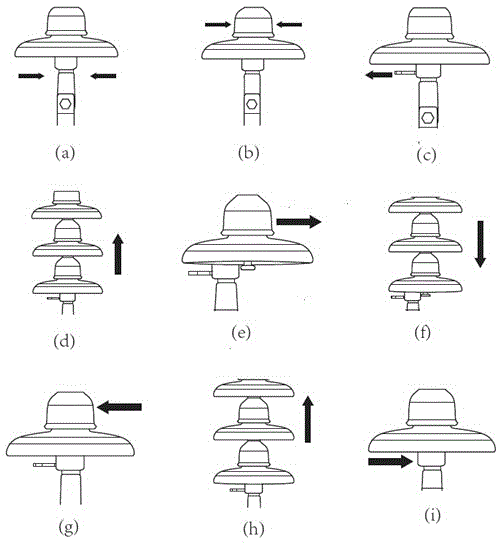

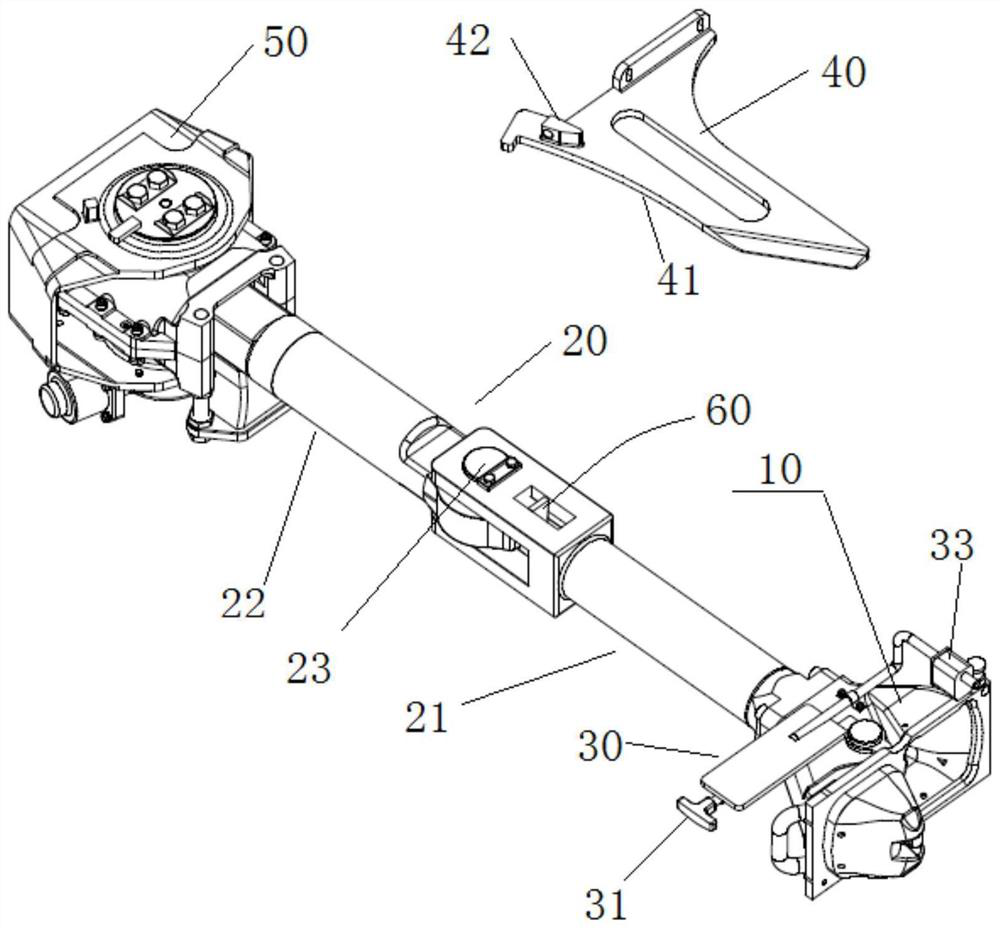

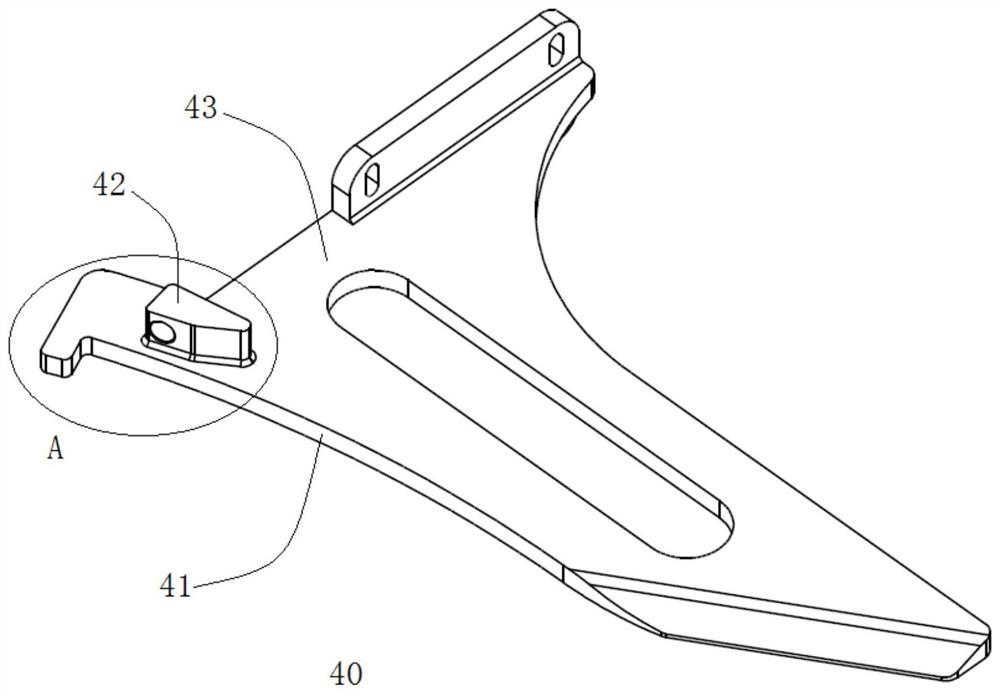

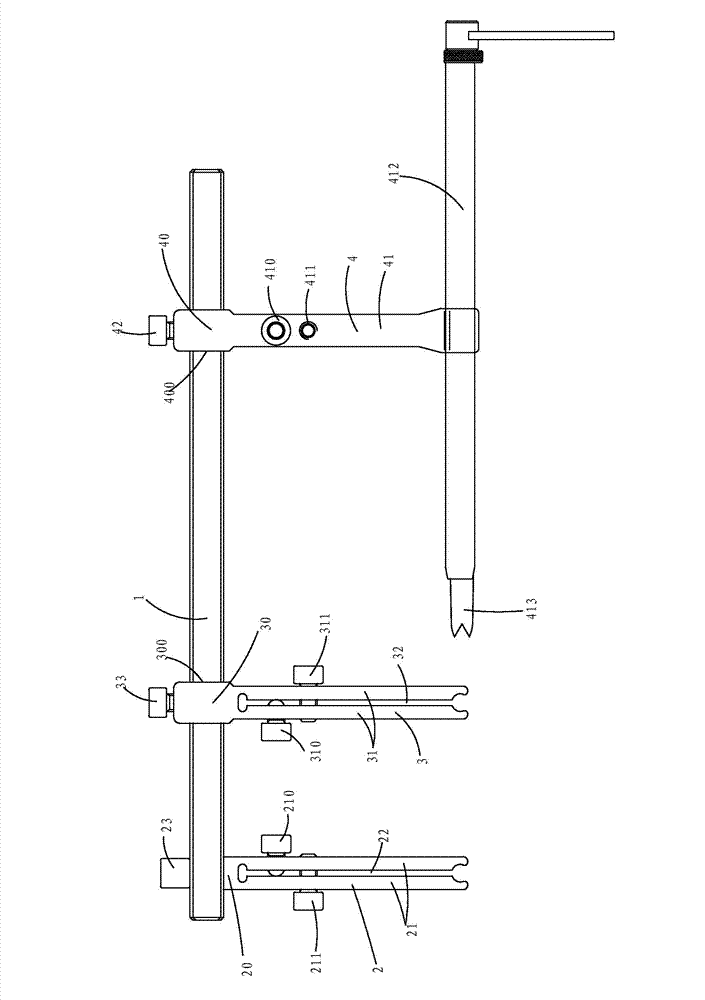

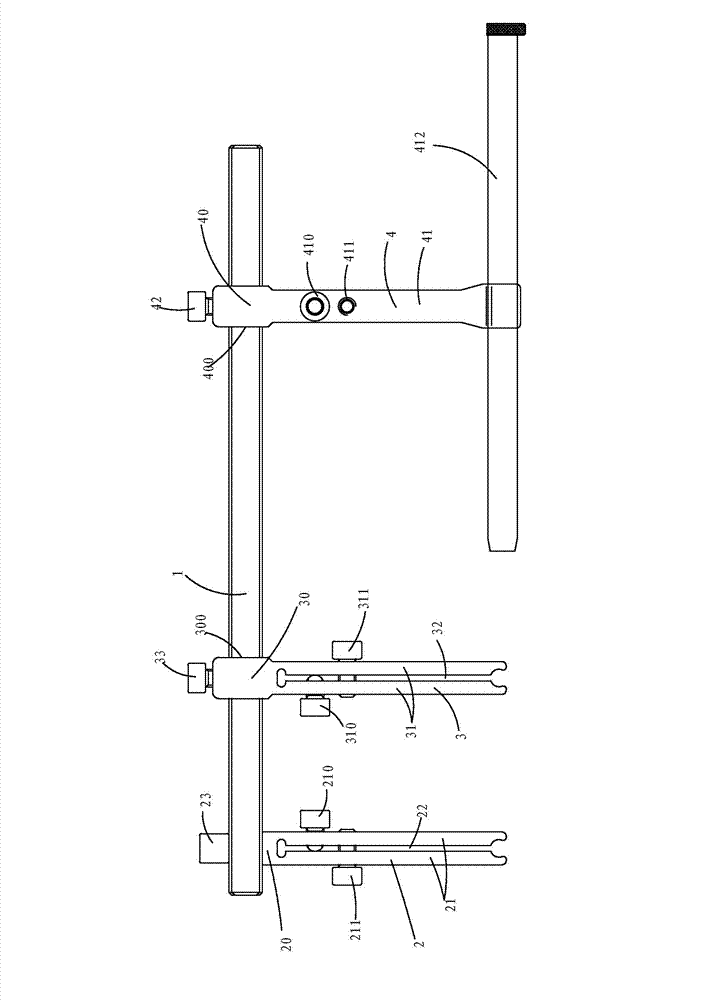

Insulator string replacement assembly and insulator string replacement method

ActiveCN105048338AStable clampingAccurate launchApparatus for overhead lines/cablesEngineeringReplacement method

The invention discloses an insulator string replacement assembly and an insulator string replacement method. The insulator string replacement assembly comprises a first mechanical arm, a W pin assembly and disassembly tail end, a second mechanical arm and an insulator string pushing tail end. According to the device and the method of the invention, insulator string replacement operation can be carried out in a live condition, hidden safety dangers are reduced to the minimal, the structure is simple, the operation is convenient, and popularization is facilitated.

