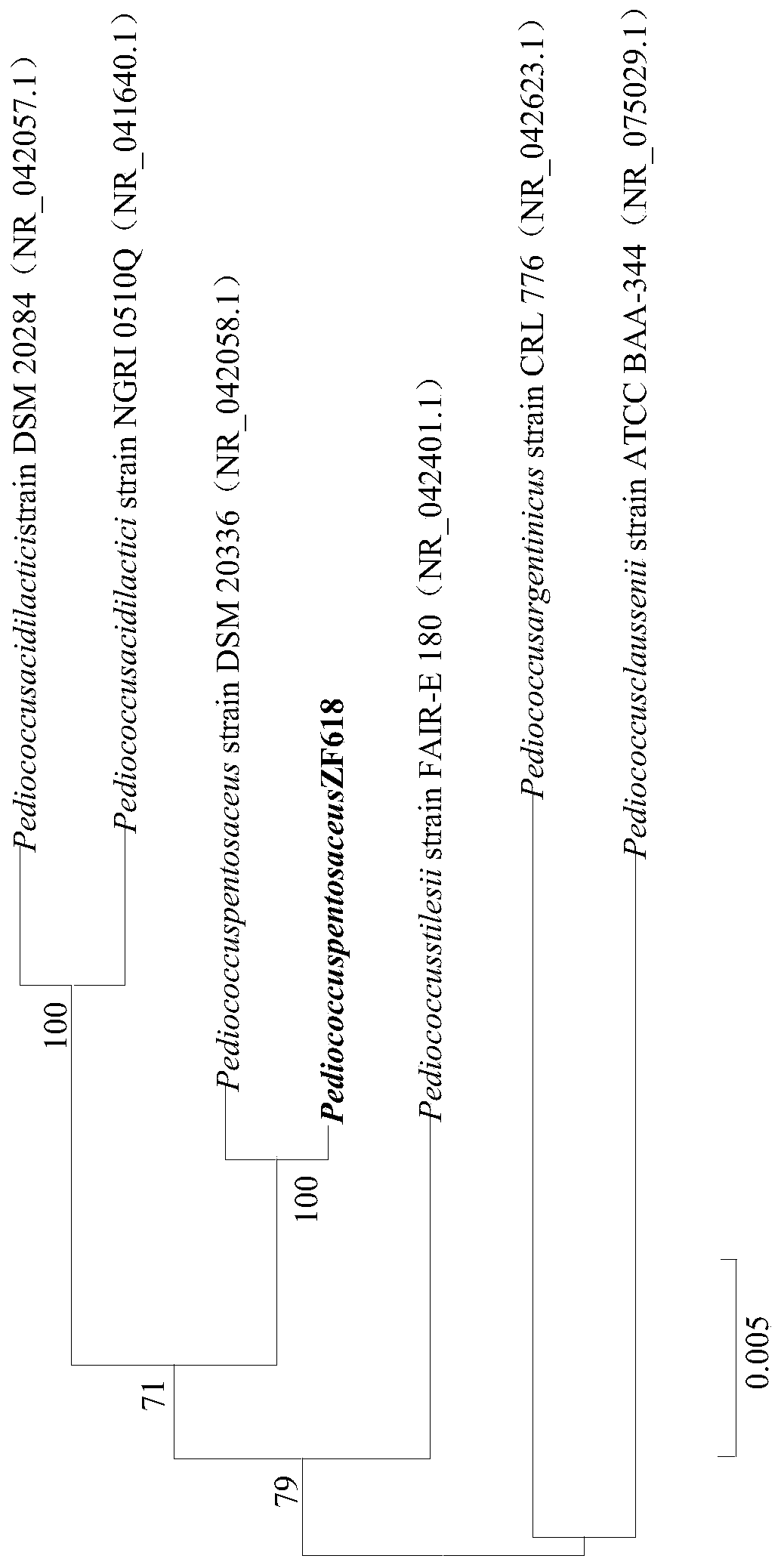

A strain of Pediococcus pentosaceus zf618 and its application

A technology of Pediococcus pentosaceae and ZF618, which is applied in the preparation of bacteria, microorganisms, and alcoholic beverages, can solve problems such as insufficient non-volatile acid and total ester content, lack of beneficial microorganisms, and taste stimulation, so as to ensure food safety, The effect of fast aroma production and simple cultivation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

