Method for producing alcohol by aid of yellow ginger hydrolysis waste water

A waste water and alcohol technology, applied in the direction of fermentation, etc., can solve the problems of pollution degree, ecological environment damage, environmental pollution, etc., and achieve the effects of high wine yield, reduced fermentation loss, and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

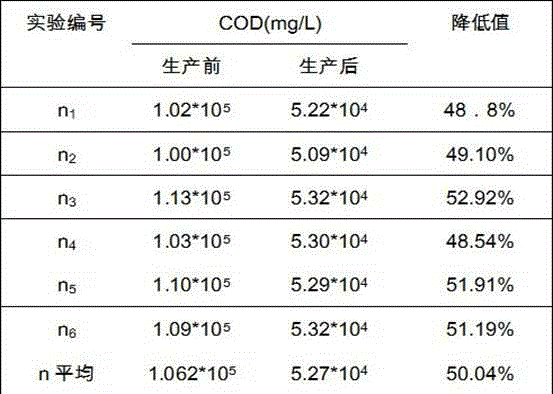

Image

Examples

Embodiment 1

[0021] Using turmeric hydrolysis wastewater as raw material, use the following steps to produce alcohol

[0022] 1. Neutralization

[0023] The general pH value of turmeric hydrolysis wastewater is about 1, which cannot meet the needs of alcohol production. First, adjust the pH value of wastewater to 2-3 through limestone, and then use Ca(OH) 2 Adjust the pH value to 3.8 and enter the next step.

[0024] 2. Fermentation

[0025] Add yeast to the wastewater that has been neutralized to meet the requirements, and use the method of semi-continuous fermentation of serial tanks to ferment. The method is to add active dry yeast 1kg / m3 to the yeast activation tank 3 , urea 4kg / m 3 , penicillin (3.2 million units) plus 1.5g / m 3 , the active dry yeast is activated (rehydrated) in warm water at 38-40°C for 15-20 minutes and immediately put into the distiller's tank, and then add the turmeric hydrolyzed wastewater that has been cooled and adjusted the pH value to the distiller's tank...

Embodiment 2

[0029] Using turmeric hydrolysis wastewater as raw material, use the following steps to produce alcohol

[0030] 1. Neutralization

[0031] The PH value of turmeric hydrolysis wastewater is generally about 1, which cannot meet the needs of alcohol production. First, adjust the PH value of the wastewater to 2-3 through limestone, and then adjust the PH value to 4 with NaOH, and enter the next step.

[0032] 2. Fermentation

[0033] The wastewater that has been neutralized to meet the requirements plus yeast is fermented by the method of semi-continuous fermentation of serial tanks. The method is to add active dry yeast 1kg / m3 to the yeast activation tank 3 , urea 4kg / m 3 , penicillin (3.2 million units) plus 3g / m 3 , the active dry yeast is activated (rehydrated) in warm water at 38-40°C for 15-20 minutes and immediately put into the distiller's tank, and then add the turmeric hydrolyzed wastewater that has been cooled and adjusted the pH value to the distiller's tank; The ...

Embodiment 3

[0037] Using turmeric hydrolysis wastewater as raw material, use the following steps to produce alcohol

[0038] 1. Neutralization

[0039] The general pH value of turmeric hydrolysis wastewater is about 1, which cannot meet the needs of alcohol production. First, adjust the pH value of wastewater to 2-3 through limestone, and then use Ca(oH) 2 Adjust the pH value to 4.2 and enter the next step.

[0040] 2. Fermentation

[0041] The wastewater that has been neutralized to meet the requirements plus yeast is fermented by the method of semi-continuous fermentation of serial tanks. The method is to add active dry yeast 1kg / m3 to the yeast activation tank 3 , urea 2kg / m 3, penicillin (3.2 million units) plus 3g / m 3 , the active dry yeast is activated (rehydrated) in warm water at 38-40°C for 15-20 minutes and immediately put into the distiller's tank, and then add the turmeric hydrolyzed wastewater that has been cooled and adjusted the pH value to the distiller's tank; The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com