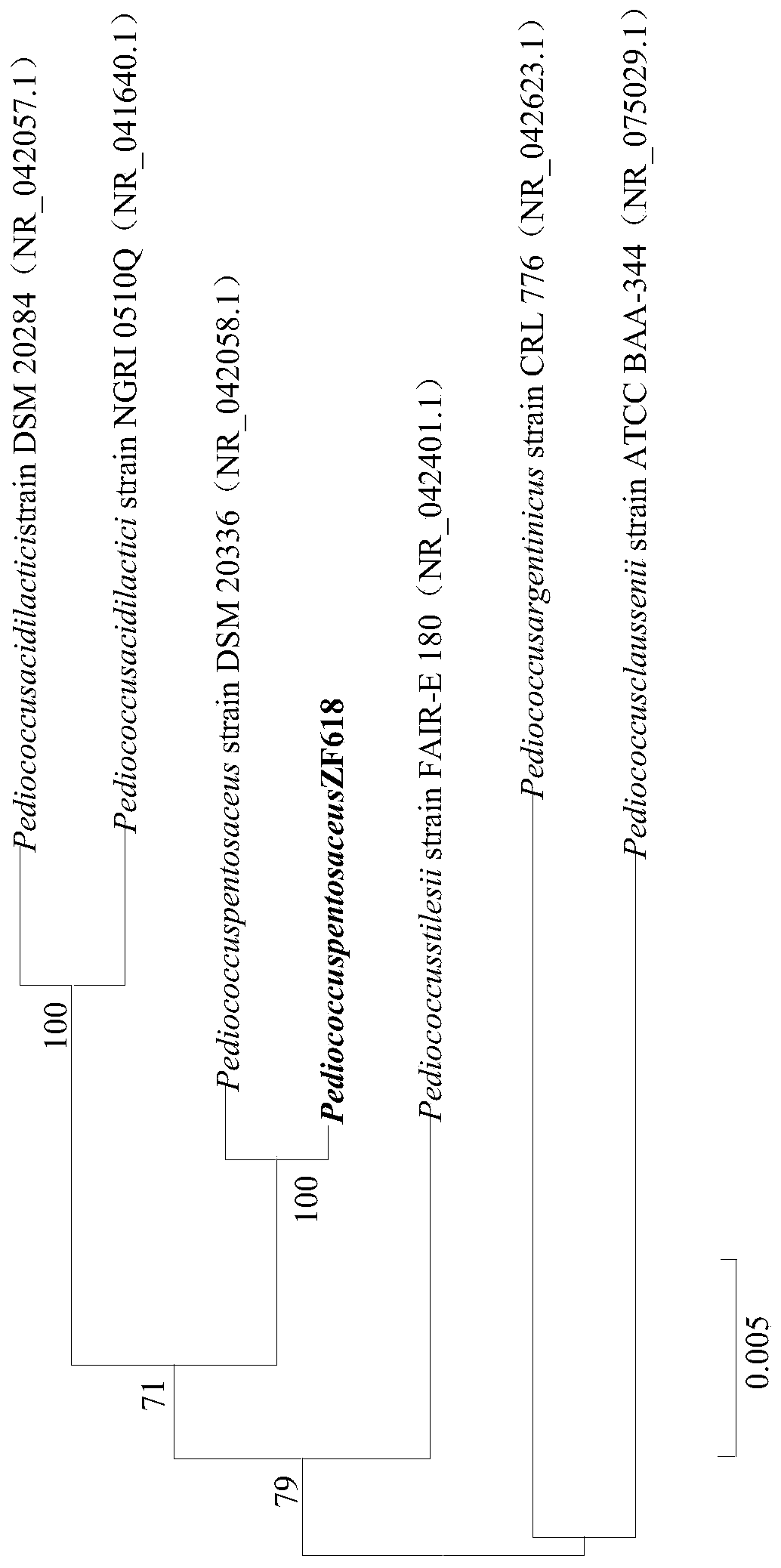

Pediococcus pentosaceus ZF618 and application thereof

A technology of Pediococcus pentosaceae and ZF618, which is applied to the preparation of bacteria, microorganisms, and vinegar, can solve the problems of insufficient content of non-volatile acid and total esters, lack of beneficial microorganisms, and high cost, so as to ensure food safety and product quality. The effect of fast incense speed and simple cultivation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

