Insulator string replacement assembly and insulator string replacement method

A technology of insulator strings and components, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of low efficiency, and achieve the effect of accurate push or push, and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that the following will specifically describe specific embodiments of the end of the robot for live-operated high-voltage transmission lines according to the patent. "Axis directions, etc. are relative directions, and this patent will clearly give definitions in each paragraph or each sub-figure, so those skilled in the art should take the specification as the basis when interpreting these terms.

[0038] It should be pointed out that the specific structures of some commonly used mechanical parts are not drawn or described in detail below, but those skilled in the art can select commonly used structures or equipment to achieve the same or similar technical goals based on the knowledge in the art, so these brief descriptions are not intended to Will affect the enforcement of this patent.

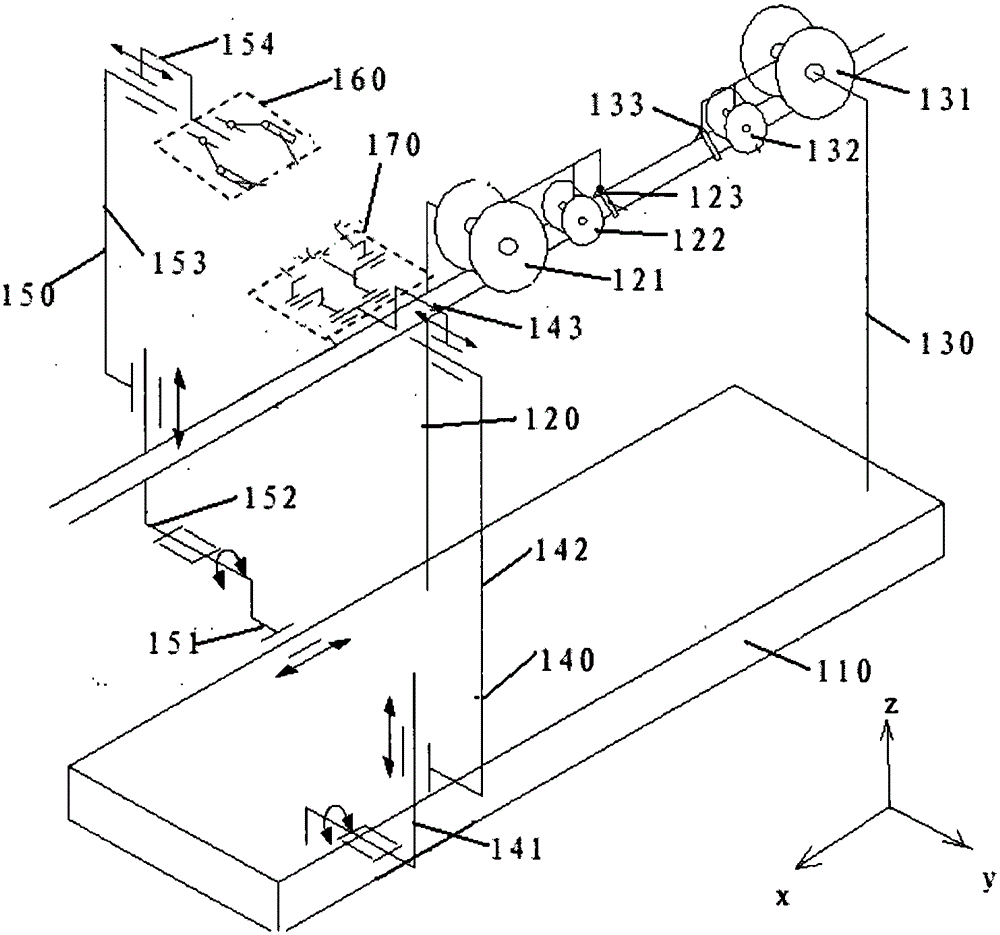

[0039] refer to figure 1 , which shows a schematic structural diagram of a robot suitable for carrying out live operations on high-voltage transmission lines. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com