Reflection mirror with honeycomb sandwiched structure silicon carbide base composite material and its preparation method

A technology of honeycomb interlayer and composite material, which is applied in the field of preparation of silicon carbide-based composite material mirrors of honeycomb interlayer structure, can solve the problems such as difficulty in preparing high-rigidity honeycomb structure, difficulty in lightweight processing, lack of potential for weight reduction, etc. Achieve excellent machinability, reduce surface defects, and obtain easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

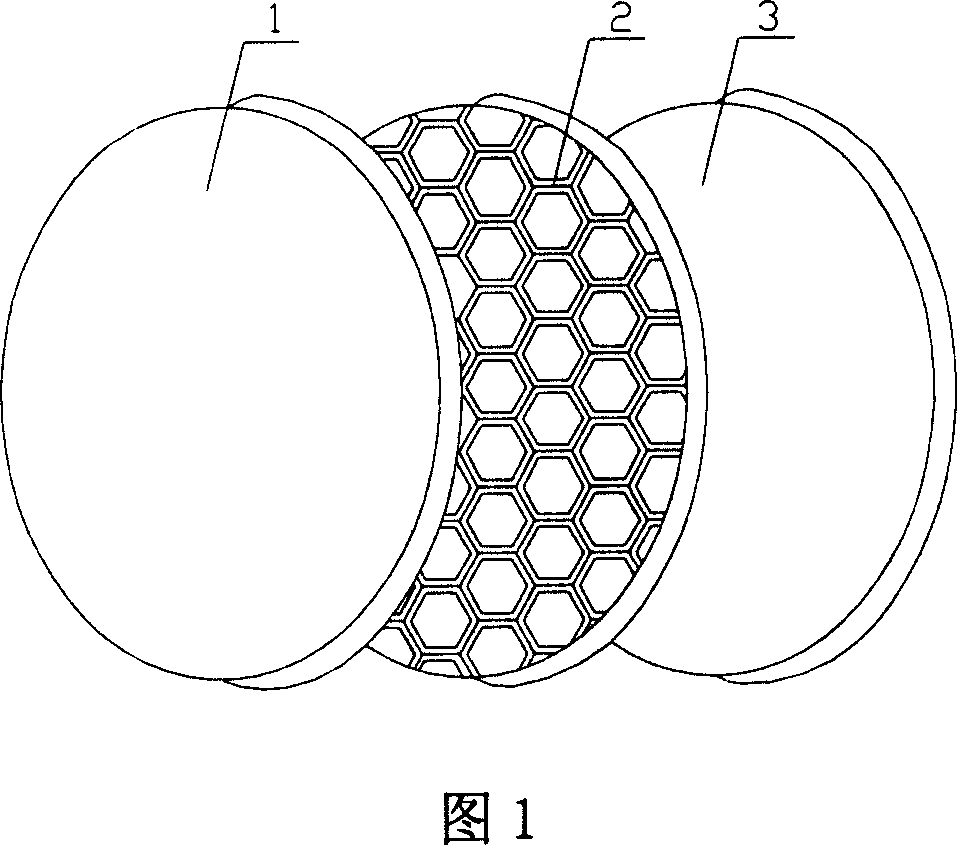

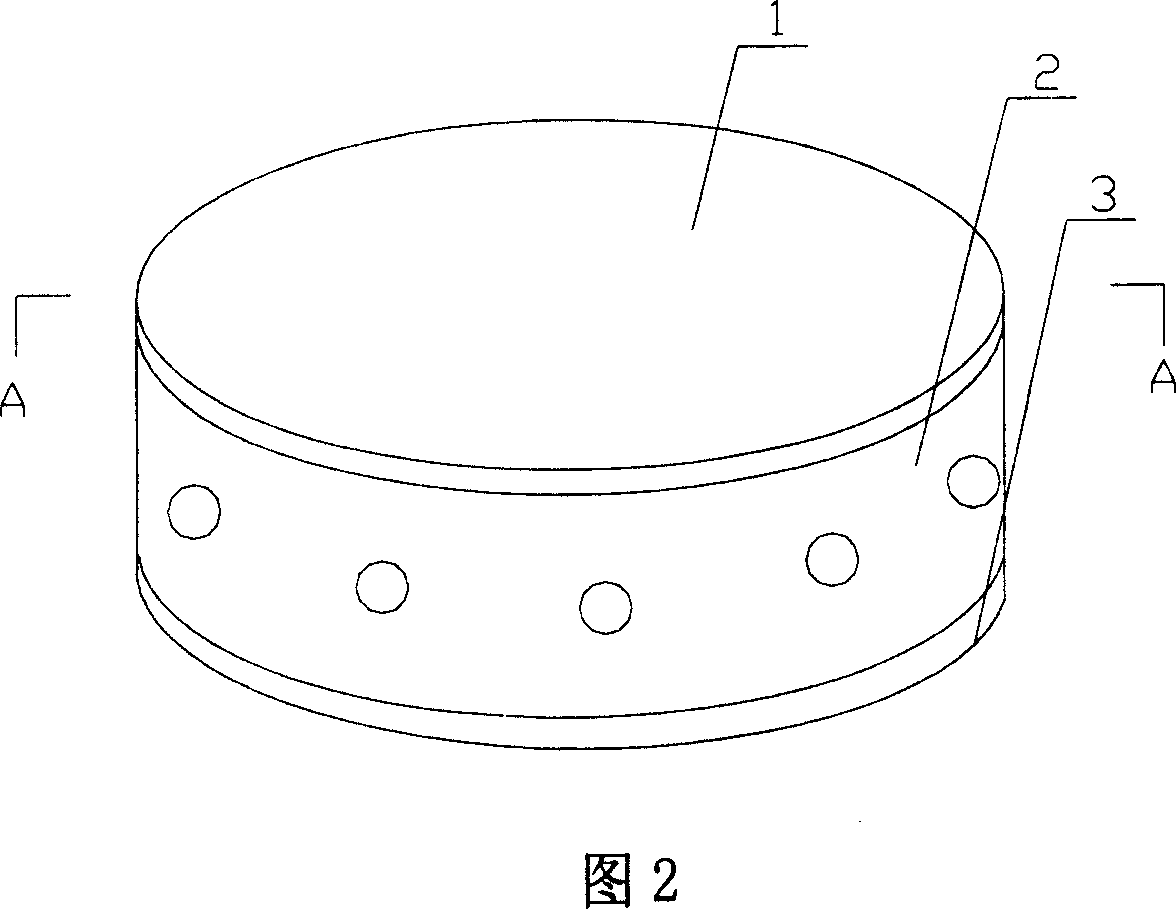

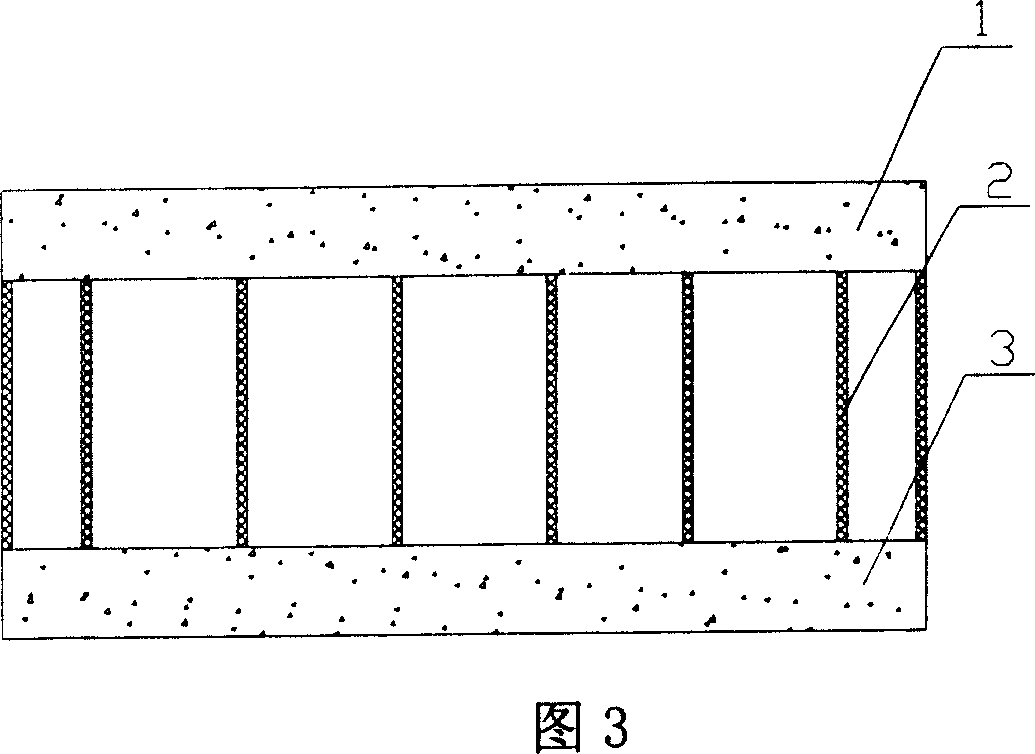

[0032] As shown in Figures 1, 2, and 3, the honeycomb sandwich structure silicon carbide-based composite reflector of the present invention is bonded by an upper cover plate 1, a honeycomb interlayer 2 with a honeycomb structure, and a lower cover plate 3, and then siliconized and sintered into a whole . Its preparation process is as follows:

[0033] Step 1, preparation of C / C porous green body

[0034] The carbon felt was impregnated with an ethanol solution of phenolic resin, and after pressure curing at 150°C, it was carbonized in a cracking furnace (temperature 1000°C, time 1 hour, heating rate 5°C / min), and the impregnation-cracking process was repeated 5 times to obtain C / C porous green body, the density of the green body is 1.1g / cm 3 , porosity 35vol%.

