Vertical gas-solid direct heat exchange device and heat exchange method using excess heat of grains

A thermal method and grain technology, applied in the direction of direct contact heat exchangers, heat exchange equipment, heat exchanger types, etc., can solve the problems of shortened equilibrium time, energy waste, etc., to achieve high utilization, improve economic benefits, Realize the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

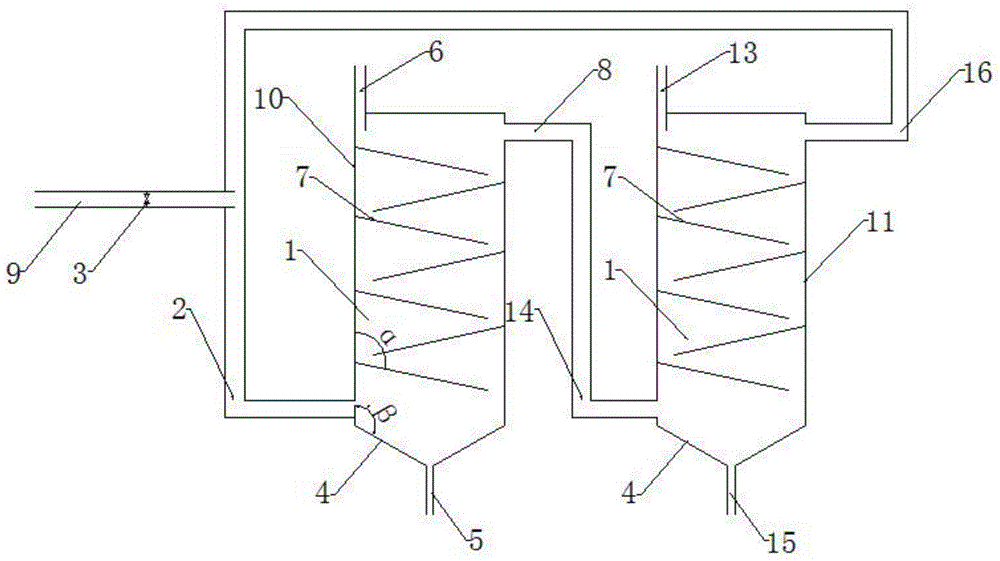

[0037] The invention provides a vertical gas-solid heat exchange device and a heat exchange method using waste heat of grains. The heat exchange device uses waste heat for high-temperature grain particles to perform gas-solid heat exchange. The retort is recovered by adopting the technical solution of the invention The energy of the barrel outlet hot grain, the specific implementation is as follows figure 1 figure 2 Shown:

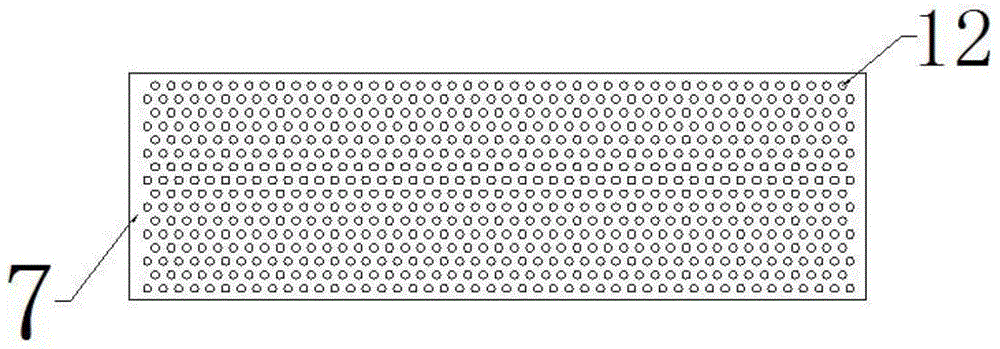

[0038] A vertical gas-solid heat exchange device utilizing waste heat from grains, which includes 1-heat exchange cylinder, 2-circulating low-temperature gas secondary inlet pipe, 3-flow regulating valve, 4-bucket grain collector, 5-completed wine steaming Grain discharge pipe for the process, 6-grain feed pipe for finishing the wine steaming process, 7-heat exchange plate, 8-secondary outlet pipe for circulating high-temperature gas, 9-gas replenishment inlet pipe, 10-grain cooling equipment, 11- Grain preheating equipment, 12-heat exchange holes, 13-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com