A kind of computer assembly equipment and operation method

A technology for assembling equipment and computers, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of computer damage, time-consuming and laborious, and low efficiency

Active Publication Date: 2022-05-31

HARBIN VOCATIONAL & TECHN COLLEGE

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the process of computer assembly and repair, the shell needs to be connected with the body with screws. The traditional manual installation is time-consuming, laborious and inefficient. It will also cause damage to the computer during the installation process. There is no automatic installation equipment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

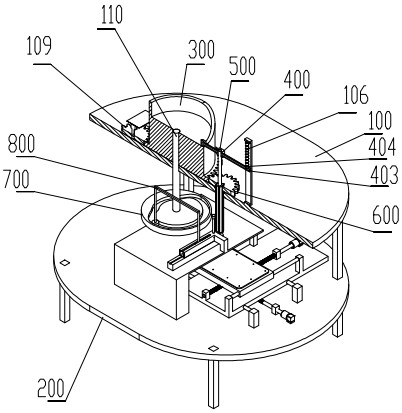

[0049] The push rod 803 is stuck in the guide groove 242 and slides in the guide groove 242, so that the second push rod slider 802 and the second rod

[0050] The fixed shaft 501 is connected to the spline shaft hole 401 through a bearing, so that the spline shaft 500 can rotate without being restricted.

[0058] In the fifth step, until the screw 901 of the computer 902 is completely assembled, 1 working cycle is completed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

