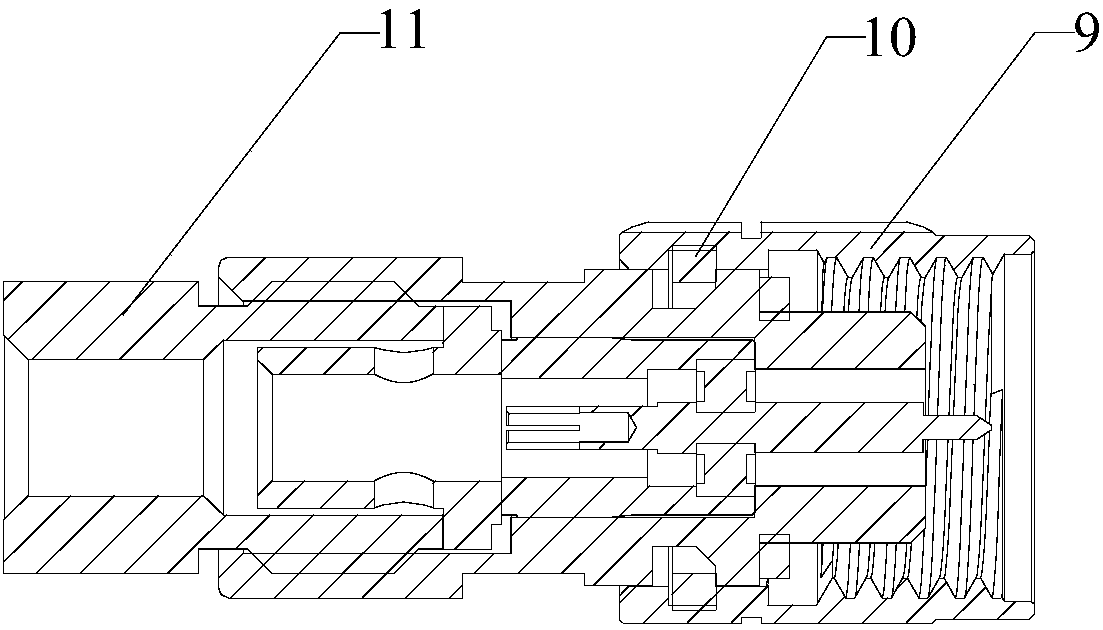

Automatic mounting equipment for screw sleeve and clamping ring

An automatic installation and snap ring technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of consumption, large man-hours and labor costs, and achieve the effect of saving manpower and man-hours, high precision and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