Owner:STATE GRID HUNAN ELECTRIC POWER CO LTD MAINTENANCE CO +2

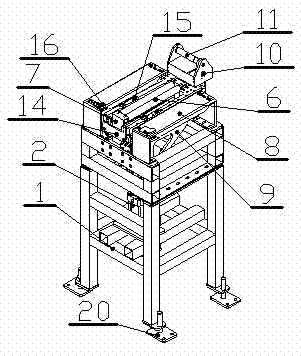

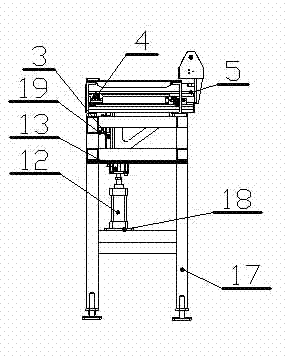

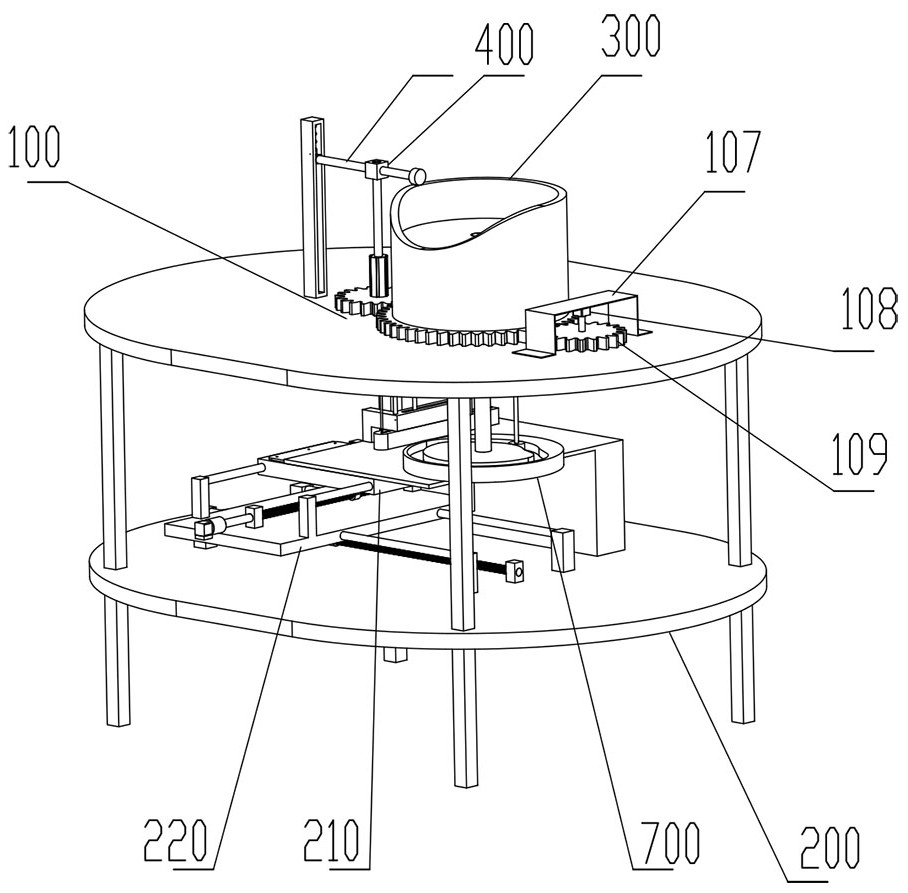

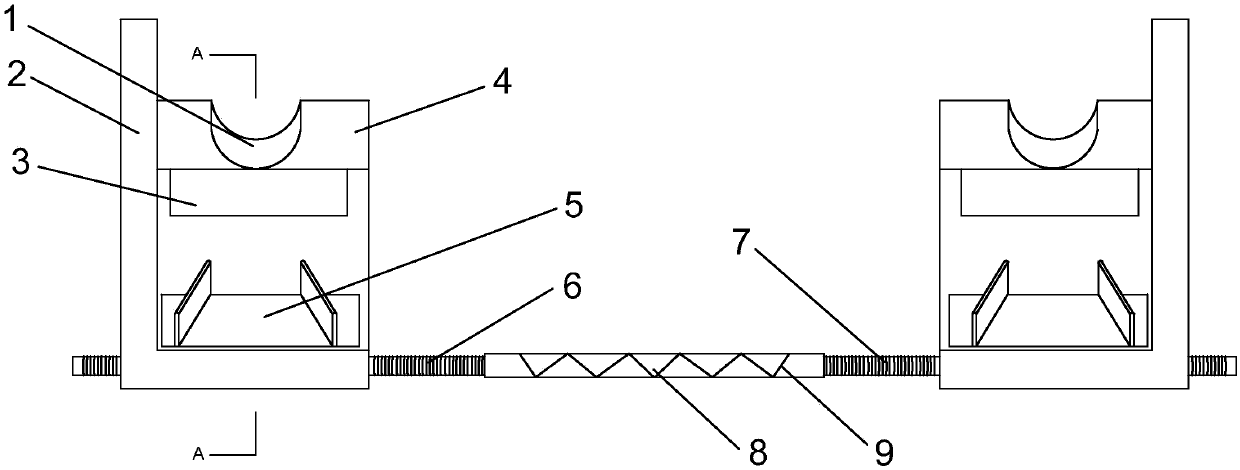

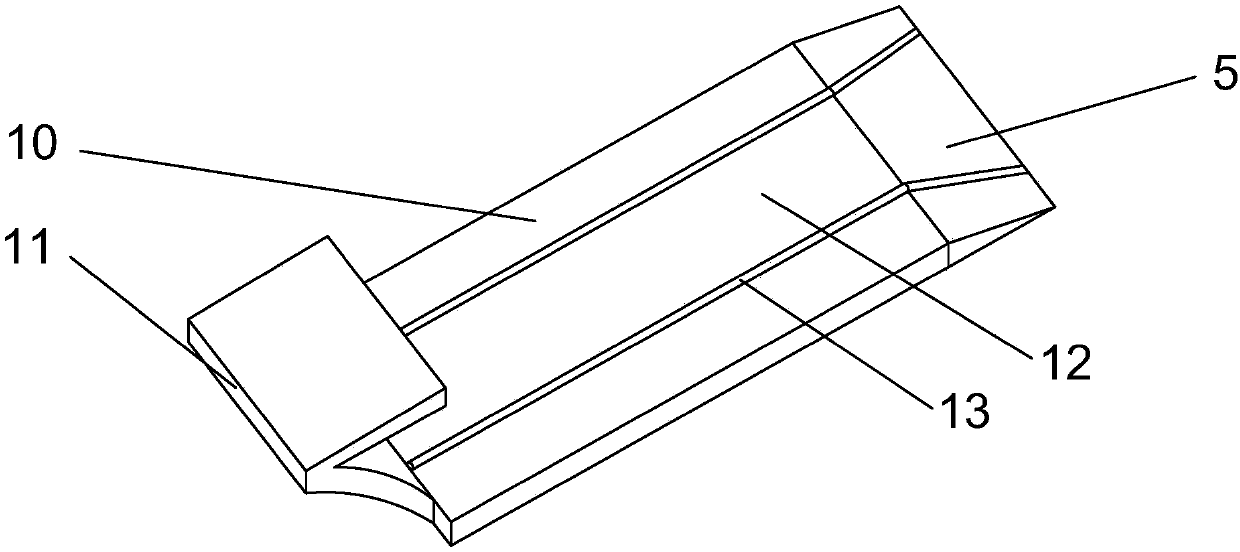

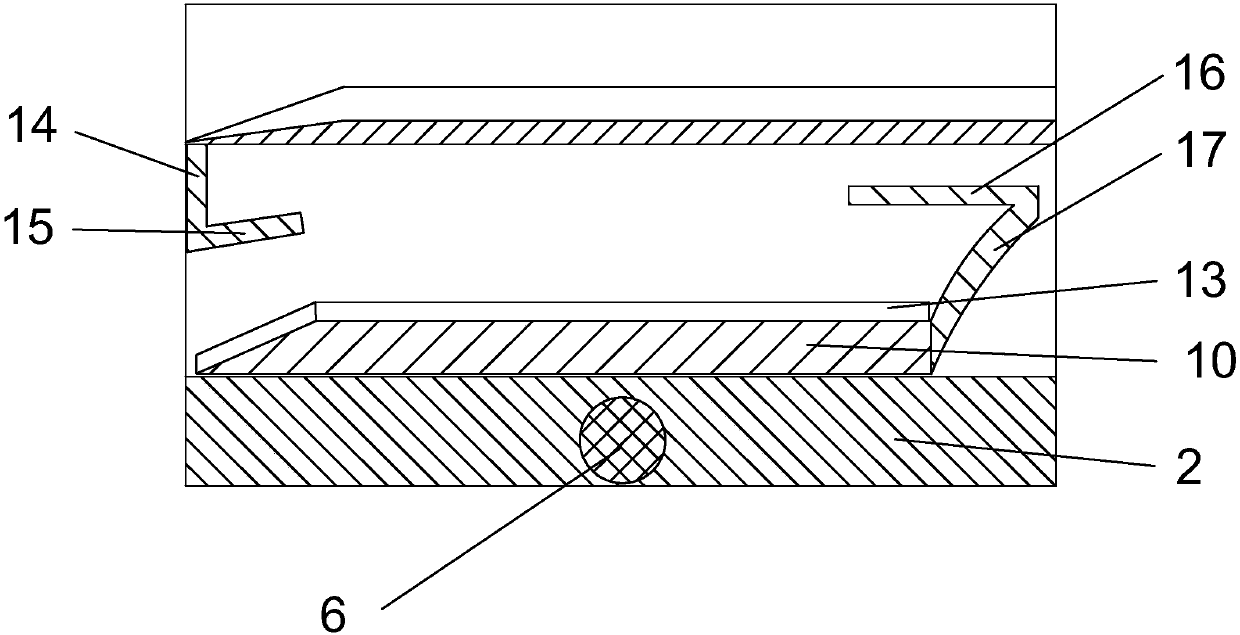

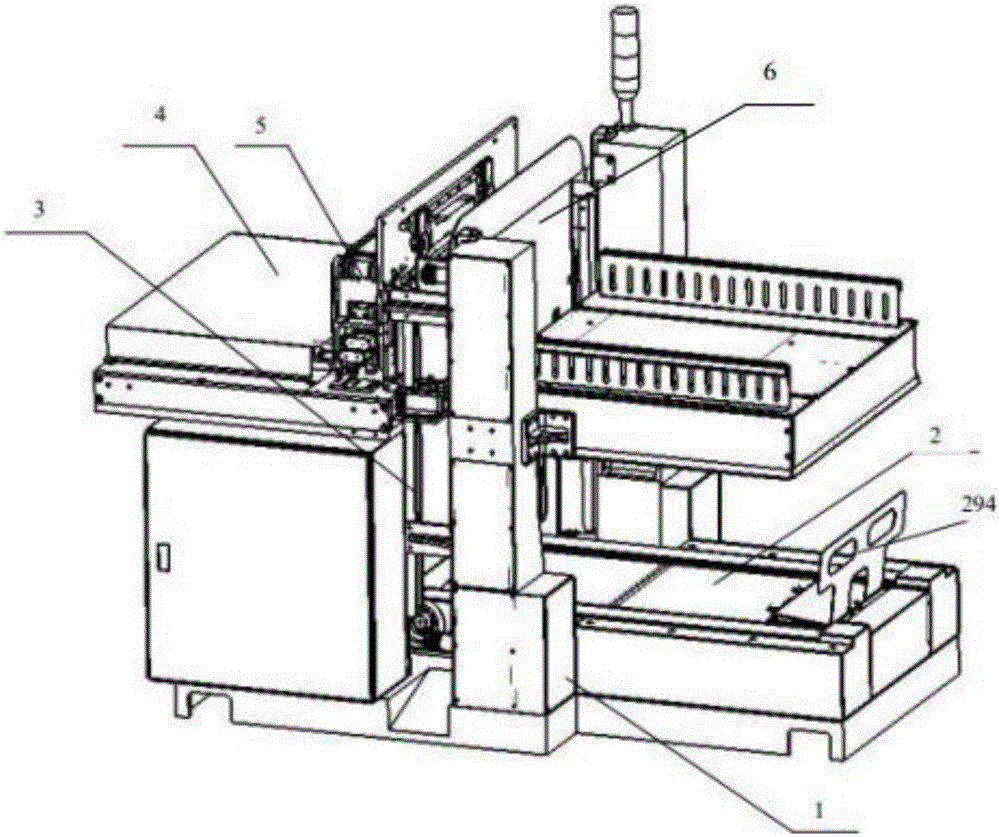

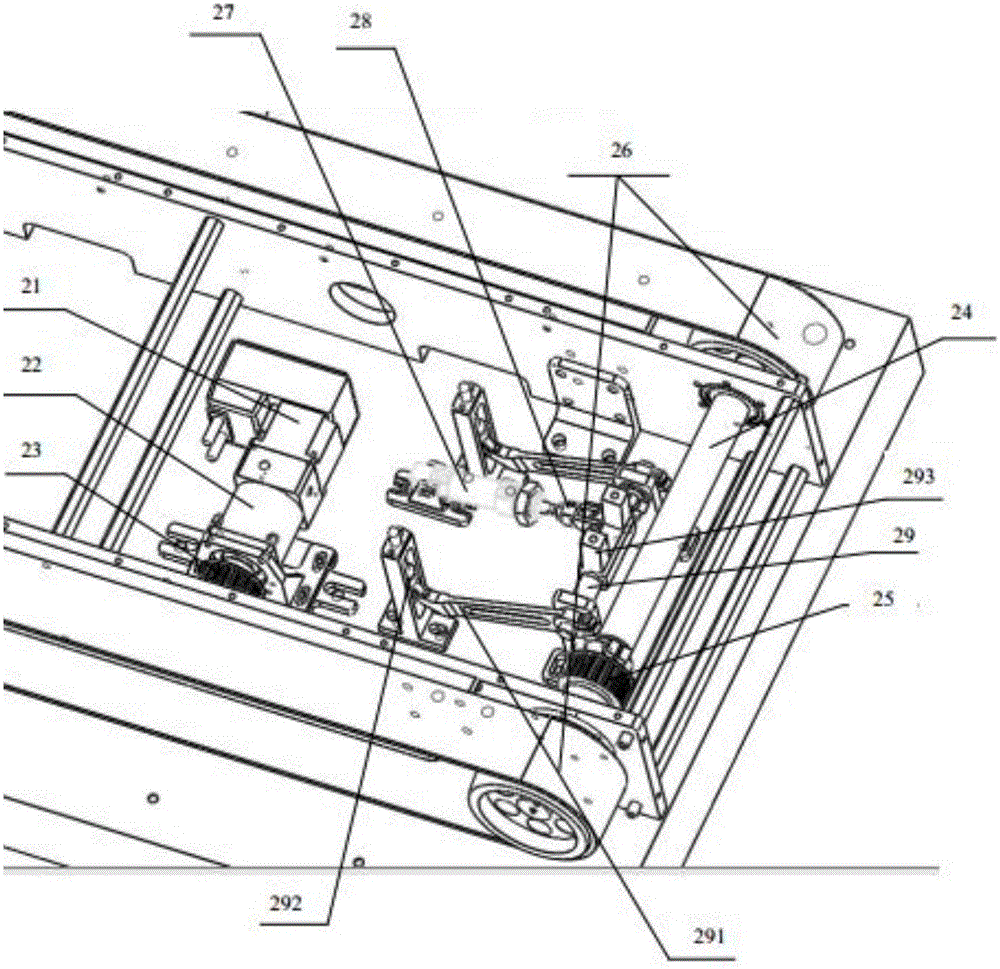

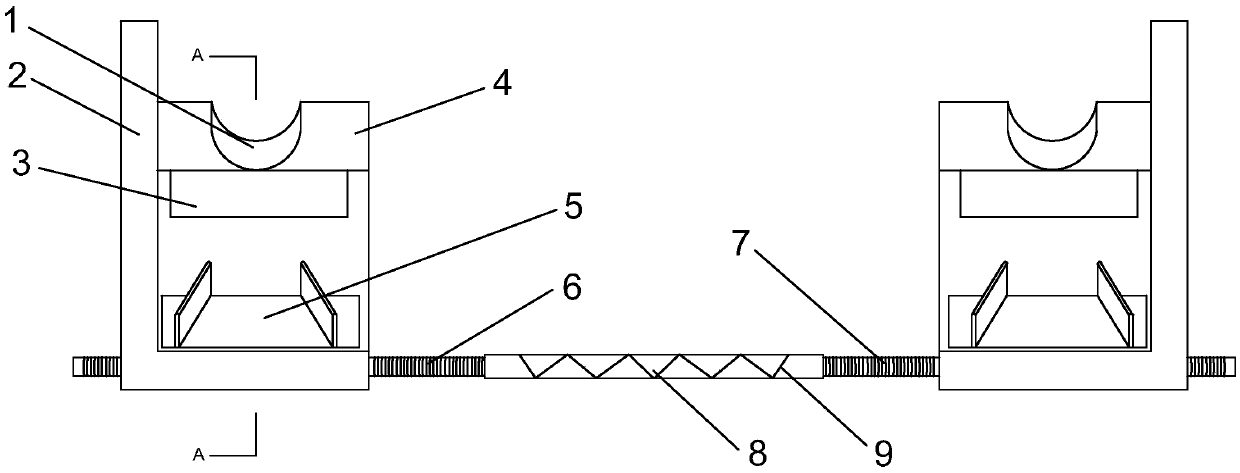

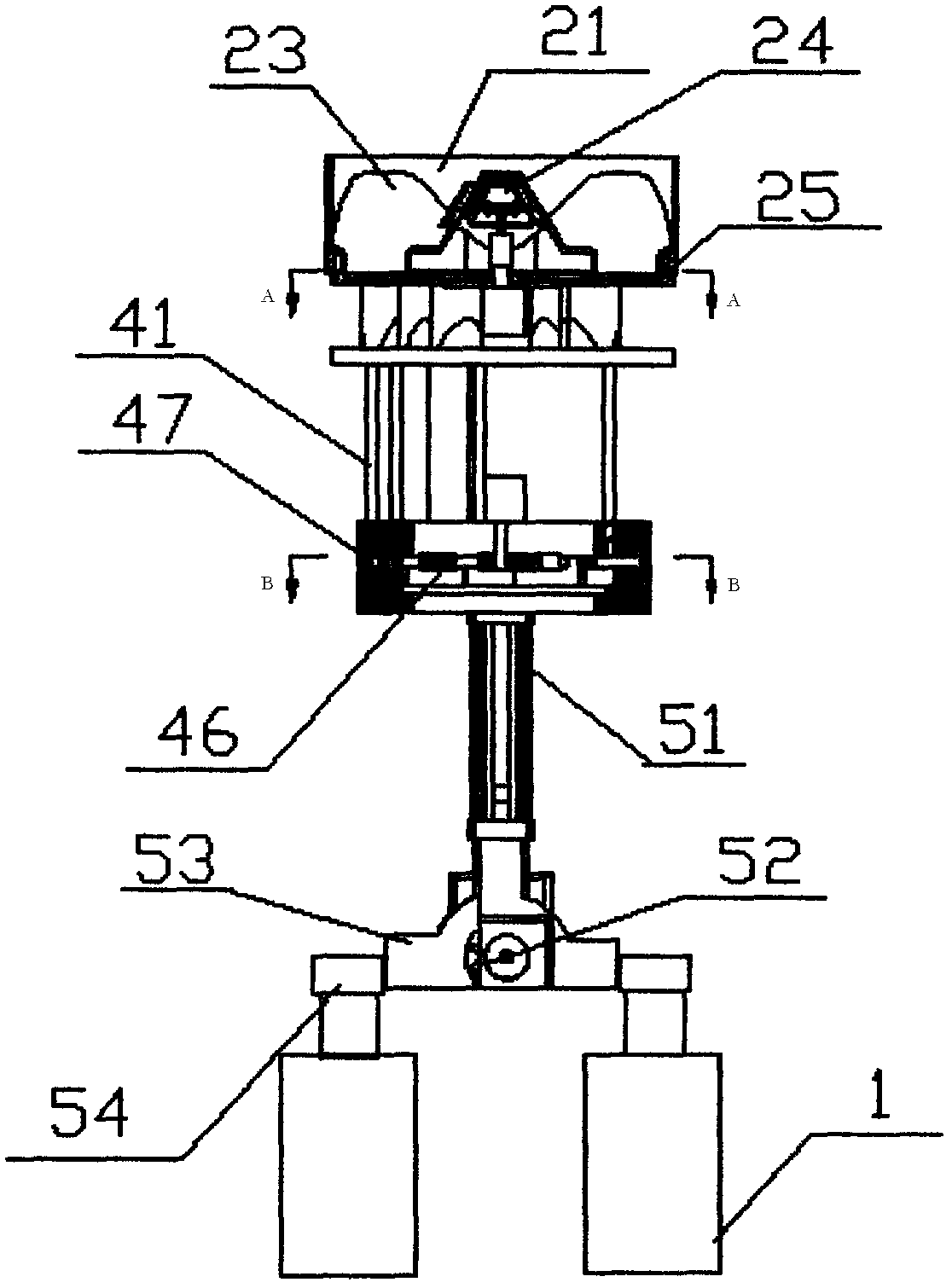

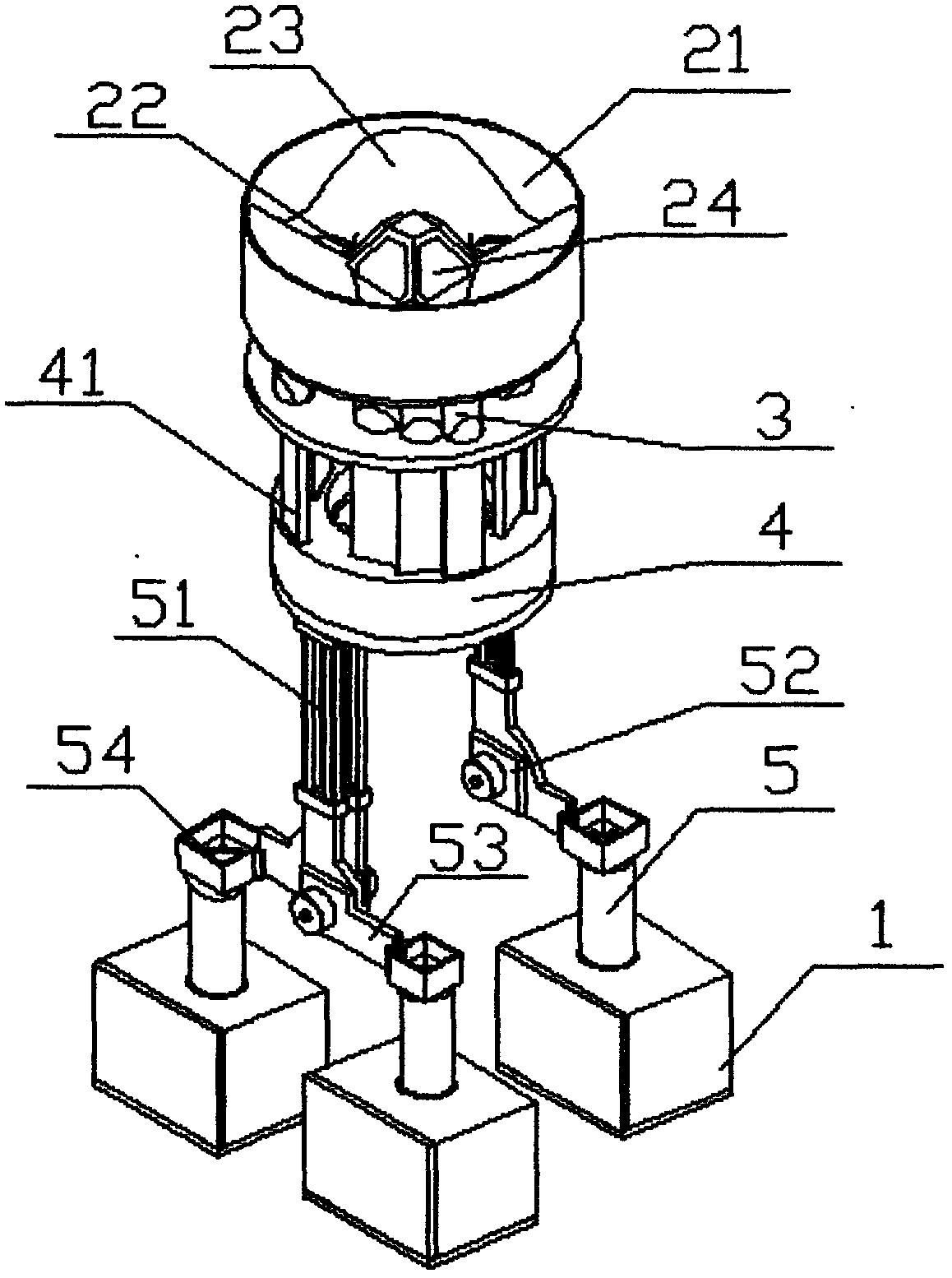

Manual feed mechanism for processing automobile engine cylinder

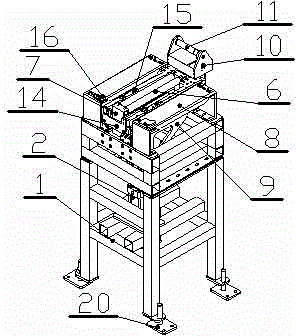

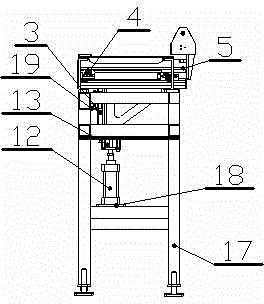

ActiveCN102814691AUnique structureSolve the problem of low efficiency of manual upper and lower fixturesMetal working apparatusWire gaugeSprocket

The invention relates to a device which is suitable for the assembly line work of engine cylinders and other parts in the automobile industry, and in particular to a manual feed mechanism for processing an automobile engine cylinder, which is characterized by comprising a support frame, wherein the lower part of the support frame is provided with an air cylinder, vertical wire gauge and a chain wheel are sequentially matched with the upper part of the air cylinder, a rack is matched with the lower part of the chain wheel, a roller is matched with the upper part of the chain wheel, vertical support plates are fixed on the support frame at the periphery of the chain wheel, one sides of the upper parts of the vertical support plates are fixed with a fork support, pneumatic control boxes are respectively fixed on the fork supports, push-in handles are respectively arranged at the upper parts of the pneumatic control boxes, and the vertical support plates at the left side and the right side of the fork support are respectively fixed with a horizontal guide support plate. The manual feed mechanism has a unique structure, can be used for solving the problem of low manual efficiency when materials are loaded and unloaded on a fixture during the processing of engine cylinders and other parts, is reliable and stable, and has high efficiency.

Owner:NINGXIA KOCEL MOLD

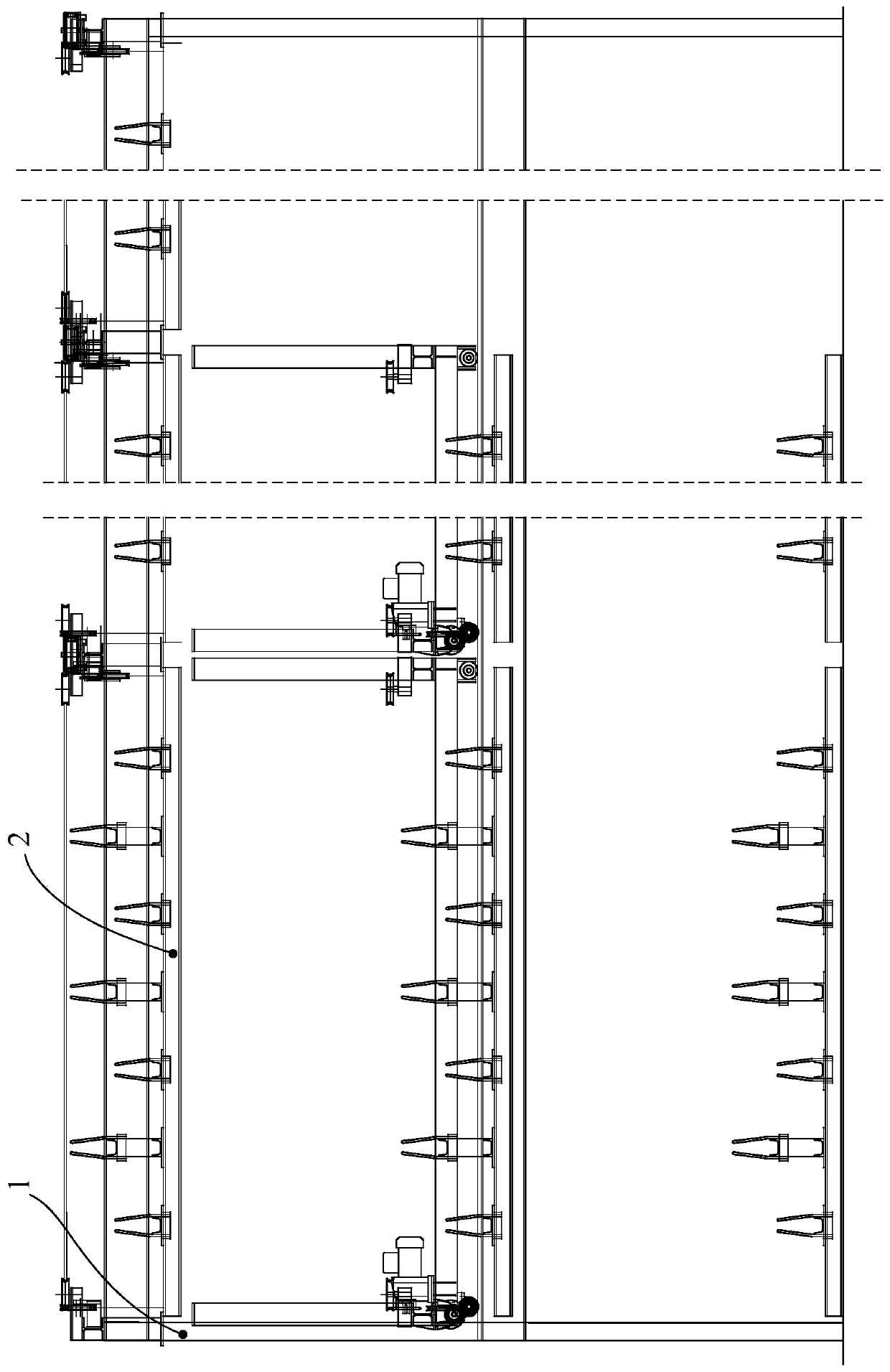

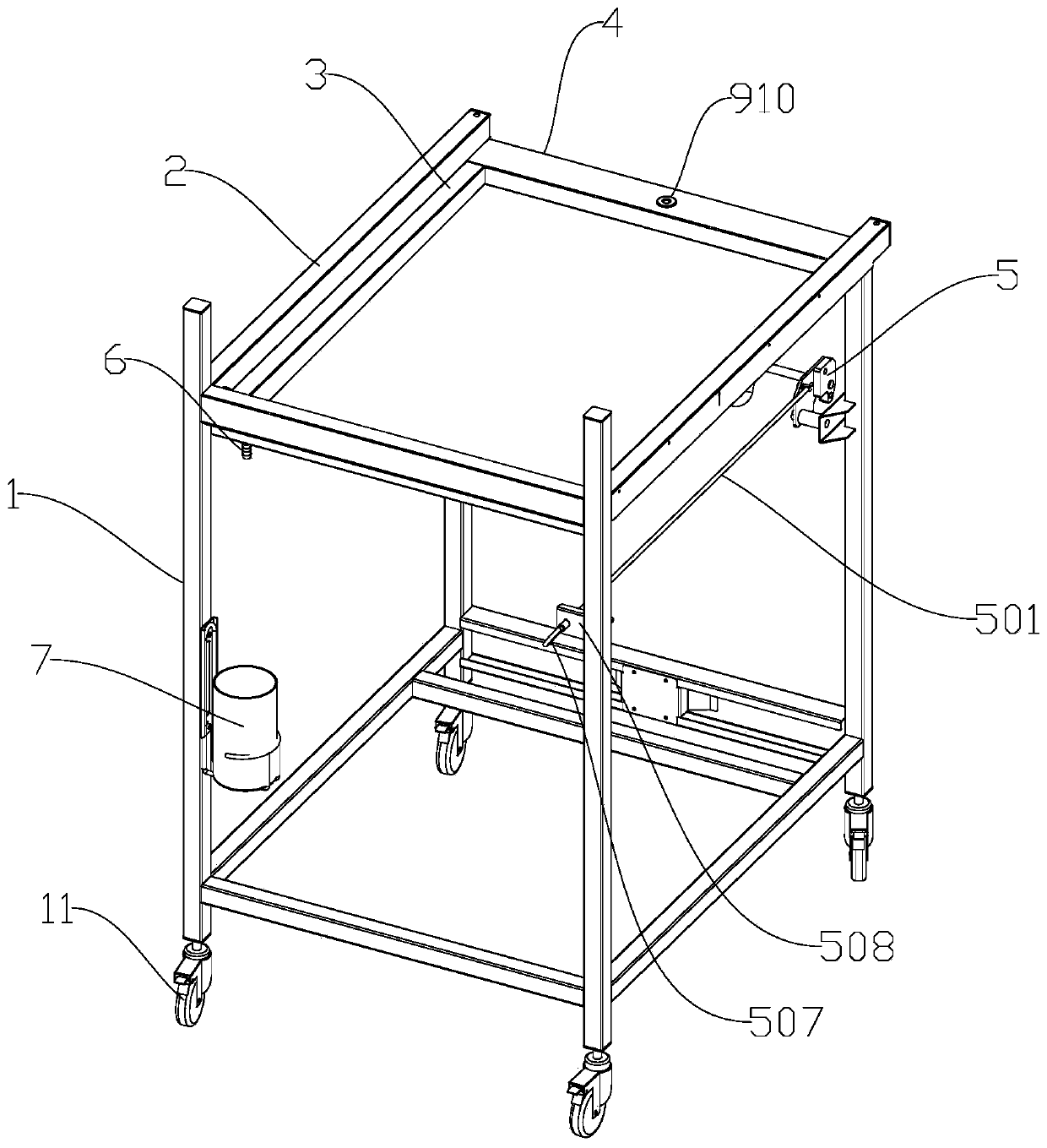

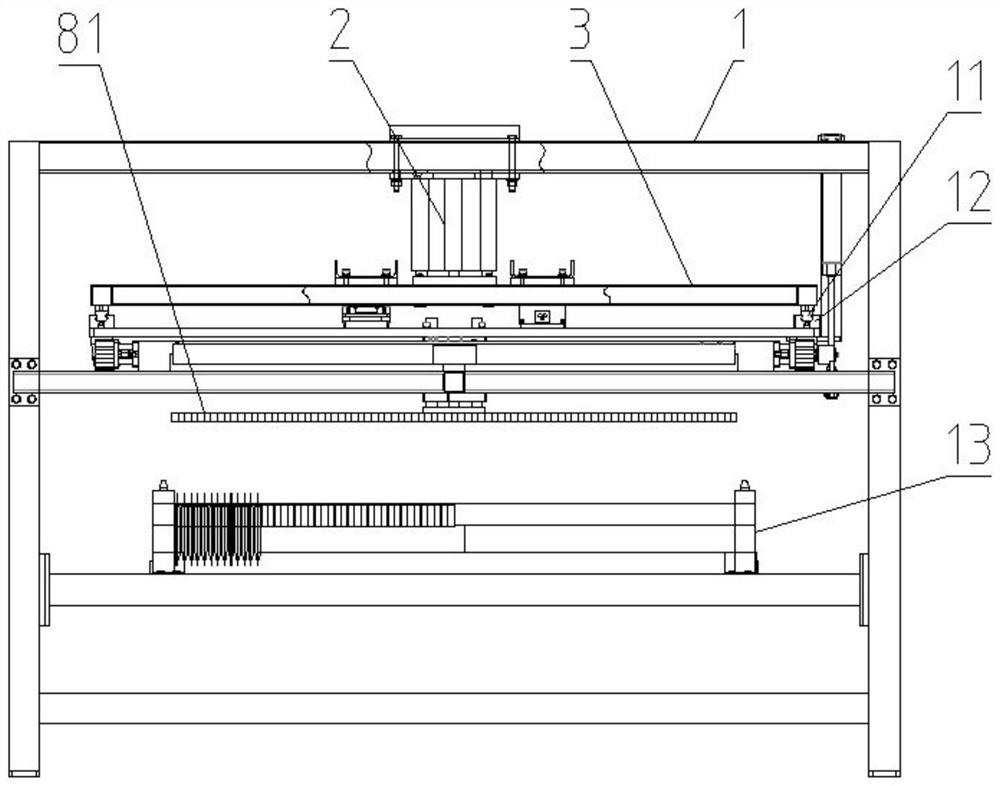

Lifting and horizontal moving bike garage

ActiveCN108019067AMeet access requirementsEasy accessCycle standsParkingsEngineeringMechanical engineering

The invention discloses a lifting and horizontal moving bike garage including a frame body, a plurality of storing layers which are used for parking bikes are arranged in the frame body from the top to the bottom, each of the storing layers is provided with a plurality of bike-carrying frames which are arranged side by side, the bike-carrying frames of a top layer of the storing layers can vertically move to a bottom layer to park the bikes, and other layers between the bottom layer and the top layer can horizontally move through a motor and move to the bottom layer to park the bikes. Comparedwith the prior art, the lifting and horizontal moving bike garage has the advantages of simple structure, convenient and rapid use, high application efficiency and the like.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

