Automatic tray filling machine and automatic tray filling method suitable for strip-bag oral liquid

A strip-bag oral liquid and plate-packing machine technology, which is applied in the directions of packaging, transportation and packaging, and single objects, can solve the problems of low efficiency of manual plate-packing, high production cost, and large number of workers, and achieves a simple structure and improved efficiency. The effect of loading efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

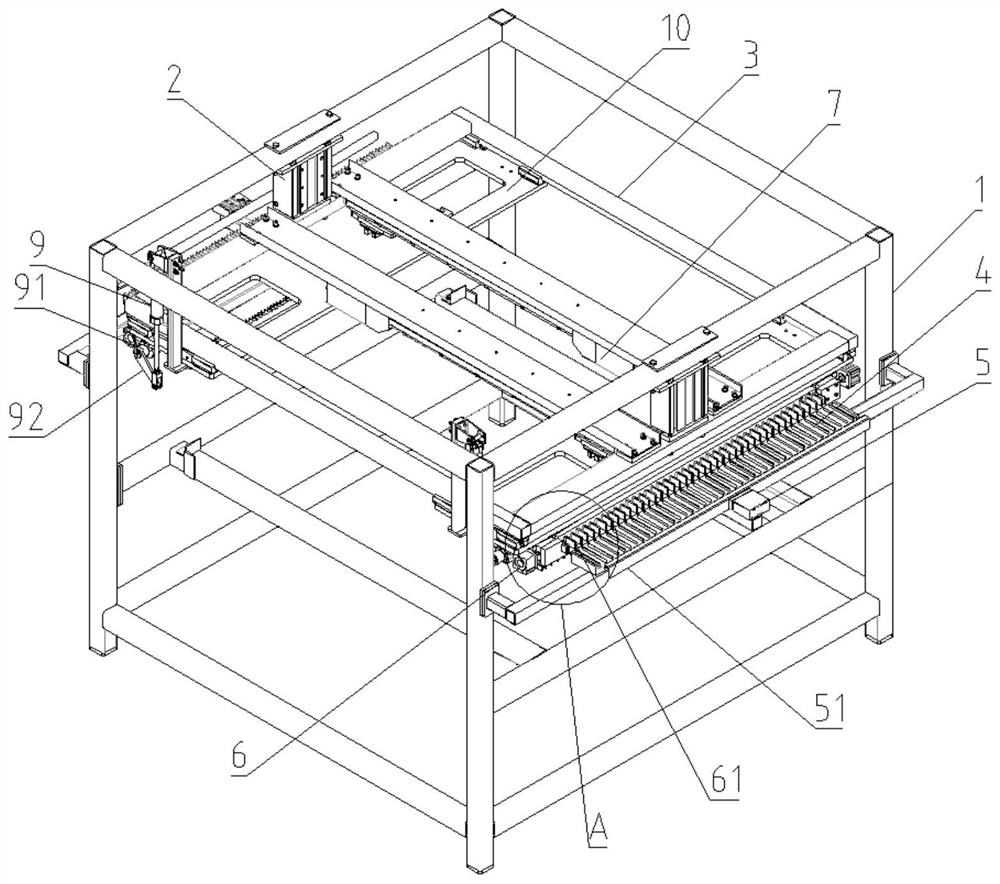

[0028] Example 1, reference Figure 1-Figure 5 , an automatic loading machine suitable for oral liquid in strips, including a frame 1, a lifting mechanism, a strip-bag conveyor, a bag-arranging mechanism and a clamping and bagging mechanism;

