Isotropical high-strength high-toughness particle reinforced aluminium-based composite material and preparation method thereof

A particle-reinforced aluminum, high-strength and high-toughness technology is applied in the field of isotropic, high-strength and high-toughness particle-reinforced aluminum-matrix composite material preparation. Differences in physical properties, etc., to achieve the effect of shortening production cycle, improving strength and plasticity, and low ball-to-material ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

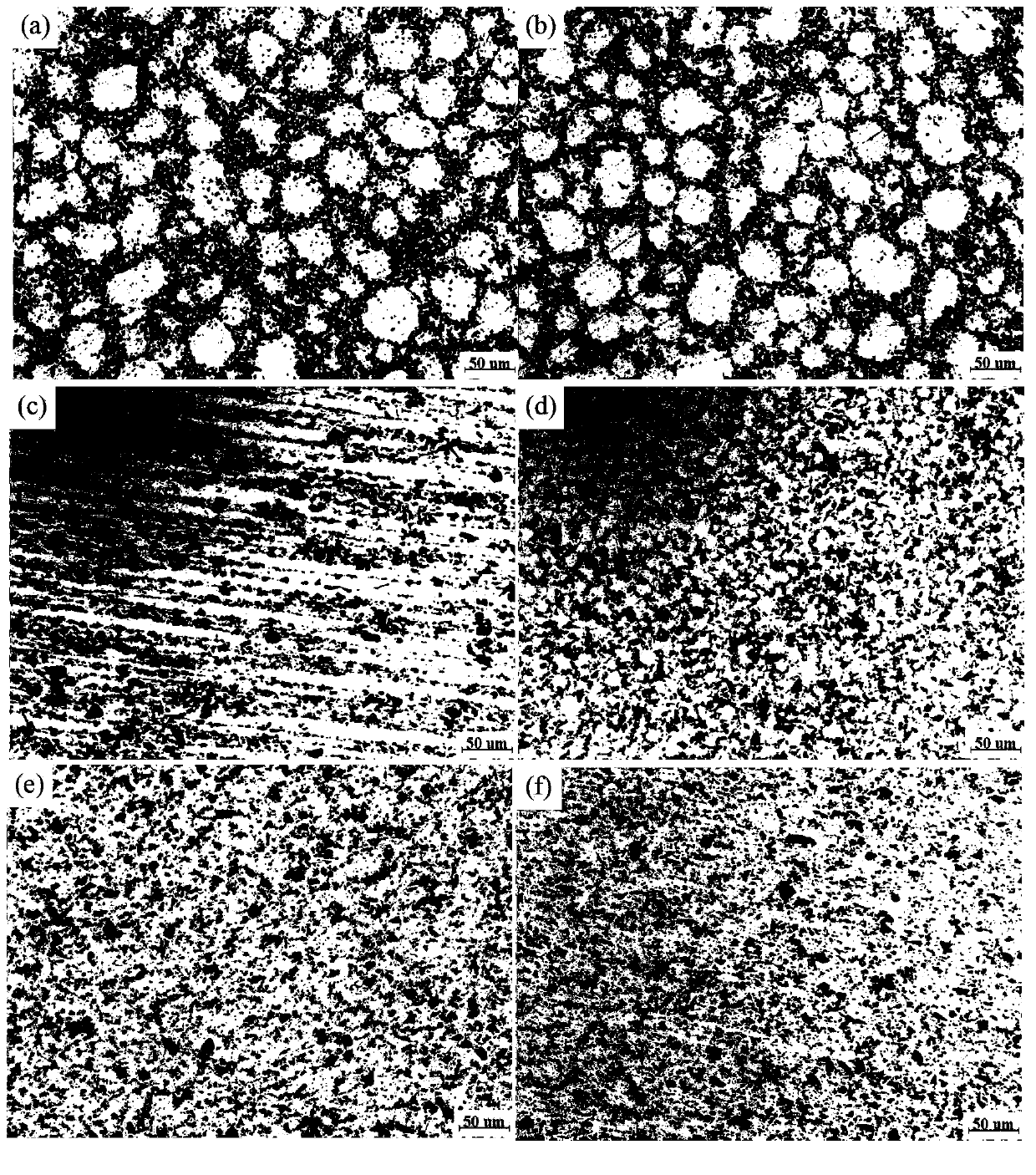

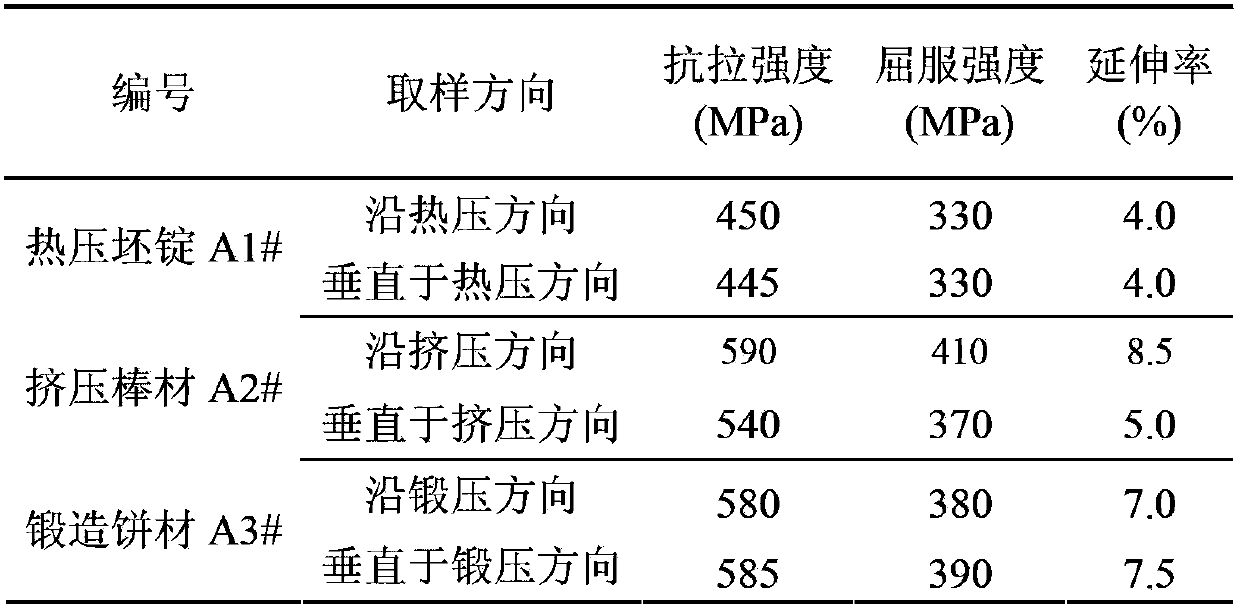

[0039] The experimental material of this embodiment is 15vol.% SiC prepared by powder metallurgy p / 2009Al composite material, the average particle size of SiC particles is 10 μm, the volume percentage is 15%, and the average particle size of 2009Al alloy powder is 40 μm.

[0040] The preparation method is to weigh 13.18kg of SiC powder, 56.82kg of 2009Al alloy powder and 70kg of Ф10mm steel ball according to the volume fraction content of reinforcement particles in the designed composite material of 15% and the ball-to-material ratio of 1:1. In the feeder, mix for 24 hours, and the speed of the mixer is 30rpm. The composite powder obtained above was vacuum hot-pressed into a Ф300mm cylindrical billet A1#, the