Medical glass tube cleaning equipment

A technology for cleaning equipment and glass tubes, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of easily polluted glass tubes, low cleaning efficiency of glass tubes, etc., to prevent secondary pollution and save money. Cleaning time, effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

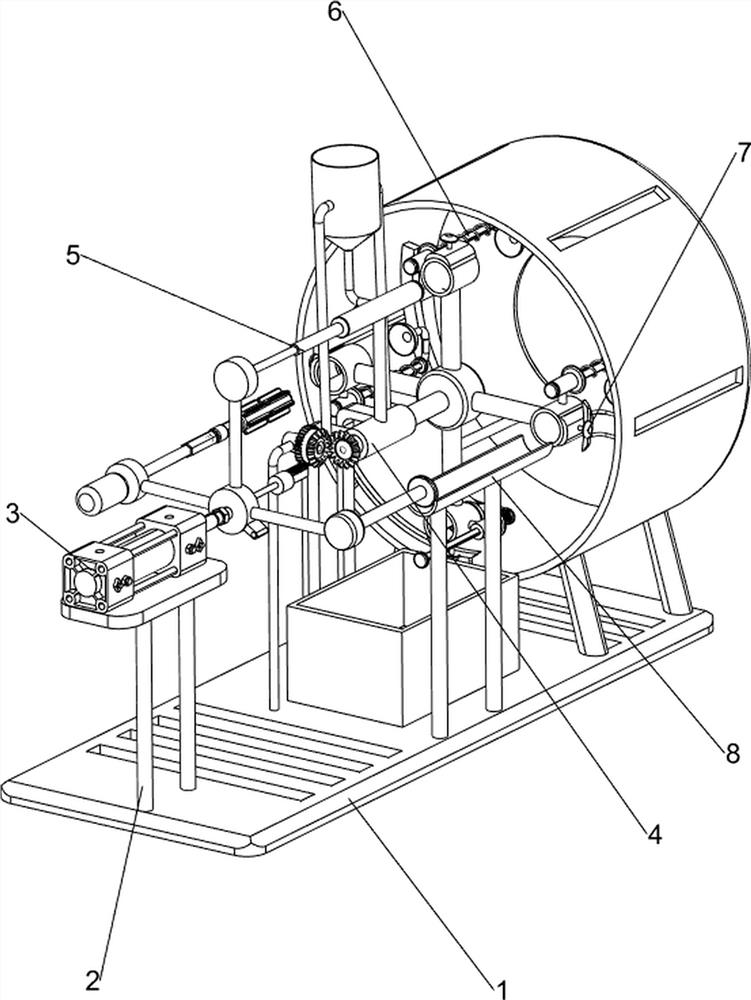

[0066] A medical glass tube cleaning equipment, such as Figure 1-5 As shown, it includes a base 1, a supporting platform 2, a pushing mechanism 3, a cleaning mechanism 4, and a rotating mechanism 5. The left side of the top of the base 1 is provided with a supporting platform 2, and the left side of the supporting platform 2 is provided with a pushing mechanism 3. A cleaning mechanism 4 is arranged in the middle of the top of the table 2, and the cleaning mechanism 4 is connected with the pushing mechanism 3, and the right side of the cleaning mechanism 4 is provided with a rotating mechanism 5.

[0067] When the medical staff needs to clean the glass tube, the medical staff puts the glass tube into the cleaning mechanism 4, and then starts the pushing mechanism 3. After the pushing mechanism 3 is started, it drives the rotating mechanism 5 to move to the right, and simultaneously drives the cleaning mechanism 4 to rotate. After the rotating mechanism 5 moves to the right pos...