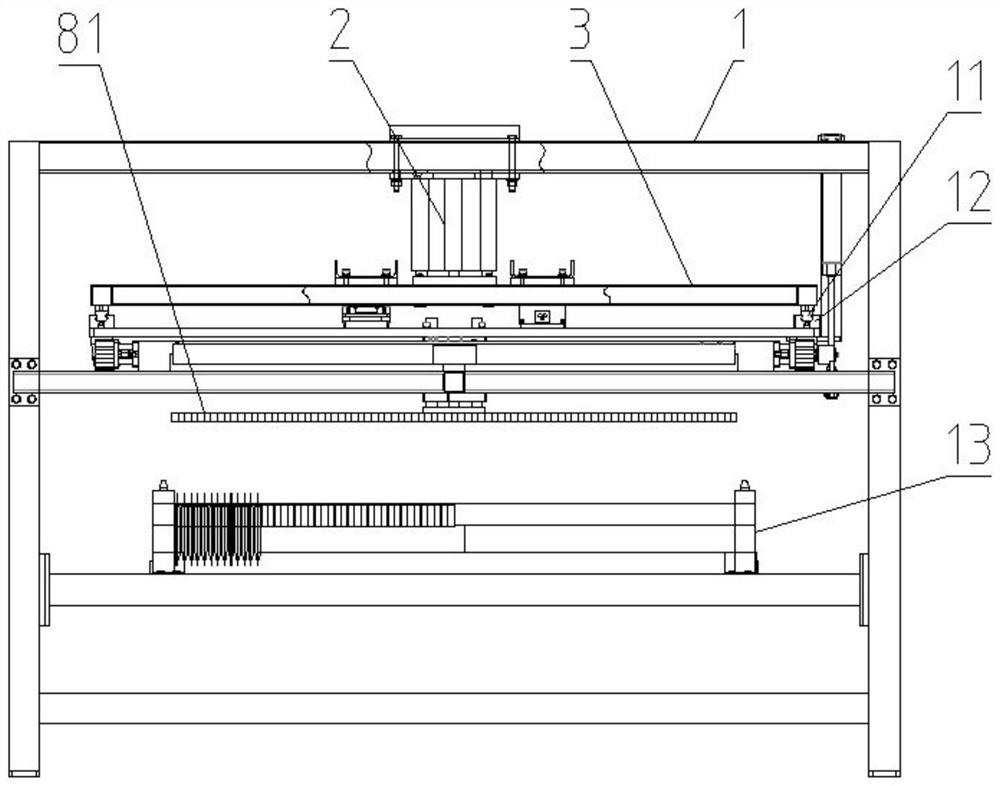

[0029] The lifting mechanism includes a lifting cylinder 2 and a lifting bracket 3, the lifting cylinder 2 is fixedly installed on the frame 1, and its power output end is connected to the lifting frame 3;

[0030] The strip bag conveyor 4 is fixedly installed on the frame 1, and the bag sorting mechanism and the clamping bagging mechanism are respectively arranged on both sides of the strip bag conveyor 4;

[0031] The bag-arranging mechanism includes a bag-arranging cylinder 5 and a bag-arranging plate 51 for flattening the bag. The bag-arranging cylinder 5 is fixedly installed on the frame 1, and the power output end of the bag-arranging cylinder 5 is connected to the bag-arranging plate 51. ;

[0032] The clamping and bagging mecha...

Embodiment 2

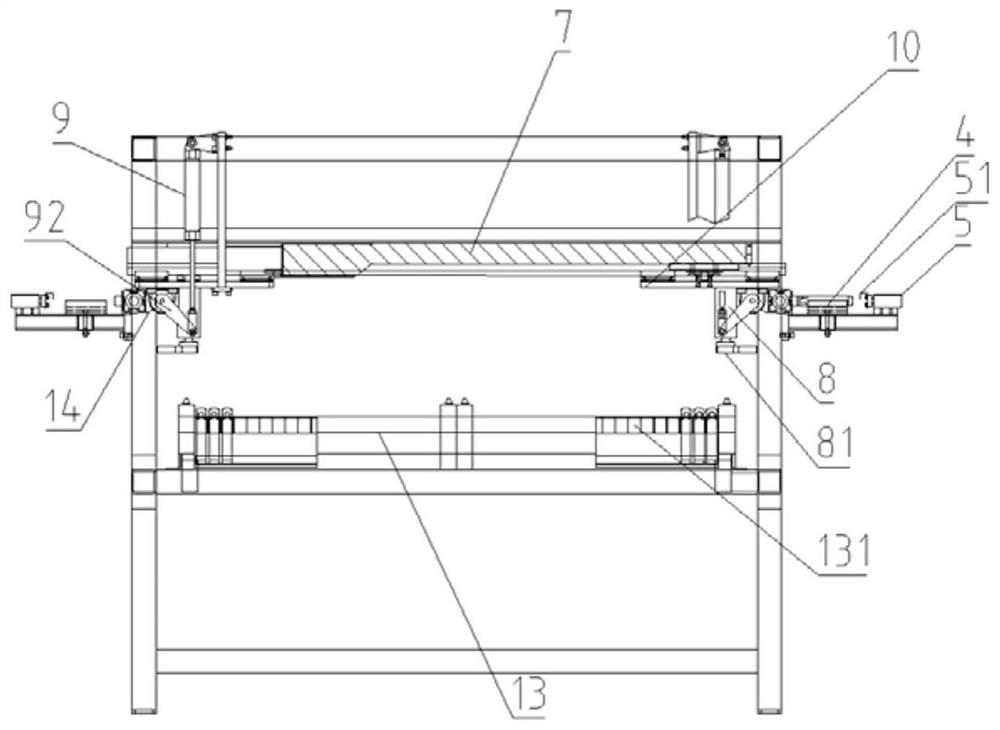

[0035] Example 2, in the automatic disk loading machine suitable for oral liquid in strips described in Example 1, the transmission member cantilever 92, the rotating shaft 93 and the fixing plate 14, the fixing plate 14 is fixedly installed on the rotating shaft 93, and the bag is clamped. The cylinder 6 is fixedly installed on the fixing plate 14, the rotating shaft 93 is arranged under the connecting plate 10, one end of the cantilever 92 is installed on the output end of the rotating cylinder 9, and the other end is installed on the rotating shaft 93; The bag protection mechanism includes a bag protection cylinder 8 fixedly installed on the connecting plate 10 and a bag protection plate 81 connected to the power output end of the bag protection cylinder 8. The bag protection plate 81 is provided with a number of strips for limiting the bag oral liquid. through slot 82.

Embodiment 3

[0036] Embodiment 3, in the automatic plate loading machine suitable for oral liquid in strips described in Embodiment 1, the translation mechanism includes a guide rail 11 and a slider 12, and the guide rail 11 is symmetrically installed at the bottom of the lifting bracket 3. , the connecting plate 10 slides freely on the guide rail 11 through the slider 12; a tray conveying platform is also installed on the frame below the lifting bracket 3; this design enables the clamping and bagging mechanism to continuously and repeatedly load trays, when the tray 13 When it is full, the pallet conveying platform will convey it to the next station, and at the same time, another pallet 13 to be loaded will be conveyed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com