A mold for making energy-saving porous bricks and a method for forming porous bricks with the mold

A technology of perforated bricks and molds, applied in molds, manufacturing tools, ceramic molding machines, etc., can solve the problem of not being able to heat the bricks evenly, and achieve the effect of ensuring heating and isotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

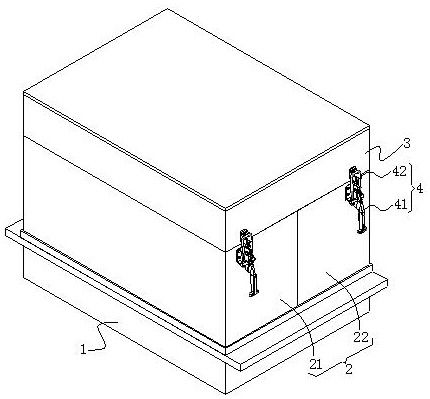

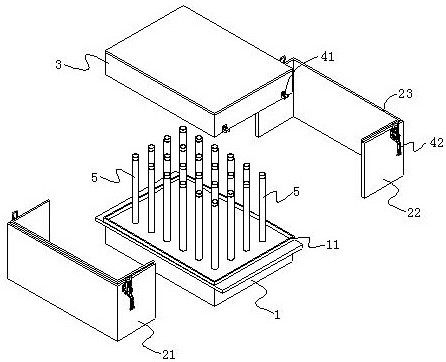

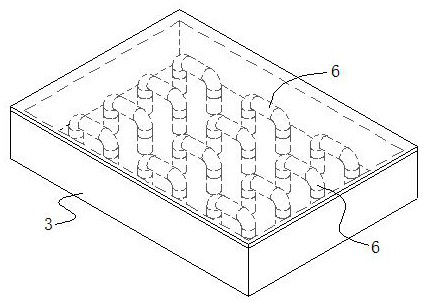

[0031] as attached figure 1 , 2 As shown in and 6, a mold for making energy-saving porous bricks and a method for forming porous bricks by the mold include an upper mold base 3, a lower mold base 1 and a mold frame 2 between the upper mold base 3 and the lower mold base 1, The upper surface of the lower mold base 1 is distributed in a linear array with several vertically upward conduits 5, and the inner space formed after the installation of the upper mold base 3, the lower mold base 1 and the mold frame 2 is the overall shape of the perforated brick. The cavity, the conduit 5 forms the holes of the porous brick. The upper surface of the lower mold base 1 is fixed with a positioning ring 11 on the periphery of the conduit 5 distributed in a linear array, and the outer dimension of the mold frame 2 is slightly smaller than the inner dimension of the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com