Brewing yeast strain, breeding method thereof, and application of the strain in alcohol production

A technology of Saccharomyces cerevisiae and alcohol, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of high environmental load, low technical level, low fermentation efficiency, etc., and achieve high resistance to ethanol toxicity , Strong fermentation ability, fast growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment one: Erlenmeyer flask shaker test

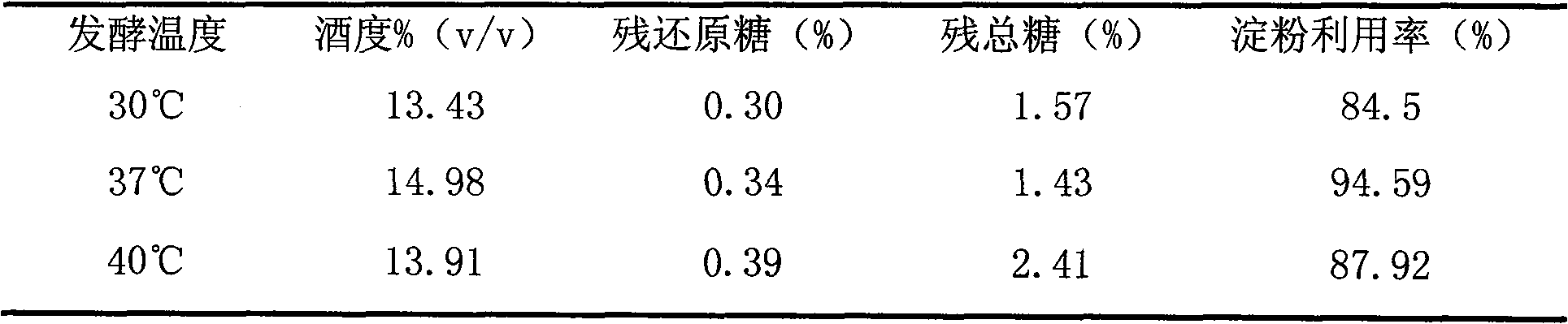

[0046] 1. High temperature fermentation experiment

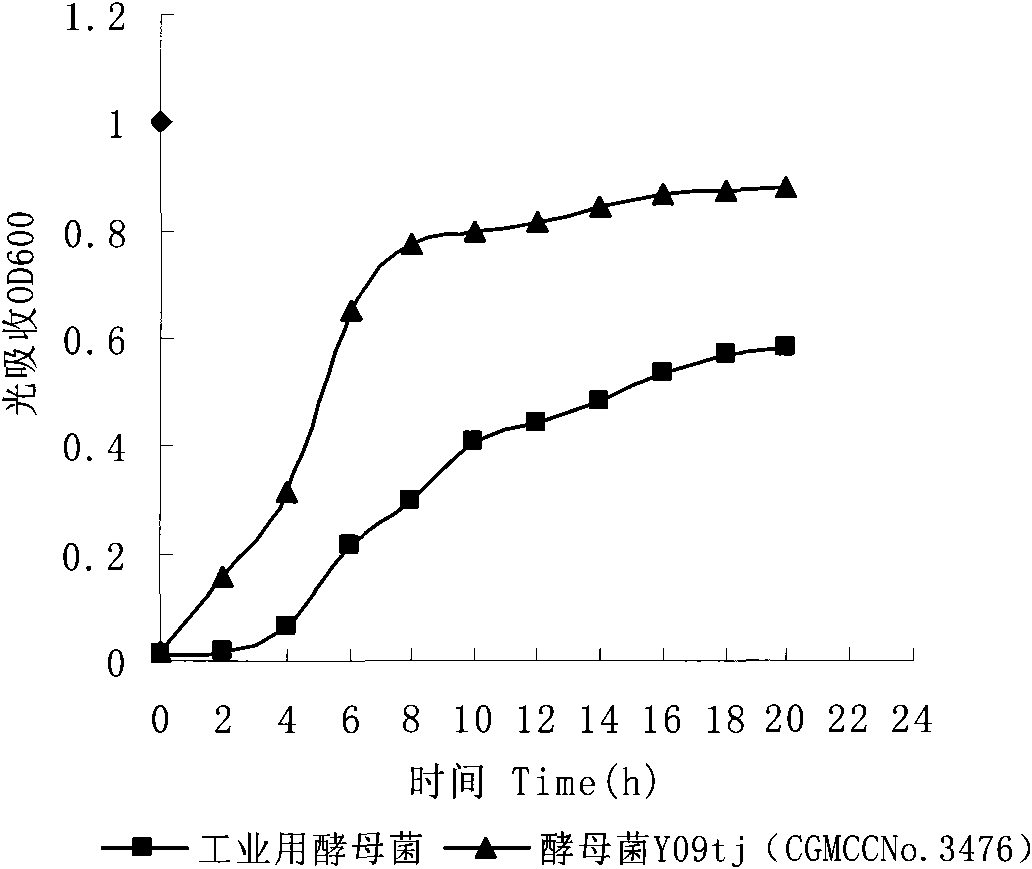

[0047] 1.1 Preparation of seed liquid: Inoculate the Saccharomyces cerevisiae CGMCC NO.3476 preserved on the slant into a conical flask containing 100mL LYPD liquid medium, culture it on a shaker at 37°C overnight, and make the OD of the seed liquid 600 About 10 or so.

[0048] 1.2 Process plan and basic conditions:

[0049] The process plan follows the steps of raw material preparation, pulping, liquefaction, adding glucoamylase, and adding urea for fermentation. The liquefaction enzyme is added at one time, the liquefaction temperature is 85-90°C, the liquefaction time is 1h, no saccharification, and Novozymes is added after cooling down to 37°C The fermentation process of saccharifying enzymes and inoculating fermentation.

[0050] The basic conditions of the experiment are as follows:

[0051] (1) Raw starch content: 33% (m / v)

[0052] (2) Mixing method: room tem...

