Manual feed mechanism for processing automobile engine cylinder

A technology of automobile engine and cylinder block, which is applied in metal processing and other directions, can solve the problems of low labor efficiency and achieve the effects of solving low efficiency, improving reliability and stability, and making production simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

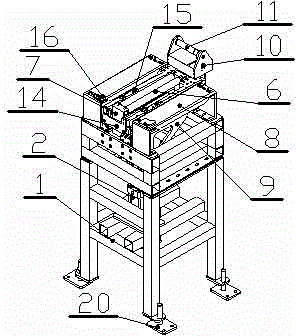

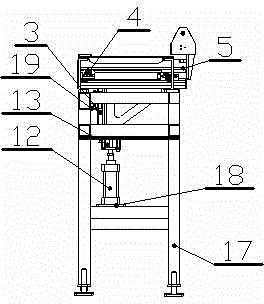

[0019] A manual feeding mechanism for automobile engine block processing, such as figure 1 and 2 As shown: it includes a support frame 1, the lower part of the support frame 1 is fixed with a cylinder 2, the upper part of the cylinder 2 is equipped with a vertical gauge 3 and a sprocket 4 in turn, the lower part of the sprocket 4 is equipped with a rack 5, and the upper part is equipped with a roller 6 A vertical support plate 7 is fixed on the support frame 1 around the sprocket 4, a fork support 9 is fixed on one side of the vertical support plate 7 top, a pneumatic control box 10 is fixed on the fork support 9, and the upper part of the pneumatic control box 10 is set There is a push-in handle 11, and a horizontal guide support plate 8 is fixed on the vertical support plate 7 on the left and right sides of the fork support 9.

[0020] A coarse positioning block 16 is fixed at the end of each vertical support plate 7 away from the pneumatic control box 10 .

[0021] Limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com