Floor type handcart switchgear integrated track

An integrated, switchgear technology, applied in the direction of switchgear, electrical components, etc., can solve the problems of increased risk, poor stability of auxiliary track, high processing cost, etc., and achieve the effect of convenient operation, simple structure, increased efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

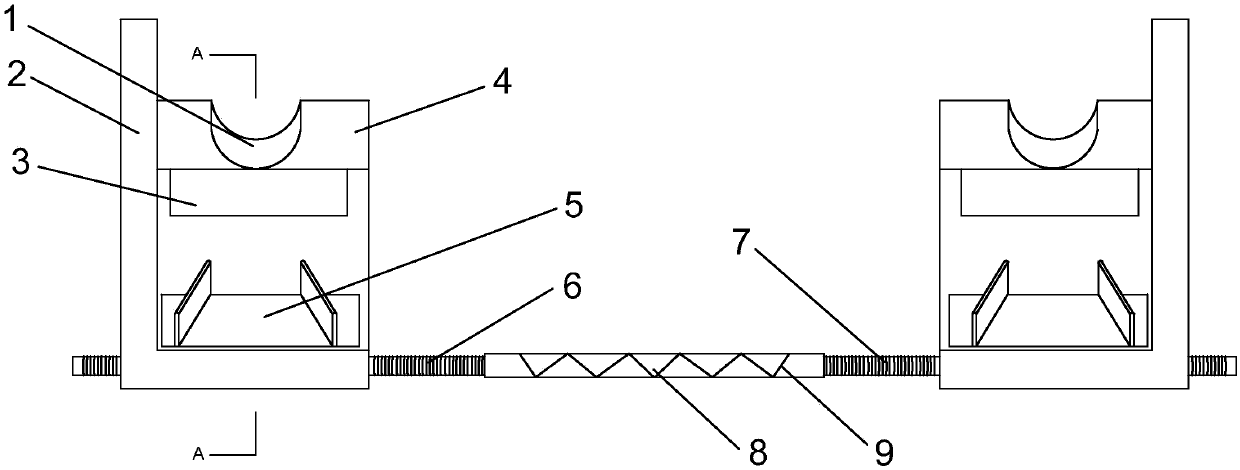

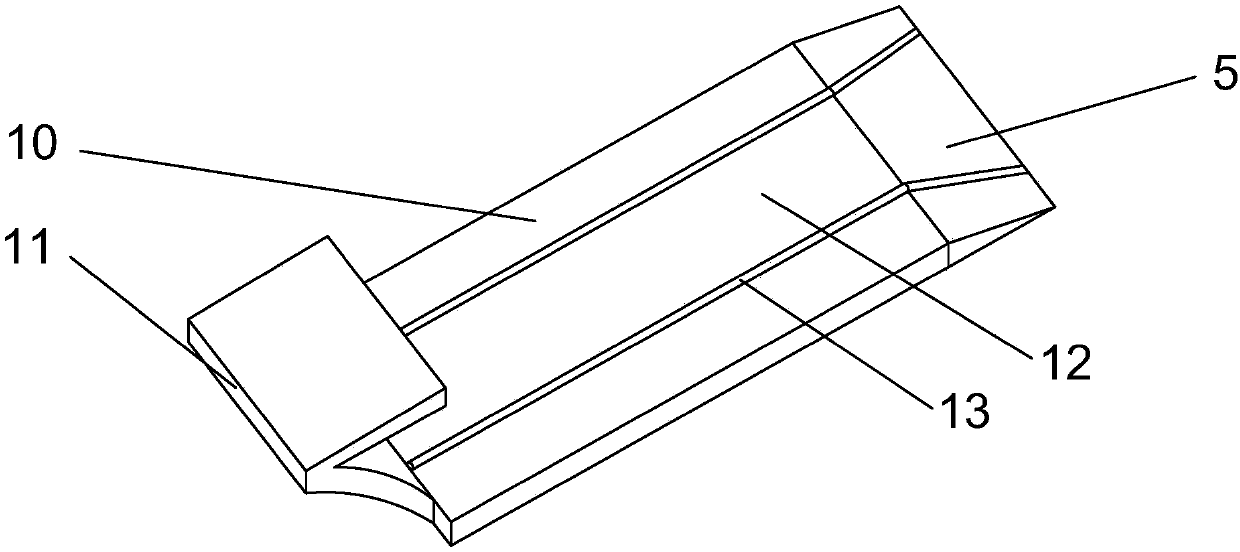

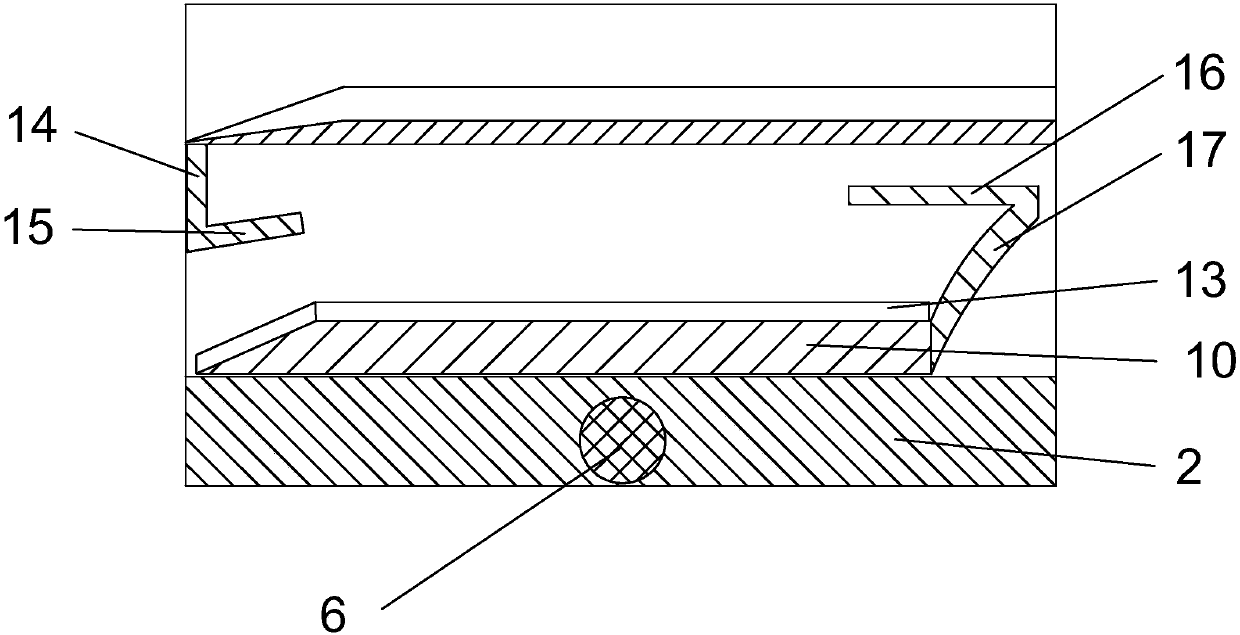

[0017] Such as figure 1 , 2 . As shown in 3, a floor-type handcart switch cabinet integrated track, including a left-handed screw 6, a right-handed screw 7 and a screw joint operating rod 8, the left-handed screw and the right-handed screw are respectively fixedly connected to the two ends of the screw joint operating rod , the outer surface of the screw joint operating rod is provided with anti-skid lines 9, and it is easier and more convenient to turn the screw joint operating rod. Both the left-handed screw and the right-handed screw are threadedly connected with an integrated track, and the rotating screw joint operating rod drives the left-handed screw and the right-handed screw. The right-handed screw rotates in the same direction at the same time. At the same time, the rotation of the integrated track threaded with the left-handed screw or the right-handed screw is constrained in the circumferential direction, so that the integrated track on the left and right sides mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com