hot-pressing temperature was 620°C, and the vacuum degree was 2×10 -3 Pa, the pressure is 80MPa. The hot-pressed ingot of the composite material obtained above was hot-extruded into a Ф80mm bar A2#, the extrusion temperature was 420°C, the extrusion ratio was 14:1, and...

Embodiment 2

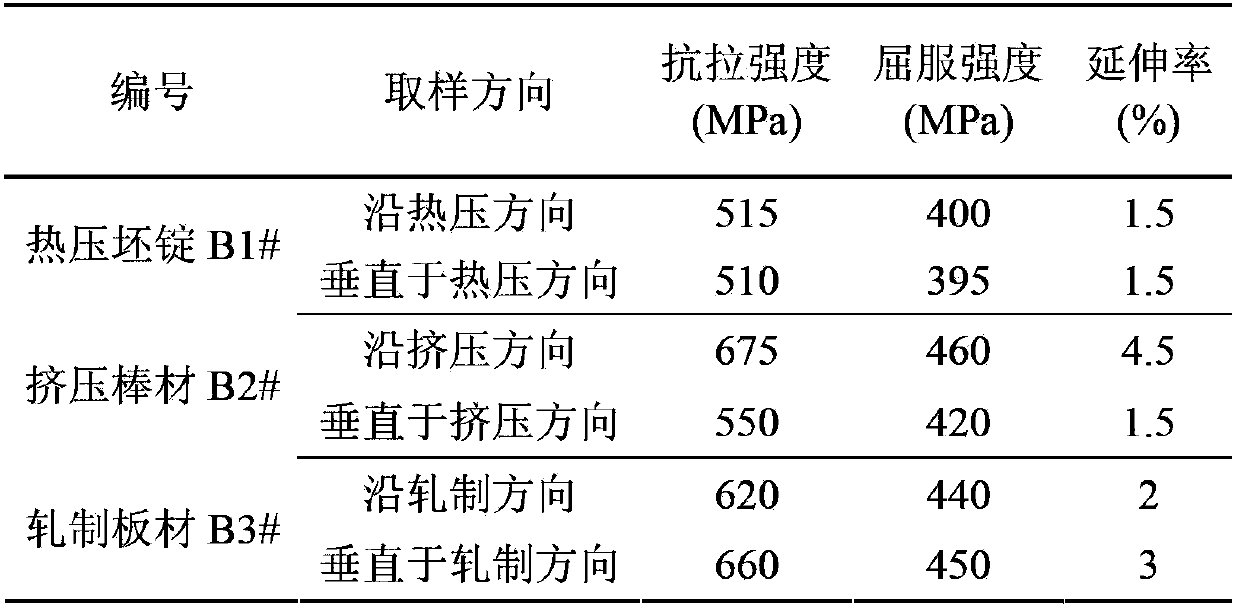

[0042] The experimental material of this embodiment is 25vol.%SiC prepared by powder metallurgy p / 2009Al composite material, the average particle size of SiC particles is 6 μm, the volume percentage is 25%, and the average particle size of 2009Al alloy powder is 30 μm.

[0043] The preparation method is to weigh 19.51kg of SiC powder, 50.49kg of 2009Al alloy powder and 70kg of Ф10mm steel ball according to the volume fraction content of reinforcement particles in the designed composite material of 25% and the ball-to-material ratio of 1:1. In the feeder, mix for 24 hours, and the speed of the mixer is 30rpm. The composite powder obtained above was vacuum hot-pressed into a Ф300mm cylindrical billet B1#, the hot-pressing temperature was 620°C, and the vacuum degree was 2×10 -3 Pa, the pressure is 80MPa. The hot-pressed ingot of the composite material prepared above was hot-extruded into a Ф80mm bar B2#, the extrusion temperature was 450°C, the extrusion ratio was 14:1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com