Environment-friendly water-based static electricity conductive corrosion-resistant coating and preparation method thereof

A static-conducting, environmentally friendly technology, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of affecting coating adhesion, impact strength, physical and mechanical properties, waste of resources and environment, and large structural differences. Achieve good adhesion and physical and mechanical properties, high crosslink density, and improve compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

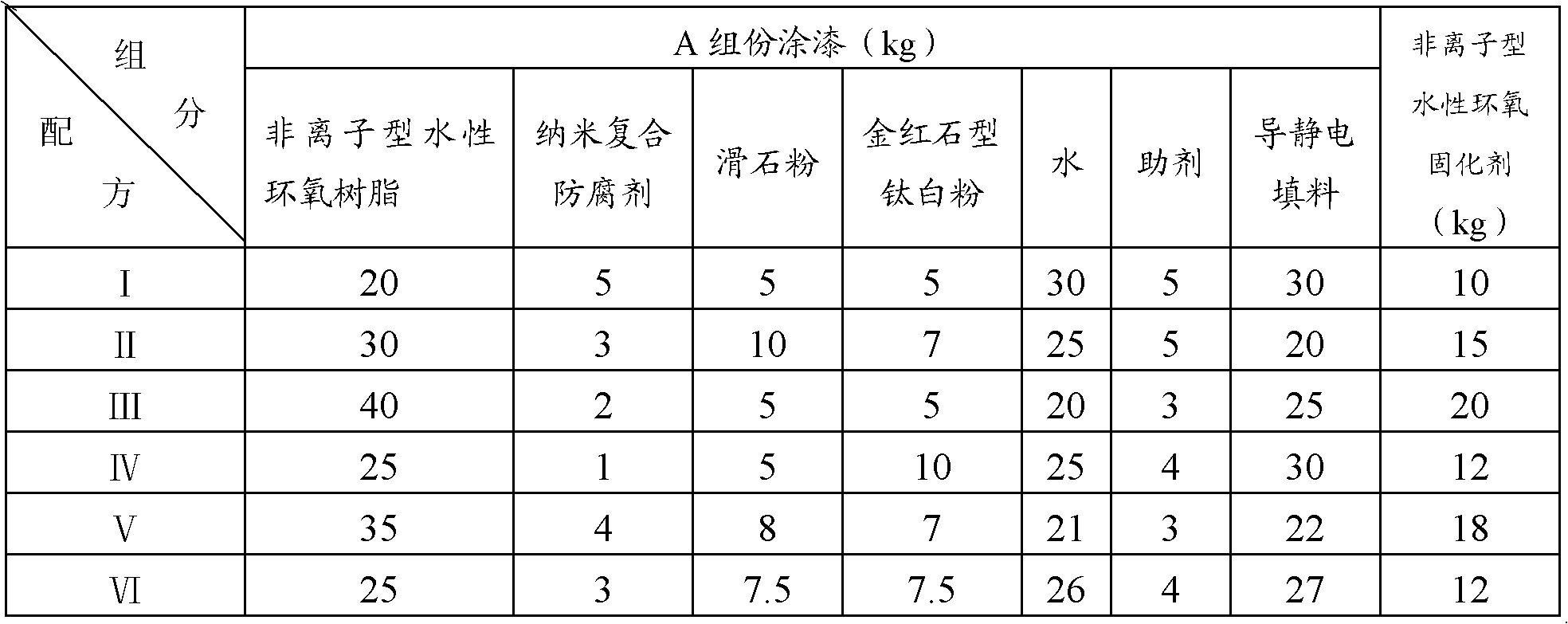

[0030] An environment-friendly water-based anti-corrosion and static-conductive coating provided by the present invention is configured from raw materials in the following weight ratio: component A: non-ionic water-based epoxy curing agent = 100: 10-20. Among them, the A component is composed of the following raw materials in weight ratio: 20-40 non-ionic water-based epoxy resin, 20-30 static conductive filler, 5-10 rutile titanium dioxide, 5-10 talcum powder, Auxiliary 3~5, nanocomposite preservative 1~5, water 20~30.