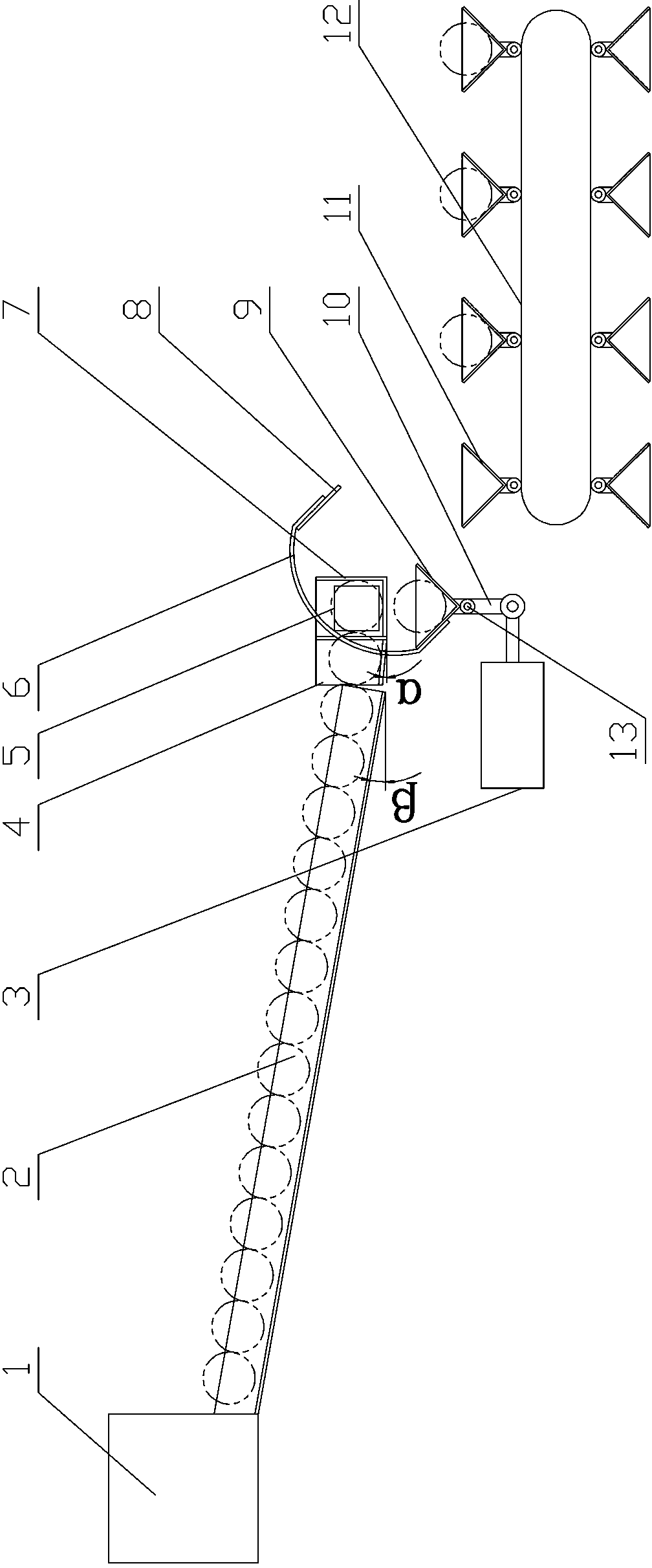

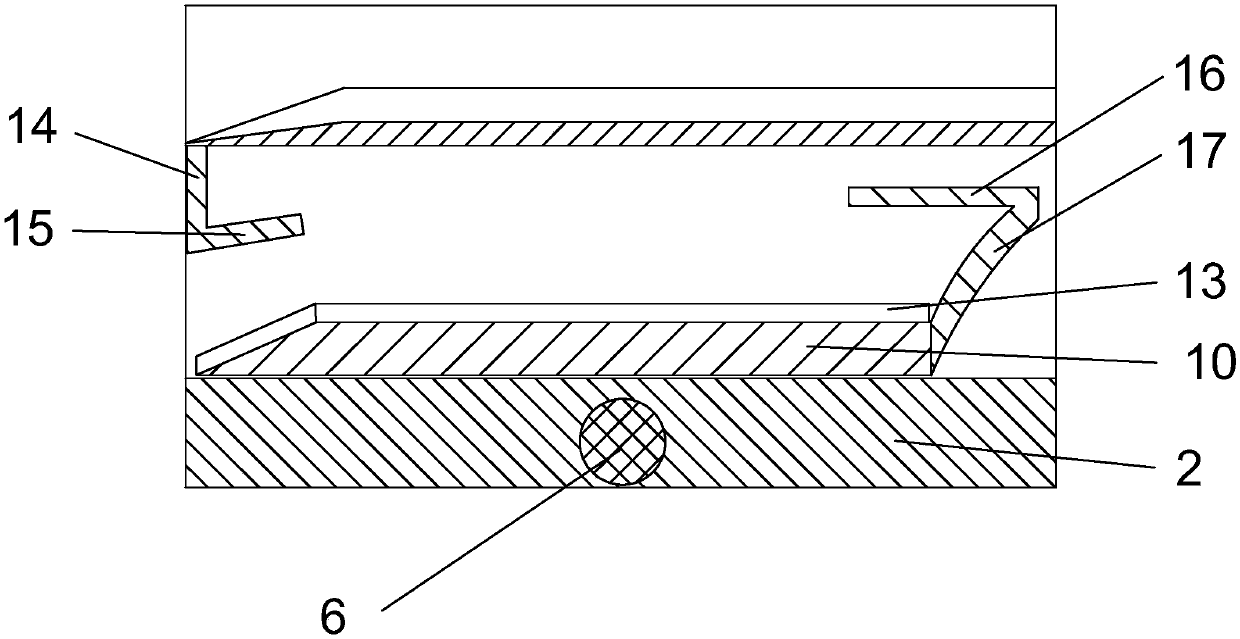

Feeding device for heat treatment of steel balls

InactiveCN103771114AAvoid not being able to pushPrevent ejectionConveyor partsFailure rateSteel ball

A feeding device for heat treatment of steel balls comprises an aggregating box, a V-shaped feeding rail and a pushing groove; the V-shaped feeding rail is arranged on one side of the aggregating box; the pushing groove is in abutting connection with the V-shaped feeding rail; the left side of the pushing groove is provided with a pushing cylinder; a V-shaped aggregating groove with a rotating shaft is formed under the right side of the pushing groove; a connecting rod is arranged under the rotating shaft; a piston head and a reversing cylinder are arranged under the V-shaped aggregating groove; the reversing cylinder is hinged to the connecting rod; a controller is connected between the reversing cylinder and the pushing cylinder; a conveyor belt with a V-shaped feeding groove is arranged under the front side of the V-shaped aggregating groove; the bottom of the V-shaped aggregating groove is level with the top of the V-shaped feeding groove which is formed above the conveyor belt. The feeding device is characterized in that a steel ball buffer groove is added between the pushing groove and the tail end of the V-shaped feeding rail; the V-shaped aggregating groove is connected with a stopping plate through arc-shaped connecting ribs; the end portion of the stopping plate is located on the outer side of the V-shaped feeding groove which is formed above the conveyor belt and is closest to the V-shaped aggregating groove when the V-shaped aggregating groove turns over to the limit position. According to the feeding device for the heat treatment of the steel balls, the steel balls can be smoothly pushed out and accurately arranged in the V-shaped feeding groove, the failure rate is low, and the use is safe and reliable.

Owner:湖北中冶窑炉有限公司

Car coupler and locking method thereof

ActiveCN112896224APush in accuratelyThe sliding track is clear and clearRailway coupling accessoriesTrackwayStructural engineering

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

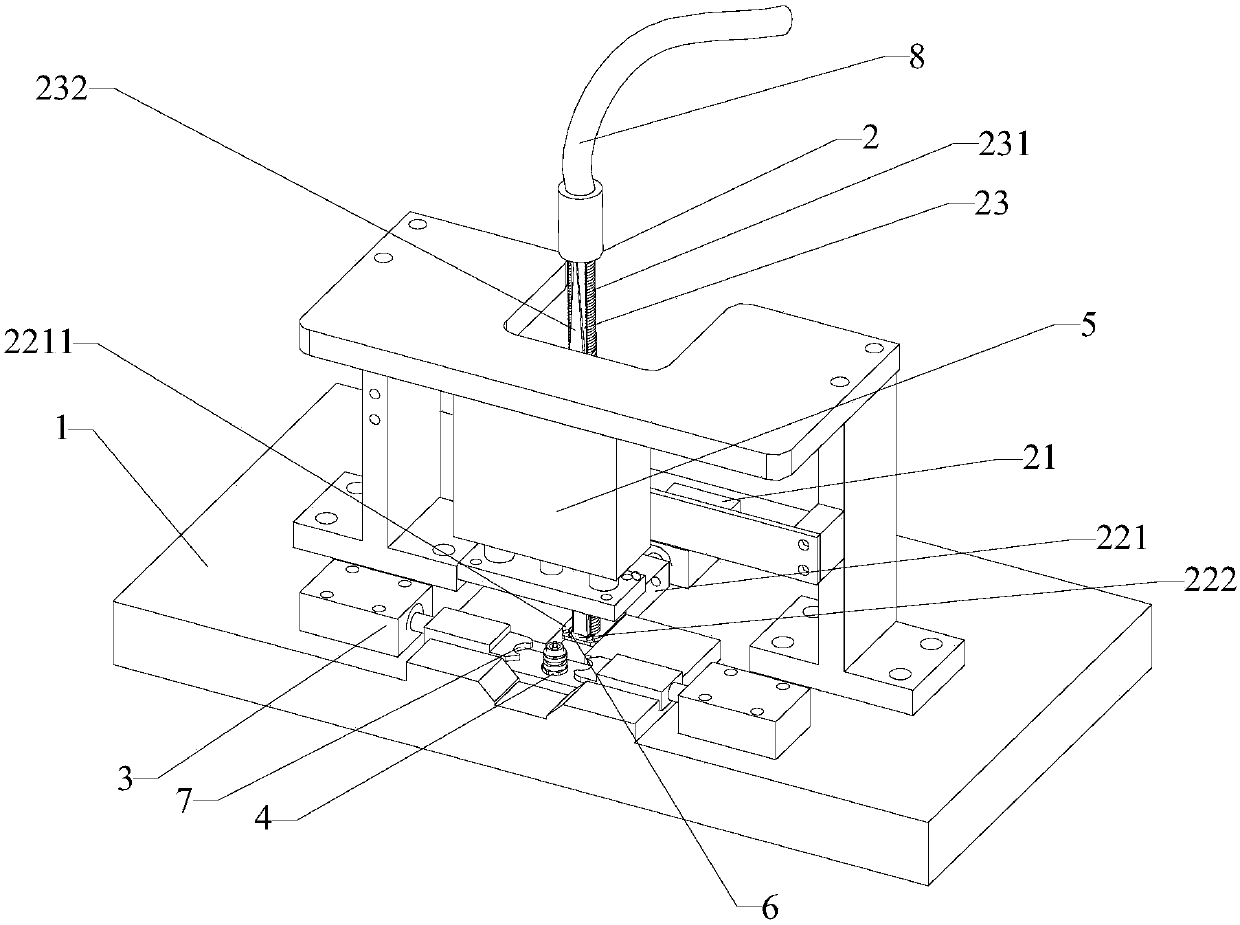

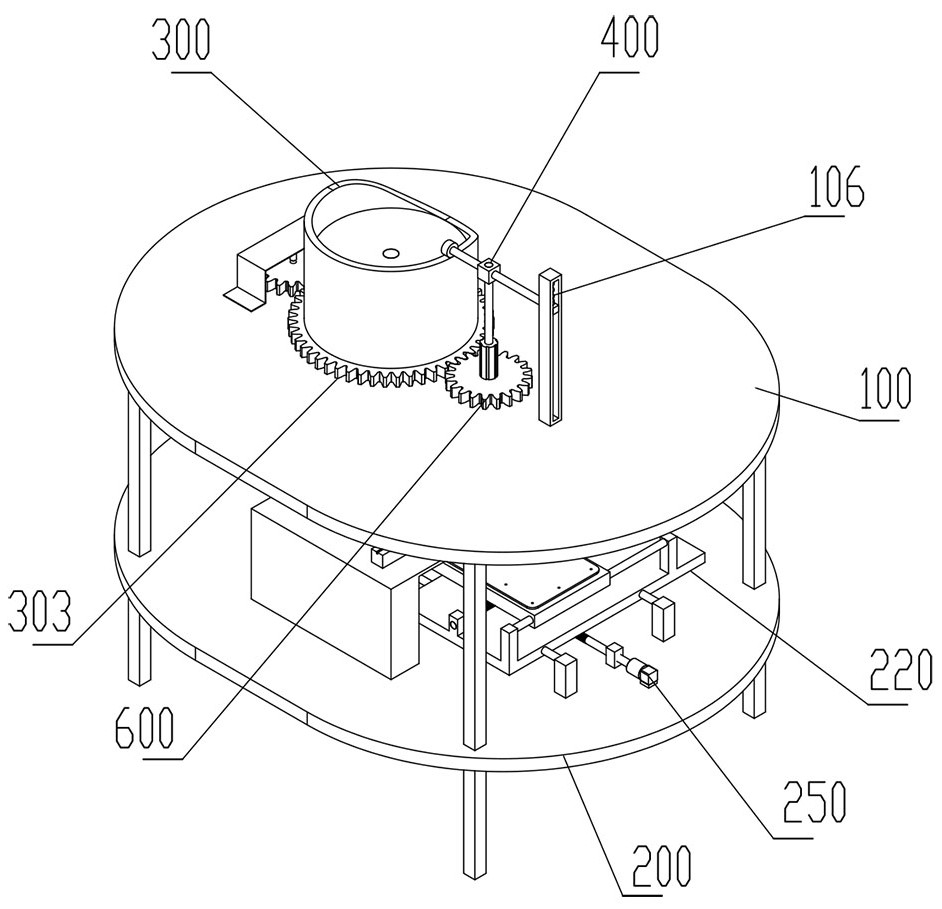

Medical glass tube cleaning equipment

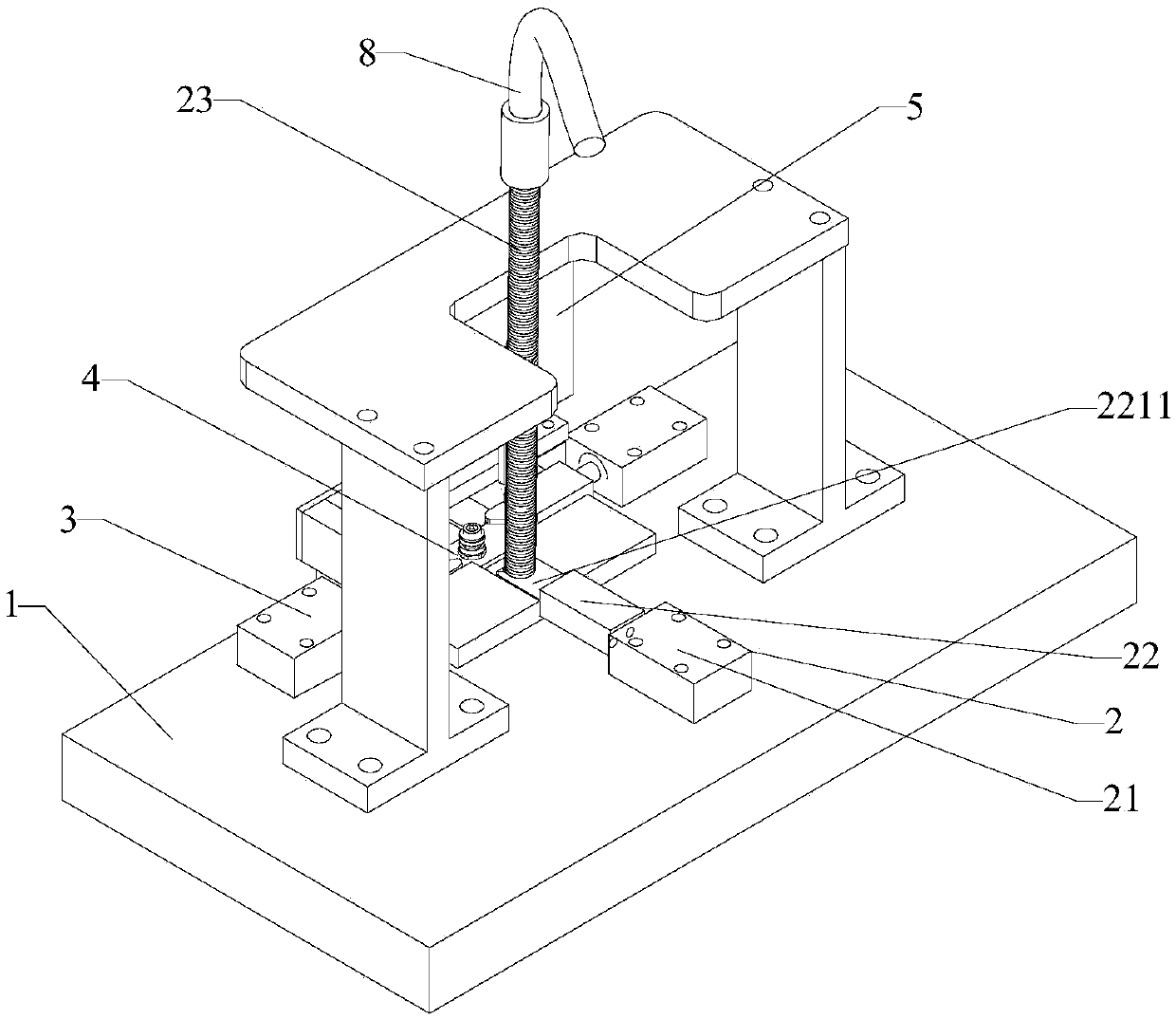

PendingCN112354998AAvoid secondary pollutionPrevent movementHollow article cleaningMedicineElectric machinery

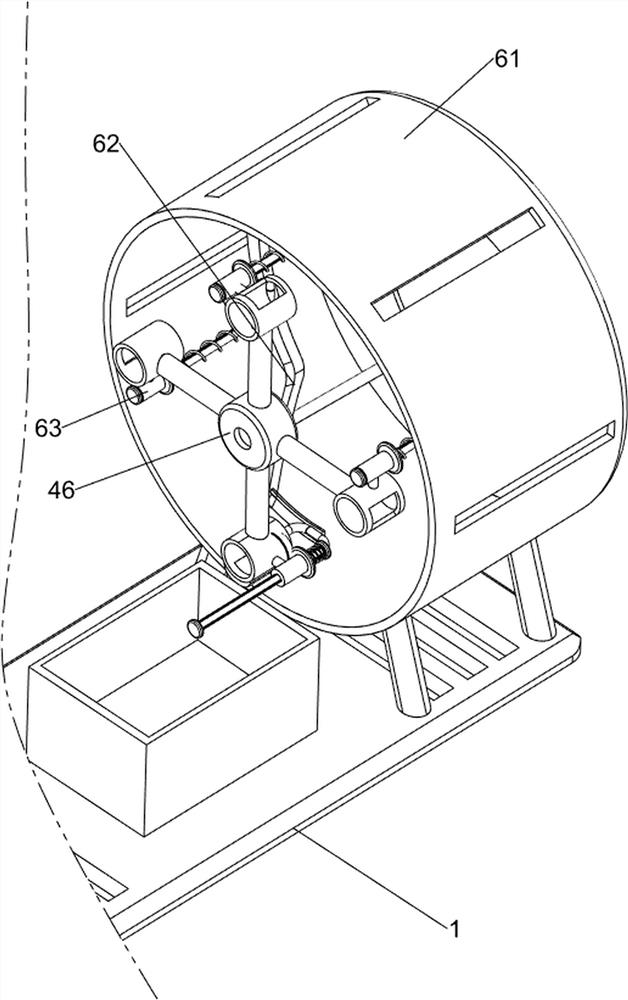

The invention relates to cleaning equipment, in particular to medical glass tube cleaning equipment. The medical glass tube cleaning equipment is high in cleaning efficiency and cannot cause secondarypollution to a cleaned glass tube. The medical glass tube cleaning equipment comprises a base, a supporting table, a pushing mechanism, a cleaning mechanism and a rotating mechanism, wherein the supporting table is arranged at the top of the base; the pushing mechanism is arranged at the top of the supporting table; the cleaning mechanism is arranged at the top of the supporting table and connected with the pushing mechanism; and the rotating mechanism is arranged on the cleaning mechanism. An air cylinder is started to drive a spring extension rod to move rightwards, so that water in a spraying pipe is sprayed out. A sponge block is driven to move rightwards to enter the glass tube, and then a motor is started to enable the sponge block to rotate to clean the glass tube, so that the glass tubes can be cleaned one by one. The air cylinder is closed, a push plate is driven to move leftwards, and a rotating rod is driven to rotate anticlockwise, and thus the glass tube is rotated to a cleaning position.