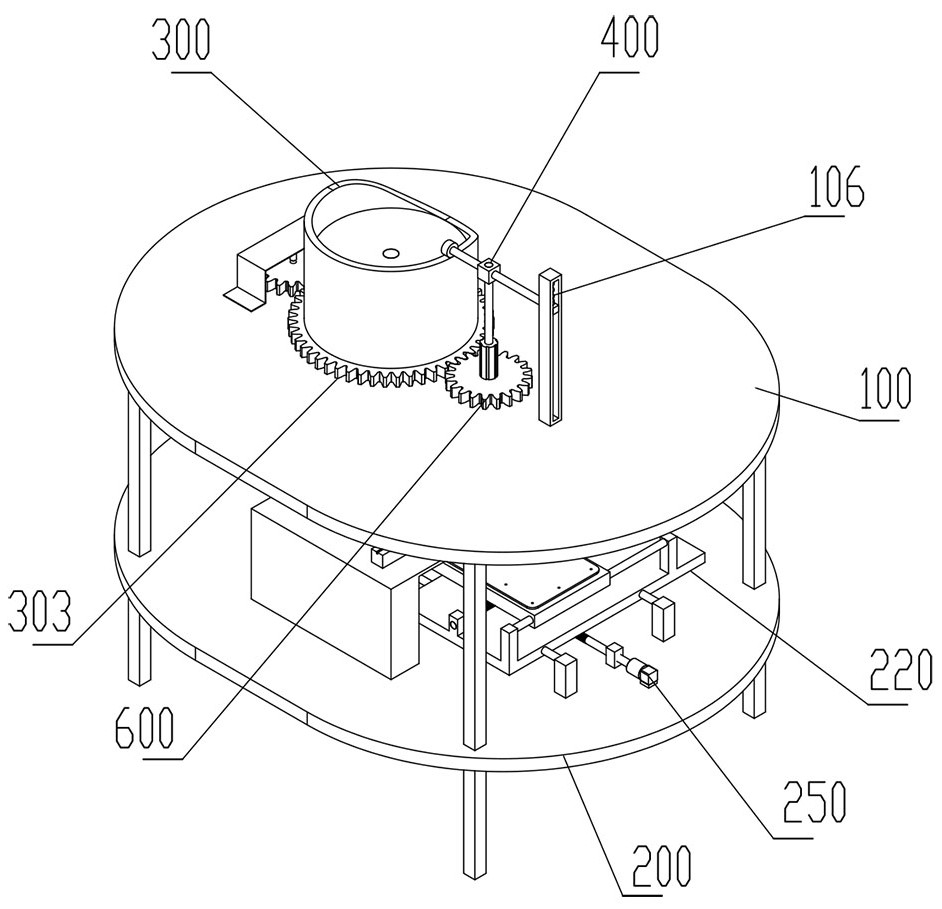

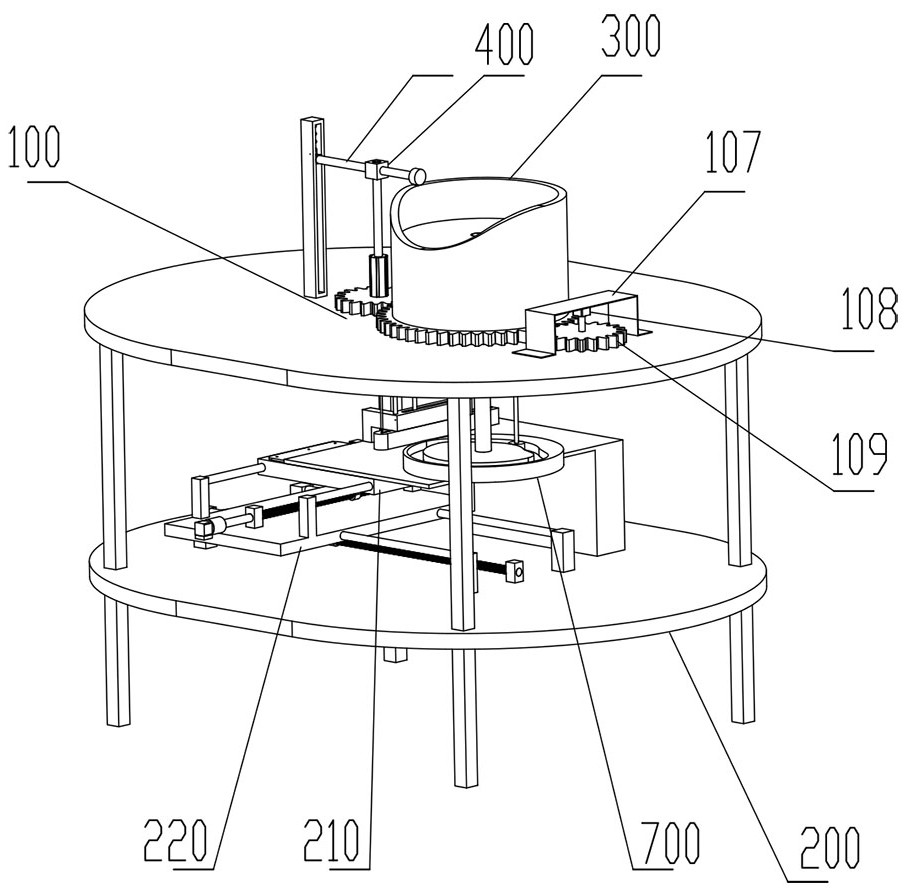

A computer assembly equipment and operation method, including a frame, a No. 1 rod frame, a No. 1 rod chute, a No. 1 spring, a motor, a motor gear, a mounting plate, a No. 1 guide rod, a No. No. 1 sliding table, No. 1 nut, No. 2 guide rod, blanking hole, material guide frame, No. 1 motor, No. 1 lead screw, No. 2 motor, No. 2 lead screw, No. 1 cam, No. 1 rod, spline Shaft, spline gear, No. 2 cam, No. 2 lever, No. 2 spring, screw, computer, the lower part of the frame has 4 supporting legs, the front part of the frame has a drive shaft hole, and the rear part of the drive shaft hole has a gear through hole. There is a gear fixing hole on the outside of the gear through hole, there is a No. 1 rod frame at the rear of the gear through hole, there is a No. 1 rod chute in the middle of the No. 1 rod frame, and there are 2 coaxial No. 1 screw holes in the middle of the mounting plate. There is a No. 1 guide rod on both sides of the No. 1 screw hole, and the right side of the mounting plate has an upper mounting surface.

Description

A computer assembly equipment and operation method technical field [0001] The present invention relates to the field of computer equipment repair, in particular to a computer assembling equipment and an operating method. Background technique In the computer assembling and repairing process, the shell needs to be connected with the body with screws, and the traditional manual installation is relatively expensive. It is time-consuming, inefficient, and will cause damage to the computer during the installation process. There is a lack of an automatic installation device. SUMMARY OF THE INVENTION [0003] The present invention provides a computer assembling device and an operating method for the above-mentioned deficiencies existing in the prior art. The object of the present invention is to realize through the following technical solutions: A kind of computer assembling equipment, comprises rack, No. 1 rod frame, No. 1 rod chute, No. 1 spring, motor, motor gear Wheel,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23P19/06B23P19/00

CPCB23P19/06B23P19/001

Inventor 姜宇张向辉黄芳王珈陈頔

Owner HARBIN VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com