Embodiment 2

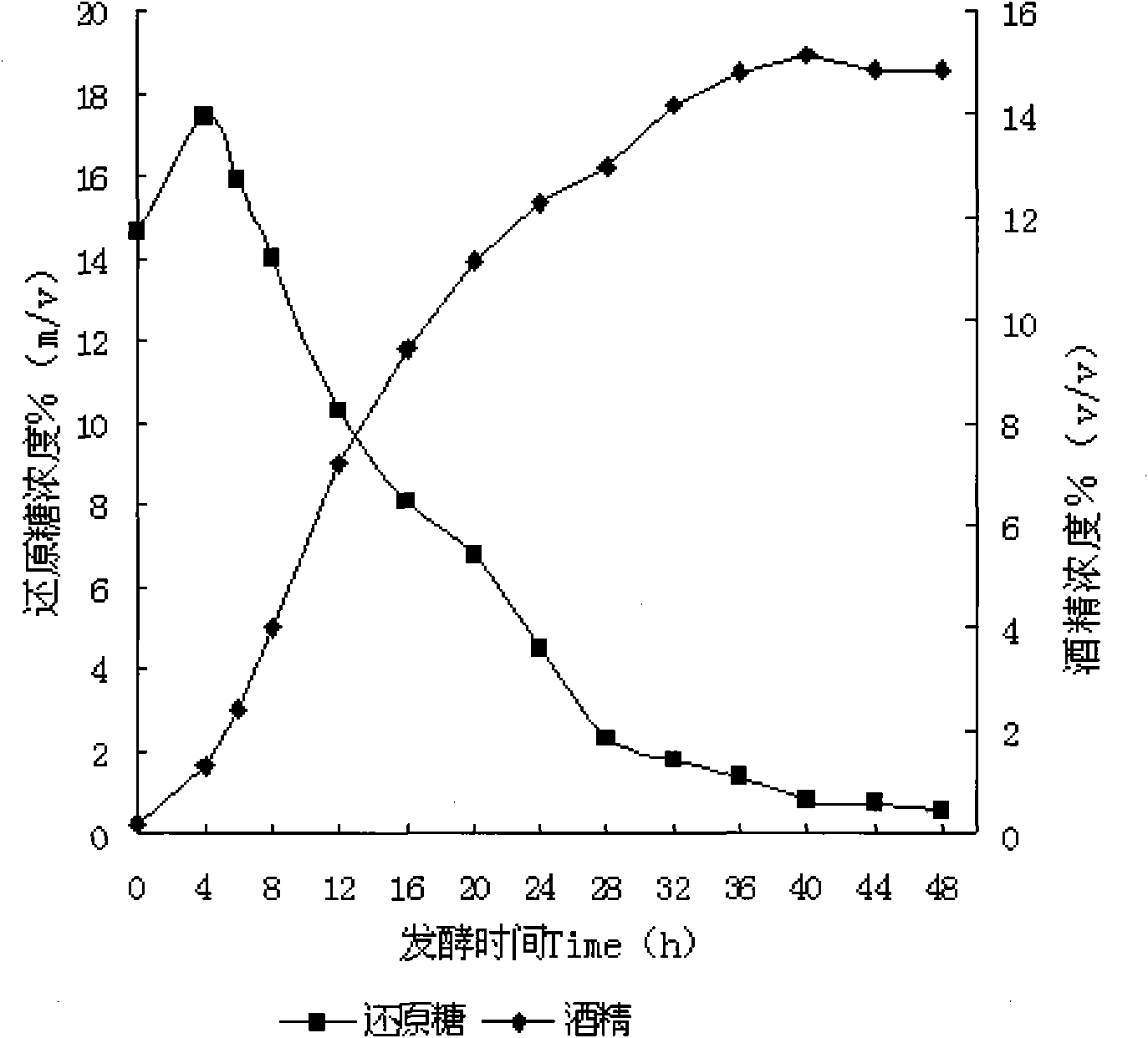

[0076] Embodiment two: 20L fermenter small test

[0077] 1. Preparation of seed liquid: Inoculate the Saccharomyces cerevisiae CGMCC NO.3476 preserved on the slant into the Erlenmeyer flask containing YPD liquid medium, and culture it on a shaker at 37°C overnight to make the OD of the seed liquid 600 About 10 or so.

[0078] 2. The process plan is as follows:

[0079] According to the steps of raw material preparation, slurry mixing, liquefaction, adding glucoamylase, and adding urea for fermentation, liquefaction enzyme is added once, liquefaction temperature is 85-90°C, liquefaction time is 1h, no saccharification, and Novozymes saccharification is added after cooling down to 37°C Enzyme and inoculated fermentation process.

[0080] 3. The basic conditions of the experiment are as follows:

[0081] (1) Raw starch content: 33% (m / v)

[0082] (2) Mixing method: room temperature, add tap water

[0083] (3) Liquefaction: heat to 90-95°C while stirring, and liquefy for 60 m...

Embodiment 3

[0090] Example three: 500L fermenter scale-up pilot test

[0091] 1. Preparation of seed solution: inoculate a ring of strains preserved on a slope into a conical flask containing 100ml of YPD liquid medium, cultivate overnight on a shaker at 37°C, and transfer to expanded culture the next day to make the OD of the seed solution 600 About 10 or so.

[0092] 2, technological scheme and basic condition are identical with embodiment two.

[0093] 3. Fermentation: Put the seed liquid into the liquefied mash, ferment for 40h-48h at a temperature of 37°C and a stirring speed of 100rpm, and measure the alcohol content and residual sugar by sampling every 4h. Repeat the test for three batches.

[0094] 4. Fermentation result: the result is as shown in Table 4. When the fermentation time is 40h, the average alcohol concentration can reach 15.0% (v / v), residual reducing sugar 0.55%, and residual total sugar 1.20%.

[0095] Table 4. Fermentation results of 3 batches of yeast CGMCC №.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com