Owner:周珂

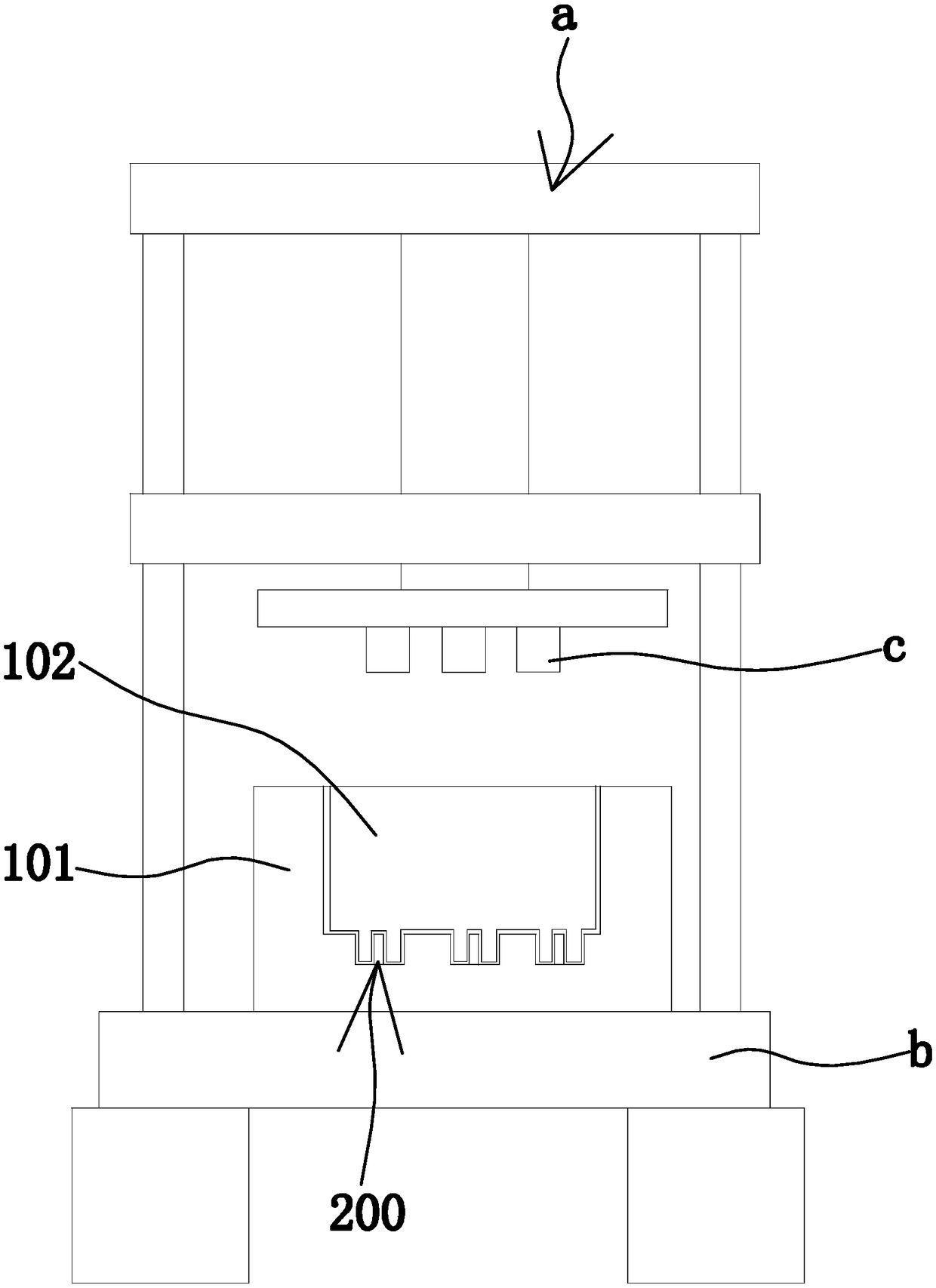

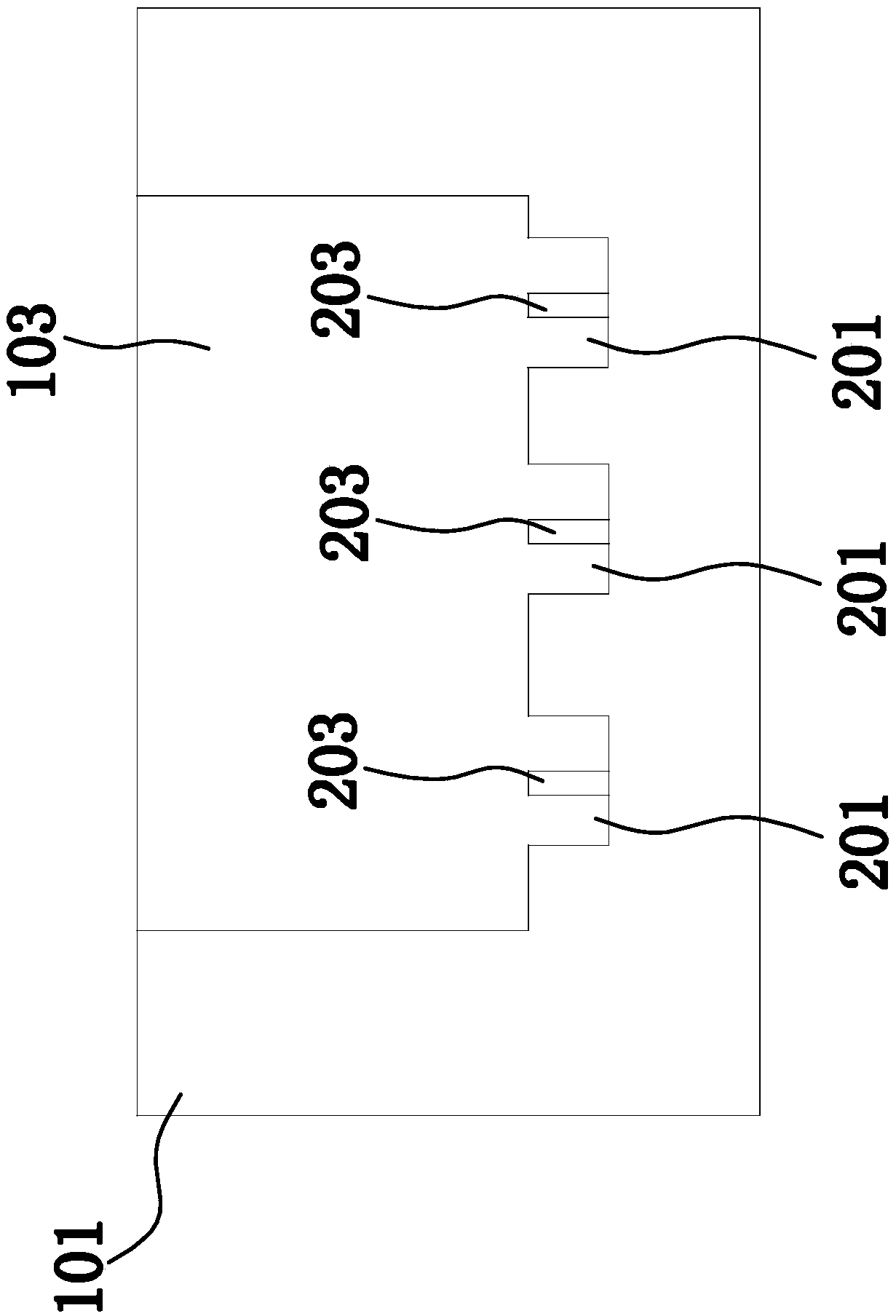

Forging and pressing die for manufacturing brake pads

InactiveCN108856621AGrasp the filling quantity in timeEasy to observeForging/hammering/pressing machinesEngineeringBrake pad

The invention provides a forging and pressing die for manufacturing brake pads and belongs to the technical field of manufacturing of automobile equipment. According to the forging and pressing die, the problems of unreasonable design and the like in the prior art are solved. The forging and pressing die for manufacturing the brake pads comprises a die mounting seat detachably arranged on a bearing platform; a press die insert groove used for mounting of a press die is formed in the side, close to an upper press head of a forging and pressing press, of the die mounting seat; a plurality of filling grooves used for storing friction materials of the brake pads are formed in the press die; the side, close to an operator, of the press die insert groove is communicated with the outside world; and sliding assemblies, etc. for sliding of the press die are arranged between the press die and the press die insert groove. The forging and pressing die for manufacturing the brake pads has the advantages that the press die insert groove used for insertion of the press die is formed in the die mounting seat so that the press die can be quite conveniently taken out from the forging and pressing press, thus, filling work of more press dies can be completed by the operator while the forging machine press conducts forging and pressing, and therefore the production efficiency is greatly improved.

Owner:ZHEJIANG HANGMO OUYI AUTOMOTIVE COMPONENTS

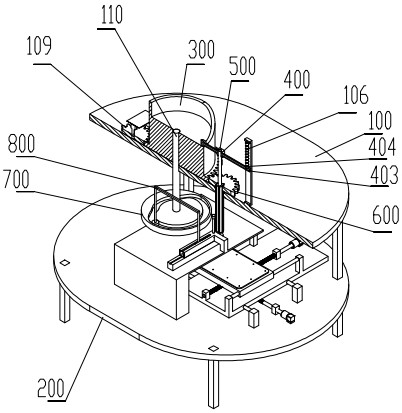

Computer assembly equipment and operation method

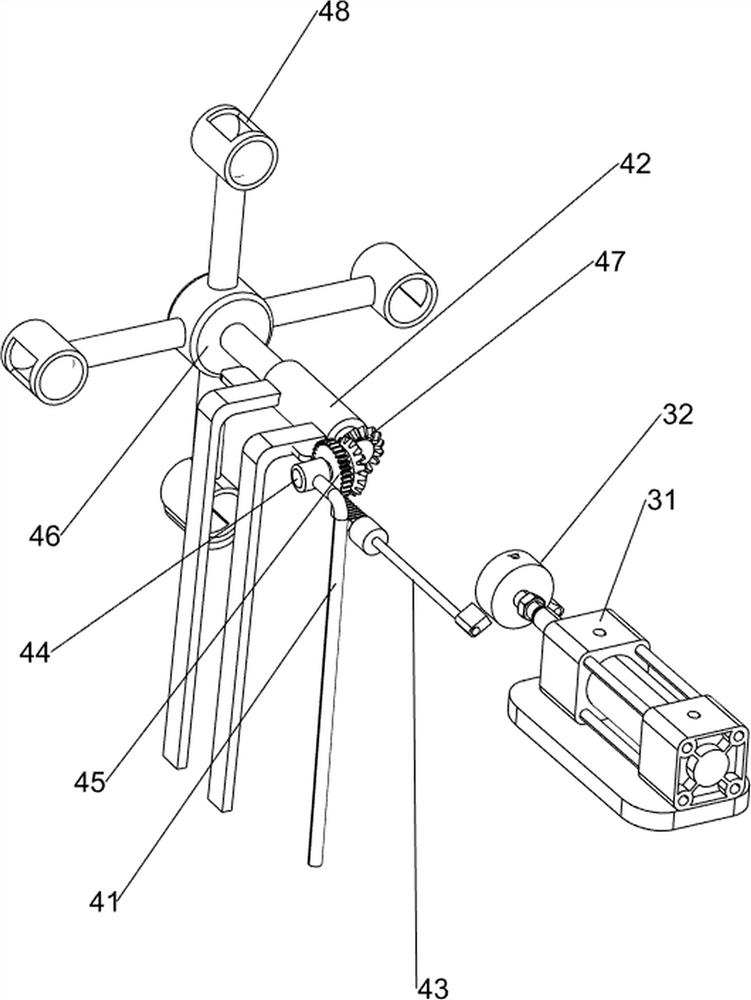

ActiveCN112975368AAchieve precise positioningAvoid uncertaintyMetal working apparatusGear wheelDrive shaft

The invention discloses computer assembly equipment and an operation method. The computer assembly equipment comprises a rack, a first rod frame, a first rod sliding groove, a first spring, a motor, a motor gear, a mounting plate, first guide rods, a second sliding table, a second nut, a first sliding table, a first nut, a second guide rod, a discharging hole, a material guide frame, a first motor, a first lead screw, a second motor, a second lead screw, a first cam, a first rod, a spline shaft, a spline gear, a second cam, a second rod, a second spring, screws and a computer. The lower part of the rack is provided with four supporting legs, the front part of the rack is provided with a transmission shaft hole, the rear part of the transmission shaft hole is provided with a gear through hole, the outer side of the gear through hole is provided with a gear fixing hole, the rear part of the gear through hole is provided with the first rod frame, the middle of the first rod frame is provided with the first rod sliding groove, and the middle of the mounting plate is provided with two coaxial first lead screw holes; and each of the two sides of the first lead screw holes is provided with one first guide rod. The right side of the mounting plate is provided with an upper mounting face.

Owner:HARBIN VOCATIONAL & TECHN COLLEGE

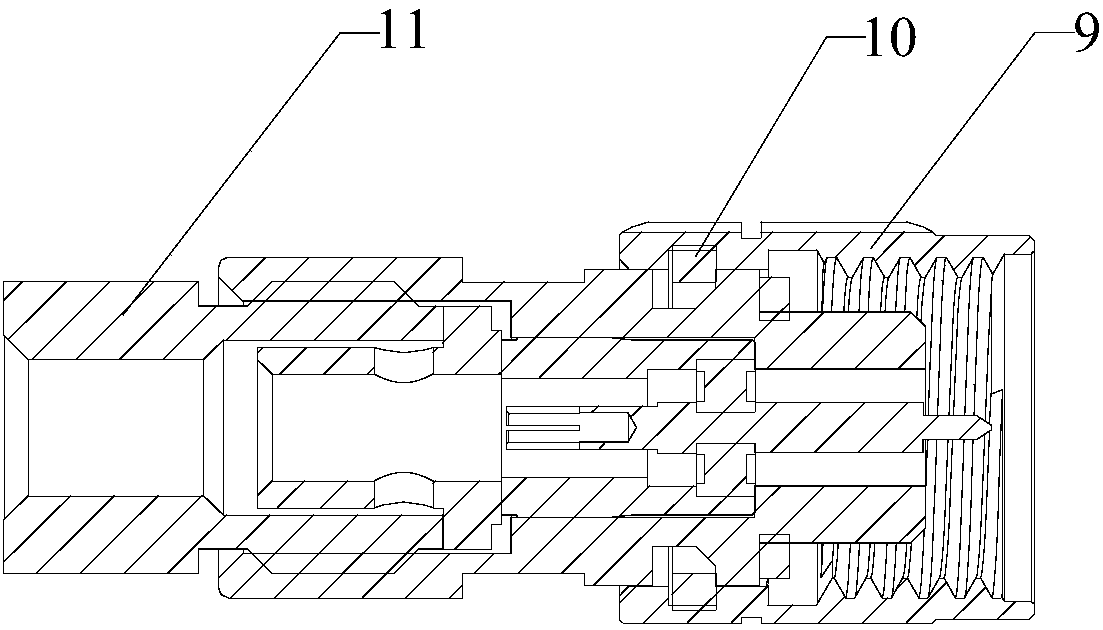

Automatic mounting equipment for screw sleeve and clamping ring

PendingCN107914137AQuick connectionFast pushMetal working apparatusEngineeringMechanical engineering

The invention relates to automatic mounting equipment for a screw sleeve and a clamping ring. The automatic mounting equipment comprises a feeding device, clamping ring air-entraining cylinders, a connector mounting seat and a screw sleeve press-in air cylinder which are arranged on a base, wherein the feeding device comprises a feeding air cylinder and a feeder connected to a piston end of the feeding air cylinder; the feeder comprises a feeder body and a containing platform, and the feeder body is connected with the containing platform through a spring; the connector mounting seat is arranged in the moving direction of the feeding air cylinder, and the clamping ring air-entraining cylinders which are mirror images of each other are respectively mounted on two sides of the connector mounting seat; and the screw sleeve press-in air cylinder is arranged above the connector mounting seat. By mounting the feeding device, the clamping ring air-entraining cylinders, the connecting mountingseat and the screw sleeve press-in air cylinder on the base, the connection between the clamping ring and the connector and the connection between the screw sleeve and a connector are automatically finished under the control of the controller.

Owner:FUJIAN MICABLE ELECTRONIC TECH GRP CO LTD

A lift and traverse bicycle garage

The invention discloses a lifting and horizontal moving bike garage including a frame body, a plurality of storing layers which are used for parking bikes are arranged in the frame body from the top to the bottom, each of the storing layers is provided with a plurality of bike-carrying frames which are arranged side by side, the bike-carrying frames of a top layer of the storing layers can vertically move to a bottom layer to park the bikes, and other layers between the bottom layer and the top layer can horizontally move through a motor and move to the bottom layer to park the bikes. Comparedwith the prior art, the lifting and horizontal moving bike garage has the advantages of simple structure, convenient and rapid use, high application efficiency and the like.

Owner:CHINA CONSTR SCI & IND CORP LTD

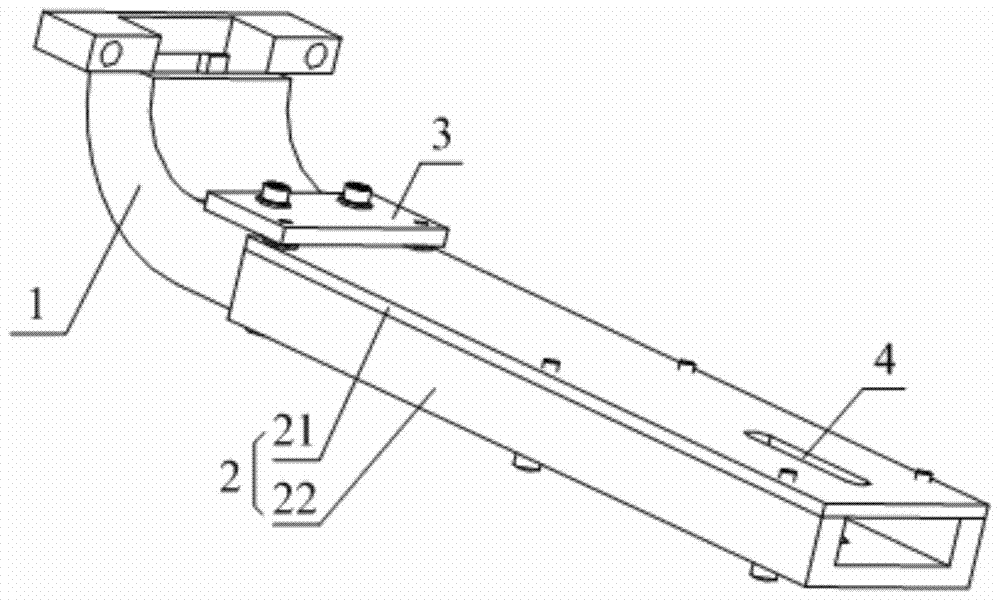

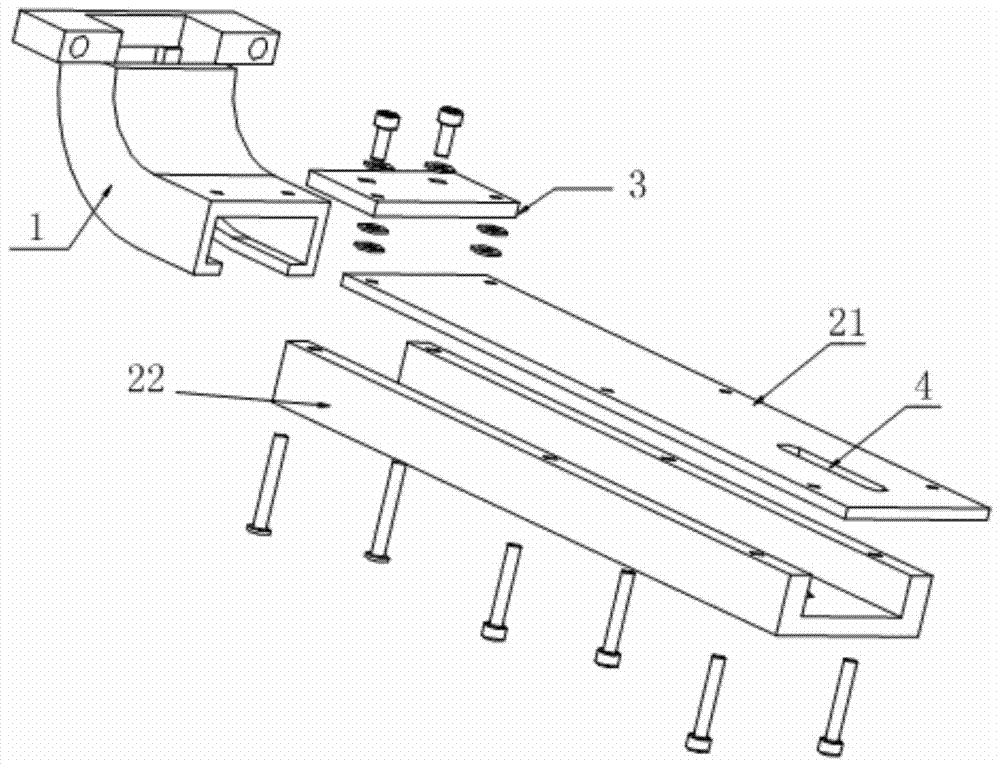

Floor type handcart switchgear integrated track

The invention relates to the field of power construction technology, and particularly to a floor type handcart switchgear integrated track. The floor type handcart switchgear integrated track comprises a left-handed screw, a right-handed screw and a screw combined operating rod. The left-handed screw and the right-handed screw are fixedly connected with two ends of the screw combined operating rod. The left-handed screw and the right-handed screw are in threaded connection with an integrated track. The integrated track comprises a fixed track base, a fixed track, a spacing bent trough and an auxiliary track. The auxiliary track comprises a base plate, a spacing bent plate, and a pair of side tracks which are parallelly arranged on the base plate. A guiding trough is formed between the twoside tracks. The side track at the side which is far from the spacing bent plate is provided with a bell mouth guiding trough which is outwards opened. The base plate at the bell mouth guiding troughis an oblique surface which inclines downwards. The floor type handcart switchgear integrated track realizes a fact that a switchgear handcart can be more safely, stably, conveniently and accurately pushed into the switchgear. Furthermore the floor type handcart switchgear integrated track has advantages of simple structure, convenient operation and effective efficiency improvement and safety improvement of personnel.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +2

