Liquor brewing method based on combination of solid fermentation and liquid fermentation

A technology of solid-liquid fermentation and solid-state fermentation, applied in the field of liquor brewing, can solve the problems of large area of solid-state fermentation process, long solid-state fermentation period, and high production cost, saving time and production cost, increasing liquor output, The effect of increasing the rate of wine production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

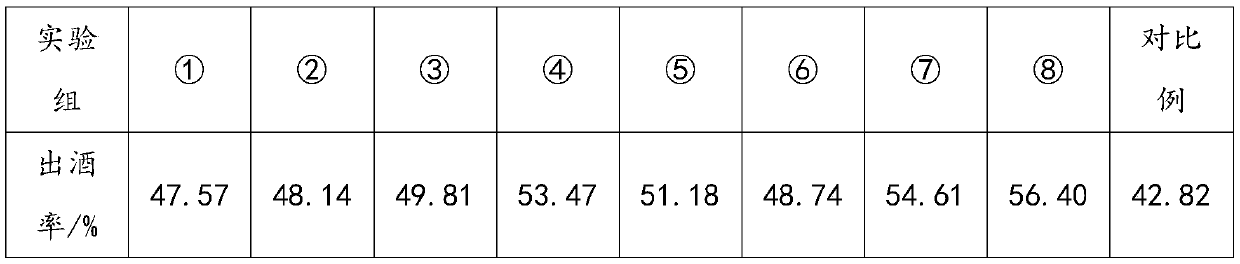

Embodiment 1

[0033] Using sorghum (japonica sorghum, 10kg) as raw material, crush the sorghum to 6-8 petals, moisten the grain for 20 hours, add steamed cooked bran (4% of the dry weight of the grain) and steam the grain until there is no heart, spread it out and add koji (grain 10% of dry weight), and fermented in tanks for 28 days.

[0034] Experimental group ①: Take the fermented Daqu Fen-flavor Dazha wine grains, take the weight of the sugar solution as the basis, put the wine grains equivalent to 10% of the weight of the sugar solution into the fermenter, add 10L of glucose solution with a sugar concentration of 10% and mix , closed fermentation at a constant temperature of 22°C for 7 days.

[0035] Experimental group ②: Take the fermented Daqu Fen-flavored Hawthorn wine grains, based on the weight of the sugar solution, put 10% of the wine grains equivalent to the weight of the sugar solution into the fermenter, add 10L of glucose solution with a sugar concentration of 10% and mix ,...

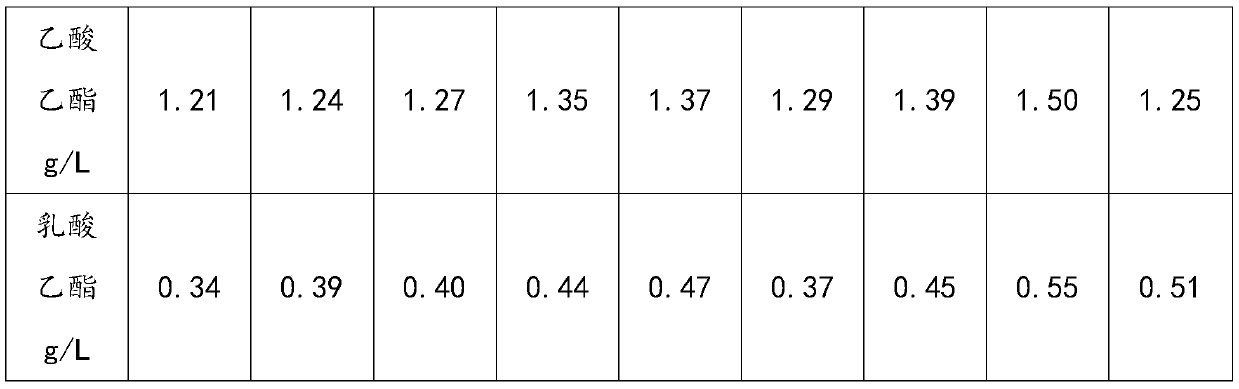

Embodiment 2

[0052] Sorghum (northeast japonica sorghum) is used as raw material. The sorghum is soaked for 8 hours, steamed for 20 minutes, steamed for 50 minutes, re-steamed for 1 hour, koji (0.5% of the dry weight of the grain) is added after spreading, cultured in the room for 24 hours, and fermented for 7 days.

