Saccharomyces cerevisiae Y12 and application of saccharomyces cerevisiae Y12 in brewing of pure macadawu raw wine

A technology of Saccharomyces cerevisiae, Y12, applied in the preparation of alcoholic beverages, microorganism-based methods, microorganisms, etc., can solve problems such as high cost and dependence on others

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

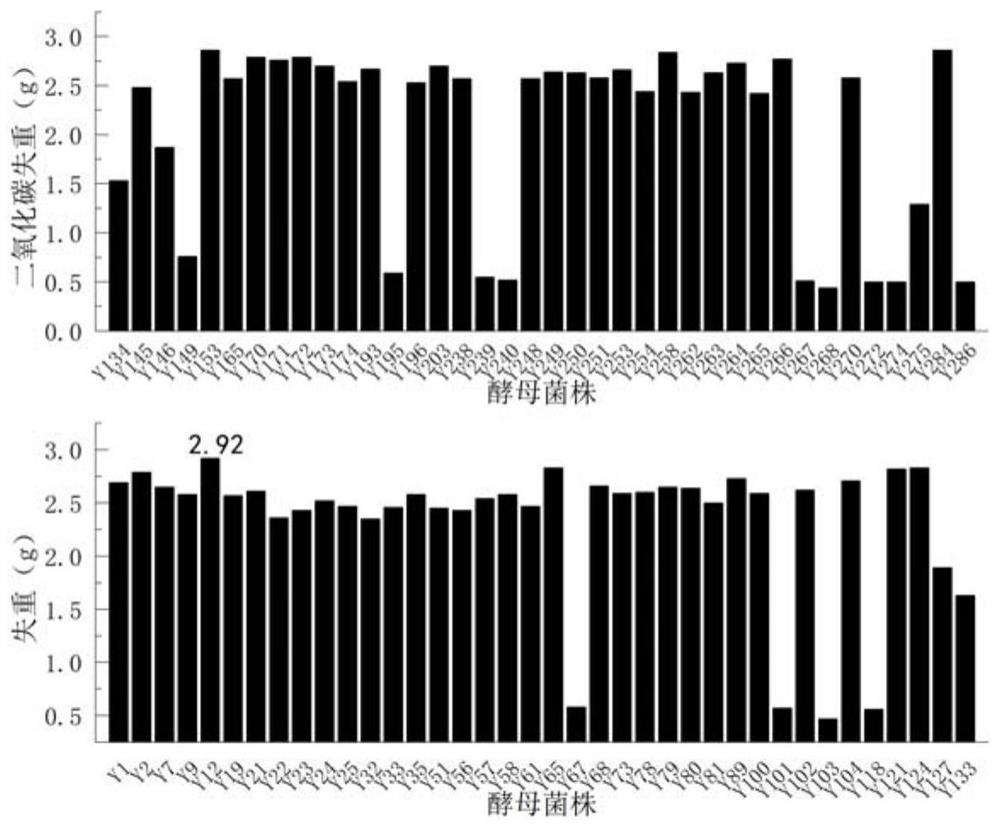

[0035] Example 1 Preliminary Screening and Identification of Saccharomyces cerevisiae Y12

[0036] (1) Isolation and screening of strains

[0037] Weigh 1g of distiller’s yeast, dissolve it in 99mL of sterile saline, shake it well, draw 1mL and dilute it 102-105 times sequentially, then take 100μL from each dilution gradient and spread it on WL identification medium, and incubate at 30°C for 3-5d , to grow colonies, and then use YPD solid medium to streak and purify until a pure culture is obtained.

[0038] (2) Primary screening of bacterial strains

[0039] The 76 yeast strains screened in step (1) were inoculated into 50 mL of wort medium, loaded into a Duchenne tube, and the fermentability of the strain was detected by the carbon dioxide weight loss method. Test results such as figure 1 , Saccharomyces cerevisiae Y12 had the highest weight loss of 2.92g, and it was preliminarily determined that strain Y12 was the target strain for screening.

[0040] (3) Molecular iden...