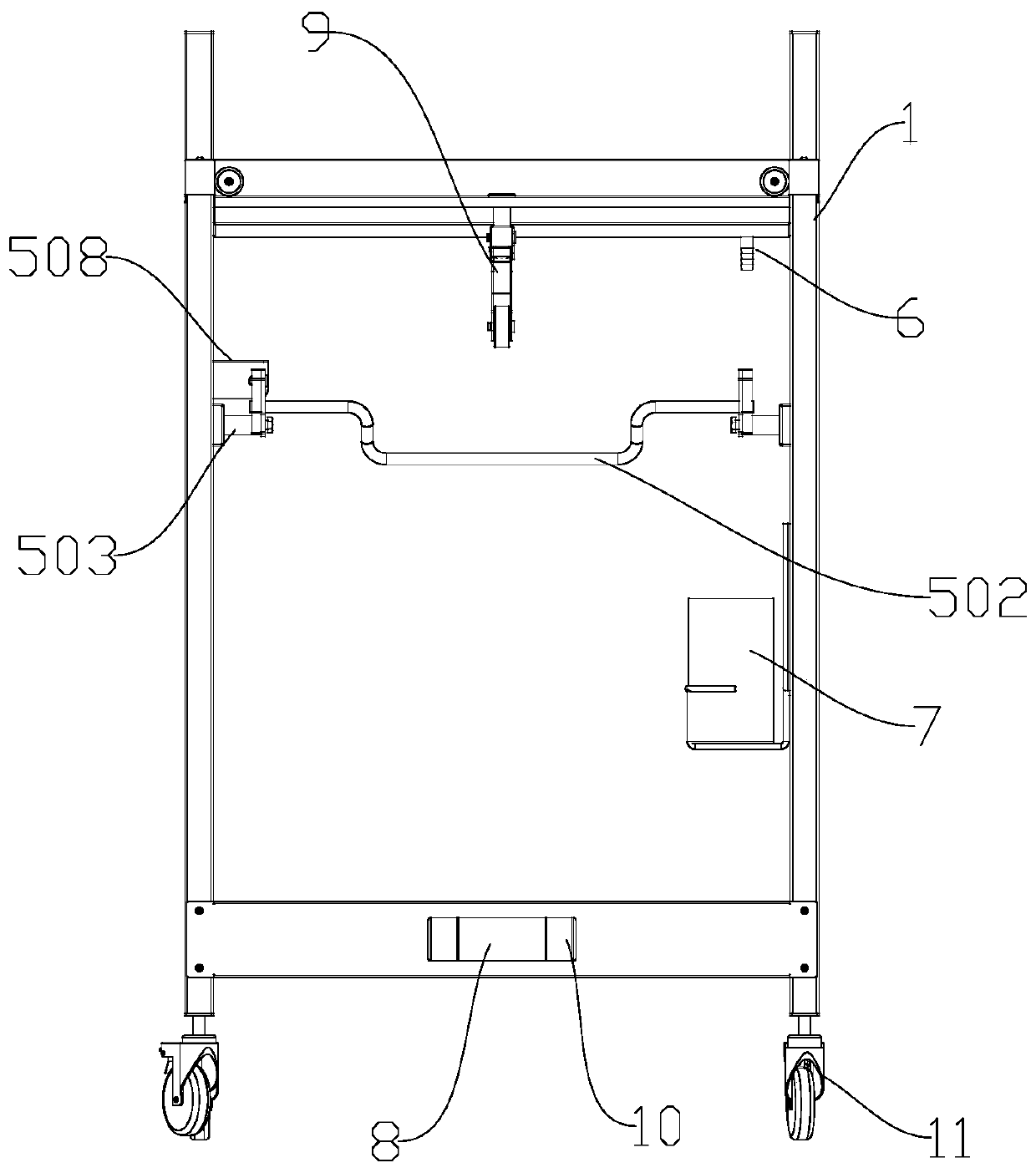

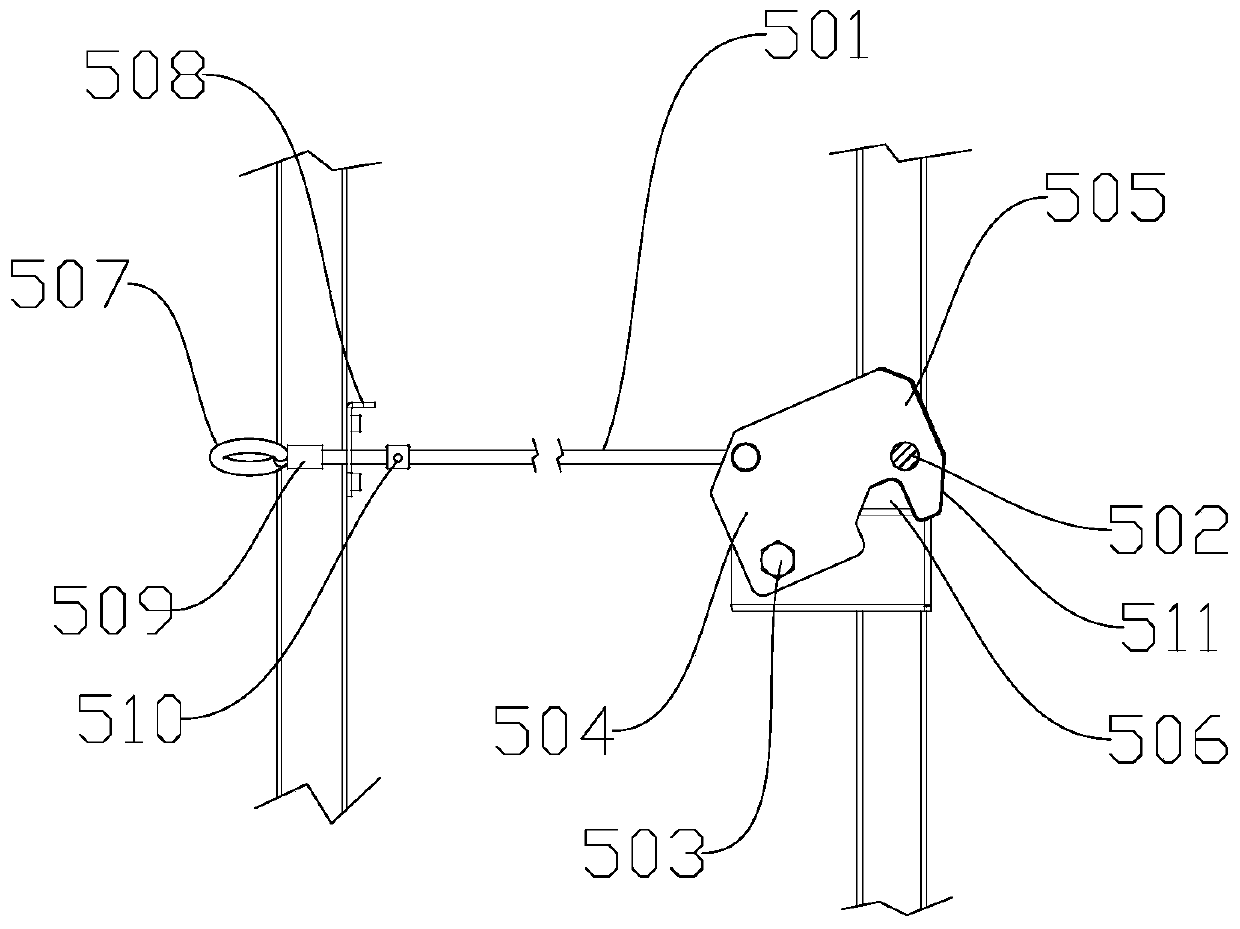

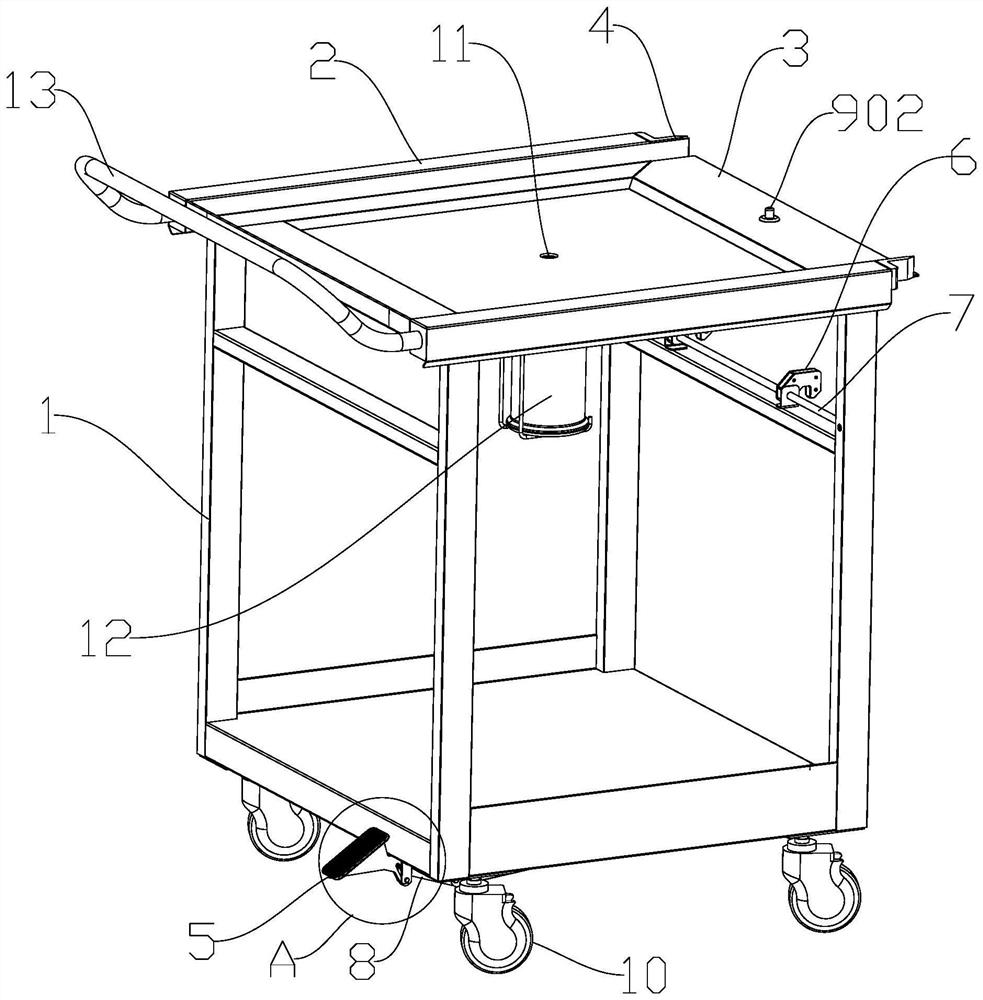

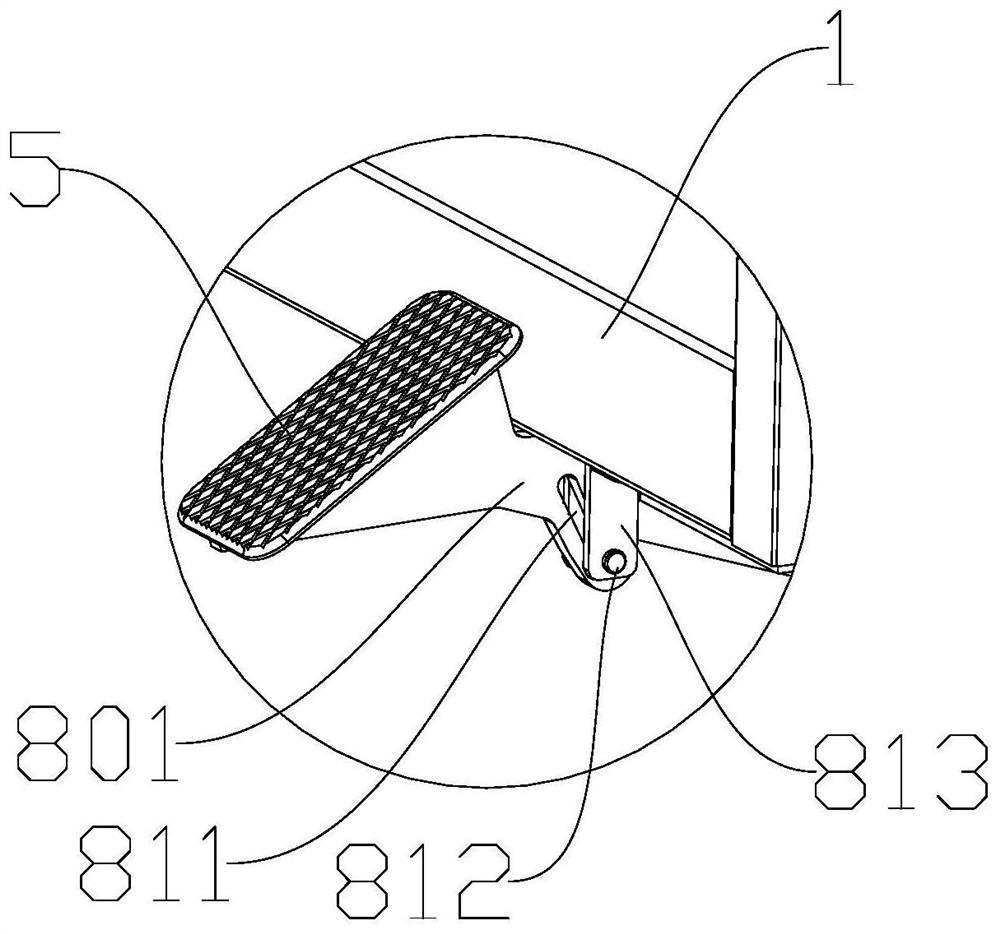

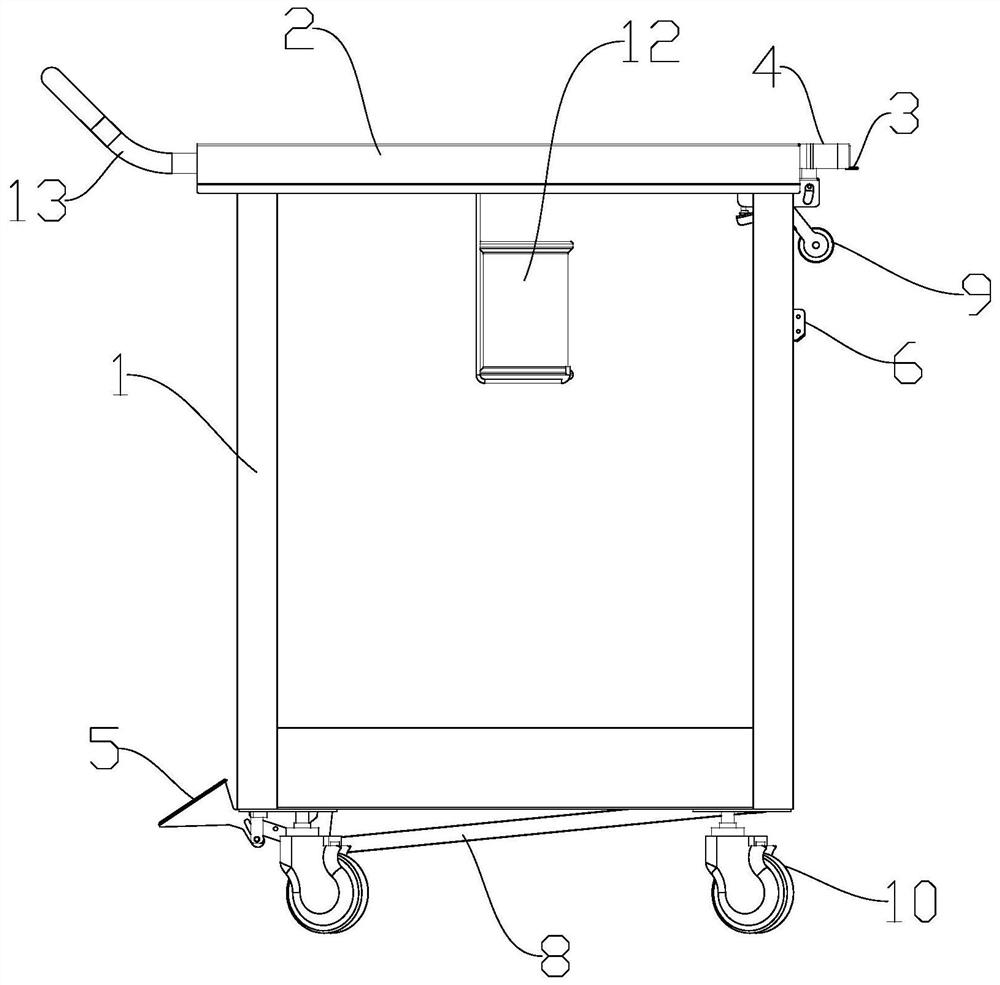

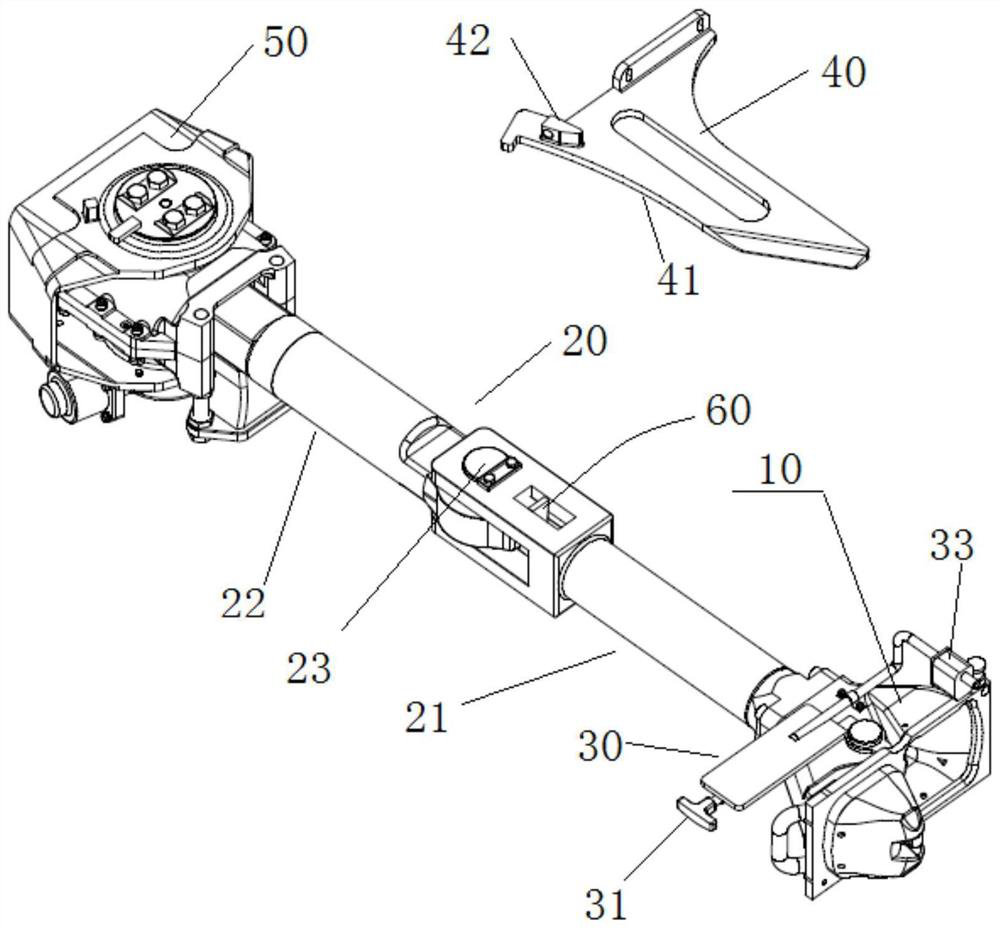

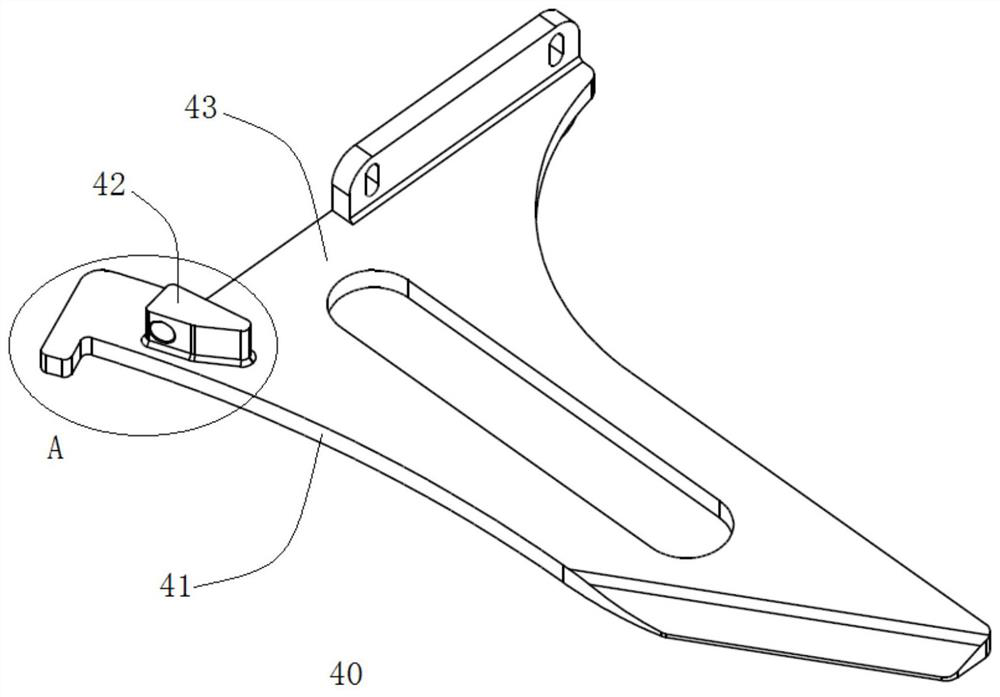

Hand-pulled cart for carrying cleaning frame of medical cleaning machine

PendingCN110979423AOvercoming gravityPrecise dockingHand carts with multiple axesHand cart accessoriesMedical equipmentEngineering

The invention relates to the technical field of medical equipment, and concretely relates to a hand-pulled cart for carrying a cleaning frame of a medical cleaning machine. The cart comprises a frame,a tank body is formed in the top of the frame and used for containing the cleaning frame, sliding rails are symmetrically arranged on the two sides in the tank body, a notch is formed in the front end of the tank body, the notch and the sliding rails are located on the same plane, a hook lock mechanism is arranged on the frame, and the hook lock mechanism comprises a pull rod, a hook lock heavy part, a pair of rotating shafts and a pair of cart hook locks. Only the cart hook locks need to be in butt joint with shackles to make the shackles hooked by the cart hook locks, so the cart can be stably connected with the cleaning machine, then the cleaning frame can be pushed to move towards a cleaning machine cabin along the sliding rails, the cleaning frame is stably and accurately pushed intothe cabin, and the convenience of carrying the cleaning frame in the using process of the medical cleaning machine is improved.

Owner:LAOKEN MEDICAL TECH

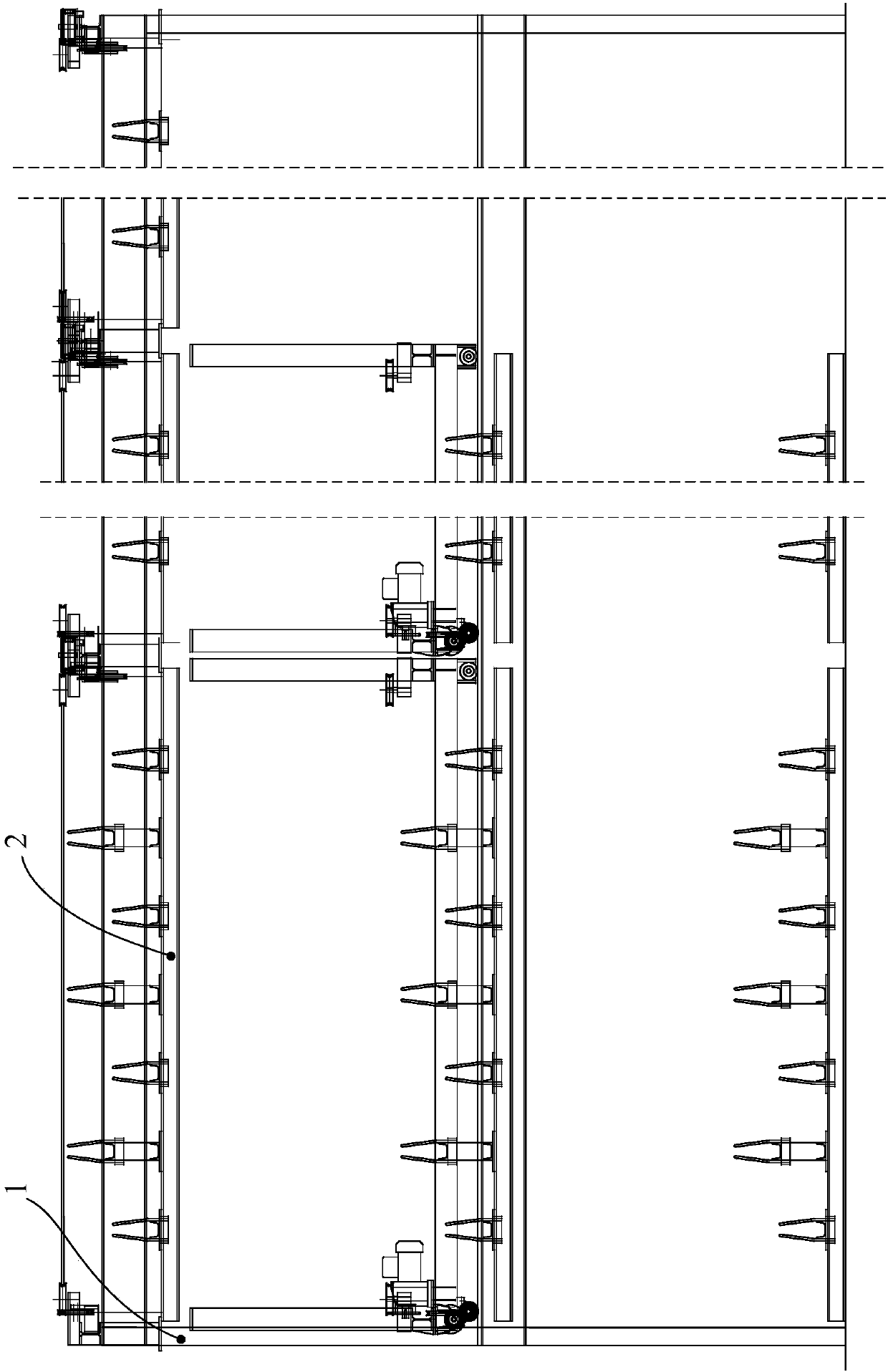

Automatic boxing machine of cigarette filter sticks

InactiveCN107521765AImprove stabilityRealize automatic reciprocating boxingTobacco smoke filtersRod-shaped articlesMechanical engineeringCigarette filter

The invention provides an automatic boxing machine of cigarette filter sticks. The automatic boxing machine comprises a rack, a box feeding mechanism, a box dragging mechanism and a pushing mechanism. The box feeding mechanism is arranged at the bottom of the rack and is used for feeding boxes to a to-be-lifted zone; the box dragging mechanism is arranged at the position of the to-be-lifted zone and used for moving the boxes up and down; and the pushing mechanism is arranged on one side of the box dragging mechanism and used for pushing the arranged and fixed-number filter sticks into the boxes. By means of the automatic boxing machine, the boxes can be fed into the to-be-lifted zone; a box feeding push plate is arranged and is pushed under the effect of a box feeding air cylinder, and the box stability in the box feeding process is improved; the boxes can be automatically lifted and descended, automatic and reciprocated boxing can be achieved until full filling is achieved; the arranged and fixed-number filter sticks can be accurately pushed into the boxes; and the automatic boxing machine is high in boxing efficiency, the labor cost is reduced, and the automatic degree is high.

Owner:LIANWEICHUANG SCI & TECH TIANJIN

A pedal trolley for carrying the cleaning frame of a medical cleaning machine

ActiveCN110979424BImprove conveniencePush smoothHand carts with multiple axesHand cart accessoriesEngineeringApparatus instruments

Owner:LAOKEN MEDICAL TECH

An automatic silkworm cocoon chipping machine and chipping method

ActiveCN104642270BUniform and reliable separationUniform and reliable movementAnimal husbandryCircular discEngineering

The invention discloses an automatic silkworm cocoon hole cutting machine and a hole cutting method, the radial direction of a disk surface of a cocoon separating disk is provided with 2 rectangular slots that are symmetrical along the center of the cocoon separating disk, a horizontal cocoon conveying belt is positioned below the cocoon separating disk, the left end of the cocoon conveying belt is positioned under the cocoon separating disk, the right end of the cocoon conveying belt is tightly connected with the left end of a cocoon conveying passage, a cocoon pushing mechanism is arranged at an upper right position of the cocoon conveying passage, and a photosensitive sensor is installed on the cocoon pushing mechanism; a conveyor belt, an active roller wheel and a passive roller wheel are arranged on the right side of the cocoon conveying passage, a fixture component is fixedly connected on the conveyor belt, a positioning and clamping mechanism is arranged at a conveyor belt position between the active roller wheel and the passive roller wheel, a pushing plate that pushes the fixture to make the fixture open is positioned on the rear side of the positioning and clamping mechanism; a cutting mechanism is arranged at the upper right position of the passive roller wheel, and a cocoon shell separating mechanism is arranged on the left side of the passive roller wheel; batched and automatic hole cutting can be carried out on the silkworm cocoon of different sizes, silkworm chrysalis and cocoon shells can be separated automatically, the positioning is reliable, the cocoon for egg production can not be crushed or injured due to cutting, the cocoon cutting quality is good, and the efficiency is high.