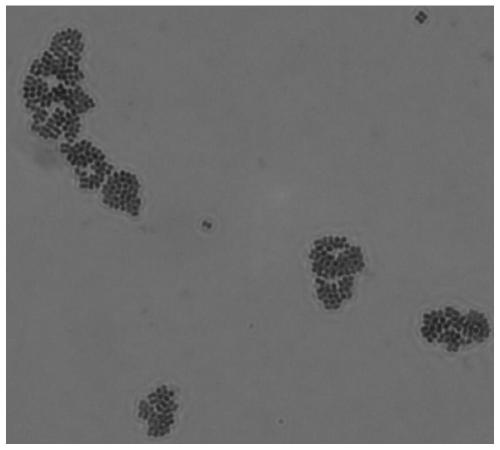

[0051] Embodiment 1, the isolation of candidate bacterial strain

[0052] Use a sterile sampling bottle to sample naturally fermented rice wine koji and bring it back at low temperature; immediately dilute to 10 with sterile water -3 、10 -4 、10 -5 , spread on the MRS solid medium; then put it into an anaerobic constant temperature incubator at 30°C, and cultivate it for 48 hours; pick candidate colonies and separate them by streaking on the plate, repeat this 4 to 5 times until a pure single colony is obtained . Glycerol tubes were prepared from the purified individual plants and stored in a -70°C refrigerator.

[0053] Among them, the formula of MRS solid medium is as follows: peptone 10.0g, beef extract powder 5.0g, yeast extract powder 4.0g, triammonium citrate 2.0g, sodium acetate 5.0g, glucose 20.0g, Tween-801.0ml, K 2 HPO 4 2.0g, MgSO 4 ·7H 2 O0.2g, MnSO 4 4H 2 O 0.05g, agar 15.0g, distilled water 1.0L, pH value 6.2±0.2.

Embodiment 2

[0054] Example 2, Primary Screening of Candidate Strains—Flavoured Rice Wine

[0055] The candidate strains and Saccharomyces cerevisiae were mixed and inoculated into rice liquefaction mash, and fermented at 30°C for 10 days. Bacillus was used as a control to evaluate the difference in the ability of candidate strains to produce non-volatile acid from rice liquefied mash under alcoholic conditions.

[0056] Among them, the preparation method of rice liquefied mash is as follows: add water to the rice vinegar raw material rice according to the mass ratio of 1:1 to 1:5, raise the temperature and keep it at 92 to 95°C, add liquefied enzyme with a volume ratio of 1‰ to 1%, and stir for 20 to 200 minutes , complete the liquefaction of raw materials, lower the temperature to 25 to 40° C., and prepare rice liquefaction mash.

[0057] The test result of this embodiment is as follows:

[0058] Table 1 Detection results of non-volatile acid content in rice wine prepared by candidat...

Embodiment 3

[0061] Example 3, re-screening of candidate strains—flavored rice vinegar

[0062] The flavored wine mash obtained in Example 2 was prepared into rice vinegar through vinegar liquid submerged fermentation process, and the non-volatile acid and aroma components in rice vinegar were determined to evaluate the application effect of candidate strains in rice vinegar. The measurement results are shown in Table 2 and Table 3.

[0063] Table 2 Detection results of non-volatile acid content of rice vinegar prepared by candidate strains and control strains

[0064]

[0065] Table 3 Detection results of aroma components and content of rice vinegar prepared by candidate strains and control strains

[0066]

[0067] It can be seen from the above results that the rice vinegar prepared by candidate strain 1 has the most non-volatile acid content; the total content of aroma components is 0.54g / 100mL, which is much higher than that of the control strain and candidate strains 2 and 3;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com