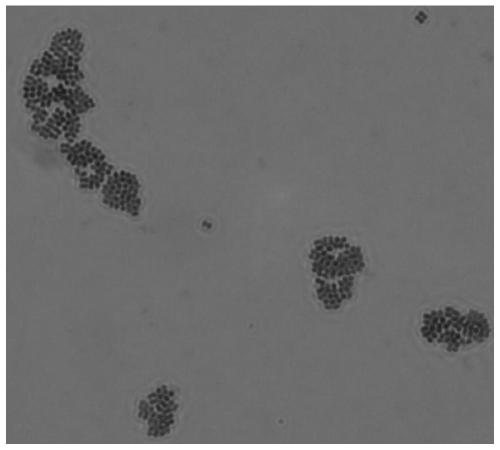

[0051] Embodiment 1, the isolation of candidate bacterial strain

[0052] Use a sterile sampling bottle to sample naturally fermented rice wine koji and bring it back at low temperature; immediately dilute to 10 with sterile water -3 、10 -4 、10 -5 , spread on the MRS solid medium; then put it into an anaerobic constant temperature incubator at 30°C, and cultivate it for 48 hours; pick candidate colonies and separate them by streaking on the plate, repeat this 4 to 5 times until a pure single colony is obtained . Glycerol tubes were prepared from the purified individual plants and stored in a -70°C refrigerator.

[0053] Among them, the formula of MRS solid medium is as follows: peptone 10.0g, beef extract powder 5.0g, yeast extract powder 4.0g, triammonium citrate 2.0g, sodium acetate 5.0g, glucose 20.0g, Tween-801.0ml, K 2 HPO 4 2.0g, MgSO 4 ·7H 2 O0.2g, MnSO 4 4H 2 O 0.05g, agar 15.0g, distilled water 1.0L, pH value 6.2±0.2.

Embodiment 2

[0054] Example 2, Primary Screening of Candidate Strains—Flavoured Rice Wine

[0055] The candidate strains and Saccharomyces cerevisiae were mixed and inoculated into rice liquefaction mash, and fermented at 30°C for 10 days. Bacillus was used as a control to evaluate the difference in the ability of candidate strains to produce non-volatile acid from rice liquefied mash under alcoholic conditions.

[0056] Among them, the preparation method of rice liquefied mash is as follows: add water to the rice vinegar raw material rice according to the mass ratio of 1:1 to 1:5, raise the temperature and keep it at 92 to 95°C, add liquefied enzyme with a volume ratio of 1‰ to 1%, and stir for 20 to 200 minutes , complete the liquefaction of raw materials, lower the temperature to 25 to 40° C., and prepare rice liquefaction mash.

[0057] The test result of this embodiment is as follows:

[0058] Table 1 Detection results of non-volatile acid content in rice wine prepared by candidat...

Embodiment 3

[0061] Example 3, re-screening of candidate strains—flavored rice vinegar

[0062] The flavored wine mash obtained in Example 2 was prepared into rice vinegar through vinegar liquid submerged fermentation process, and the non-volatile acid and aroma components in rice vinegar were determined to evaluate the application effect of candidate strains in rice vinegar. The measurement results are shown in Table 2 and Table 3.

[0063] Table 2 Detection results of non-volatile acid content of rice vinegar prepared by candidate strains and control strains

[0064]

[0065] Table 3 Detection results of aroma components and content of rice vinegar prepared by candidate strains and control strains

[0066]

[0067] It can be seen from the above results that the rice vinegar prepared by candidate strain 1 has the most non-volatile acid content; the total content of aroma components is 0.54g / 100mL, which is much higher than that of the control strain and candidate strains 2 and 3;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com