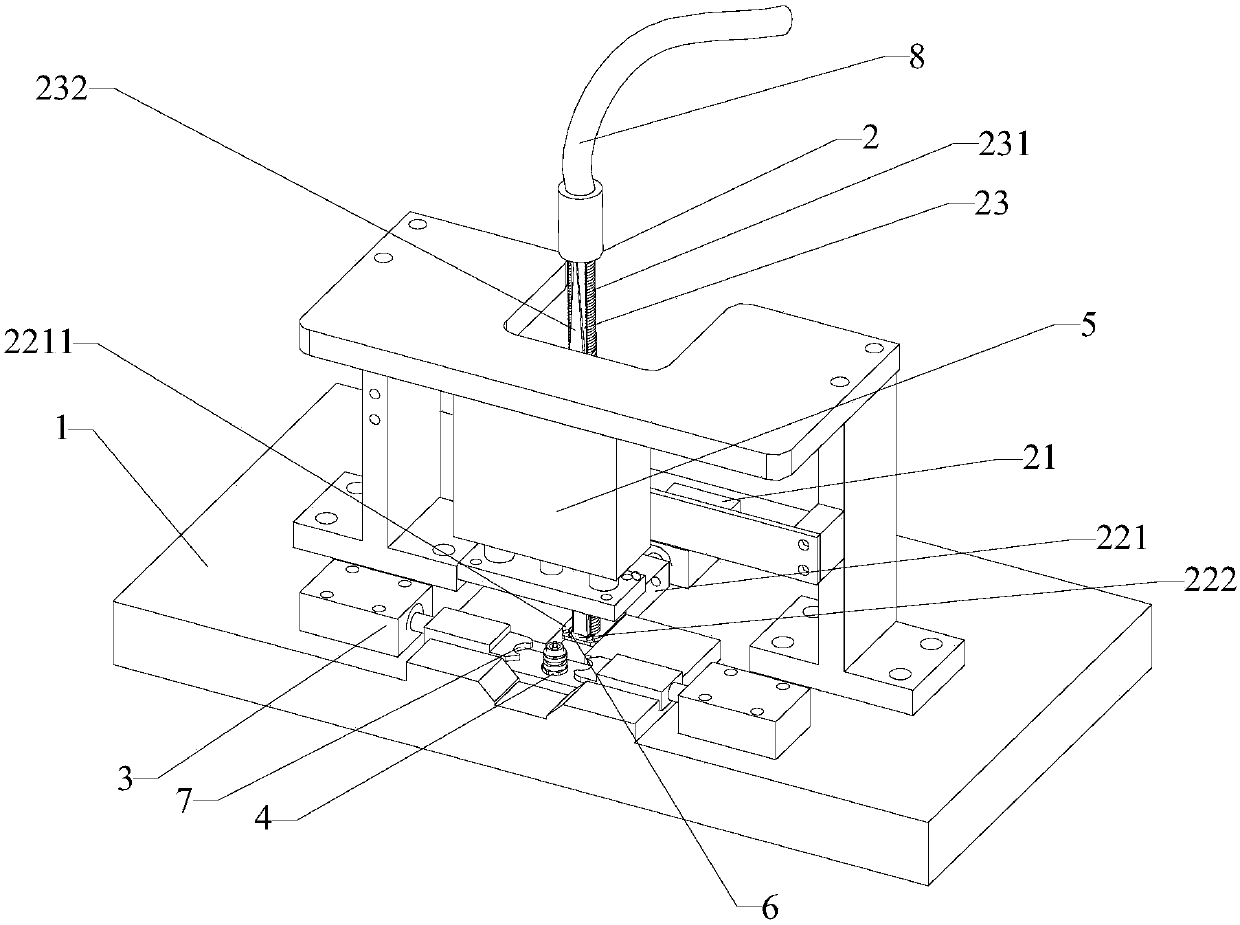

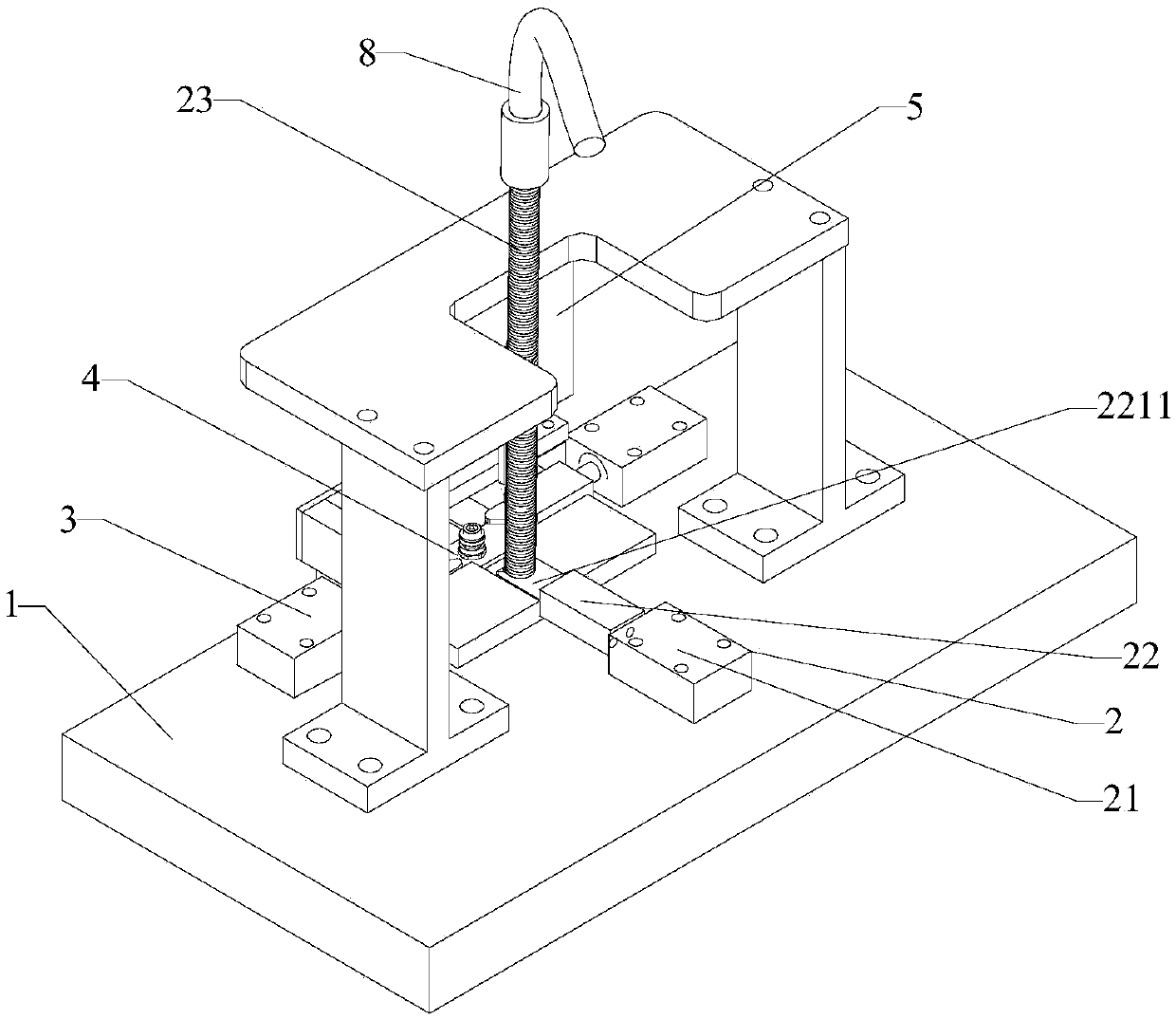

Embodiment 1

[0041] A screw sleeve and snap ring automatic installation equipment, including a feeding device 2 installed on a base 1, a clasp clamp cylinder 3, a connector mounting seat 4 and a screw sleeve pressing cylinder 5; the feeding device 2 includes a feeding cylinder 21 and the feeder 22 that is connected to the piston end of the feeding cylinder 21; the feeder 22 includes a feeder body 221 and a material holding platform 222, and the feeder body 221 is connected with a material holding platform 222 by a spring 223; the feeding cylinder 21 A connector mounting seat 4 is provided on the moving direction of the connector mounting seat 4, and snap ring clip cylinders 3 which are mirror images of each other are respectively provided on both sides of the connector mounting seat 4; The feeding device 2 also includes a snap ring guide rail 23; the snap ring guide rail 23 includes a cylindrical guide rail body 231 and a limiting flange 232 arranged on the guide rail body 231; the limiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com