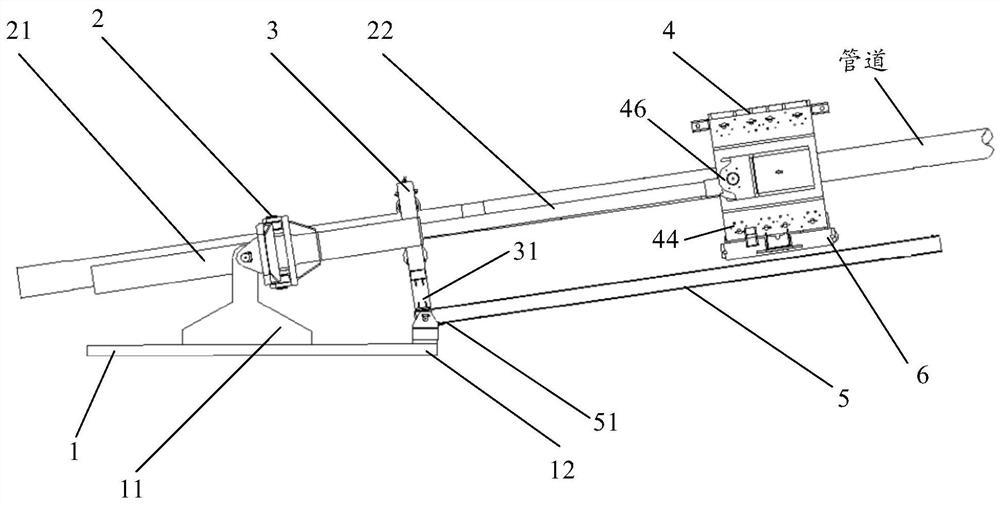

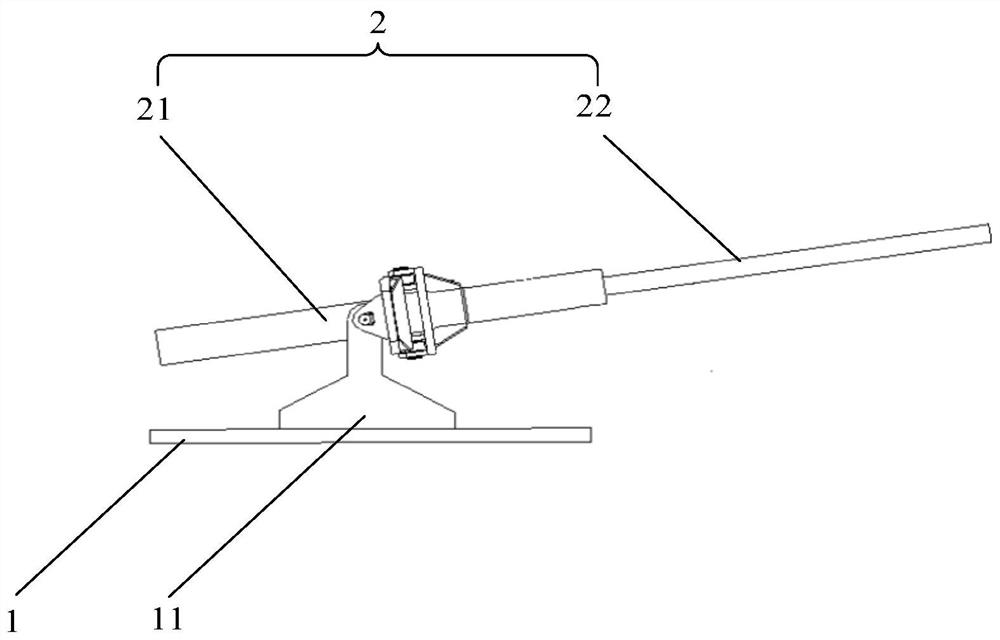

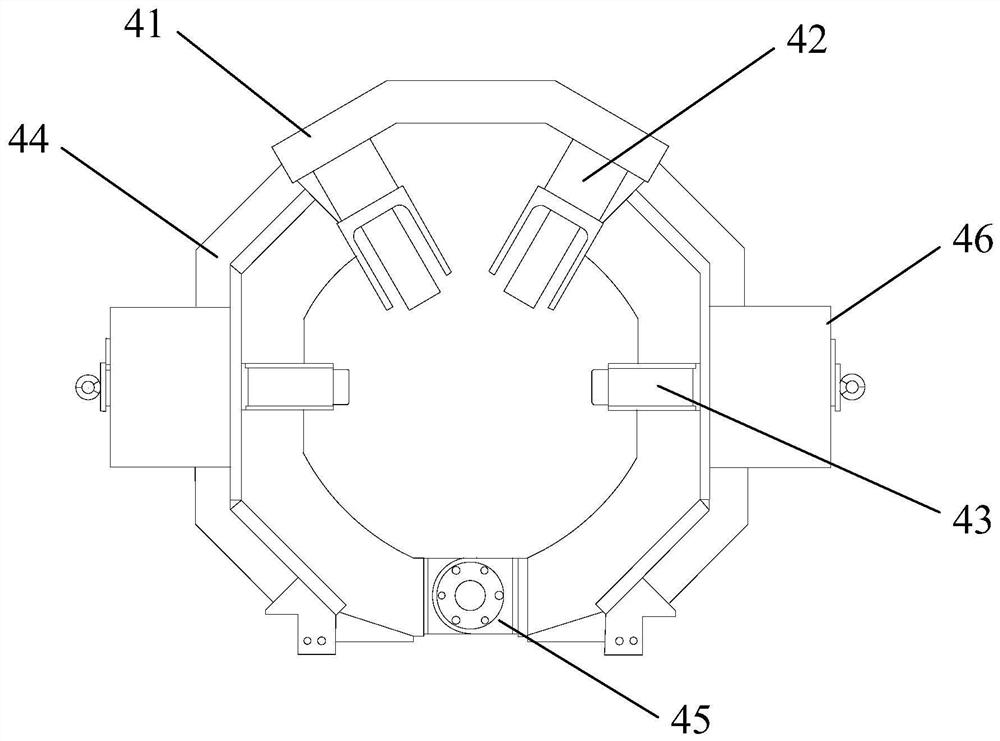

Pipe pushing device

A pipe and pipe gripper technology, which is applied in the direction of pipe laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve problems such as pipe pushing, pipe gripper bending, and pipe gripper weight. Achieve the effect of prolonging service life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

[0050] Before explaining the embodiment of the present application in detail, the application scenario of the embodiment of the present application will be described first.

[0051] With the maturity of the pipeline laying technology, the application range of the pipe pushing device can be expanded by utilizing the pushing and pulling function of the pipe pushing device to the pipeline. For example, when there is a problem in the directional drilling pipeline laying process, the pipe pushing device can pull out the pipeline in the hole together with the tunnel boring machine, so as to realize the emergency construction of the directional drilling pipeline; When crossing, use the pipe pushing device on land to push the pipeline to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com