Owner:JIANGSU UNIV OF SCI & TECH

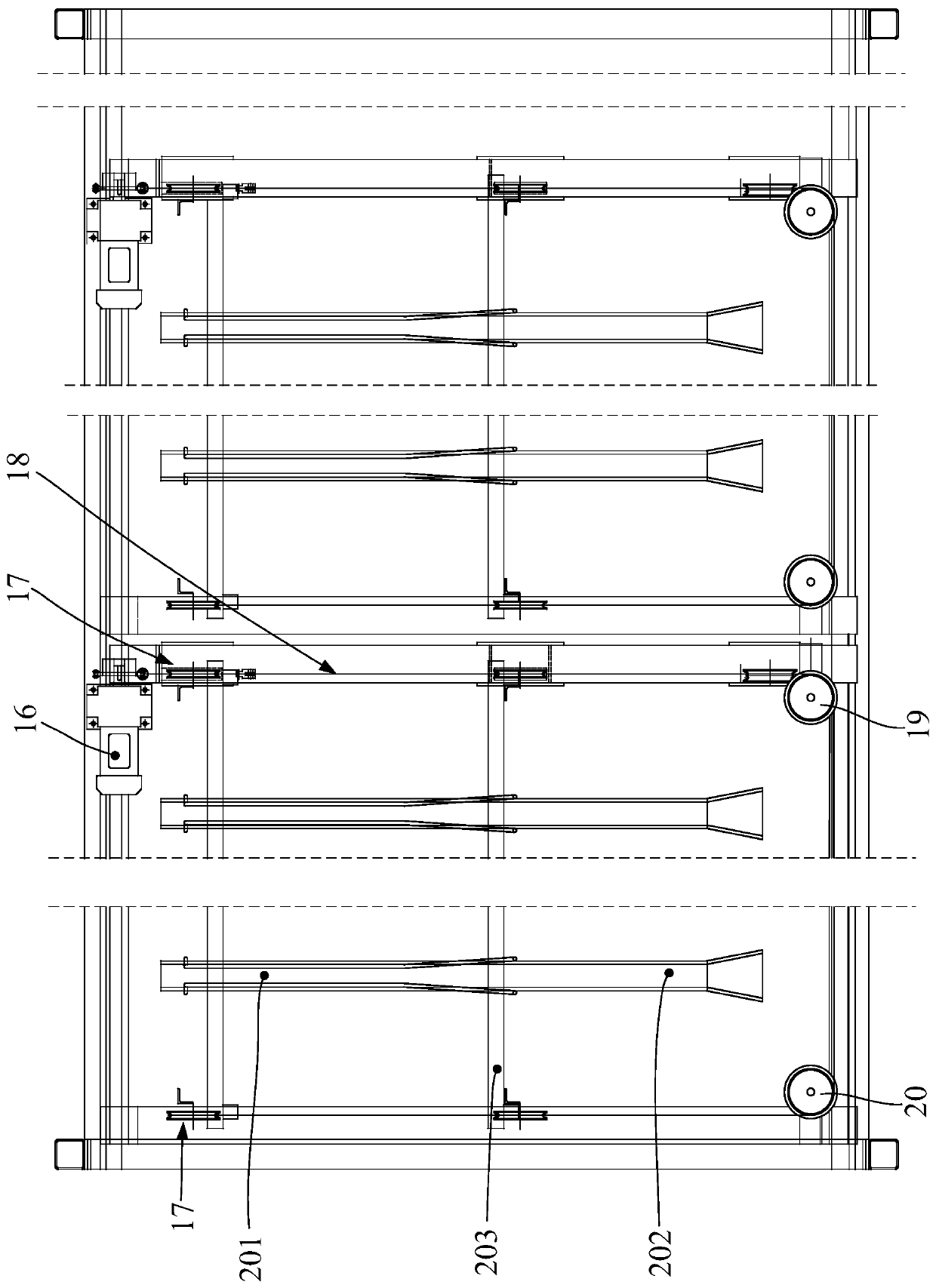

Pipe pushing device

ActiveCN112984212AReduce frictionReduce wearPipe laying and repairCylinder blockMechanical engineering

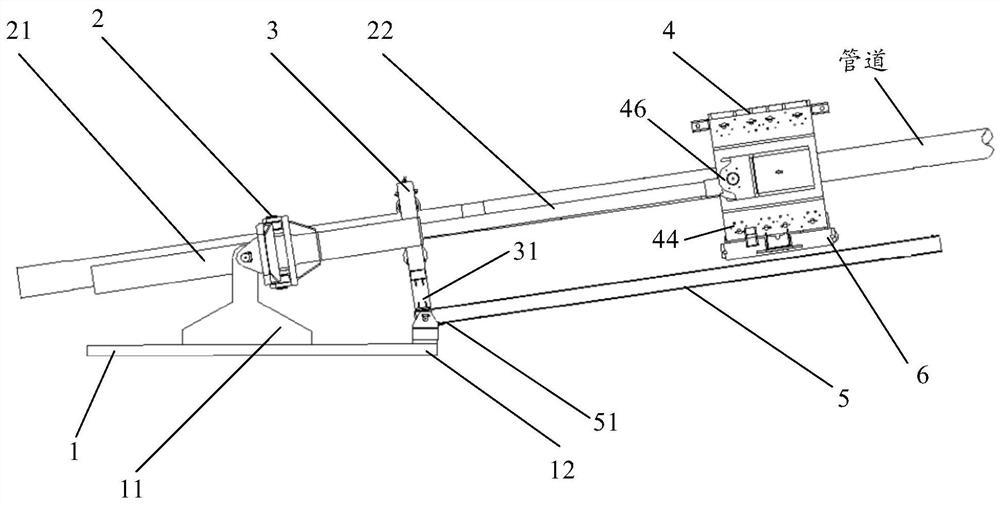

The invention discloses a pipe pushing device, and belongs to the technical field of pipeline non-excavation. The device comprises a base, a main pushing oil cylinder, a first righting frame, a pipe clamping device, a sliding rail and a sliding piece. A cylinder body in the main pushing oil cylinder is connected with the first part of the base, the first end of a piston rod in the main pushing oil cylinder is located in the cylinder body, the second end of the piston rod is connected with a connecting base of the pipe clamping device, and the pipe clamping device is used for clamping a pipeline. The bottom of the first righting frame and the second part of the base are both connected with the first end of the sliding rail, and the first righting frame is used for limiting the radial displacement of the pipeline clamped by the pipe clamping device. The frame of the pipe clamping device is connected with the sliding piece, and the sliding piece makes contact with a track of the sliding rail and can move on the track of the sliding rail. Thus, when pipe pushing construction is carried out, the weight of the pipe clamping device can be borne by the sliding rail, and therefore the pipeline cannot be bent by the pipe clamping device. Due to the fact that the first righting frame can limit the pipeline in the radial direction, the pipeline can be accurately pushed into a formed hole.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

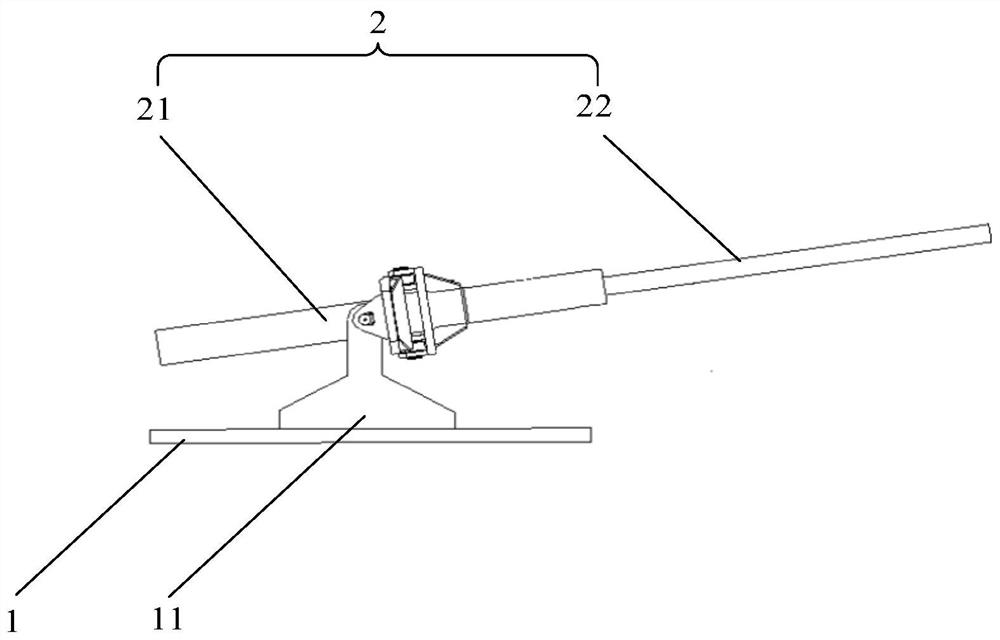

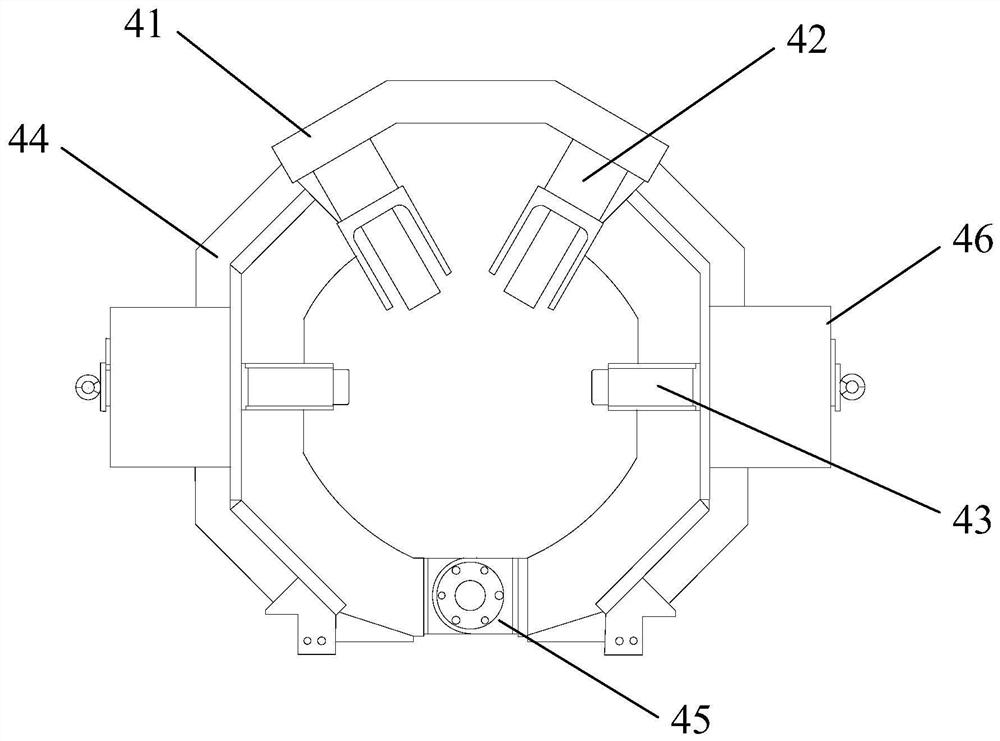

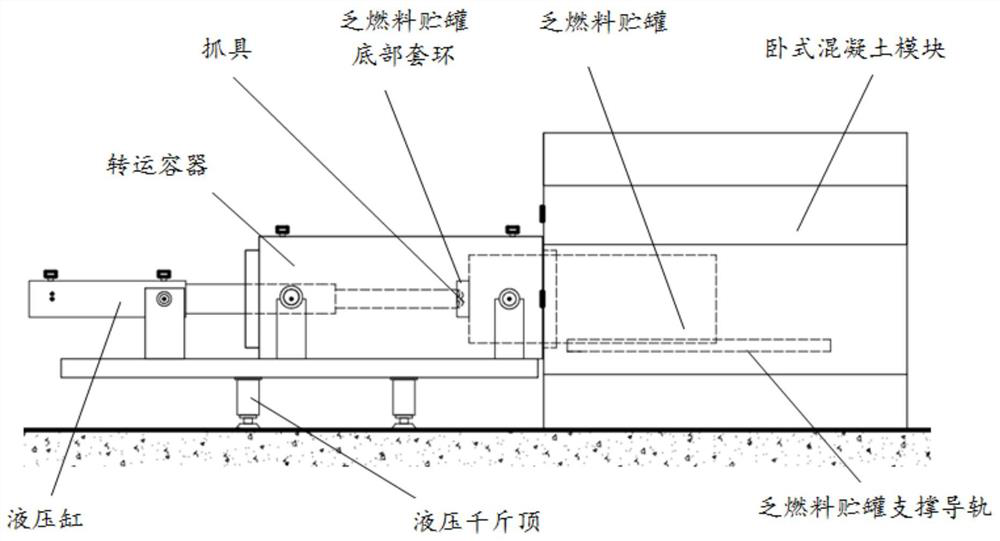

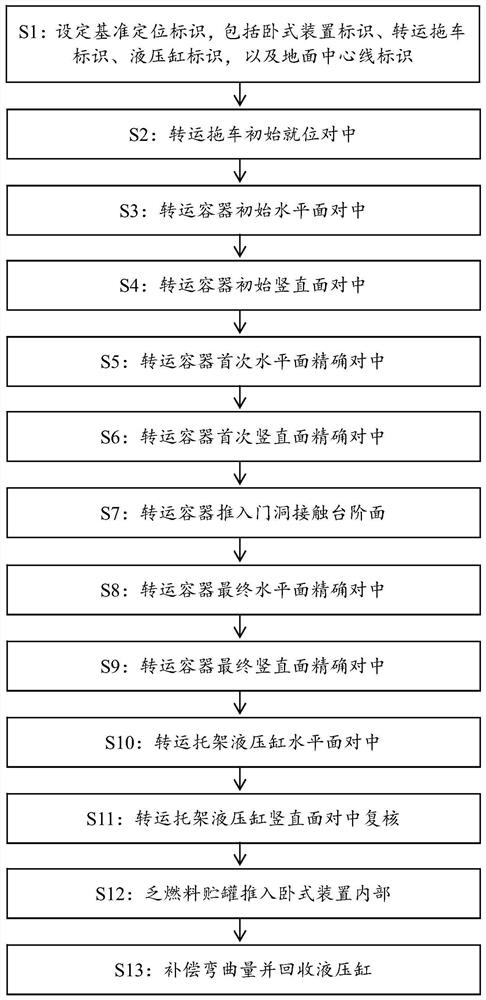

Spent fuel storage tank storage and recovery method

PendingCN112562876ASafe pushPush in accuratelyNuclear energy generationReactor fuel elementsHydraulic cylinderStructural engineering

The invention discloses a spent fuel storage tank storage and retrieval method which comprises the following steps: S1, setting a reference positioning identifier which comprises a horizontal concretemodule identifier, a transfer bracket identifier, a hydraulic cylinder identifier and a ground center line identifier; S2, initially positioning and centering a transfer bracket; S3, centering the initial horizontal plane of a transfer container; S4, centering the initial vertical surface of the transfer container; S5, accurately centering the transfer container on the horizontal plane for the first time; S6, accurately centering the vertical surface of the transfer container for the first time; S7, pushing the transfer container into a door opening of a horizontal concrete module to make contact with the step surface; S8, accurately centering the final horizontal plane of the transfer container; S9, accurately centering the final vertical surface of the transfer container; S10, centeringthe horizontal plane of a hydraulic cylinder of the transfer bracket; S11, centering and rechecking the vertical surface of the hydraulic cylinder of the transfer bracket; S12, pushing a spent fuel storage tank into the horizontal concrete module; and S13, compensating the bending amount, and recycling the hydraulic cylinder.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +3

