Brewing process of mouldy bran strong-flavor Baijiu

A technology of gluten-flavored and Luzhou-flavored liquor, which is applied in the preparation of alcoholic beverages, can solve the problems of insufficient stability in the quality and output of raw liquor, small production scale, and complicated process, and achieve the improvement of the style of liquor , improve the yield of wine, and increase the purity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

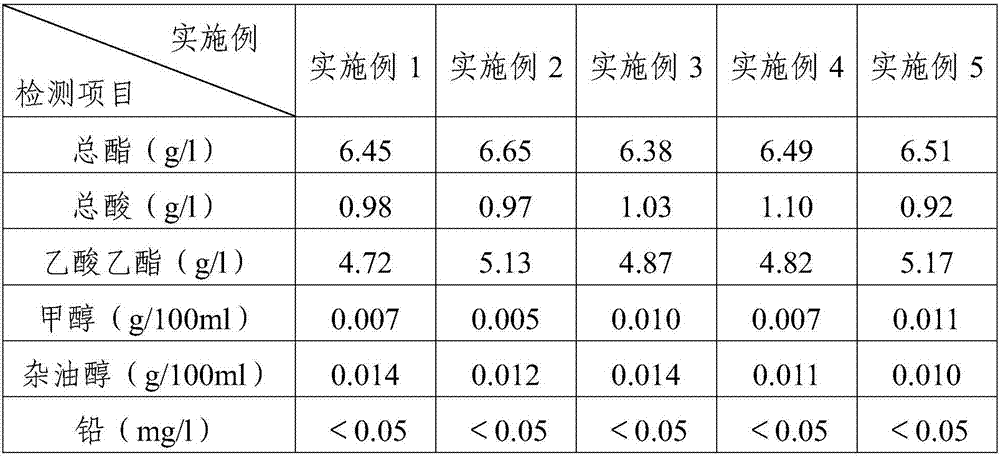

Examples

Embodiment 1

[0027] A brewing process of bran koji Luzhou-flavor liquor, comprising the following steps:

[0028] (1) Crush Luzhou glutinous red sorghum into 4 or 6 petals, crush wheat into 2 or 3 petals, crush glutinous rice into broken rice, grind peas and corn into flour, put the sorghum on the drying hall, add Hot water at 80°C equal to the weight of sorghum, mix well, then cover glutinous rice and wheat on top, pile up for 30 minutes, add pea flour and corn flour, then add hot water at 75°C with 80% weight of sorghum, stir evenly, Cover the chaff and continue to pile up for 4 hours;

[0029] (2) Put the raw materials of the previous step into the retort pot and cover them with rice husks, steam them with the open mouth for 1 hour, turn off the gas and simmer overnight, steam again the next day for 1 hour, take out the retort, turn over, and spread to dry;

[0030] (3) Mix Hanoi white koji, cerevisiae, bacterial koji and medium-temperature koji evenly. When the material temperature dr...

Embodiment 2

[0035] A brewing process of bran koji Luzhou-flavor liquor, comprising the following steps:

[0036] (1) Crush Luzhou glutinous red sorghum into 4 or 6 petals, crush wheat into 2 or 3 petals, crush glutinous rice into broken rice, grind peas and corn into flour, put the sorghum on the drying hall, add Hot water at 75°C equal to the weight of sorghum, mix well, then cover glutinous rice and wheat on top, pile up for 30 minutes, add pea flour and corn flour, then add hot water at 80°C with 80% of the weight of sorghum, stir well, Cover the chaff and continue to pile up for 3 hours;

[0037] (2) Put the raw materials of the previous step into the retort pot and cover them with rice husks, steam them with the open mouth for 1 hour, turn off the gas and simmer overnight, steam again the next day for 1 hour, take out the retort, turn over, and spread to dry;

[0038] (3) Mix Hanoi white koji, cerevisiae, bacterial koji and medium-temperature koji evenly. When the material temperatu...

Embodiment 3

[0043] A brewing process of bran koji Luzhou-flavor liquor, comprising the following steps:

[0044] (1) Crush Luzhou glutinous red sorghum into 4 or 6 petals, crush wheat into 2 or 3 petals, crush glutinous rice into broken rice, grind peas and corn into flour, put the sorghum on the drying hall, add Hot water at 70°C equal to the weight of sorghum, mix well, then cover the glutinous rice and wheat on top, pile up for 30 minutes, add pea flour and corn flour, then add hot water at 85°C with 80% of the weight of sorghum, stir well, Cover the chaff and continue to pile up for 5 hours;

[0045] (2) Put the raw materials of the previous step into the retort pot and cover them with rice husks, steam them with the open mouth for 1 hour, turn off the gas and simmer overnight, steam again the next day for 1 hour, take out the retort, turn over, and spread to dry;

[0046] (3) Mix Hanoi white koji, wine-producing yeast, bacterial koji and medium-temperature koji evenly. When the mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com