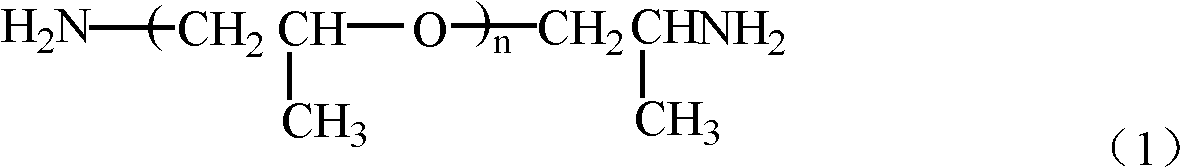

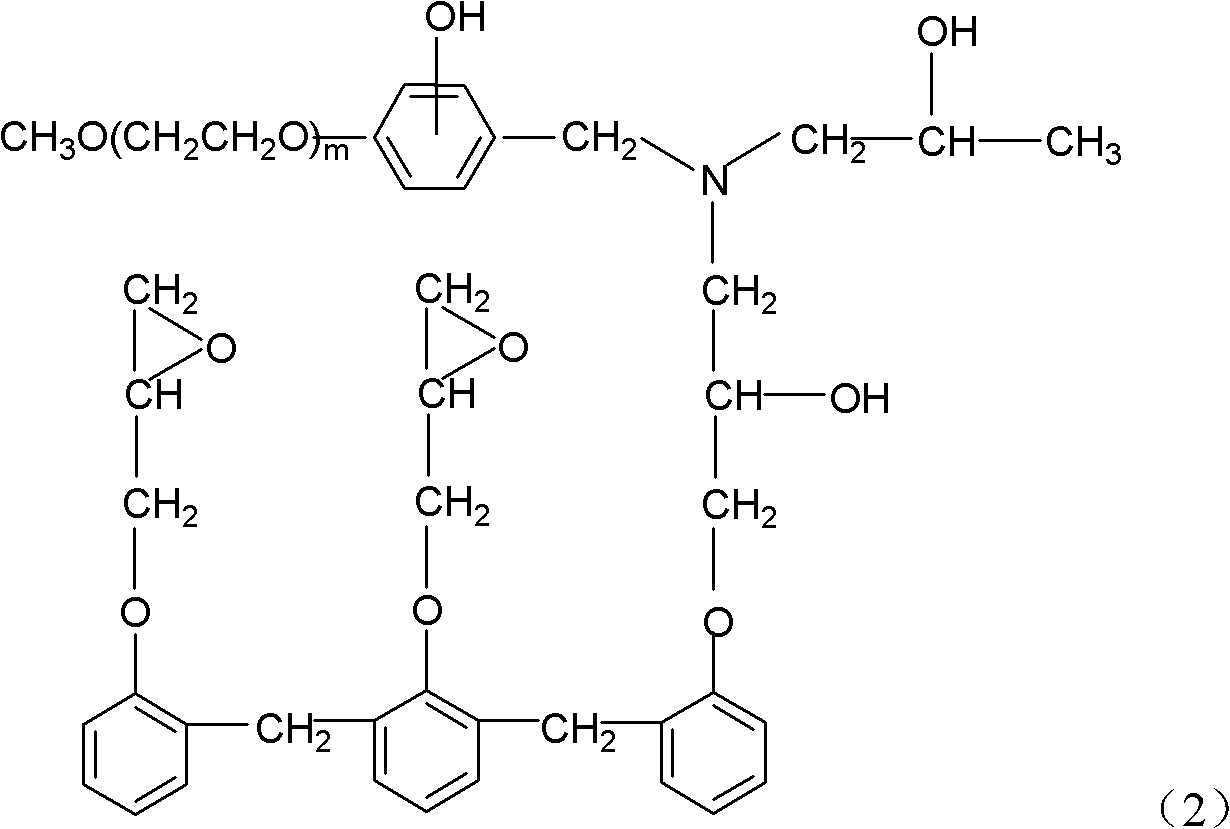

[0031] Wherein, the static conductive filler is flake-shaped mica powder coated with nano-tin oxide or antimony oxide, the particle size is 5-20 μm, and the resistivity is less than 60Ω·cm. The film-forming substance is composed of non-ionic water-based epoxy resin and non-ionic water-based epoxy curing agent, and the non-ionic water-based epoxy resin can be synthesized by the inventor's previous patented technology (ZL200810046750.7). The non-ionic water-bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com