Computer assembly equipment and operation method

A technology for assembling equipment and computers, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of computer damage, time-consuming and laborious, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

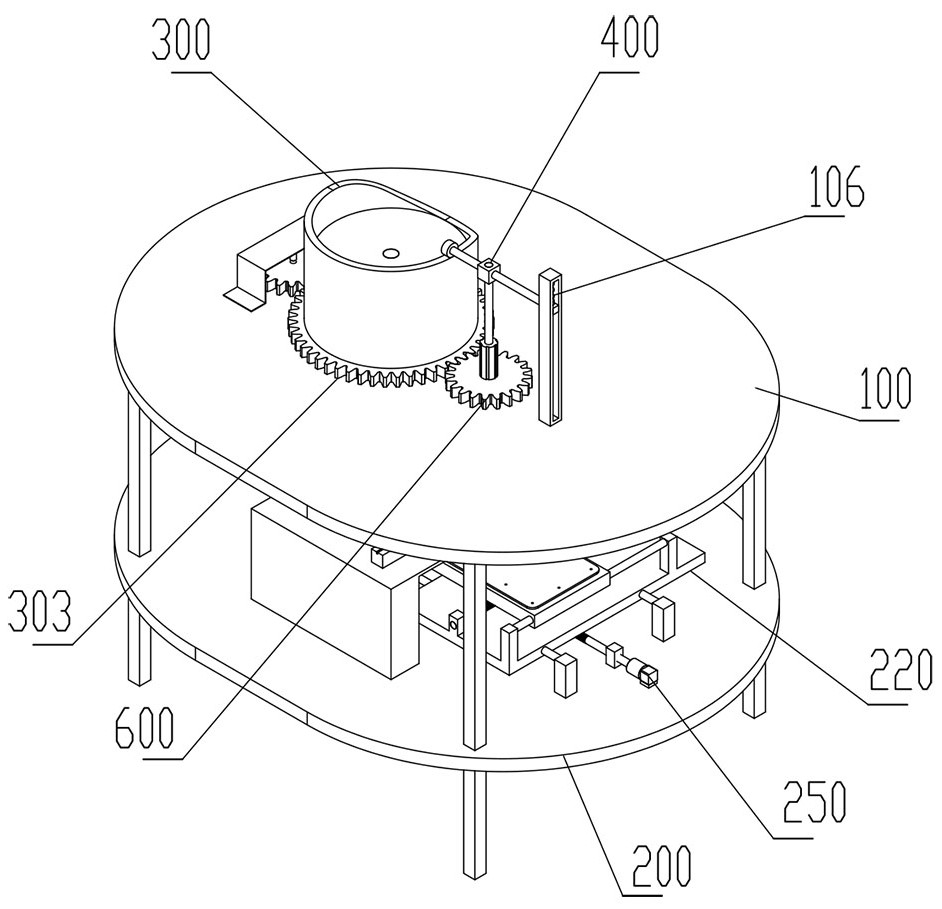

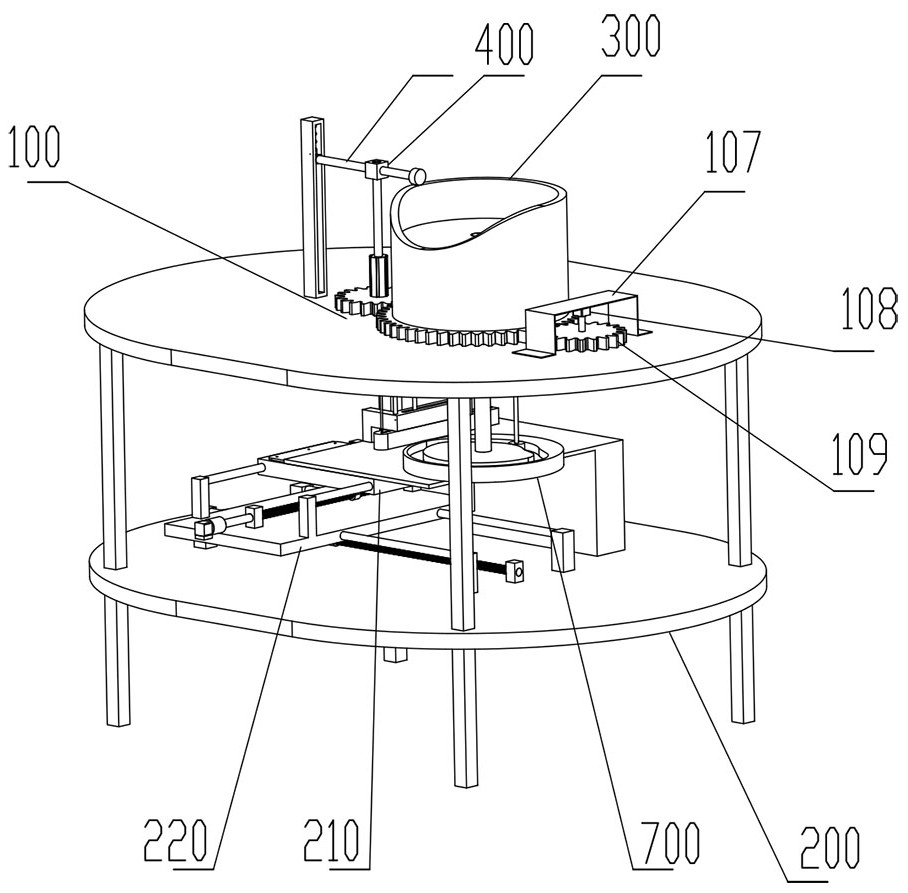

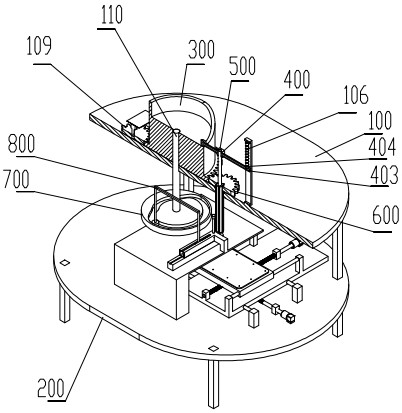

[0038] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

[0039] A computer assembly equipment, including a frame 100, a No. 1 rod frame 104, a No. 1 rod chute 105, a No. 1 spring 106, a motor 108, a motor gear 109, a mounting plate 200, a No. 1 guide rod 203, and a No. 2 sliding table 210, No. 2 nut 211, No. 1 sliding table 220, No. 1 nut 221, No. 2 guide rod 224, blanking hole 231, material guide frame 240, No. 1 motor 250, No. 1 screw 251, No. 2 motor 252, No. two leading screw 253, No. one cam 300, No. one bar 400, spline shaft 500, spline gear 600, No. two cam 700, No. two bar 800, No. two spring 900, screw 901, computer 902, described machine The lower part of the frame 100 has four supporting legs 101, the front of the frame 100 has a drive shaft hole 103, the rear of the drive shaft hole 103 has a gear through hole 102, the outer side of the gear through hole 102 has a gear fixing hole 111, and the rear o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com