[0035] Step 2, preparation of C / C honeycomb structure prefabricated parts

[0036] Use CNC machine tools to process porous C / C blanks to the required shape of the upper cover plate 1, the lower cover plate 3, and t...

Embodiment 2

[0045] Step 1, preparation of C / C porous green body

[0046] Fully mix and disperse chopped carbon fiber and ethanol solution of phenolic resin, pressurize and solidify at 200°C, and then carbonize in a cracking furnace (temperature 900°C, time 1 hour, heating rate 1°C / min) to obtain C / C Porous green body, repeat the impregnation-cracking process 5 times, the density can be 1.3g / cm 3 The C / C bisque.

[0047] Steps 2, 3, 4, and 5 are the same as steps 2, 3, 4, and 5 in Example 1.

Embodiment 3

[0049] Steps 1 and 2 are the same as steps 1 and 2 in Example 1.

[0050]Step 3. Silicon infiltration and sintering of honeycomb sandwich structure SiC mirror body

[0051] Put the C / C honeycomb sandwich structure preform into a graphite crucible containing silicon powder, heat it in a high-temperature vacuum furnace to 1600°C, and keep the vacuum state in the furnace for 0.5 hours, thereby preparing C / Si / SiC with a honeycomb sandwich structure Mirror body.

[0052] Steps 4 and 5 are the same as steps 4 and 5 in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com