Automatic boxing machine of cigarette filter sticks

An automatic cartoning machine and filter rod technology, which is applied to e-liquid filter elements, tobacco, packaging, etc., can solve the problems of time-consuming, high labor cost, large production volume, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, an embodiment of the present invention will be specifically described below in conjunction with the accompanying drawings.

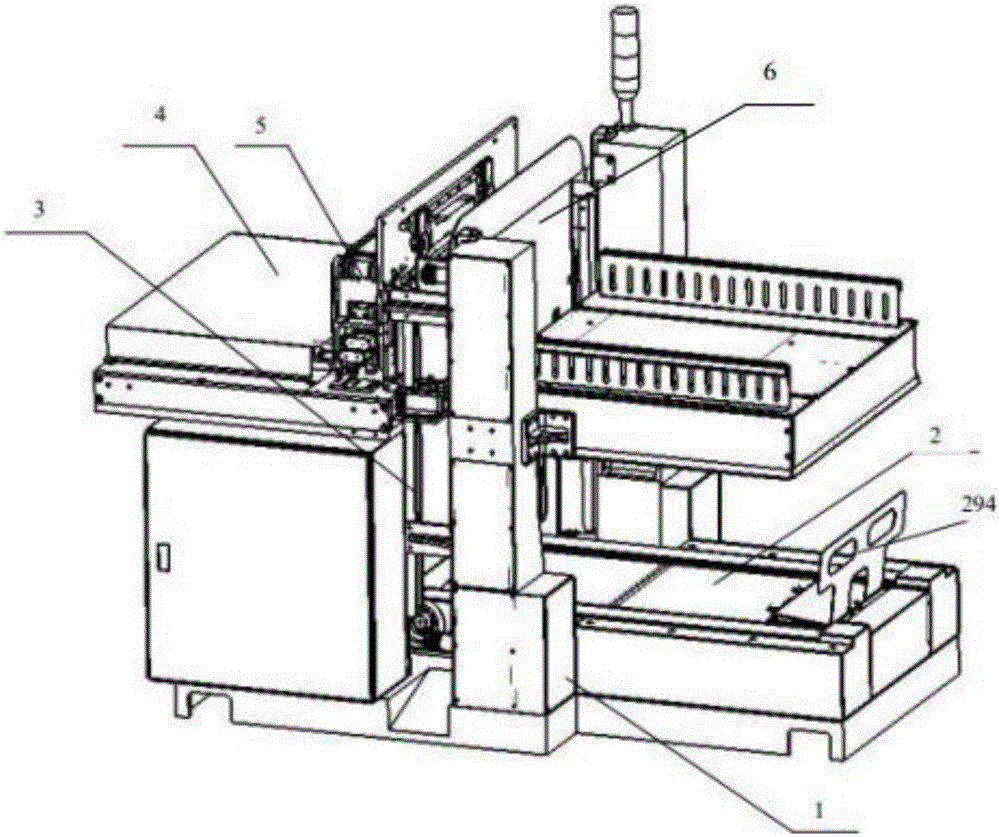

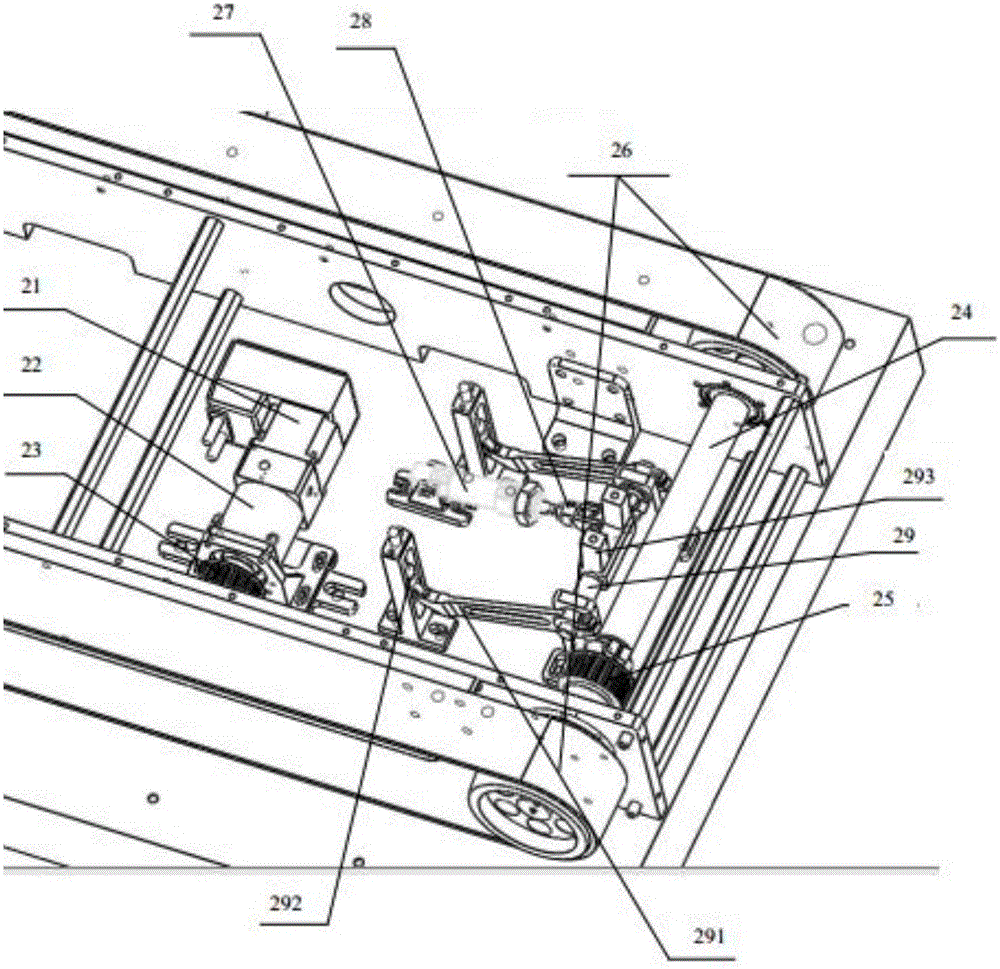

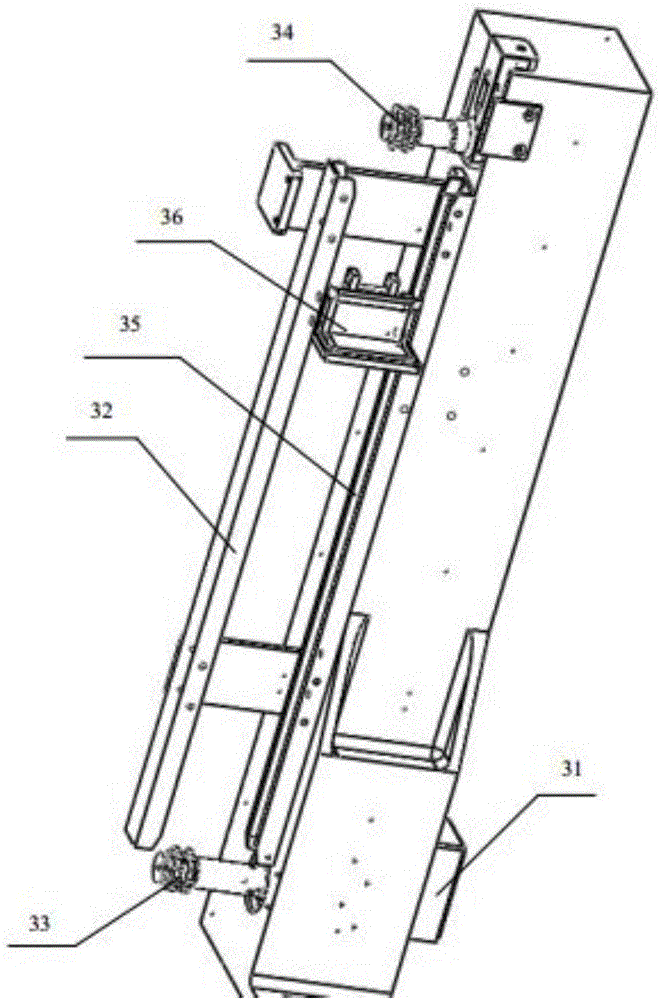

[0031] The invention provides a cigarette filter rod automatic boxing machine, such as figure 1 As shown, it includes a frame 1, a box feeding mechanism 2, a box dragging mechanism 3, and a pushing mechanism 4; wherein the box feeding mechanism is arranged at the bottom of the frame for sending the box 6 to the area to be lifted; the box dragging mechanism is located at The area to be lifted is used to move the box up and down; the pushing mechanism is located on the side of the box dragging mechanism, and is used to accurately push the filter rods arranged in a fixed number into the box. A sorting mechanism 5 is arranged between the material pushing mechanism and the drag box mechanism, and the finishing mechanism nea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com