Embodiment 2

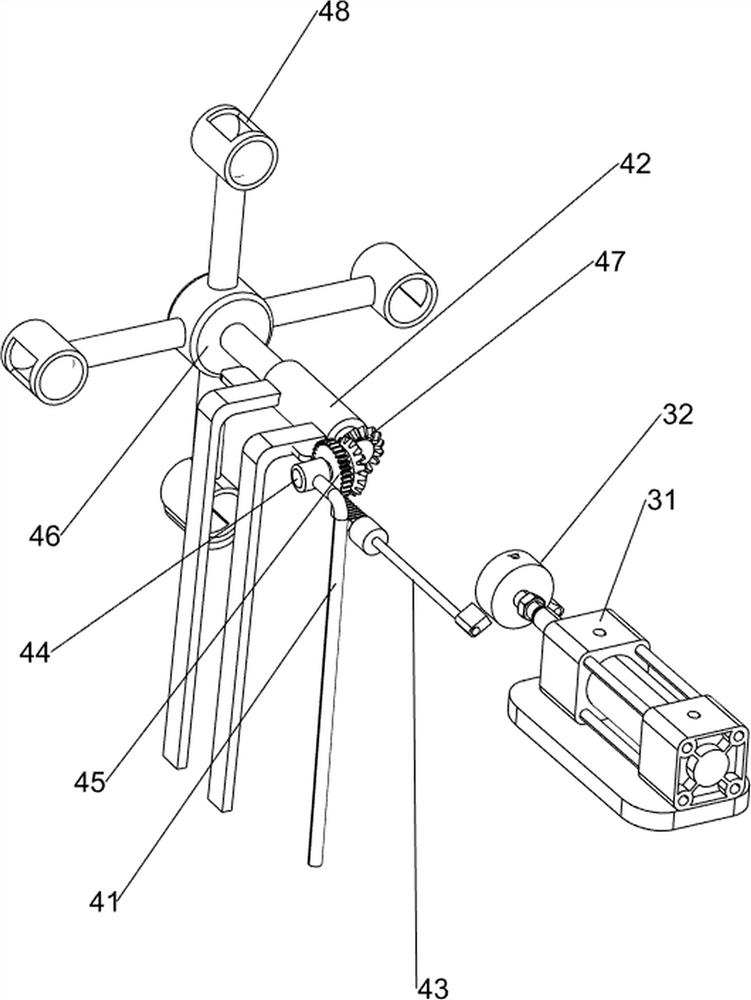

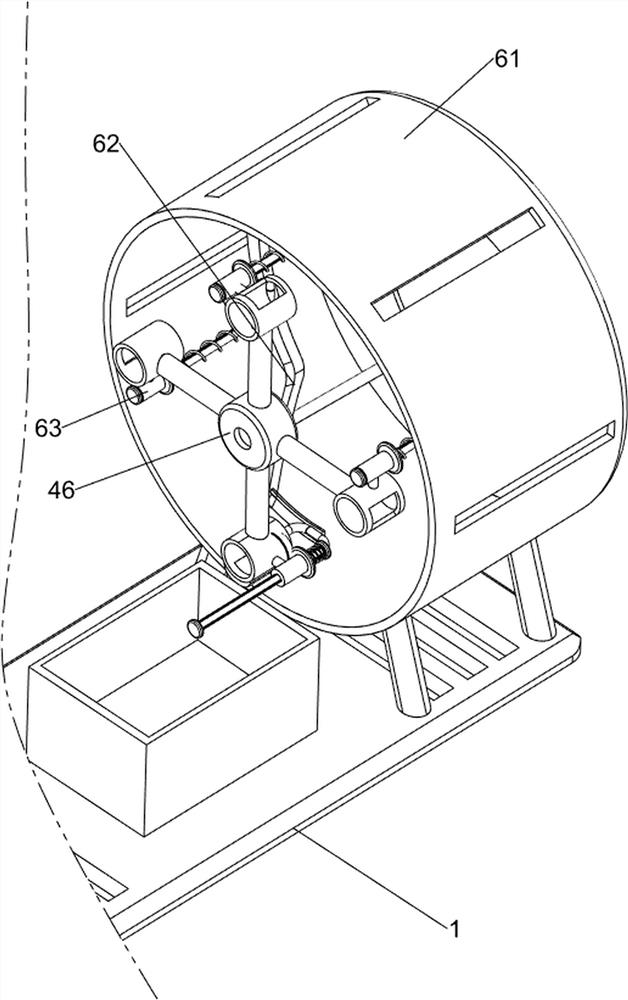

[0075] On the basis of Example 1, such as Figure 6-10 As shown, it also includes a blanking mechanism 6, a clamping mechanism 7 and a loading mechanism 8. The right side of the top of the base 1 is provided with a blanking mechanism 6, and the cleaning mechanism 4 and the blanking mechanism 6 are provided with a clamping mechanism 7. The base 1. A feeding mechanism 8 is arranged in the middle of the top, and the feeding mechanism 8 is located at the front side of the rotating mechanism 5.

[0076] In order to clean the glass tube better, people can put the glass tube into the feeding mechanism 8, and drive the feeding mechanism 8 to move through the push plate 32, thereby pushing the glass tube into the material receiving block 48, and the clamping mechanism 7 can better The fixed glass tube, when the glass tube rotates to the lower side, will cooperate with the blanking mechanism 6, and the blanking mechanism 6 will push out the glass tube, so that people can better collect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com