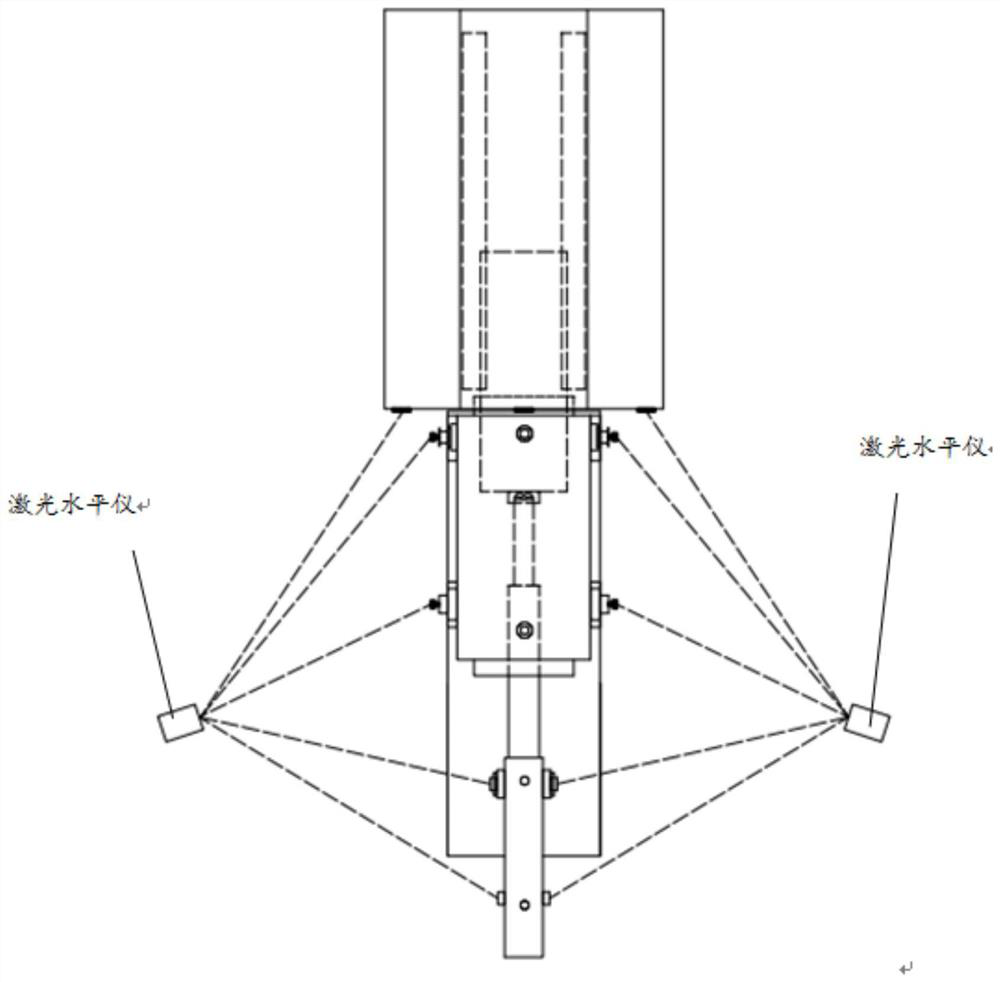

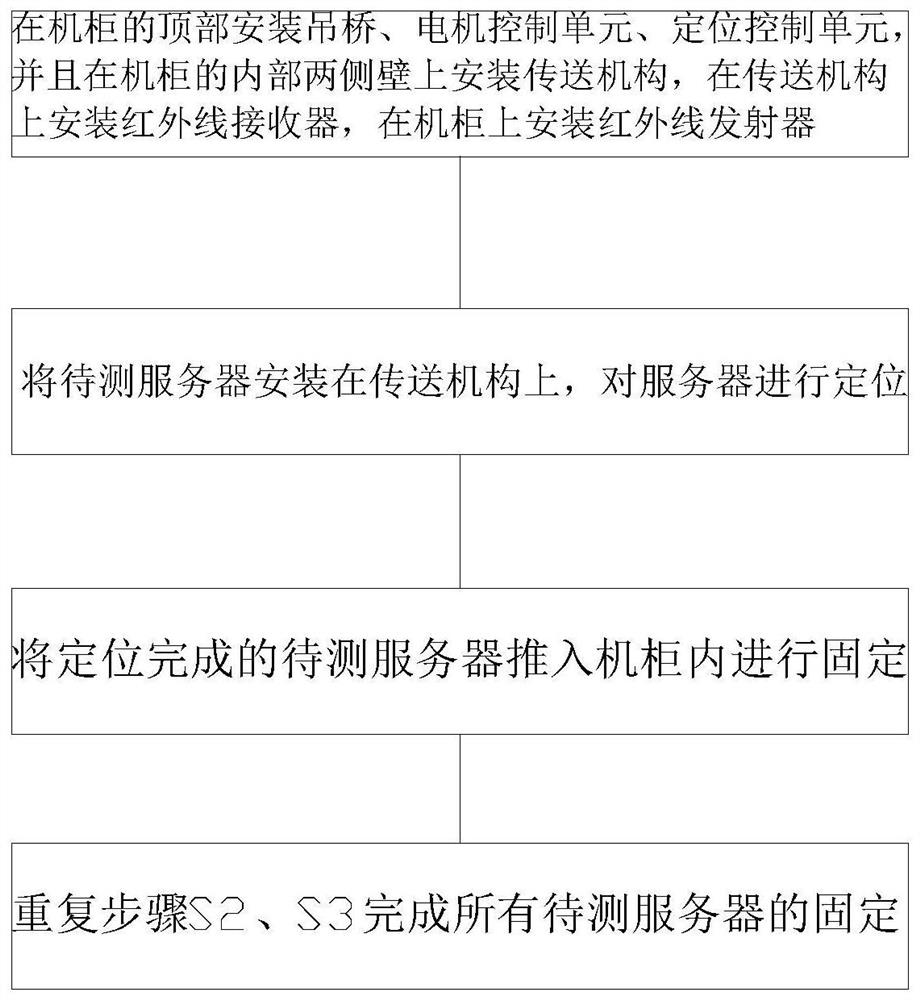

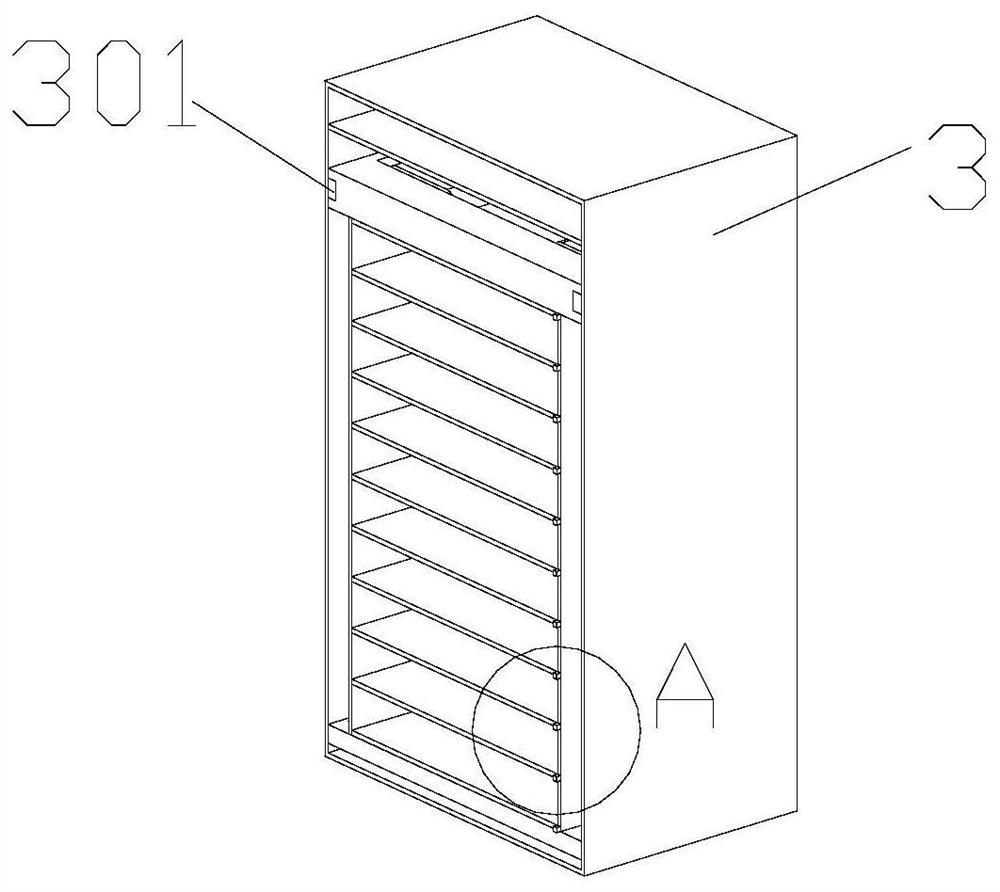

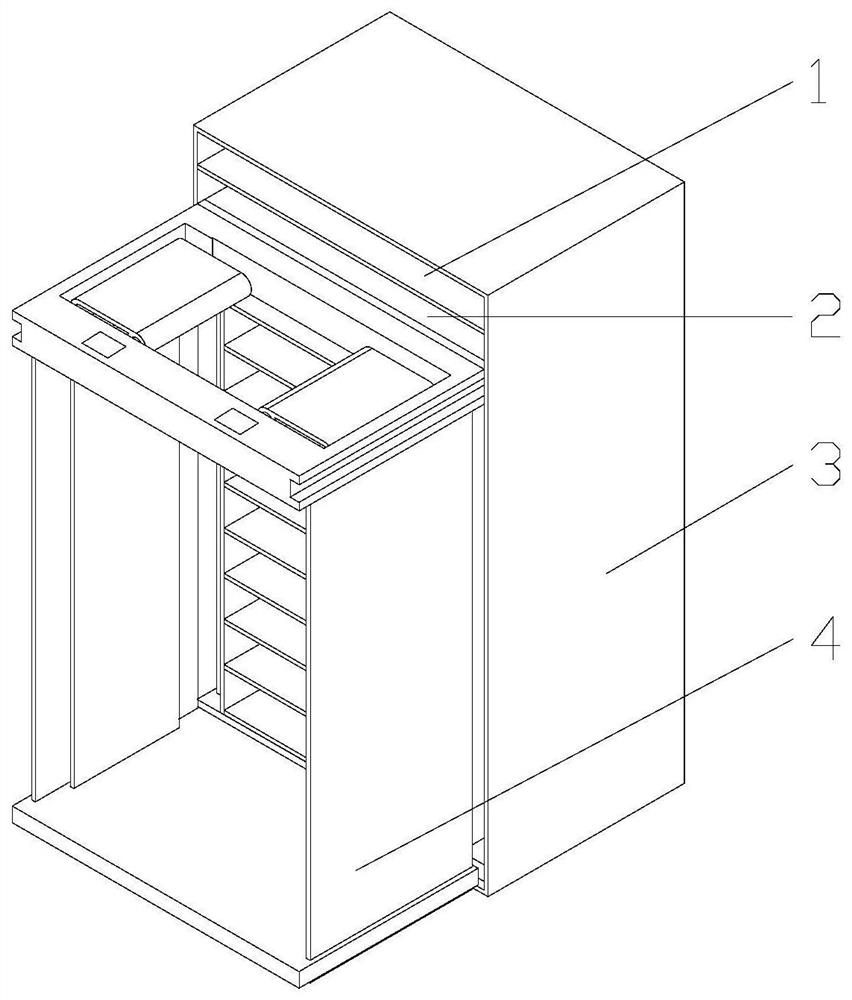

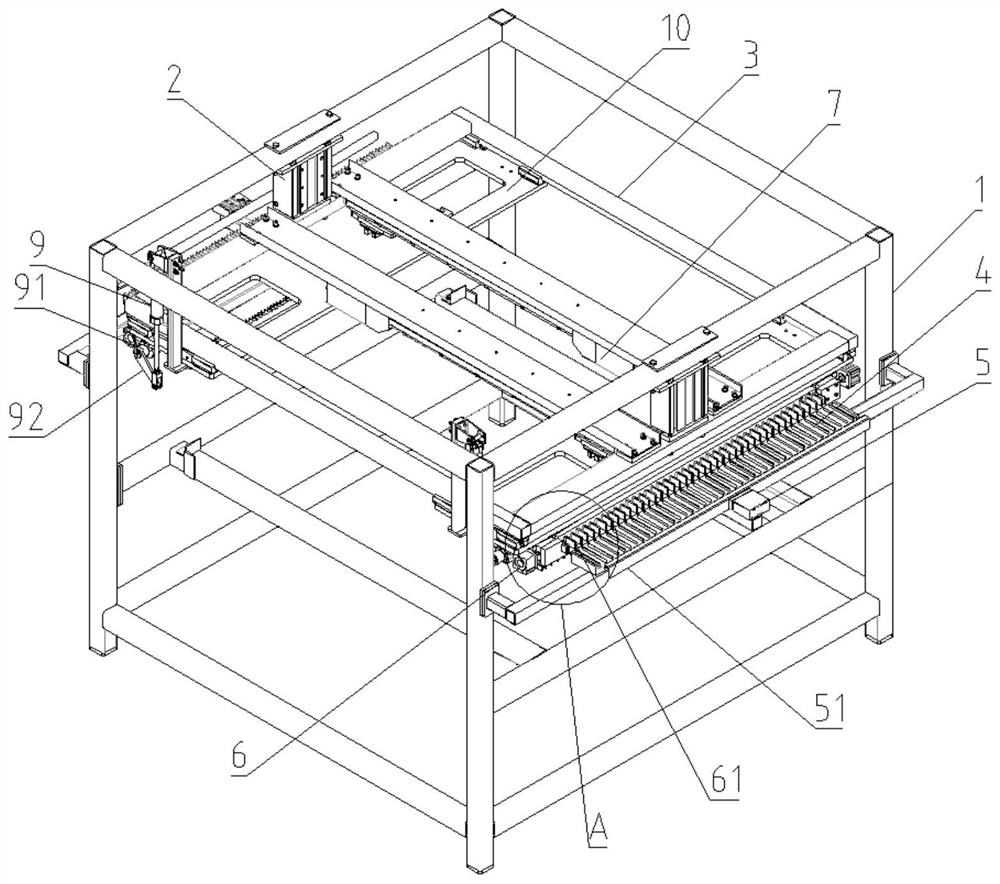

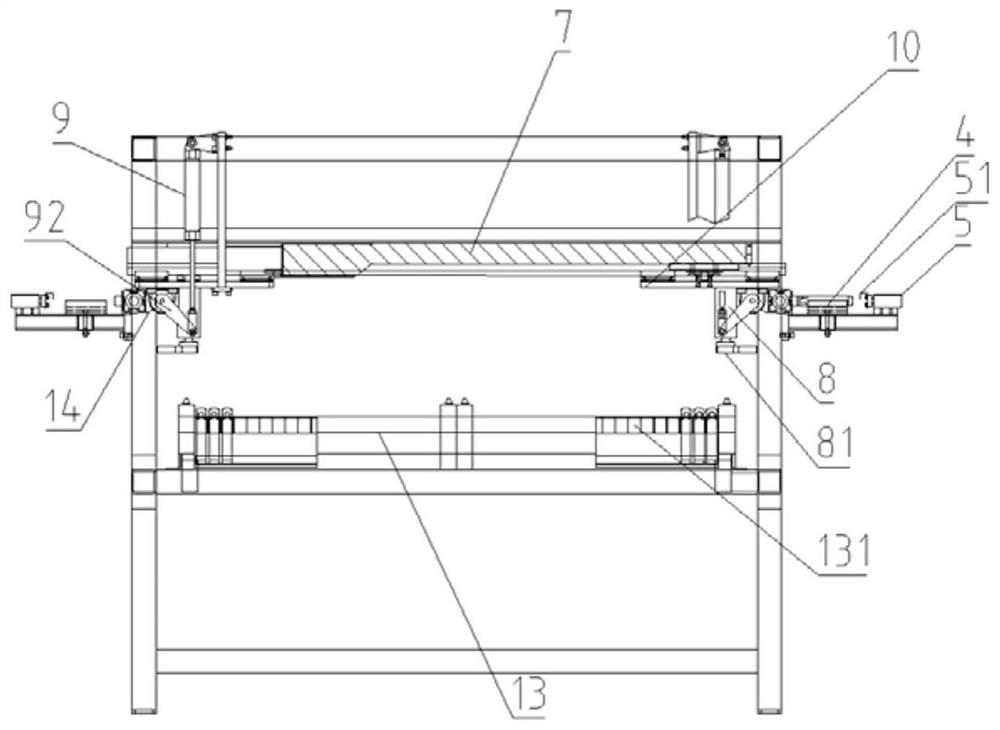

Aerver shelving installation method

ActiveCN111998770AGuaranteed accuracyImprove test efficiencyStructural/machines measurementUsing optical meansElectric machineryStructural engineering

The invention discloses a server shelving installation method which comprises the steps: installing a suspension bridge, a motor control unit and a positioning control unit at the top of a cabinet, installing conveying mechanisms on the two side walls of the interior of the cabinet, installing infrared receivers installed on the conveying mechanisms, and installing infrared emitters on the cabinet; installing to-be-tested servers on the conveying mechanisms, and locating the server; pushing the located to-be-tested servers into a cabinet for fixing; and repeating the S2 and S3 to fix all the to-be-tested servers. An electric control unit controls a driving motor to move to drive a server placement plate to move up and down, and the server is located under the cooperation of the infrared receivers and the infrared emitters, so that the server installation accuracy is ensured, the server test efficiency is improved, the labor intensity can be greatly reduced, and the working efficiency is improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

A floor-type handcart switch cabinet integrated track

The invention relates to the field of power construction technology, and particularly to a floor type handcart switchgear integrated track. The floor type handcart switchgear integrated track comprises a left-handed screw, a right-handed screw and a screw combined operating rod. The left-handed screw and the right-handed screw are fixedly connected with two ends of the screw combined operating rod. The left-handed screw and the right-handed screw are in threaded connection with an integrated track. The integrated track comprises a fixed track base, a fixed track, a spacing bent trough and an auxiliary track. The auxiliary track comprises a base plate, a spacing bent plate, and a pair of side tracks which are parallelly arranged on the base plate. A guiding trough is formed between the twoside tracks. The side track at the side which is far from the spacing bent plate is provided with a bell mouth guiding trough which is outwards opened. The base plate at the bell mouth guiding troughis an oblique surface which inclines downwards. The floor type handcart switchgear integrated track realizes a fact that a switchgear handcart can be more safely, stably, conveniently and accurately pushed into the switchgear. Furthermore the floor type handcart switchgear integrated track has advantages of simple structure, convenient operation and effective efficiency improvement and safety improvement of personnel.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +2

A kind of computer assembly equipment and operation method

ActiveCN112975368BAchieve precise positioningAvoid uncertaintyMetal working apparatusGear wheelDrive shaft

A computer assembly equipment and operation method, including a frame, a No. 1 rod frame, a No. 1 rod chute, a No. 1 spring, a motor, a motor gear, a mounting plate, a No. 1 guide rod, a No. No. 1 sliding table, No. 1 nut, No. 2 guide rod, blanking hole, material guide frame, No. 1 motor, No. 1 lead screw, No. 2 motor, No. 2 lead screw, No. 1 cam, No. 1 rod, spline Shaft, spline gear, No. 2 cam, No. 2 lever, No. 2 spring, screw, computer, the lower part of the frame has 4 supporting legs, the front part of the frame has a drive shaft hole, and the rear part of the drive shaft hole has a gear through hole. There is a gear fixing hole on the outside of the gear through hole, there is a No. 1 rod frame at the rear of the gear through hole, there is a No. 1 rod chute in the middle of the No. 1 rod frame, and there are 2 coaxial No. 1 screw holes in the middle of the mounting plate. There is a No. 1 guide rod on both sides of the No. 1 screw hole, and the right side of the mounting plate has an upper mounting surface.

Owner:HARBIN VOCATIONAL & TECHN COLLEGE

Manual feed mechanism for processing automobile engine cylinder

ActiveCN102814691BUnique structureSolve the problem of low efficiency of manual upper and lower fixturesMetal working apparatusEngineeringSprocket

The invention relates to a device which is suitable for the assembly line work of engine cylinders and other parts in the automobile industry, and in particular to a manual feed mechanism for processing an automobile engine cylinder, which is characterized by comprising a support frame, wherein the lower part of the support frame is provided with an air cylinder, vertical wire gauge and a chain wheel are sequentially matched with the upper part of the air cylinder, a rack is matched with the lower part of the chain wheel, a roller is matched with the upper part of the chain wheel, vertical support plates are fixed on the support frame at the periphery of the chain wheel, one sides of the upper parts of the vertical support plates are fixed with a fork support, pneumatic control boxes are respectively fixed on the fork supports, push-in handles are respectively arranged at the upper parts of the pneumatic control boxes, and the vertical support plates at the left side and the right side of the fork support are respectively fixed with a horizontal guide support plate. The manual feed mechanism has a unique structure, can be used for solving the problem of low manual efficiency when materials are loaded and unloaded on a fixture during the processing of engine cylinders and other parts, is reliable and stable, and has high efficiency.

Owner:NINGXIA KOCEL MOLD

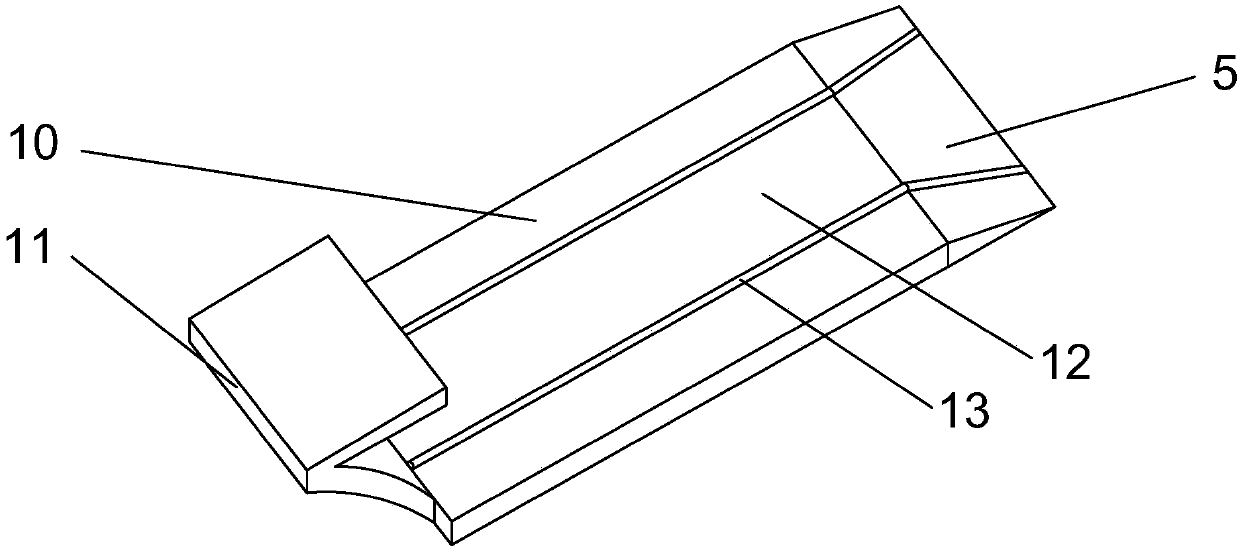

Bearing inner/outer ring grinding machine and bearing inner/outer ring conveying mechanism

The invention provides a bearing inner / outer ring conveying mechanism, including a pushing mechanism and a feeding mechanism, the pushing mechanism includes a support plate and a pushing device, the feeding mechanism includes a feeding channel with an elbow seat, and the elbow seat is detachable Installed on the support plate, the guide channel of the elbow seat is opposite to the pushing direction of the pushing device. The guide channel of the elbow seat is opposite to the pushing direction of the pushing device, ensuring that the pushing device can accurately push the inner / outer ring collar of the bearing into the feeding mechanism, and the detachable installation of the elbow seat and the support plate will make the pushing mechanism It is set as a general model. When it is necessary to change the feeding mechanism to suit a specific type of bearing, the elbow seat part can be disassembled from the support plate for replacement, which avoids dismantling the entire structure of the elbow seat part and the pushing device. Replacement reduces the difficulty of disassembly. The invention also provides a bearing inner / outer ring grinding machine.

Owner:慈溪市大道机械厂

Coupler and its locking method

ActiveCN112896224BPush in accuratelyThe sliding track is clear and clearRailway coupling accessoriesStructural engineeringMechanical engineering

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

Emergency plugging mechanical plug for ferronickel heating furnace

The invention discloses an emergency plugging mechanical plug for a ferronickel heating furnace. A steel plate is fixedly installed on the right side of a plug body, and a steel pipe is welded to the right side of the steel plate. The emergency plugging mechanical plug comprises a transmission inner threaded pipe, an outer connecting sleeve and a button. The transmission inner threaded pipe is in threaded connection with the steel pipe, the right side of the transmission inner threaded pipe is in threaded connection with a transmission outer threaded pipe, and the transmission outer threaded pipe is connected with a drill rod of an external trepanning machine. The outer connecting sleeve is arranged on the surface of the plug body in a sleeving mode, and a deep groove is formed in the outer connecting sleeve. The button is movably installed in the outer connecting sleeve. According to the emergency plugging mechanical plug for the ferronickel heating furnace, the steel pipe is welded to the rear portion of the plug body, then the steel pipe is connected with the drill rod of the trepanning machine through the transmission inner threaded pipe and a transmission outer threaded pipe, the drill rod can be accurately pushed into a slag iron hole through rotation of the trepanning machine and a large arm, and then the plug is beaten into the slag iron hole through the rapping function of the trepanning machine. Sag iron is prevented from flowing out.

Owner:临沂城发钢基新材料科技有限公司

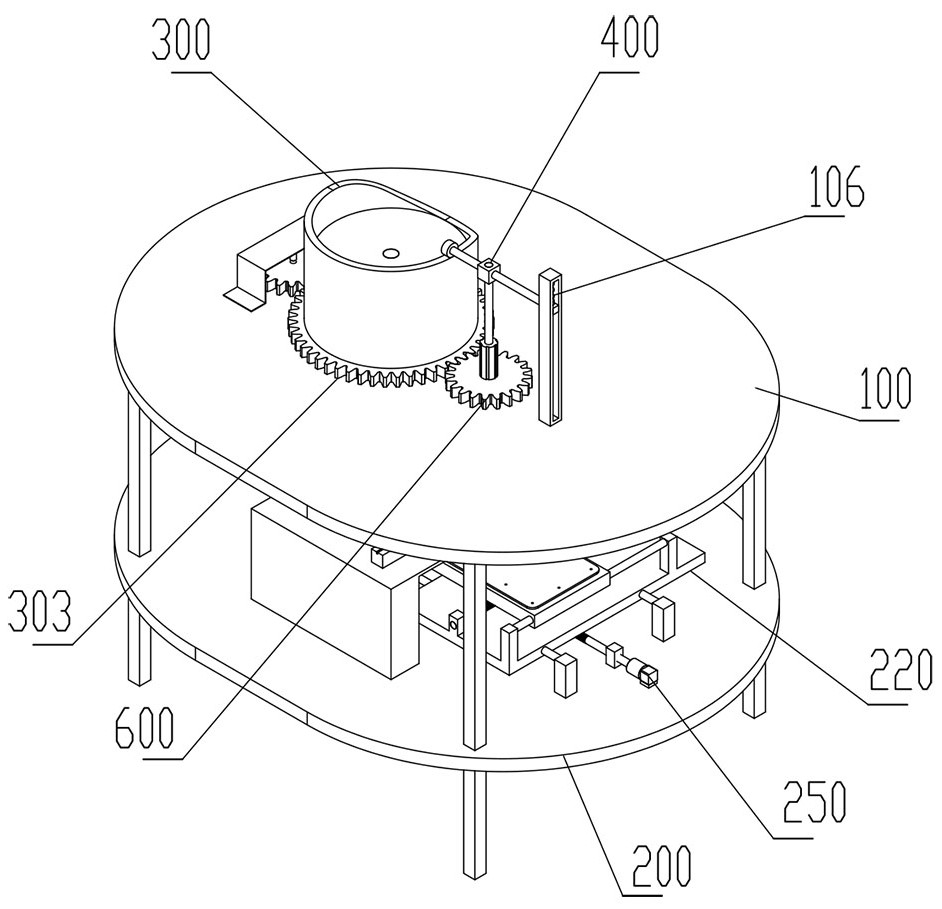

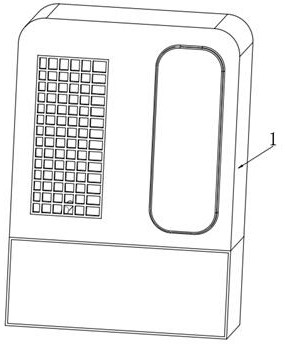

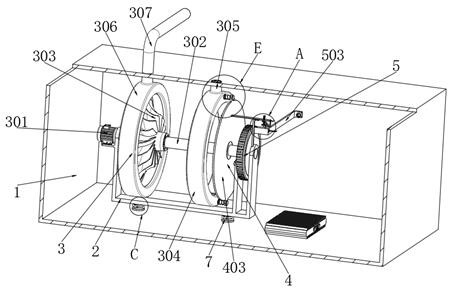

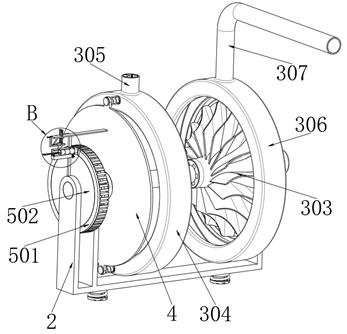

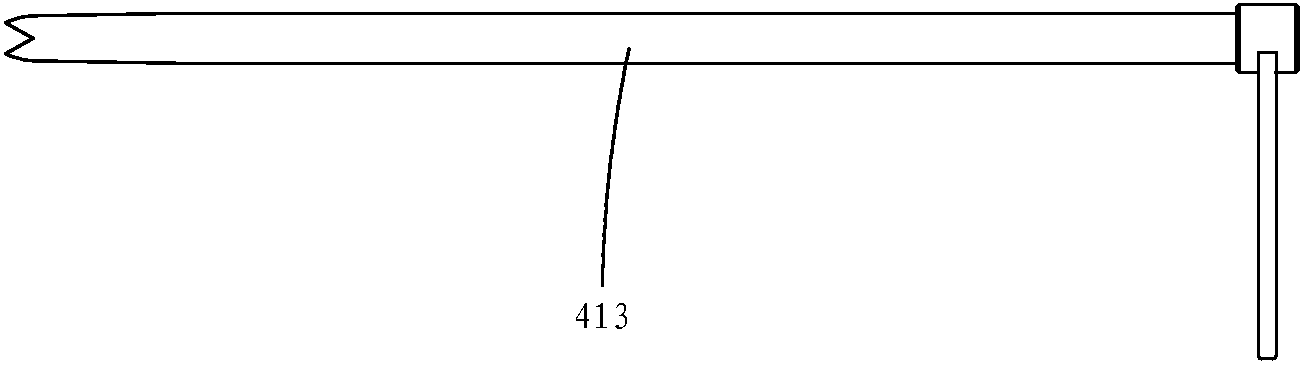

Dynamic balance self-adjusting type fan system

The invention relates to the technical field of gas conveying equipment, in particular to a dynamic balance self-adjusting type fan system. The dynamic balance self-adjusting type fan system comprises a machine body, and a C-shaped frame is arranged in the machine body; an air suction mechanism is arranged on the outer surface of the C-shaped frame and is used for exchanging external airflow; a counterweight mechanism is arranged at one end of the C-shaped frame and is used for balancing the air suction mechanism; the counterweight mechanism comprises a fixing ring, a rotating disc, a fixing block, a placing groove, a counterweight ball, a supporting plate, a push rod, a push plate, a push spring and a counterweight groove, the fixing ring is fixedly connected to the inner surface of the C-shaped frame, the outer surface of the rotating disc is rotationally connected with the inner surface of the fixing ring, and the fixing block is fixedly connected to the outer surface of the upper end of the fixing ring. According to the dynamic balance self-adjusting type fan system, by arranging the counterweight ball in the placing groove, a material pushing mechanism pushes the counterweight ball to roll into the counterweight groove formed in the outer surface of the rotating disc, so that weight of a turbine can be balanced, and the turbine can stably operate.