Embodiment 2

[0046] Example 2 Saccharomyces cerevisiae Y12 and commercial Saccharomyces cerevisiae small-scale brewing comparison test

[0047] Saccharomyces cerevisiae Y12 and 5 strains of commercial yeast were inoculated in 100 mL of wort medium, and cultured at 30 °C and 150 rpm for 24 h as seed liquid. The seed liquid was inoculated into 1L of wort medium according to the inoculum amount of 2%, installed in a durchene tube, left to ferment at 30°C for 48 hours, and the fermented mash was distilled twice to obtain a whiskey liquor sample. Detect the fusel oil (isobutanol, isoamyl alcohol) content in the wine sample by gas chromatography (GC), measure the total acid, total ester and total aldehyde content of the wine sample according to GB / T 11857-2008, The measurement results are shown in Table 2. The results of fusel oil, total acid, total ester and total aldehyde content are all converted according to 100% ethanol concentration.

[0048]Table 2 Comparison of indicators of yeast strai...

Embodiment 3

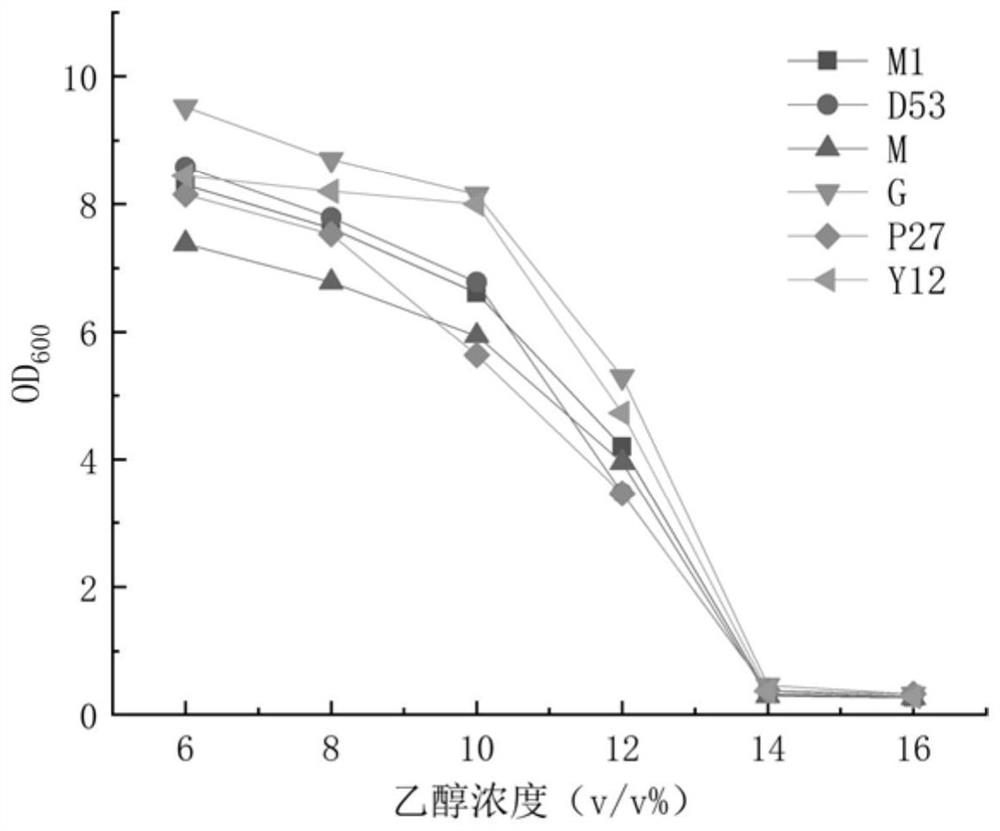

[0052] The ethanol resistance test of embodiment 3 yeast strains

[0053] Whiskey yeast is generally a high-alcohol-producing yeast, with a high rate of fermentation and alcohol production, and a high concentration of ethanol in the fermented mash. High concentrations of ethanol will affect the growth and metabolism of yeast cells, and can cause yeast to stagnate or even die, which is an important stress factor restricting yeast. Only by adapting to the conditions of high ethanol concentration can the fermentation activities proceed smoothly. Therefore, an ethanol tolerance test was performed on the S. cerevisiae Y12 strain as follows:

[0054] Pick a ring of yeast cells and inoculate them in 5mL YPD liquid medium, cultivate them at 30°C and 150rpm for 24 hours, then inoculate them into YPD liquid medium containing different concentrations of ethanol according to the inoculum size of 2%, and the concentrations of ethanol in the medium are as follows: 6%, 8%, 10%, 12%, 14%, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com