[0053] Experimental group ①: Take the fermented Xiaoqu Qingxiang wine grains, take the weight of the sugar solution as the basis, put the wine grains equivalent to 10% of the weight of the sugar solution into the fermenter, add 10L of glucose solution with a sugar concentration of 10% and mix them, and mix them at 22 Sealed fermentation at a constant temperature of ℃ for 7 days.

[0054] Experimental group ②: Take the fermented Xiaoqu Qingxiang wine grains, take the weight of the sugar solution as the basis, put the wine grains equivalent to 10% of the weight of the sugar solution into the fermenter, add 10L of glucose solution with a sugar concentration of 10% to mix, and mix...

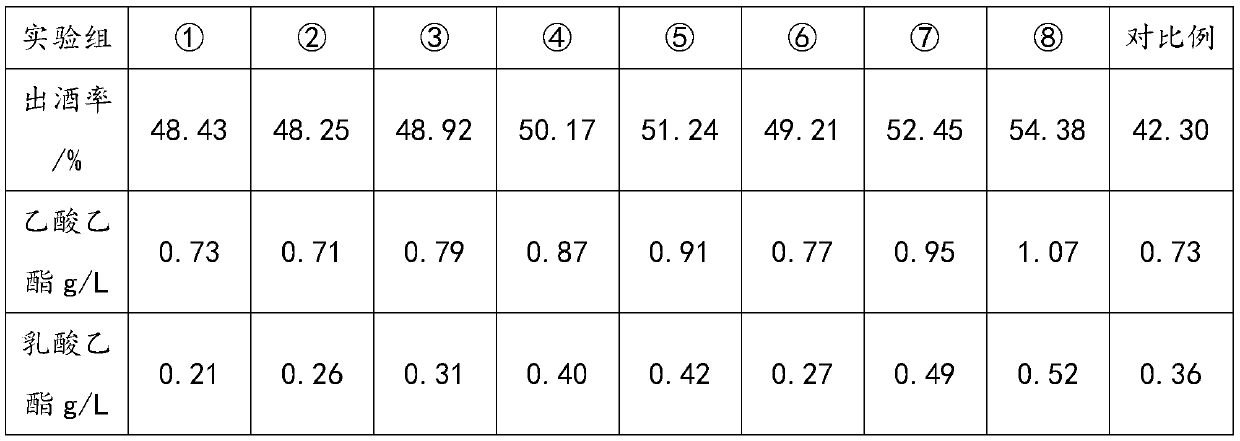

Embodiment 3

[0070] Using sorghum as raw material (northeast japonica sorghum), soak the sorghum (8h), steam the grain (2h or until flowering), add the steamed rice husk (addition amount 22%), add Luzhou-flavor Daqu (grain 20% of the dry weight), the continuous grain ratio is 1:4.5 (the dry weight of the grain is 1: the wet weight of the grain is 4.5); the total moisture is controlled at 54%; the periodical fermentation is 60 days.

[0071] Experimental group ①: Take the fermented Daqu Luzhou-flavor sorghum wine grains, take the weight of the sugar solution as the basis, put the wine grains equivalent to 10% of the weight of the sugar solution into the fermenter, add 10L of glucose solution with a sugar concentration of 10% and mix , closed fermentation at a constant temperature of 22°C for 7 days.

[0072] Experimental group ②: Take the fermented Daqu Luzhou-flavor sorghum wine grains, take the weight of the sugar solution as the basis, put the wine grains equivalent to 10% of the weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com