Owner:DEZHOU KERUITE FAN

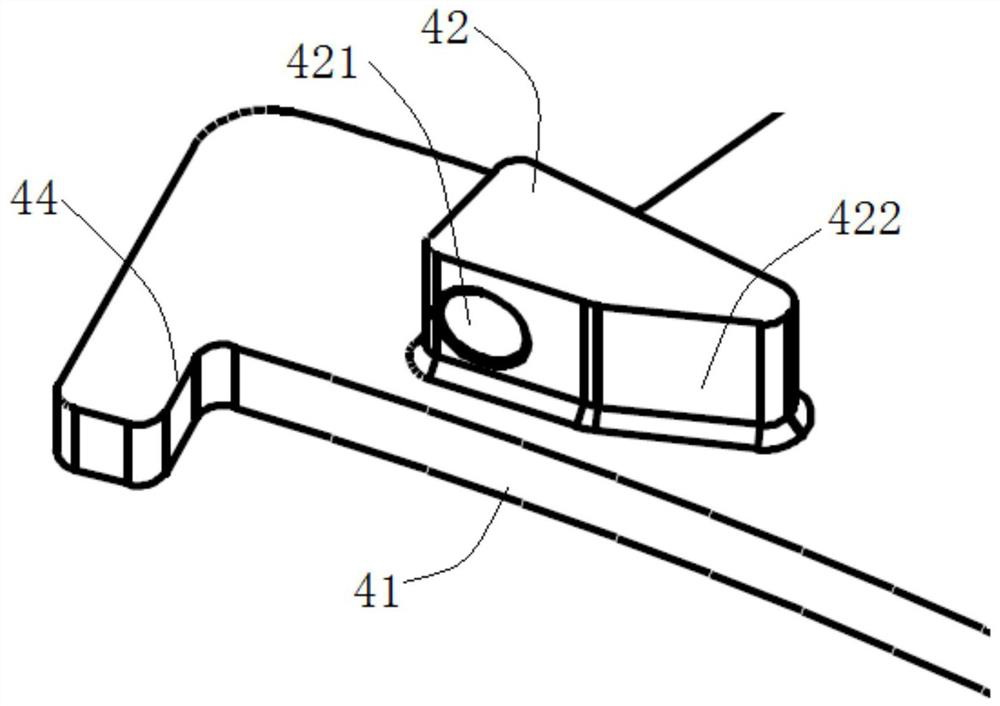

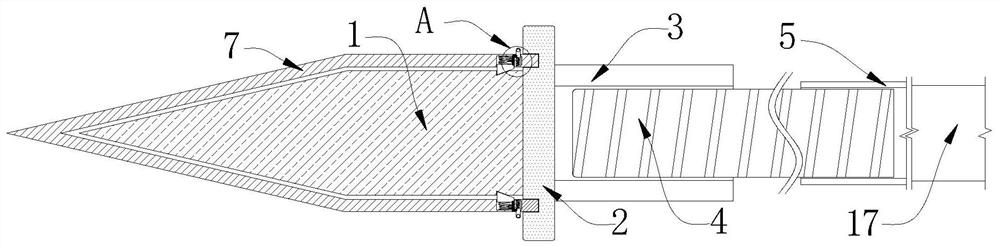

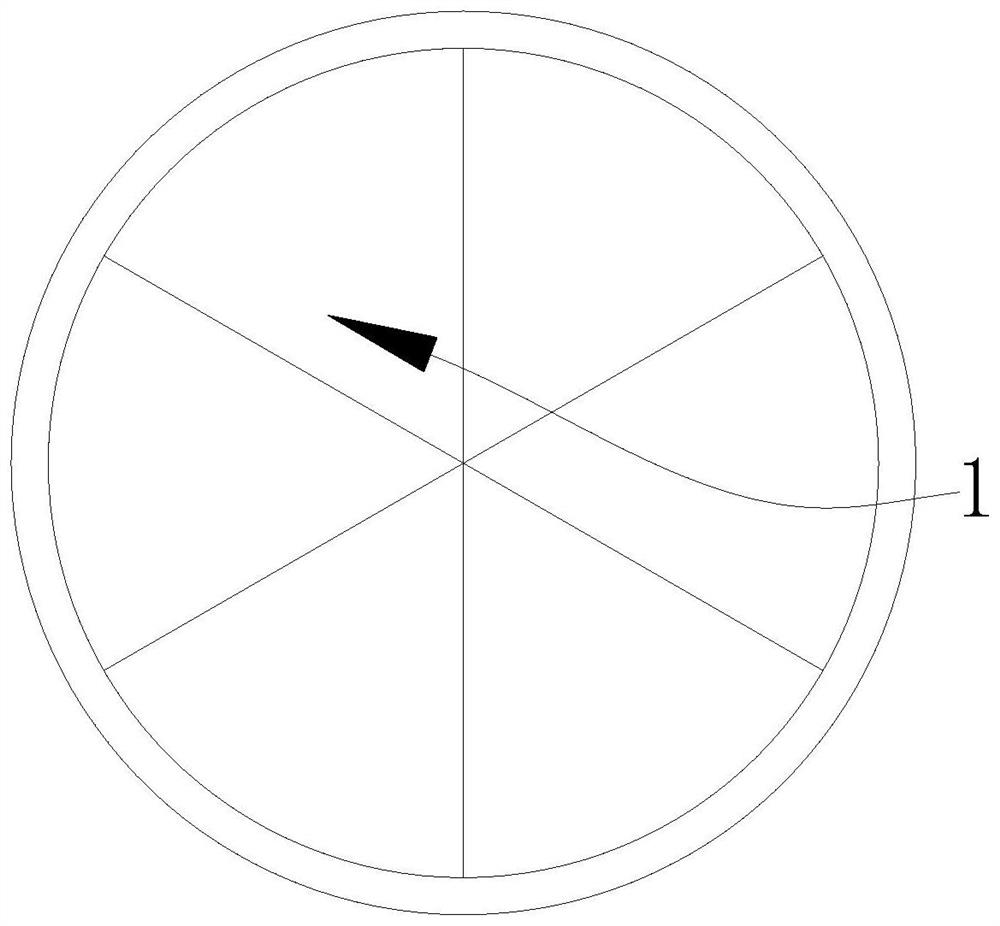

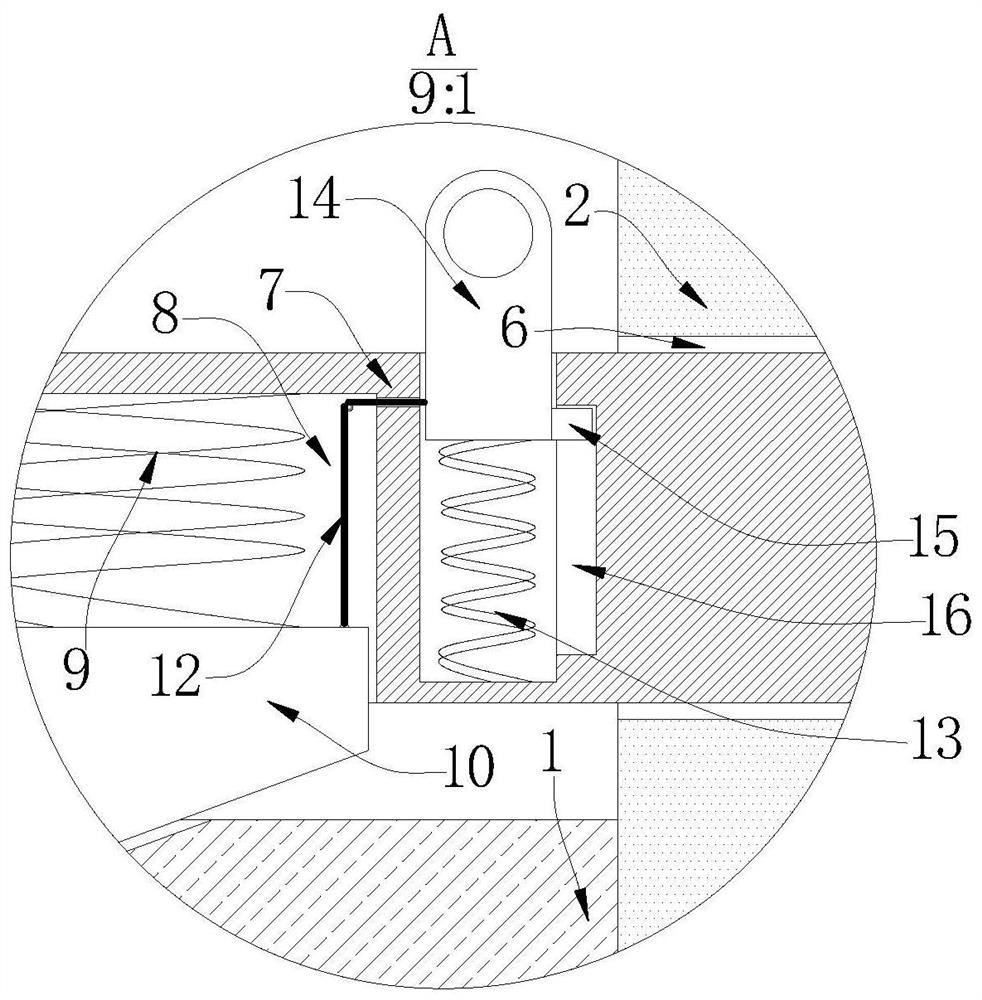

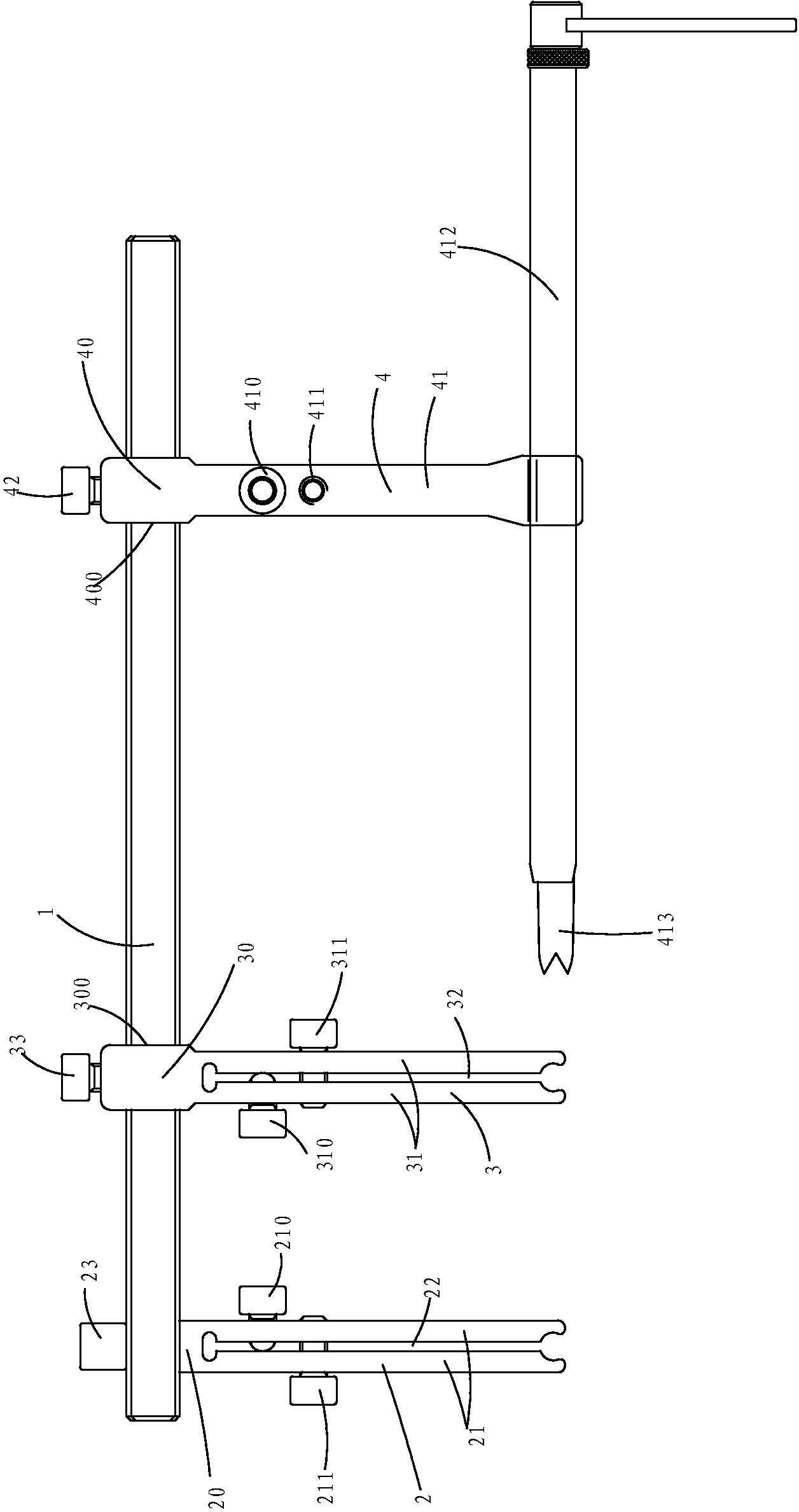

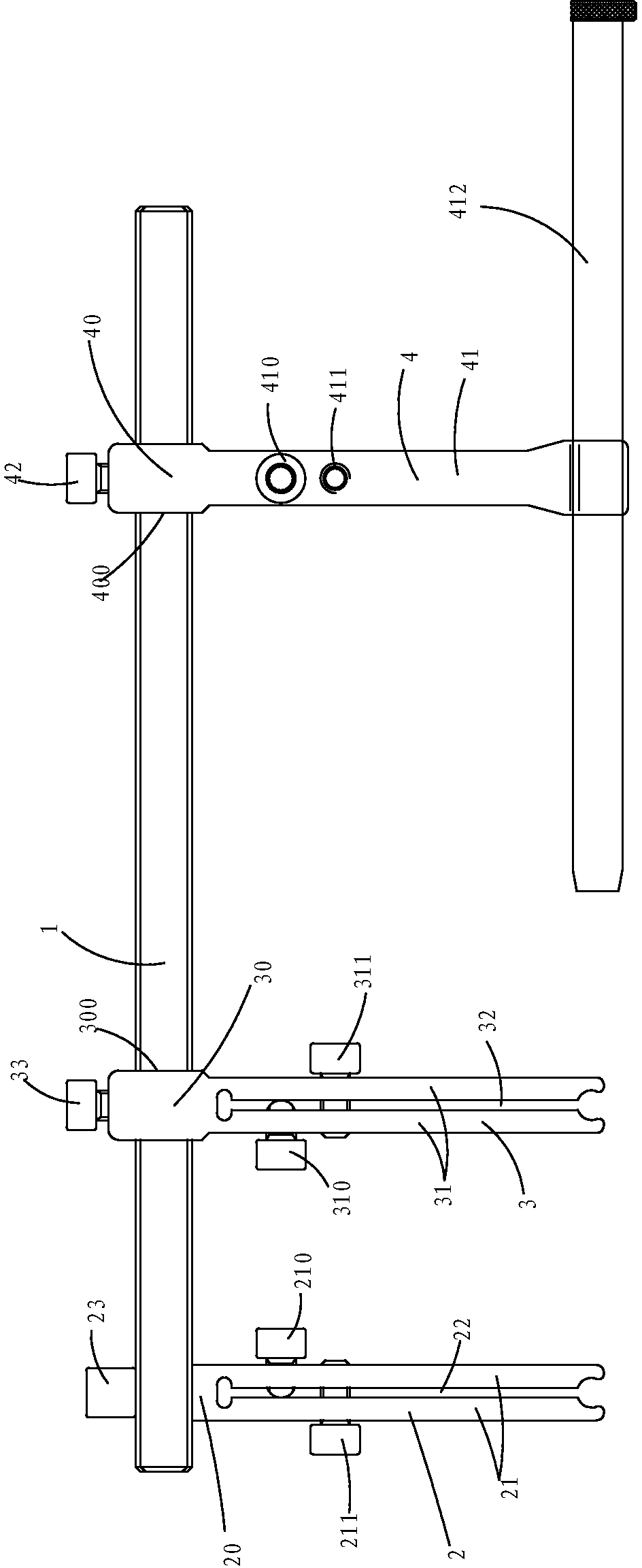

Minimally invasive sighting device

Owner:SUZHOU KANGLI ORTHOPEDICS INSTR +1

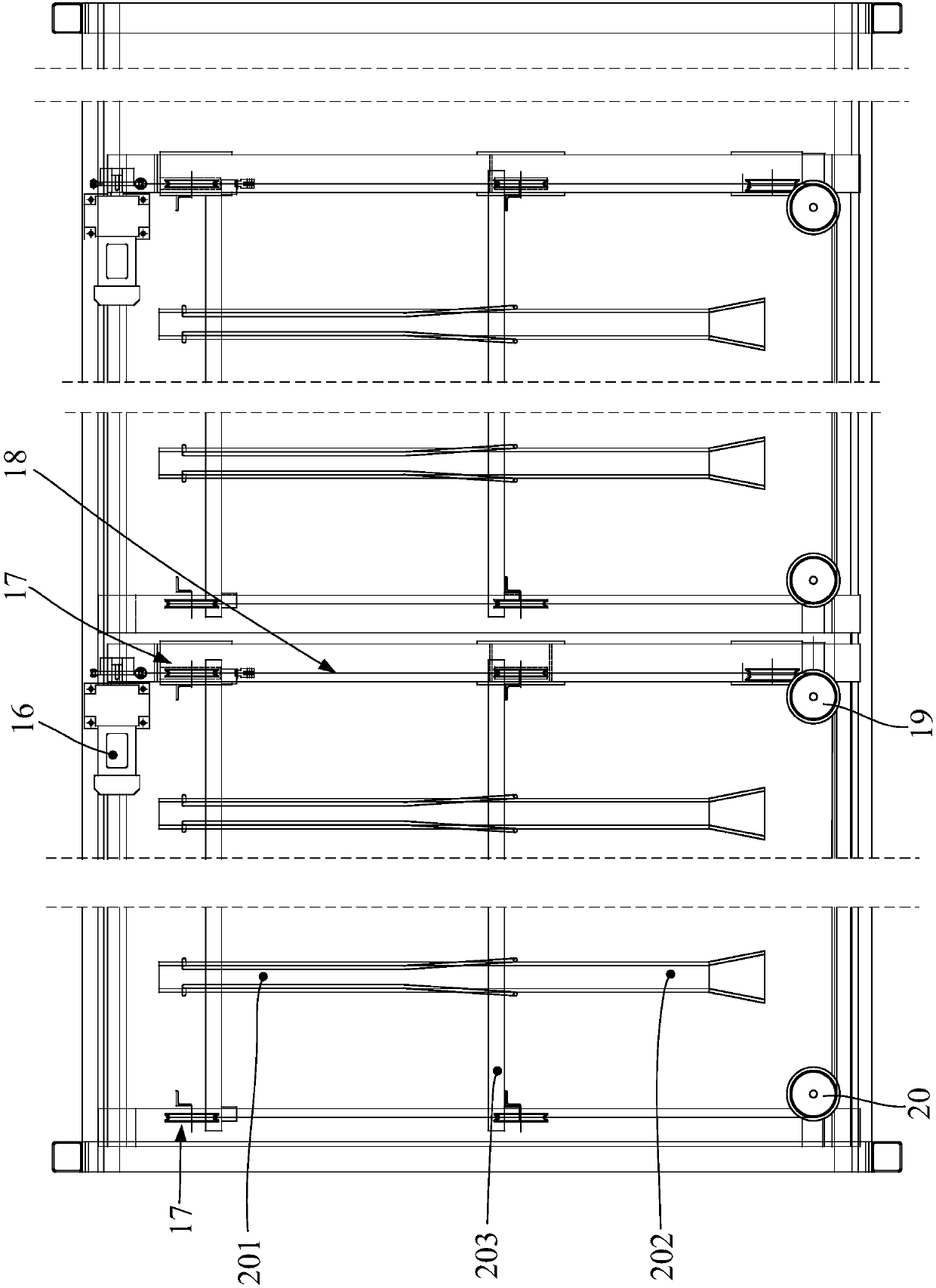

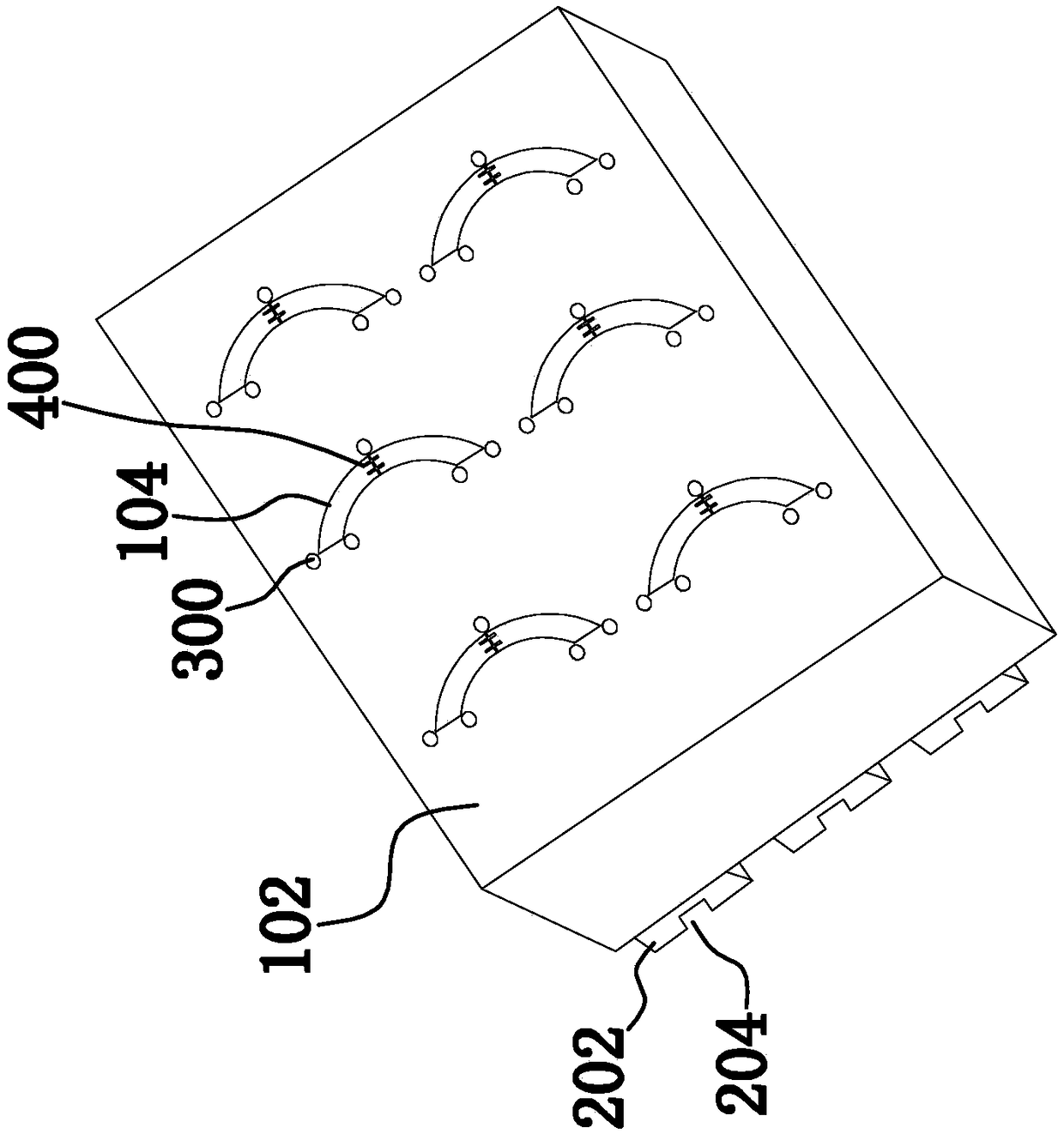

Automatic tray filling machine and automatic tray filling method suitable for strip-bag oral liquid

PendingCN114684399AAvoid misalignmentImprove loading efficiencyIndividual articlesPower apparatusPower output

The invention discloses an automatic tray filling machine suitable for strip oral liquid, and belongs to the technical field of oral liquid tray filling machines. Comprising a rack, a lifting mechanism, a strip bag conveyor, a bag arranging mechanism and a clamping and bagging mechanism. The lifting mechanism comprises a lifting air cylinder and a lifting support, the lifting air cylinder is fixedly installed on the rack, and the power output end of the lifting air cylinder is connected with the lifting rack. The bag arranging mechanism comprises a bag arranging air cylinder and a bag arranging plate, and the bag arranging plate is installed at the power output end of the bag arranging air cylinder. The clamping and bagging mechanism comprises a bag moving mechanism, a bag clamping mechanism and a rotating mechanism; the bag clamping mechanism comprises a bag clamping power device, a connecting rod, a supporting plate and a bag clamping plate, the power output end of the bag clamping power device is connected with the bag clamping plate through the connecting rod, and the supporting plate is fixedly installed on the connecting rod and supports the bag clamping plate. The invention further discloses a strip bag oral liquid dishing method. The device is ingenious in design and reasonable in structure, the labor intensity of workers can be relieved, the production efficiency can be improved, and the production cost can be saved.

Owner:连云港千樱医疗设备有限公司

Minimally invasive sighting device

Owner:SUZHOU KANGLI ORTHOPEDICS INSTR +1

A sorting and counting packaging machine for coins

InactiveCN106683265BEasy to sort and packReduce in quantityCoin countersEngineeringPackaging machine

The invention relates to a coin classifying, counting and packing machine which comprises a coin classifier and a coin packer. The coin classifier comprises a coin pushing-in device, a coin turning device, a coin gathering device and a coin flow limiting device which are sequentially connected from top to bottom. The coin classifying, counting and packing machine is compact in structure, high in reliability, good in performance, low in cost, high in coil classifying efficiency and capable of avoiding blockage, stacking and malposition in the process of classifying.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com